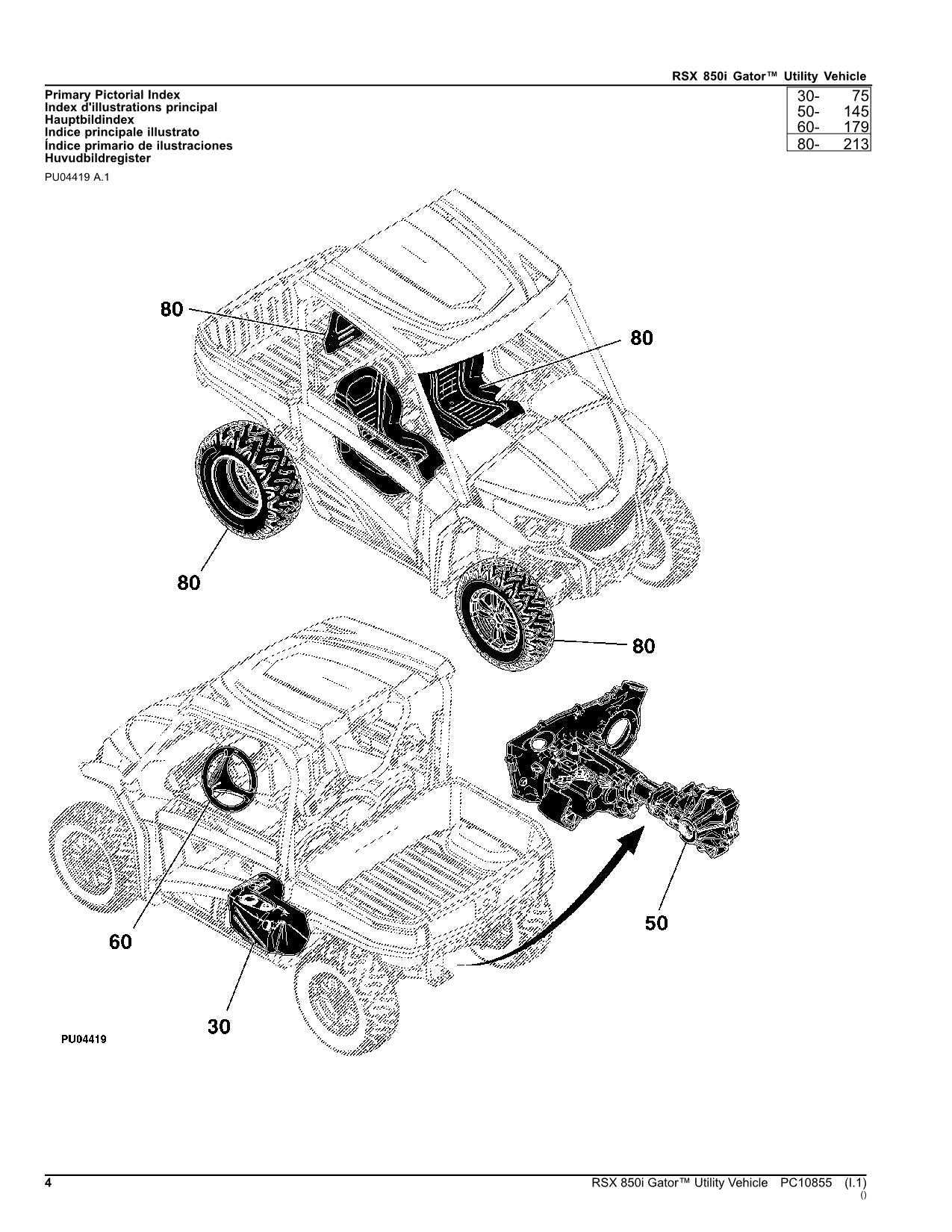

John Deere 825i Parts Diagram Overview

The efficient operation of any utility vehicle relies on a thorough comprehension of its various elements. Knowing how each component interacts and contributes to overall performance is crucial for maintenance and troubleshooting. This knowledge empowers owners to enhance their experience and ensure longevity.

