Understanding the John Deere E100 Engine Parts Diagram

The efficient functioning of any outdoor machinery relies heavily on the intricate network of its individual elements. Each component plays a crucial role in ensuring optimal performance, making it essential for users to familiarize themselves with the various pieces that constitute these systems. Whether for maintenance or repair, having a clear visual representation can significantly enhance one’s ability to manage and troubleshoot the equipment effectively.

In the realm of lawn care and outdoor maintenance, the importance of a reliable machine cannot be overstated. Recognizing how different segments interact can lead to better decision-making when it comes to upkeep or modifications. This knowledge not only empowers owners but also fosters a deeper appreciation for the engineering behind these machines.

Moreover, understanding the layout and functionality of each element can aid in identifying potential issues before they escalate. By delving into the specific arrangement of components, users can gain insights that will contribute to more efficient operation and longevity of their equipment. With this in mind, exploring a comprehensive illustration of the various elements can serve as a valuable resource for both novice and experienced operators alike.

Understanding John Deere E100 Engine Parts

Grasping the intricacies of machinery components is essential for optimal performance and maintenance. Familiarity with various elements allows for better troubleshooting and ensures longevity. This section will explore key components, enhancing your knowledge and efficiency.

Key Components

- Cylinder Block

- Piston Assembly

- Crankshaft

- Valves and Timing Gear

Maintenance Tips

- Regularly check fluid levels.

- Inspect belts and hoses for wear.

- Clean air filters consistently.

- Schedule routine service checks.

Overview of E100 Engine Components

This section provides an insightful examination of the essential elements that make up the power system, focusing on their functions and interrelationships. Understanding these components is crucial for maintenance, troubleshooting, and enhancing overall performance.

Main Functional Elements

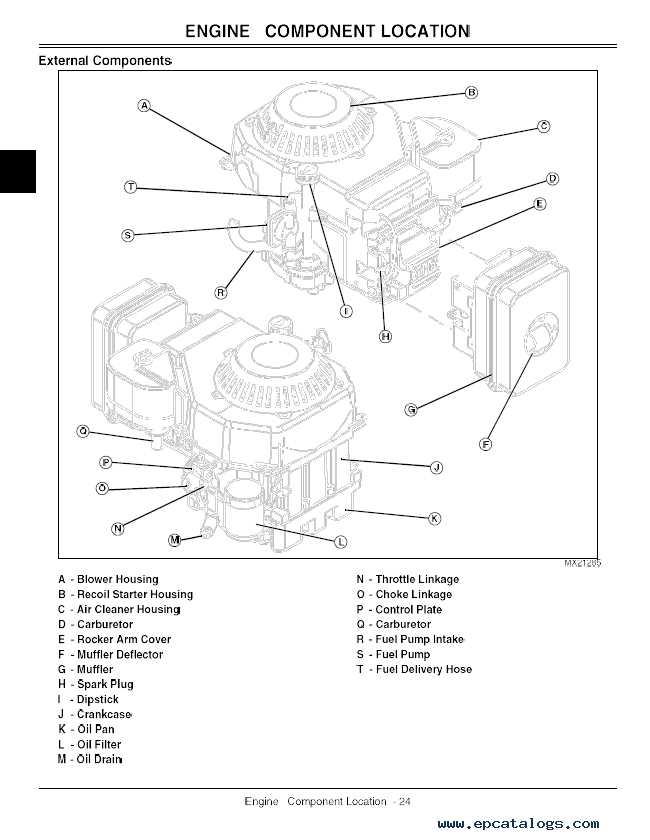

The primary components work in harmony to ensure optimal operation. Each part serves a distinct role, contributing to the efficiency and reliability of the machinery. Key elements include the ignition system, fuel delivery mechanisms, and various support structures.

| Component | Function | Importance |

|---|---|---|

| Ignition System | Ignites fuel for combustion | Crucial for starting and smooth operation |

| Fuel Pump | Delivers fuel to combustion chamber | Ensures consistent fuel flow |

| Cylinders | House the combustion process | Vital for power generation |

| Exhaust System | Manages emission gases | Reduces environmental impact |

Familiarity with these components facilitates better care and enhances the longevity of the machine, ensuring efficient operation over time.

