Comprehensive Guide to John Deere E150 Parts Diagram

When working with a lawn tractor, having a clear overview of its various systems and elements is crucial for efficient maintenance. Each section of the vehicle plays a specific role, ensuring smooth operation, and knowing how everything fits together can make repairs and part replacements easier.

Breaking down the individual mechanical sections allows for a better grasp of how these machines function as a whole. This understanding can significantly improve troubleshooting efforts, helping identify issues and maintain the vehicle in optimal condition for years to come.

Comprehensive knowledge of each mechanical part is the key to extending the life of your equipment. Whether it’s the engine, drivetrain, or other operational components, familiarity with their layout can save time and reduce frustration during repair processes.

Understanding John Deere E150 Parts

To maintain peak performance of your equipment, it’s crucial to familiarize yourself with its components and how they interact. A well-structured system relies on the seamless function of each element, ensuring longevity and efficiency in operation. Identifying key elements and understanding their roles will help in routine care and replacements when necessary.

The following list breaks down essential aspects of the machine’s design:

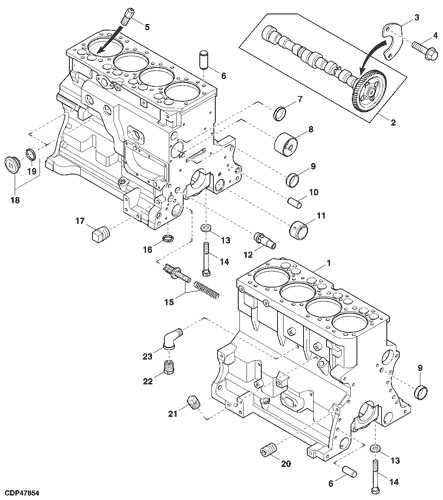

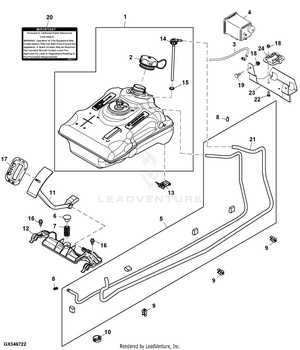

- Engine components – essential for powering the machine, these include mechanisms like cylinders and fuel systems.

- Transmission system – responsible for controlling speed and torque, it ensures smooth transitions during use.

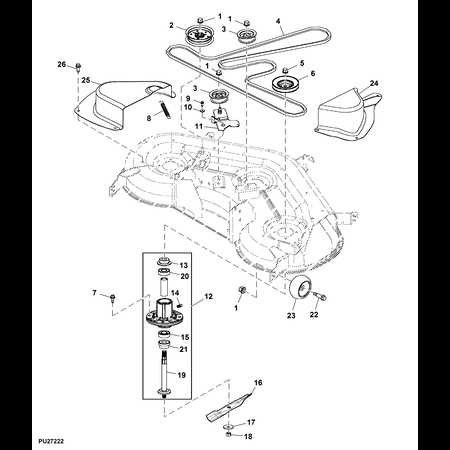

- Cutting mechanisms – blades and deck work together to provide precise and even results on the field.

- Electrical systems – from ignition to lights, these manage various automated functions for user convenience.

By recognizing the roles of these elements, you can better address issues and perform preventative care, helping the machine run smoothly for years to come.

Overview of E150 Lawn Tractor

The E150 lawn tractor is a reliable choice for maintaining medium to large residential yards. Built for durability and ease of use, this machine offers a comfortable riding experience combined with efficient cutting performance. It’s designed to simplify yard work, providing consistent results with minimal effort. Whether you’re mowing expansive lawns or navigating tighter spaces, the model ensures a balanced and controlled operation.

Key Features

This lawn tractor comes equipped with a sturdy frame, a powerful engine, and a precise cutting system. Its ergonomic controls and adjustable settings cater to a wide range of user preferences, making it a versatile tool for any landscaping task. The model also offers enhanced maneuverability, allowing users to navigate around obstacles with ease.

Performance and Usability

With its responsive steering and smooth transmission, this lawn tractor delivers a reliable performance under various conditions. The well-thought-out design ensures not only efficiency but also longevity, making it a valuable addition to any lawn care routine.

Key Components of E150

The essential elements of this model consist of a robust set of interconnected systems designed to enhance performance, reliability, and user experience. Each part plays a critical role in ensuring smooth operation and efficient handling, while the machine’s structure provides the necessary support for a wide range of functions.

Engine and Transmission

The power unit is the core driving force behind the vehicle, delivering consistent energy to handle various tasks. Coupled with the transmission system, it ensures that power is distributed effectively to maintain optimal performance under different conditions.