Whether you are an avid enthusiast or a casual user, familiarizing yourself with the essential pieces that make up your vehicle can lead to better care and informed decision-making. By delving into the intricacies of the assembly, you can identify potential issues before they escalate, ultimately saving time and resources.

This guide offers a detailed exploration of the key components, highlighting their functions and interrelations. Equipped with this information, you will be well-prepared to address repairs, upgrades, or modifications, ensuring your vehicle remains in top condition for all your needs.

Understanding the John Deere 825i

This section aims to provide insights into a versatile utility vehicle designed for various outdoor tasks. Known for its reliability and performance, this machine serves as a valuable asset for both recreational and work-related activities. Its robust engineering and thoughtful design make it an ideal choice for those who require strength and adaptability in their equipment.

Key Features

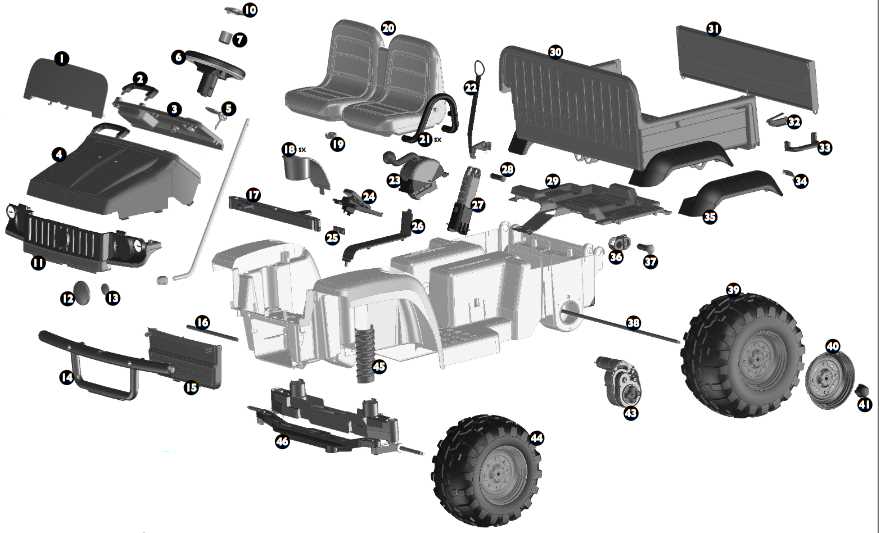

The vehicle boasts a range of essential characteristics that enhance its functionality. Equipped with a powerful engine, it ensures efficient operation across diverse terrains. Additionally, its spacious cargo area offers ample storage, making it suitable for transporting tools and supplies. The user-friendly controls contribute to a seamless driving experience, allowing operators to focus on their tasks with ease.

Maintenance and Care

Proper upkeep is crucial for sustaining the performance of this robust machine. Regular inspections and timely servicing can significantly extend its lifespan. Familiarity with the various components will aid in identifying potential issues before they escalate. By prioritizing maintenance, users can ensure their vehicle remains reliable and efficient for years to come.

Key Features of the 825i Model

This exceptional utility vehicle stands out due to its remarkable design and advanced capabilities, making it a preferred choice for various outdoor tasks. Equipped with cutting-edge technology, it delivers both efficiency and reliability, ensuring optimal performance in diverse environments.

Powerful Performance

The vehicle is engineered with a robust engine that offers impressive horsepower, enabling it to tackle challenging terrains with ease. Its advanced drivetrain ensures smooth acceleration and seamless navigation, whether on rugged trails or flat surfaces.

Enhanced Comfort and Versatility

Featuring a spacious cabin, the vehicle prioritizes user comfort during long hours of operation. The seating arrangement is designed to accommodate multiple passengers, while the customizable storage options provide ample space for tools and equipment. Durability is also a key attribute, with high-quality materials that withstand the rigors of frequent use.

Additionally, advanced suspension systems enhance stability, ensuring a smooth ride even on bumpy paths, making it an ideal companion for both work and recreation.