Importance of Engine Diagrams

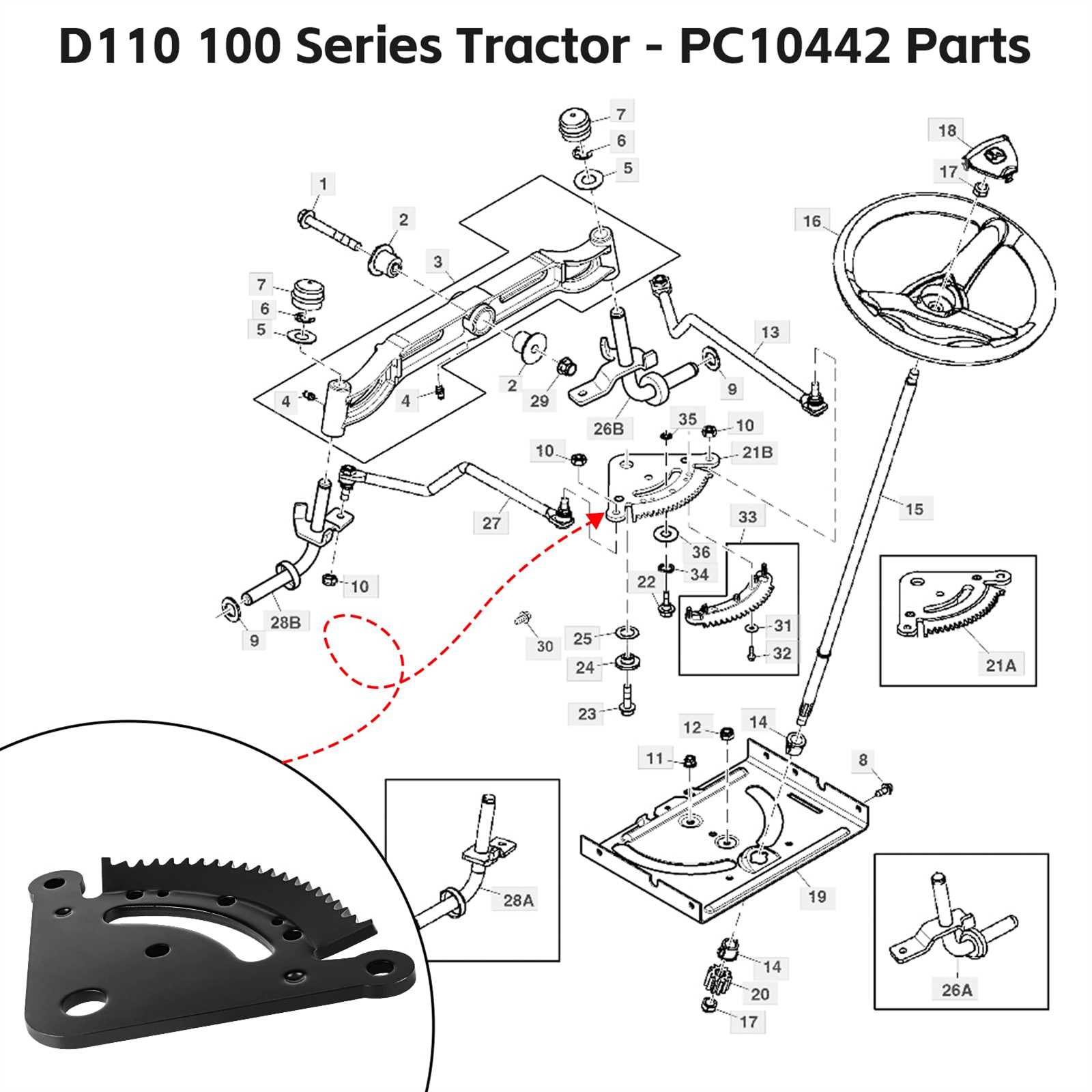

Visual representations of machinery components play a crucial role in understanding and maintaining complex systems. They serve as valuable tools for both novice and experienced technicians, facilitating a deeper comprehension of how various elements interact within an assembly.

