Comprehensive Guide to John Deere F620 Parts Diagram

Maintaining the efficiency of agricultural machinery is crucial for optimal performance. This section aims to provide a comprehensive overview of the key elements that contribute to the functionality and longevity of your equipment. By exploring the intricate relationships between these components, you can ensure seamless operation.

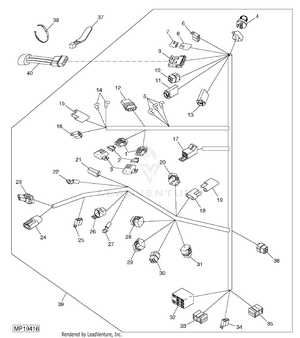

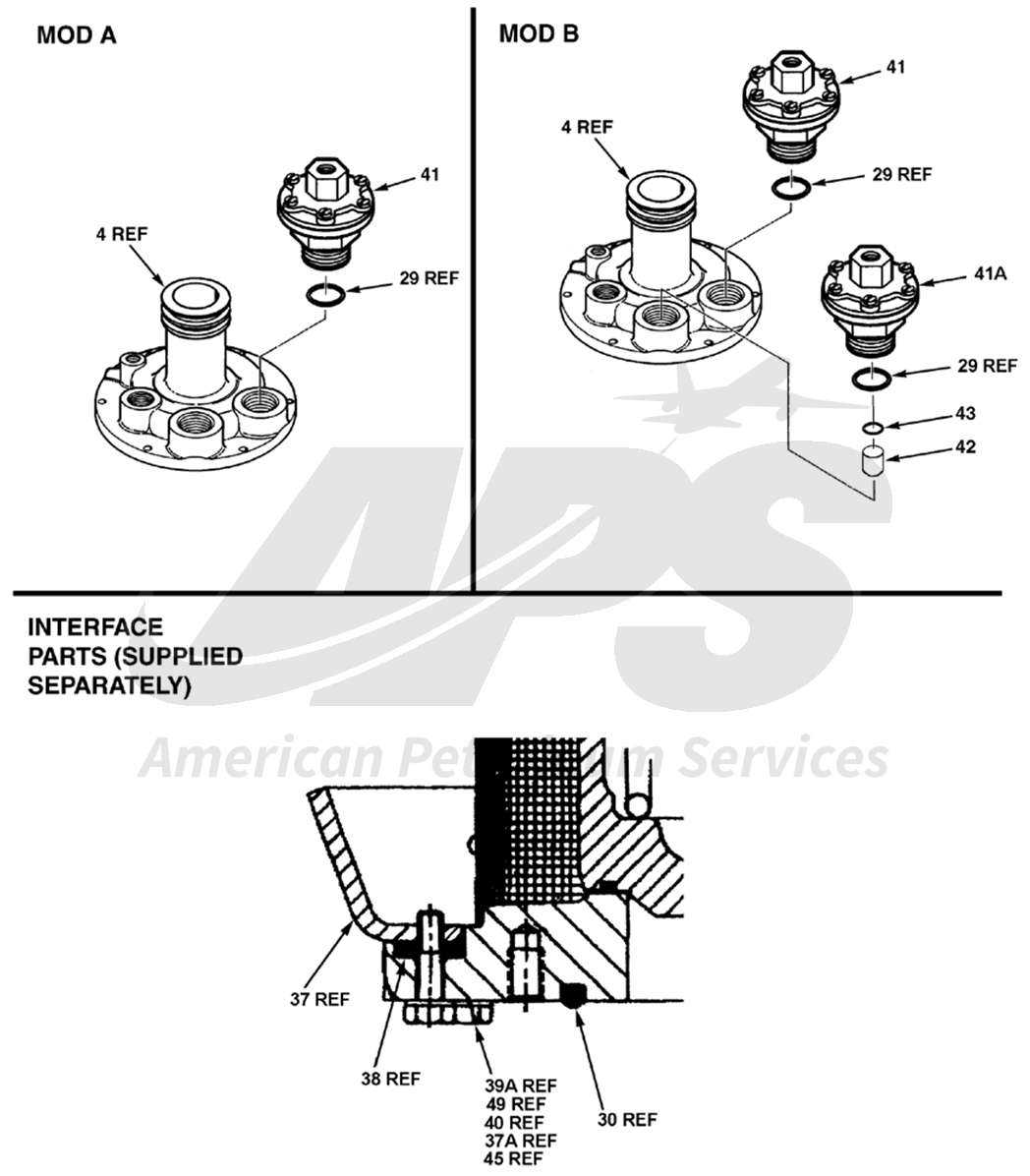

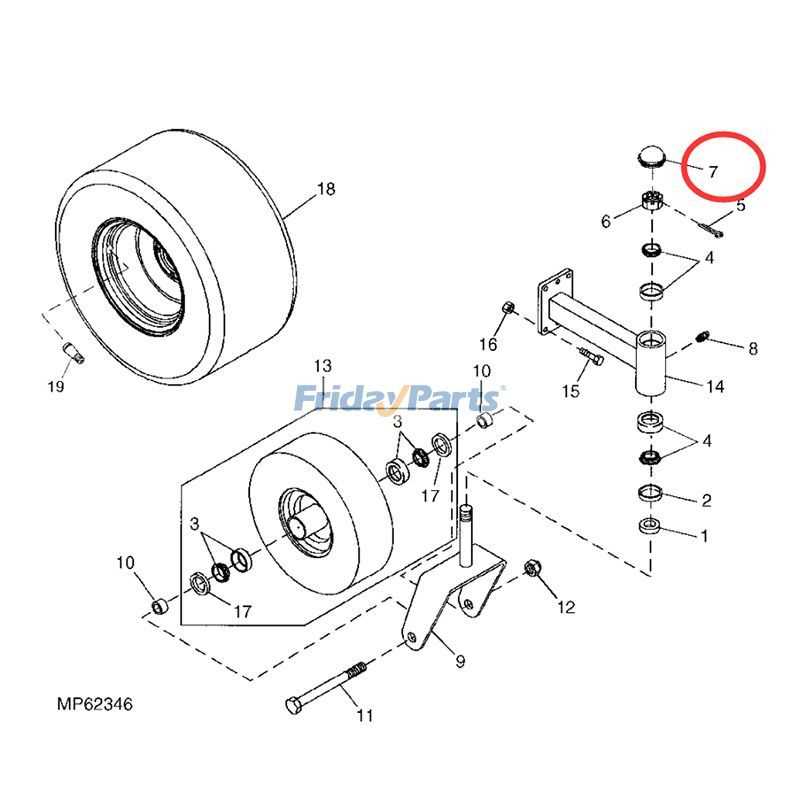

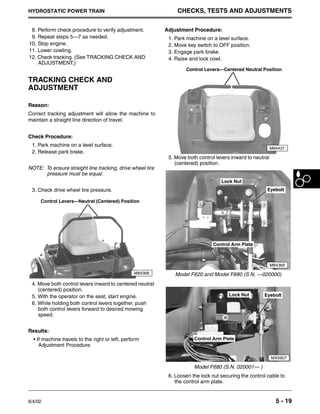

Visualizing the layout of these critical elements can significantly enhance your ability to troubleshoot and perform maintenance tasks. A well-organized representation not only simplifies the understanding of how each part interacts but also assists in identifying potential issues before they escalate.

By delving into the specifics of each section, you’ll gain the ultimate insight necessary for effective management of your machinery. This knowledge empowers you to make informed decisions regarding repairs and upgrades, ultimately leading to improved productivity and reduced downtime.

Understanding John Deere F620 Parts

Grasping the components of a specific lawn maintenance machine is crucial for effective operation and upkeep. This knowledge empowers users to identify essential elements and ensures optimal performance. An organized overview of each segment can greatly enhance one’s ability to troubleshoot and maintain their equipment.

Key Components: Familiarity with the main elements such as the engine, transmission, and cutting deck allows operators to recognize signs of wear and tear. Regular inspection and understanding of these vital parts lead to improved longevity and functionality.

Maintenance Tips: Adopting a proactive approach towards care can prevent costly repairs. Routine checks and timely replacements of worn components ensure that the machine remains in peak condition, contributing to a seamless experience during use.

Overview of F620 Components

This section provides a comprehensive look at the various elements that make up the model in question. Understanding these components is essential for effective maintenance and operation, ensuring optimal performance in various tasks.

The assembly consists of several crucial units, each designed to contribute to the overall functionality. Key segments include the powertrain, which facilitates movement and propulsion, and the cutting mechanism, responsible for achieving precise results in landscaping and mowing applications.