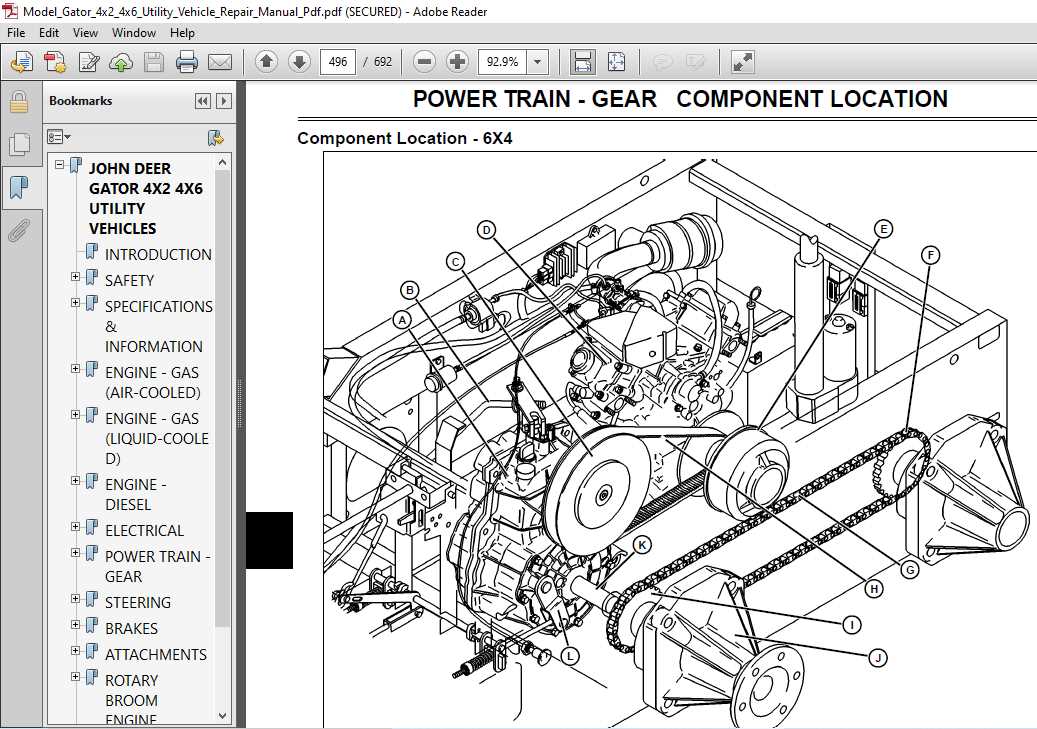

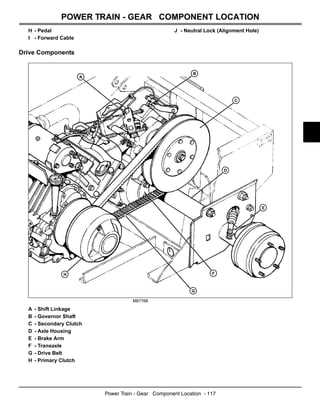

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for maintenance and repair. Visual representations of various elements not only simplify identification but also enhance overall efficiency in servicing. They serve as valuable tools for technicians, ensuring accurate work and minimizing errors.

- Enhanced Clarity: Visual aids provide a clear view of how each component interacts, making it easier to grasp complex assemblies.

- Efficient Troubleshooting: Identifying issues becomes more straightforward when you can refer to a visual guide, speeding up the diagnostic process.

- Informed Ordering: When replacement items are needed, clear visuals help ensure the correct parts are acquired, reducing the risk of mismatches.

- Streamlined Repair Process: Having a reference at hand can significantly expedite repairs, allowing for quicker turnaround times.

Utilizing visual representations fosters a deeper understanding of equipment, promoting effective maintenance practices and extending the lifespan of machinery.