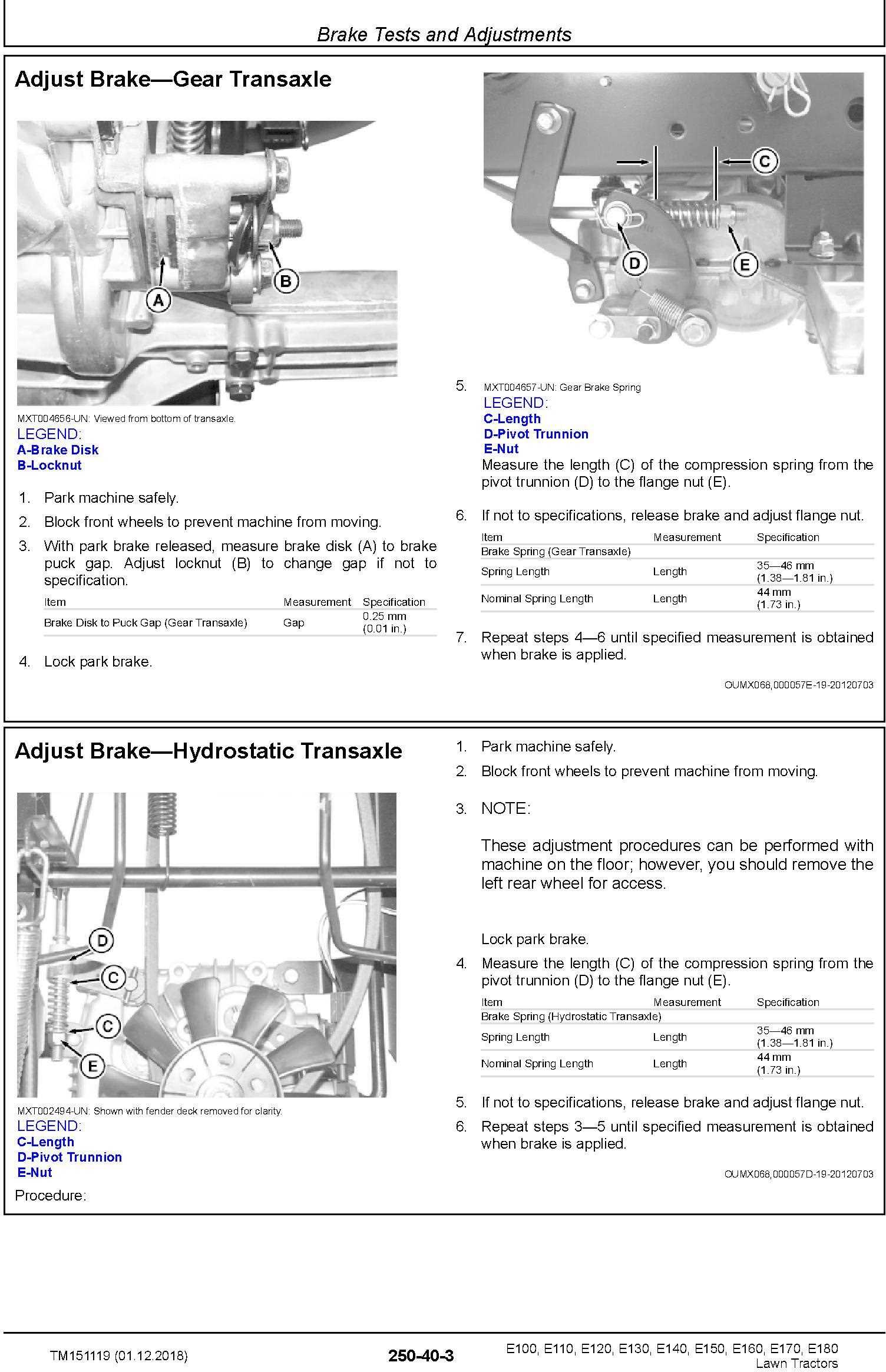

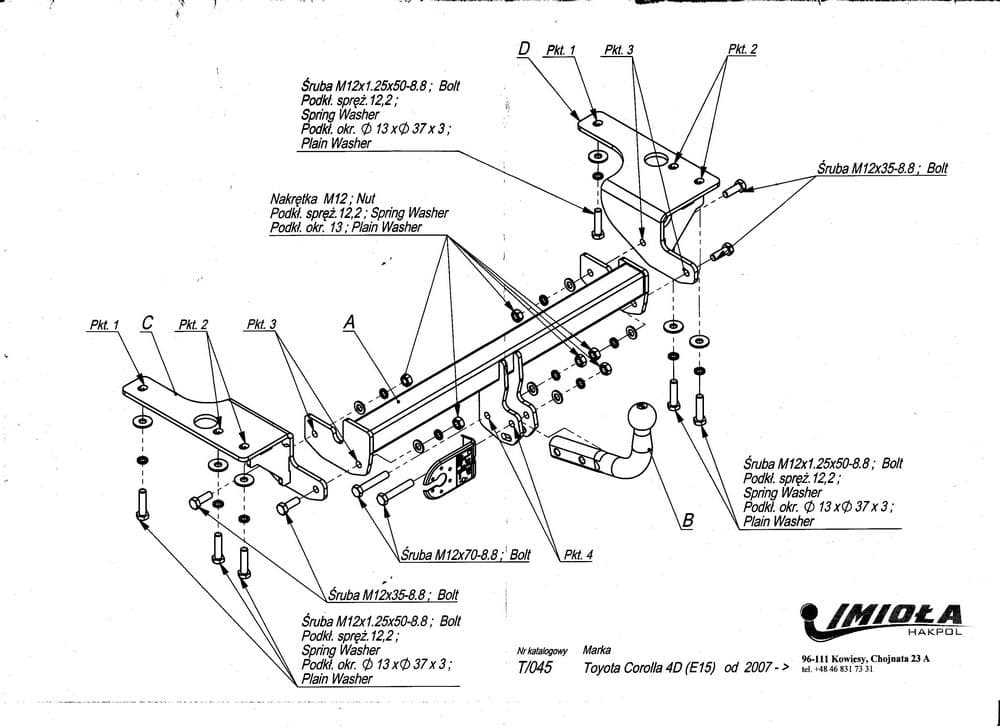

Steering and Braking Systems

Efficient control is achieved through a precise steering mechanism, allowing for smooth maneuvering. The braking system ensures safety and reliability, providing strong stopping power when needed. Together, these systems offer excellent control and handling, even in challenging environments.

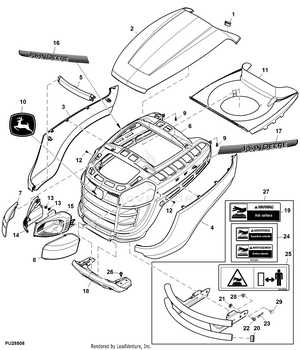

Importance of Parts Diagrams

Understanding how components fit together is crucial for efficient maintenance and repair. A clear visual guide allows technicians and users alike to identify individual elements and see how they interact within the whole system. Without this organized reference, even simple tasks can become challenging, leading to potential errors and unnecessary downtime.

There are several key benefits to using these visual references:

- Accuracy: They provide detailed layouts, ensuring that each component is placed correctly during repairs.

- Efficiency: With all elements clearly marked, identifying what needs replacement or adjustment becomes faster.

- Safety: Proper assembly reduces the risk of accidents or damage caused by incorrect installations.

- Cost savings: Correct identification of faulty elements helps avoid unnecessary purchases of wrong or additional components.

In summary, utilizing these tools streamlines the entire process of repairing and maintaining complex machines, enhancing both safety and productivity.

How to Read Parts Diagrams

Understanding technical illustrations is essential when working with machinery. These drawings represent how different components fit together and provide a clear visual guide for assembly or repair. By following the schematic, you can identify individual elements, their connections, and ensure proper alignment during installation or replacement.

Identifying Symbols and Labels

Each component in a schematic is typically represented by a symbol or code. Learning to recognize these symbols helps you quickly locate what you need. Often, the symbols are accompanied by labels or numbers that refer to the specific component’s name or order code.

Following the Assembly Sequence

Another critical aspect is understanding the sequence of assembly or disassembly. Diagrams often depict the order in which components should be installed or removed, which ensures the machine operates smoothly and reduces the risk of mistakes during maintenance.