Additionally, the control systems play a vital role in maneuverability and ease of operation. These features enhance user experience, allowing for better handling in diverse environments. Each component is engineered for durability and efficiency, reflecting the high standards expected in modern agricultural machinery.

By familiarizing oneself with these essential parts, operators can ensure longevity and reliability, minimizing downtime and enhancing productivity in the field.

Importance of Accurate Parts Diagrams

Precise illustrations of components are essential in any machinery maintenance or repair process. They provide a clear visual reference that aids in identifying each element’s function and placement, ensuring efficient assembly or disassembly. By utilizing detailed representations, technicians can minimize errors and enhance their understanding of complex systems.

These visual aids not only streamline repairs but also improve communication among team members. When everyone refers to the same accurate representation, the risk of misinterpretation is significantly reduced. Moreover, such clarity contributes to time efficiency, allowing for quicker resolution of issues and better overall performance of the equipment.

Ultimately, reliable visuals serve as a foundational resource that empowers users to approach maintenance tasks with confidence and competence. Ensuring that these illustrations are up-to-date and accurate can lead to improved longevity and reliability of machinery, making them invaluable tools in the field.

Common Issues with F620 Parts

When it comes to maintaining outdoor machinery, several common challenges often arise. Users frequently encounter difficulties that can affect performance and longevity. Understanding these issues can help in making informed decisions about repairs and replacements.

One prevalent concern involves wear and tear on components due to regular usage. As time goes on, parts may degrade, leading to reduced efficiency and increased strain on the overall system. It’s crucial to monitor these elements closely to prevent more significant problems.

Another frequent issue is improper installation or alignment of various elements. This can result in miscommunication between connected systems, causing malfunctions. Ensuring that all parts are correctly fitted and aligned is essential for optimal functionality.

Additionally, exposure to harsh environmental conditions can lead to rust and corrosion, particularly in metal components. Regular maintenance, including cleaning and protective treatments, can mitigate these risks and extend the lifespan of the equipment.

Lastly, inadequate lubrication can contribute to friction-related issues. Keeping moving parts well-lubricated is vital for smooth operation and to avoid unnecessary wear. Regular checks and timely maintenance can help address these common concerns effectively.

Where to Find Genuine Parts

Finding authentic components for your machinery is crucial for maintaining optimal performance and longevity. Reliable sources ensure quality and compatibility, allowing for seamless operation and reduced downtime.

Authorized Dealers

- Visit local authorized distributors.

- Check official websites for recommendations.

- Utilize online dealer locators for convenience.

Online Marketplaces

- Explore reputable e-commerce platforms.

- Read customer reviews to gauge trustworthiness.

- Verify seller ratings and return policies.

Repair Techniques for F620 Models

Maintaining and restoring machinery requires a blend of skill and knowledge about various components and their interactions. Effective troubleshooting and repair methods not only enhance performance but also extend the lifespan of equipment. This section outlines essential techniques to ensure optimal operation and reliability of your model.

Diagnostic Procedures

Before embarking on any repair, a thorough diagnostic process is crucial. Begin by observing the equipment’s behavior and identifying any irregularities. Utilize specialized tools to assess performance metrics and gather data. This systematic approach allows for pinpointing issues accurately, ensuring that repairs address the root causes rather than merely symptoms.

Replacement and Maintenance Strategies

Once the problems have been identified, focus on replacement and upkeep of worn components. Regular inspection and timely replacement of critical elements can prevent more extensive damage. Consider using high-quality materials and reputable suppliers to ensure longevity. Moreover, adopting a routine maintenance schedule can greatly enhance efficiency and reduce the likelihood of unexpected breakdowns.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your machinery requires consistent upkeep and attention to detail. Proper maintenance not only extends the lifespan of your equipment but also enhances its performance, ultimately saving you time and money.

Regular Inspections

Conducting routine checks is essential. Look for signs of wear, fluid leaks, and any irregularities. Early detection can prevent more significant issues down the line.

Keep It Clean

Maintaining cleanliness is vital for optimal functionality. Regularly clean filters and surfaces to avoid buildup that can hinder performance. A clean machine is a reliable machine.

Upgrading Your F620 Equipment

Enhancing your machinery can significantly improve performance and efficiency. By selecting the right upgrades, you can extend the life of your equipment while boosting productivity. This section will explore various options available to optimize your device’s functionality.