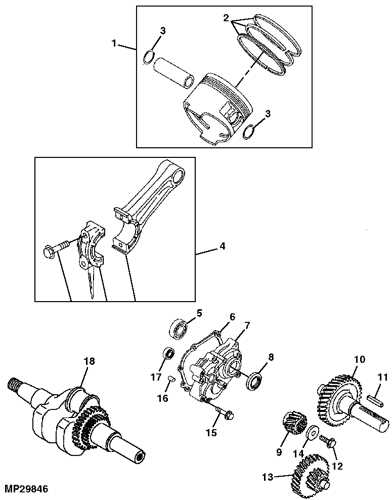

Common Issues with 825i Parts

When operating utility vehicles, various components can experience wear and tear, leading to common complications. Understanding these issues is essential for maintaining optimal performance and longevity of the machine.

One prevalent problem is the failure of the electrical system, which may manifest as flickering lights or complete power loss. This often results from corroded connections or damaged wiring, necessitating thorough inspections and timely replacements.

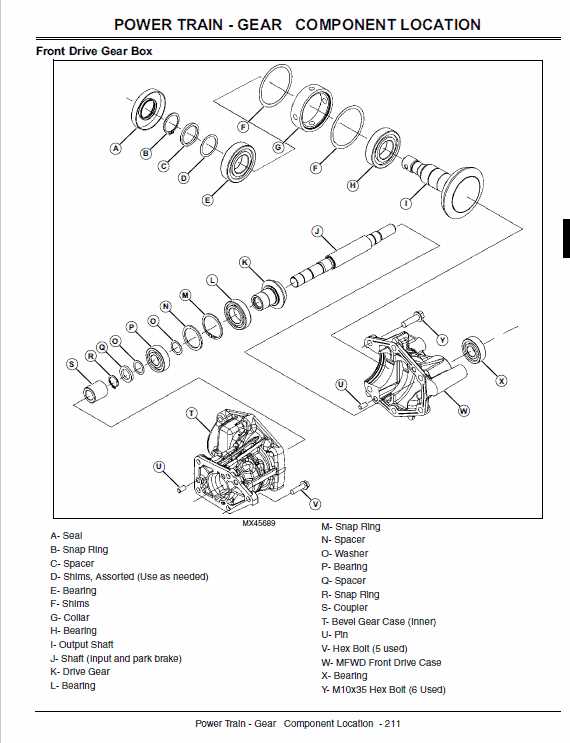

Another frequent concern involves the drivetrain, where components such as the belt or transmission can wear out, affecting acceleration and overall efficiency. Regular maintenance and prompt replacement of these parts are crucial to prevent more significant issues.

Additionally, the suspension system can be prone to problems, especially in rough terrain. Components like shock absorbers and bushings may degrade, leading to a rough ride and decreased stability. Monitoring these parts for signs of wear can enhance comfort and control.

Finally, fluid leaks are a common issue that can arise from worn seals or gaskets. This not only affects performance but can also lead to severe engine damage if left unchecked. Regular fluid checks and prompt repairs can mitigate this risk.

Where to Find Official Diagrams

Accessing accurate and detailed illustrations for machinery components is essential for effective maintenance and repairs. These visuals provide invaluable guidance for both professionals and enthusiasts, ensuring that every part is correctly identified and assembled. Fortunately, there are several reliable sources to obtain these resources.

Manufacturer’s Website: The primary source for official illustrations is the manufacturer’s official website. Most brands offer a dedicated section for service manuals and technical documents, where users can download high-quality images and schematics. This is the most trustworthy source, as it is regularly updated with the latest information.

Authorized Dealers: Visiting or contacting an authorized dealer can also be beneficial. These dealers often have access to proprietary resources and can provide you with physical copies or digital files of the necessary illustrations. They can also offer expert advice tailored to specific models.

Online Forums and Communities: Joining online forums or communities dedicated to machinery enthusiasts can be another great option. Members frequently share resources, including illustrations, and can guide you to where to find them. However, it’s important to verify the accuracy of shared information.

Service Centers: Certified service centers are equipped with official documentation. Scheduling a maintenance appointment can provide access to the necessary illustrations, along with professional assistance in understanding them. This option is particularly useful for those who prefer hands-on guidance.

Utilizing these sources will ensure that you have access to accurate and reliable visual aids, enhancing your repair and maintenance tasks significantly.