Common Replacement Parts for E150

Regular upkeep of outdoor equipment often involves swapping out various components due to wear and tear. Knowing which elements are most prone to deterioration can help maintain optimal performance and extend the lifespan of your machinery. Below is a list of frequently replaced elements that ensure smooth and efficient operation.

| Component | Function |

|---|---|

| Air Filter | Ensures clean air intake, preventing engine damage from debris. |

| Blades | Responsible for precise cutting and maintaining a uniform lawn appearance. |

| Belts | Transmits power between various parts of the system, ensuring seamless operation. |

| Spark Plug | Ignites the fuel, allowing for consistent engine start and performance. |

| Oil Filter | Prevents contaminants from

Finding OEM Parts for E150When maintaining or repairing equipment, sourcing original manufacturer components is essential for ensuring optimal performance and long-term reliability. Selecting high-quality items guarantees that the machinery operates as designed, with the added benefit of preserving warranties and minimizing potential breakdowns. Why Choose Original Components?Authentic components are specifically designed for the equipment they support. By using these, you can be confident in the exact fit and durability, unlike generic alternatives that might not offer the same level of precision or quality. This not only reduces wear but also improves overall efficiency. How to Source the Right ComponentsTo find the correct replacements, it is recommended to consult official guides or reach out to certified retailers who specialize in providing the exact items for your specific model. This ensures that you get the right match and avoid costly mistakes. Aftermarket vs. OEM PartsWhen maintaining or repairing machinery, one of the key decisions is choosing between aftermarket and original equipment manufacturer (OEM) components. Both options have their unique advantages and disadvantages, making it essential to understand how they differ to make an informed decision. Key Differences

Which Option is Better?

The best choice depends on your priorities. If long-term reliability and perfect fit are most important, OEM is likely the safer option. However, if you are looking for a more cost-effective solution with potentially quicker availability, aftermarket alternatives may be more appealing.

|