Key Components for Enhancement

When considering enhancements, focus on components that directly impact operational capacity. These may include improved engines, advanced control systems, or better traction mechanisms. Upgrading these areas can lead to noticeable improvements in output and reliability.

Maintenance and Compatibility

Ensure that any new additions are compatible with existing systems. Regular maintenance checks should accompany upgrades to avoid any potential issues. Proper integration of new features will maximize benefits and ensure smooth operation.

| Upgrade Type | Benefits | Considerations |

|---|---|---|

| Engine Performance | Increased power and efficiency | Compatibility with existing systems |

| Control Systems | Enhanced precision and ease of use | Installation complexity |

| Traction Mechanisms | Better stability and handling | Cost of implementation |

Identifying Compatible Replacement Parts

When it comes to ensuring optimal performance of your equipment, selecting the right substitute components is crucial. Understanding the nuances of compatibility can help you make informed choices, enhancing efficiency and longevity.

- Research manufacturer specifications to find equivalent alternatives.

- Consult user manuals for recommended substitutes and installation guidelines.

- Utilize online forums and communities for shared experiences and advice.

Additionally, consider the following factors:

- Material quality: Ensure that replacements meet or exceed original standards.

- Compatibility checks: Confirm that the dimensions and fittings match your equipment.

- Warranty implications: Verify how substitutions affect existing warranties.

Benefits of OEM vs. Aftermarket Parts

The choice between original components and alternative solutions can significantly impact performance, reliability, and overall satisfaction. Each option presents distinct advantages that can cater to various needs and preferences, making it essential to understand their implications for machinery maintenance and repair.

| Aspect | OEM Components | Aftermarket Solutions |

|---|---|---|

| Quality | Manufactured to exact specifications, ensuring optimal compatibility and performance. | Varies widely; some may match or exceed OEM quality, while others may not meet standards. |

| Warranty | Typically comes with a warranty that covers defects and ensures longevity. | May have limited or no warranty, leading to potential risks in case of failure. |

| Availability | Readily available through official channels, ensuring quick access. | Often found at a wider range of suppliers, providing more options for sourcing. |

| Cost | Generally more expensive due to brand reputation and quality assurance. | Usually more affordable, appealing to budget-conscious consumers. |

| Performance | Designed to maintain the original performance characteristics of the machinery. | Can offer enhanced features or different performance metrics, depending on the manufacturer. |

Understanding the benefits of both types of components enables informed decisions that align with individual priorities, whether that be quality, cost-effectiveness, or specific performance needs.

Tools Needed for F620 Repairs

Performing maintenance and repairs on your equipment requires a specific set of instruments to ensure efficiency and effectiveness. Having the right tools not only simplifies the process but also enhances safety and precision during repairs. Below is a list of essential tools that will aid you in keeping your machinery in optimal condition.

- Socket Set: A comprehensive socket set is crucial for loosening and tightening various fasteners.

- Wrenches: Adjustable wrenches and combination wrenches are necessary for different bolt sizes.

- Screwdrivers: Both flathead and Phillips screwdrivers are needed for handling various screws.

- Pliers: Needle-nose and standard pliers help with gripping and twisting components.

- Torque Wrench: This tool ensures that bolts are tightened to the manufacturer’s specifications.

- Jack and Jack Stands: These are essential for safely lifting the machinery during repairs.

- Multimeter: For electrical diagnostics, a multimeter is invaluable in troubleshooting electrical issues.

- Grease Gun: Regular lubrication is vital; a grease gun facilitates this process.

- Diagnostic Software: Utilizing software can help in identifying mechanical issues quickly.

By equipping yourself with these tools, you can perform repairs with greater confidence and achieve better results. Regular maintenance not only prolongs the lifespan of your equipment but also enhances its overall performance.

Resources for Further Research

Exploring the intricacies of machinery components can greatly enhance understanding and maintenance capabilities. A variety of sources are available to facilitate deeper insights into equipment and its essential elements.

| Resource Type | Description | Link |

|---|---|---|

| Manufacturer Manuals | Official guides detailing specifications and assembly. | Visit |

| Online Forums | Communities where enthusiasts share tips and experiences. | Visit |

| Parts Suppliers | Websites offering component listings and pricing. | Visit |

| Technical Blogs | Articles providing insights and tutorials on equipment upkeep. | Visit |