- Enhanced Understanding: Illustrations break down intricate configurations, allowing individuals to grasp the relationships between different components more easily.

- Efficient Troubleshooting: By referencing visual aids, technicians can quickly identify potential issues, saving time and reducing frustration during repairs.

- Improved Communication: Diagrams provide a common language for professionals, ensuring everyone involved in a project can discuss specifics without ambiguity.

- Accurate Reassembly: After maintenance or repairs, these visual guides ensure that all elements are correctly reinstalled, minimizing the risk of future problems.

Overall, detailed illustrations are essential in promoting efficiency and effectiveness in maintenance and repair tasks, leading to better performance and longevity of machinery.

Key Parts of the E100 Engine

This section delves into the essential components that contribute to the functionality and performance of the power unit. Understanding these elements is crucial for effective maintenance and troubleshooting.

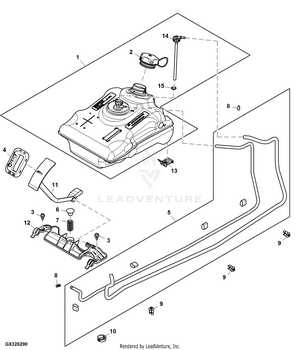

- Fuel System: Responsible for delivering the necessary fuel to the combustion chamber, ensuring optimal performance.

- Ignition Mechanism: This system generates the spark needed to ignite the fuel-air mixture, playing a vital role in starting the unit.