Aftermarket Parts vs. Original Parts

When it comes to maintaining machinery, enthusiasts often face the choice between sourcing components from the manufacturer or opting for alternatives. Each option presents its own set of advantages and challenges, which can significantly impact performance and cost-effectiveness. Understanding these differences can help make an informed decision.

Benefits of Original Components

- Quality Assurance: Original components are designed to meet specific standards, ensuring optimal performance.

- Manufacturer Support: These components often come with warranties and customer service support.

- Perfect Fit: Designed specifically for the machinery, they ensure compatibility and reliability.

Advantages of Alternative Options

- Cost-Effectiveness: Alternatives are frequently priced lower, making them budget-friendly.

- Variety: A wider selection can be found in the aftermarket, offering more choices for users.

- Accessibility: These options may be easier to find through various retailers or online platforms.

Ultimately, the choice between original and alternative components hinges on individual preferences, budget constraints, and specific needs related to machinery performance. Evaluating these factors is crucial for ensuring long-term satisfaction and functionality.

Maintenance Tips for 825i Owners

Proper upkeep of your utility vehicle ensures optimal performance and longevity. Regular maintenance not only enhances functionality but also prevents costly repairs down the line. Here are some essential tips to keep your machine in top condition.

First, regularly check and change the oil to ensure the engine runs smoothly. Fresh oil helps in reducing friction and wear, contributing to better fuel efficiency. Follow the manufacturer’s recommendations for oil type and change intervals.

Inspect the air filter periodically to maintain airflow to the engine. A clean filter improves performance and helps prevent contaminants from entering the engine. Replace it as needed to ensure efficient operation.

Pay attention to tire pressure and tread condition. Properly inflated tires enhance handling and traction, while adequate tread depth is crucial for safety. Rotate the tires as per the guidelines to promote even wear.

Examine the battery regularly for corrosion and ensure the terminals are clean. A well-maintained battery is essential for reliable starts and overall vehicle performance. Consider replacing it every few years to avoid unexpected failures.

Lastly, keep the vehicle clean and free from debris. Regular washing and inspection help identify potential issues early, while also preserving the appearance of your machine. A little effort goes a long way in maintaining your investment.

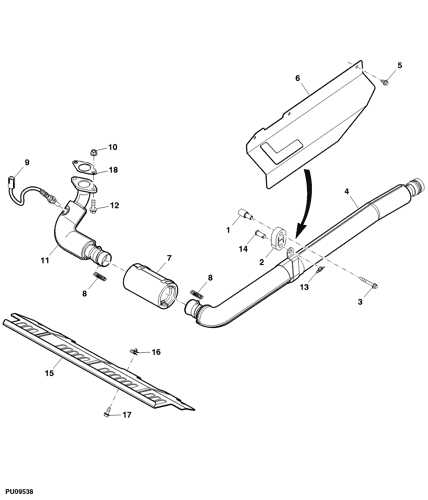

Tools Needed for Parts Replacement

When it comes to maintaining and servicing machinery, having the right tools is essential for effective component swaps. Proper equipment ensures that tasks are completed efficiently and minimizes the risk of damage to both the machine and the replacement elements.

Essential Hand Tools

A well-equipped toolbox is the foundation of any repair process. Basic hand tools such as wrenches, screwdrivers, and pliers are crucial for loosening and securing components. Additionally, a socket set is invaluable for reaching difficult areas and applying the necessary torque.

Specialized Equipment

In some cases, specific jobs may require specialized tools. For instance, a torque wrench is important for applying the correct tension on bolts, while a pry bar can assist in removing tightly fitted parts. Having these tools on hand can significantly streamline the replacement process and enhance overall efficiency.

Step-by-Step Guide to Repairs

This section provides a comprehensive approach to conducting effective repairs on your utility vehicle. By following a systematic method, you can ensure that each task is performed with precision and care, minimizing the risk of future issues.

1. Gather Necessary Tools and Materials: Before starting any repair, collect all essential tools and components. This includes wrenches, screwdrivers, replacement parts, and safety gear. Having everything on hand will streamline the process.