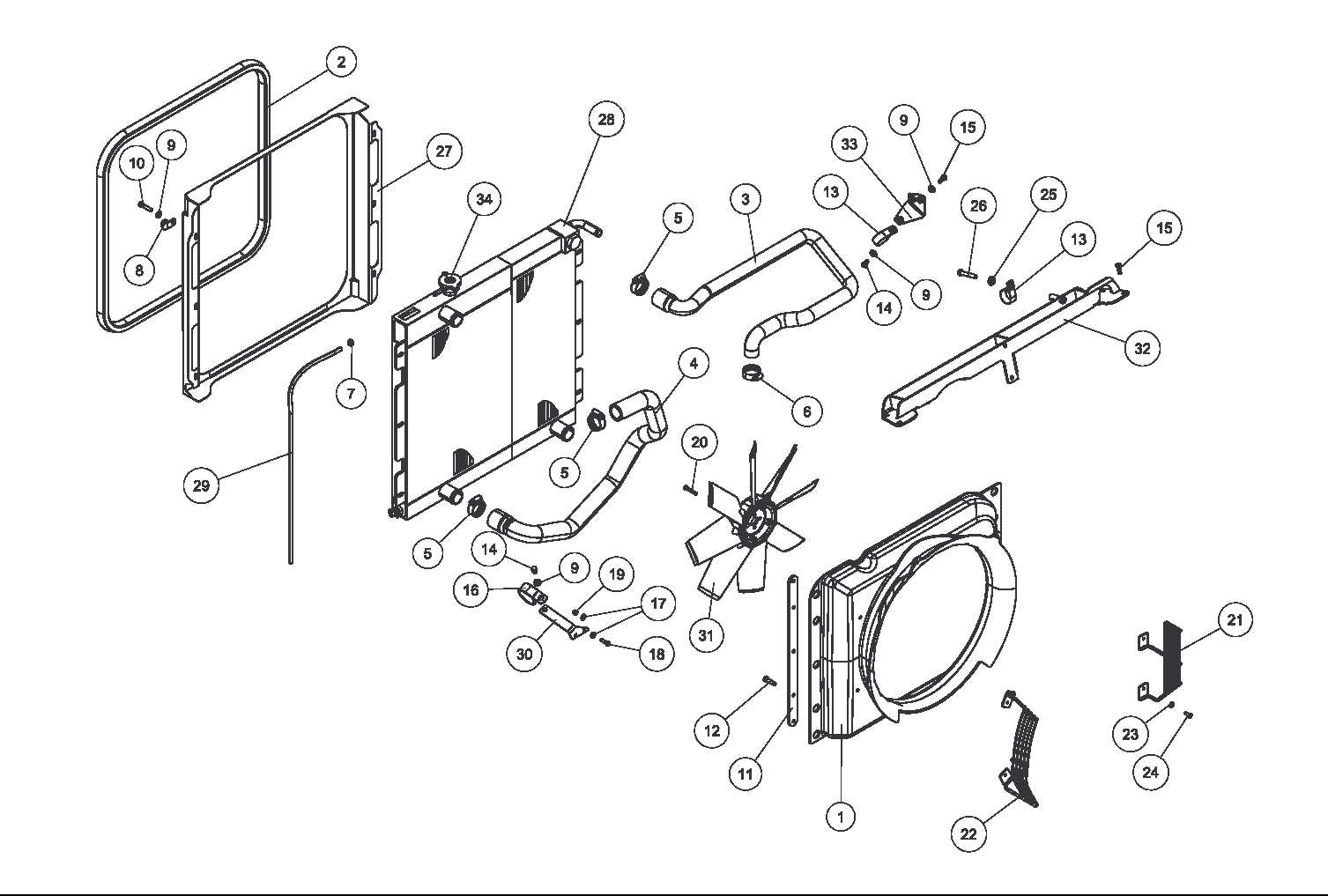

- Cooling Assembly: Helps regulate temperature, preventing overheating and ensuring efficiency during operation.

- Exhaust System: Directs harmful gases away from the unit, maintaining a safe and clean operating environment.

- Lubrication System: Provides necessary oil to reduce friction between moving parts, enhancing longevity and performance.

Each component plays a significant role in the overall operation, and regular inspection can help maintain peak performance and reliability.

Common Issues with E100 Engine Parts

Maintaining optimal performance in lawn care equipment often hinges on addressing prevalent challenges associated with various components. Understanding these common issues can help users troubleshoot and enhance the longevity of their machines.

- Fuel System Problems:

- Clogs in fuel filters can lead to reduced power.

- Issues with fuel lines may cause leaks or improper fuel delivery.

- Electrical Failures:

- Battery issues, such as low charge or corrosion, can prevent starting.

- Faulty wiring can lead to intermittent performance or complete shutdown.

- Cooling System Malfunctions:

- Debris in the cooling fins can lead to overheating.

- Failed thermostats may cause improper temperature regulation.

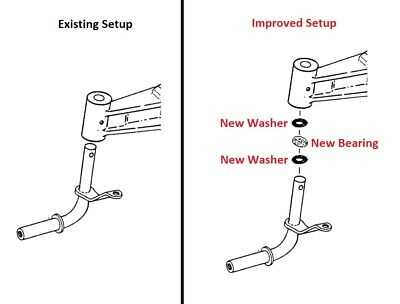

- Wear and Tear:

- Belts can fray or snap over time, affecting performance.

- Bearings may become worn, resulting in unusual noises or vibrations.

Being aware of these common issues allows for proactive maintenance, ensuring that equipment operates smoothly and efficiently.

How to Read Engine Diagrams

Understanding technical illustrations is essential for anyone involved in machinery maintenance and repair. These visuals provide crucial information about components, their connections, and the overall system layout. By mastering the art of interpreting these representations, you can enhance your troubleshooting skills and perform repairs more efficiently.

1. Familiarize Yourself with Symbols: Each illustration uses specific icons to represent various elements. Take time to learn these symbols, as they simplify complex information into easily recognizable forms. This knowledge will allow you to quickly identify parts and their functions.

2. Follow the Flow: Most visuals are designed to show the flow of processes. Pay attention to arrows and lines that indicate movement or direction. Understanding this flow helps in grasping how components interact with one another, enabling better analysis of issues.

3. Refer to the Legend: Many illustrations include a legend or key that defines the symbols and lines used. Always refer to this section for clarification. It ensures that you accurately interpret the information presented, avoiding potential misunderstandings.

4. Break it Down: Don’t try to absorb everything at once. Focus on one section or component at a time. This method allows for a more thorough understanding and helps you avoid feeling overwhelmed by the complexity of the entire visual.