2. Consult the Manual: Reference the vehicle’s manual for specific instructions and guidelines related to your repair. This document will offer insights into the correct procedures and torque specifications, ensuring accuracy.

3. Assess the Problem: Carefully examine the area requiring attention. Identify the root cause of the issue and determine whether it can be fixed or if replacement is necessary. Document any visible damage for future reference.

4. Execute the Repair: Begin by removing any affected components as outlined in the manual. Take care to avoid damaging surrounding parts. Once the faulty item is removed, install the new or repaired part according to the provided instructions.

5. Test the Vehicle: After completing the repair, conduct a thorough test of the vehicle to ensure everything functions as intended. Pay attention to any unusual noises or performance issues during operation.

6. Clean Up: Once the repair is verified, tidy up your workspace. Properly dispose of any old parts and materials. Keeping your area organized will make future repairs more efficient.

7. Document the Process: Finally, record details of the repair, including the date, parts replaced, and any observations. This log can be invaluable for future maintenance and troubleshooting.

Identifying Genuine John Deere Parts

Ensuring the use of authentic components is essential for maintaining the performance and longevity of machinery. Recognizing the signs of originality can significantly impact the efficiency of your equipment, reducing the likelihood of malfunction and ensuring optimal operation.

Here are key indicators to help you distinguish authentic components from counterfeit or substandard alternatives:

| Indicator | Description |

|---|---|

| Brand Markings | Genuine items often feature distinctive logos and markings that signify authenticity. |

| Packaging Quality | Original components are typically packaged securely, with high-quality materials and informative labels. |

| Serial Numbers | Check for unique identifiers that can be verified through official channels. |

| Price | While authenticity comes at a cost, prices that seem too low may indicate counterfeit products. |

| Vendor Reputation | Purchasing from authorized dealers or reputable suppliers reduces the risk of acquiring non-genuine items. |

By adhering to these guidelines, you can confidently select components that uphold the integrity of your machinery, ensuring reliable and efficient performance in every task.

Cost Considerations for 825i Parts

When maintaining or upgrading a utility vehicle, evaluating expenses is crucial for making informed decisions. The financial aspects of component acquisition can significantly impact overall ownership costs. Understanding various factors can help owners budget effectively and ensure longevity of their machinery.

| Factor | Description |

|---|---|

| Quality vs. Price | High-quality components often come at a premium but can lead to better performance and longer life. Weighing the benefits against initial costs is essential. |

| Aftermarket Options | Aftermarket alternatives may offer lower prices, but assessing their reliability and compatibility is vital to avoid future issues. |

| Shipping Costs | Consider additional expenses for shipping when ordering from distant suppliers, as these can add significantly to the total cost. |

| Installation Fees | If professional installation is required, factor in labor costs, which can vary widely depending on the service provider. |

| Warranty Options | Components with warranties may have higher upfront costs, but they provide protection against defects and potential replacement expenses. |

Ultimately, a thorough analysis of these considerations can lead to smarter investments in the upkeep of your vehicle, ensuring it remains reliable and efficient over time.

FAQs About John Deere 825i Parts

This section addresses common inquiries regarding components and accessories for a specific utility vehicle model. Whether you are looking for replacement items, upgrades, or maintenance advice, this guide aims to clarify your questions.

- What should I consider when purchasing replacements?

When buying new components, it is crucial to verify compatibility, quality, and warranty options. Ensure that the item matches the specifications of your vehicle model.

- Where can I find reliable sources for components?

Authorized dealers, reputable online retailers, and local auto shops are excellent places to start. Always check reviews and ratings to ensure quality.

- How often should I replace worn-out items?

Regular inspections are essential. Look for signs of wear and tear, and replace items as needed to maintain optimal performance.

- Can I install components myself?

Many owners prefer DIY installations to save on costs. However, certain replacements may require professional assistance. Consult the user manual for guidance.

- What is the average lifespan of various components?

The lifespan varies depending on usage, environment, and maintenance. Regular upkeep can significantly extend the longevity of each part.