5. Practice Regularly: The more you engage with these representations, the more proficient you’ll become at reading them. Consider working with various illustrations to diversify your understanding and improve your ability to troubleshoot different systems.

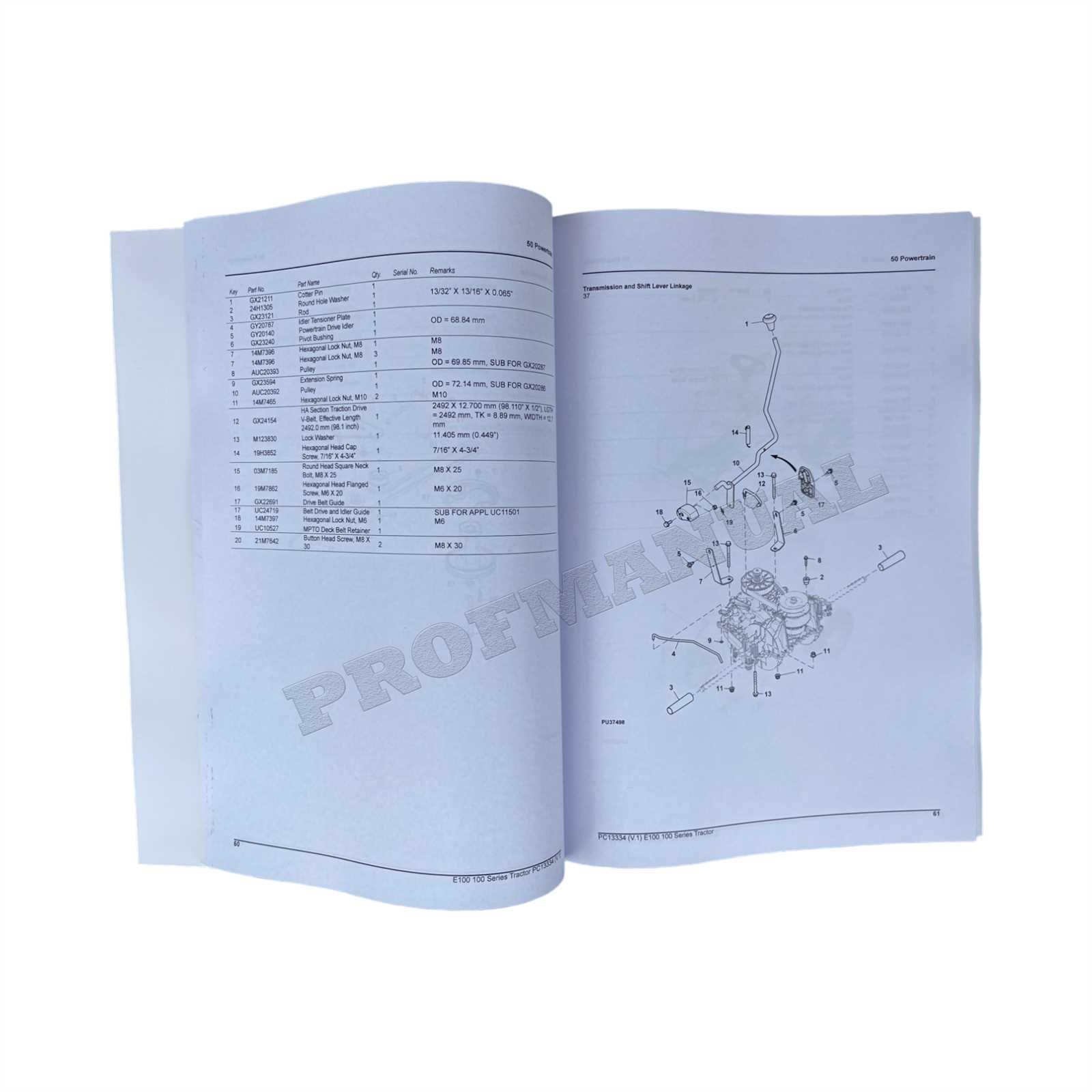

Replacement Options for E100 Components

When it comes to maintaining outdoor machinery, exploring alternatives for key components is essential for ensuring optimal performance. Various options exist for those looking to replace worn-out or damaged elements, each with its advantages.

- OEM Components: Original parts offer reliability and perfect compatibility with your machinery.

- Aftermarket Parts: Often more affordable, these alternatives can provide similar performance but may vary in quality.

- Rebuilt Components: Reconditioned parts can be a cost-effective solution, ensuring functionality while being environmentally friendly.

- Custom Solutions: Tailored parts designed for specific needs can enhance performance beyond standard offerings.

Choosing the right option depends on budget, performance needs, and how often you use the equipment.

Maintenance Tips for E100 Engine

Regular upkeep is essential for ensuring the longevity and optimal performance of your machinery. Implementing a consistent maintenance routine can prevent unexpected issues and enhance efficiency. Here are some key strategies to keep in mind.

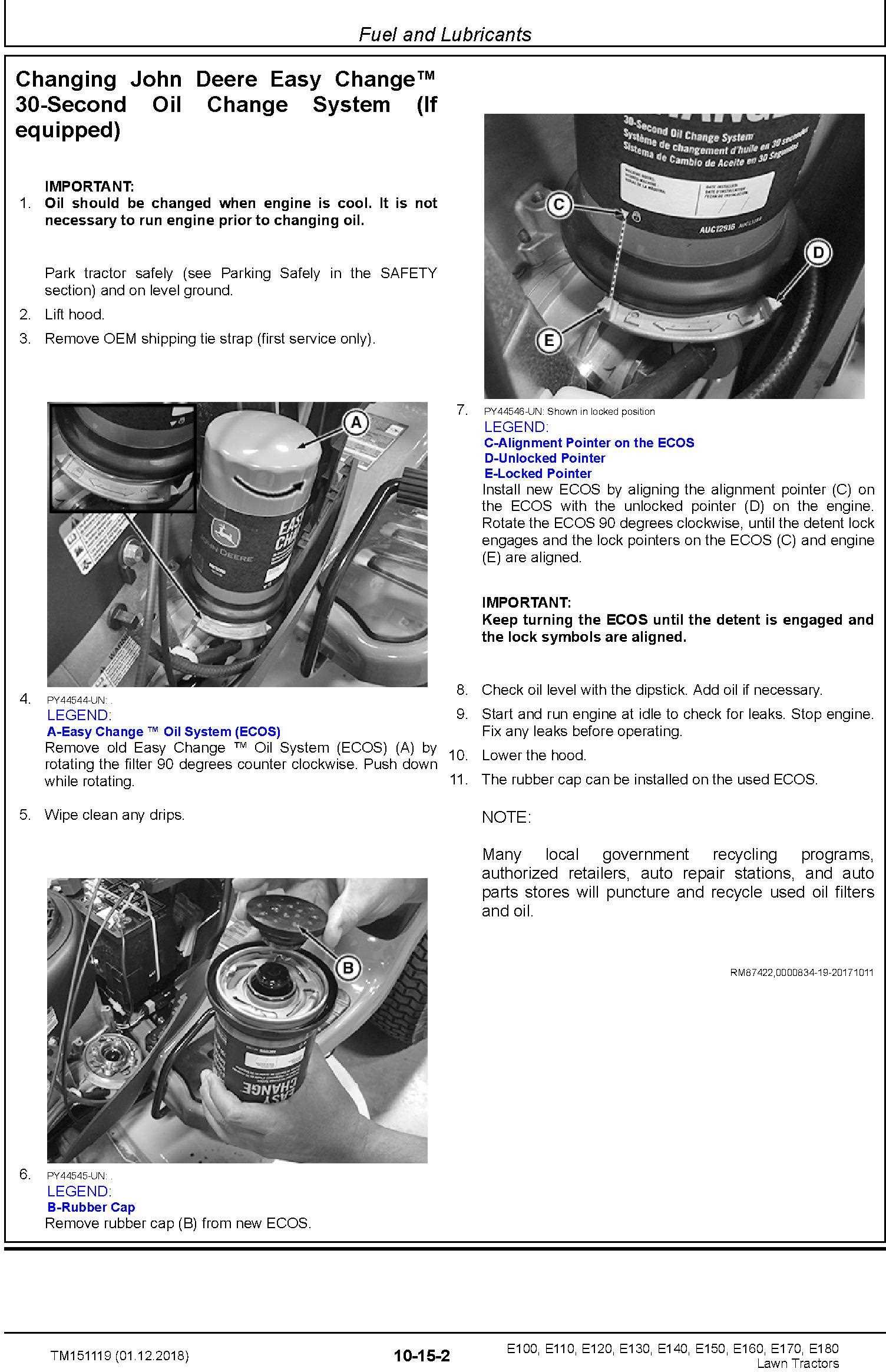

1. Regular Oil Changes: Keeping the lubricant fresh is crucial for smooth operation. Check the manufacturer’s recommendations for intervals and use the correct type of oil.

2. Air Filter Inspection: A clean air filter is vital for proper airflow. Examine and replace the filter periodically to prevent dust and debris from affecting performance.

3. Spark Plug Maintenance: Inspecting and replacing spark plugs as needed can significantly improve starting and fuel efficiency. Ensure they are clean and free of corrosion.

4. Battery Care: Regularly check the battery terminals for corrosion and ensure a secure connection. Keep the battery charged, especially during off-seasons.

5. Fuel System Checks: Ensure that the fuel system is free of contaminants. Use high-quality fuel and consider adding a fuel stabilizer if the equipment will not be used for an extended period.

6. Cleaning: Regularly clean the exterior and undercarriage to remove dirt and debris, which can affect performance and lead to corrosion.

By adhering to these maintenance practices, you can enhance the reliability and lifespan of your equipment, ensuring it operates effectively when you need it most.

Comparing E100 with Other Models

This section aims to explore the differences and similarities between a specific lawn care machine and its counterparts. By analyzing various features, performance metrics, and overall efficiency, we can gain insight into how this model stands out in its category.

Key Features Overview

When assessing various models, it’s essential to consider crucial aspects such as power, durability, and user-friendliness. Below is a comparative table highlighting these features:

| Feature | Model A | Model B | Model C |

|---|---|---|---|

| Power Output | 15 HP | 18 HP | 12 HP |

| Cutting Width | 42 inches | 46 inches | 38 inches |

| Fuel Efficiency | 2.5 L/h | 2.8 L/h | 2.2 L/h |

Performance Metrics

Performance is another vital factor that differentiates these machines. Factors such as handling on uneven terrain, speed, and maintenance requirements are critical for potential users. Analyzing these metrics allows buyers to make informed decisions based on their specific needs.

Resources for Parts and Repair

Accessing quality components and guidance for maintenance is crucial for ensuring optimal performance of machinery. Various resources exist to assist enthusiasts and professionals alike in finding what they need for effective repairs and replacements.

Online Platforms

Numerous websites provide comprehensive catalogs of available components along with helpful repair guides. These platforms often include user reviews, pricing comparisons, and availability details to streamline the purchasing process.

Local Retailers and Distributors

Visiting nearby shops can be beneficial for obtaining components quickly and receiving personalized advice from knowledgeable staff. Many local distributors also offer support for repairs and maintenance tips.

| Resource Type | Examples | Notes |

|---|---|---|

| Online Stores | eBay, Amazon, Specialty Websites | Wide selection, shipping options vary. |

| Local Shops | Hardware Stores, Specialty Shops | Immediate availability, expert assistance. |

| Manufacturer Websites | Official Brand Sites | Direct access to genuine items. |

Frequently Asked Questions About E100

This section addresses common inquiries related to the model, providing clarity and insights for users. Here, you’ll find answers to essential questions that help enhance understanding and operational efficiency.

What maintenance is required for optimal performance?

Regular upkeep is crucial for ensuring longevity. This includes checking fluid levels, replacing filters, and maintaining the cutting blades. Proper care leads to improved functionality and a smoother operation.

How can I troubleshoot common issues?

Identifying problems often starts with simple checks. Ensure that fuel is fresh and connections are secure. For more complex issues, consulting the manual or a professional can provide valuable guidance. Understanding these aspects enhances your overall experience.