Understanding the John Deere Gator 825i Front Differential Parts Diagram

The intricate design of utility vehicles plays a crucial role in their functionality and performance. These machines are engineered with a variety of components that work in harmony to ensure efficient operation across diverse terrains. Analyzing the structure of these vehicles can provide valuable insights into their maintenance and repair.

One essential aspect of these vehicles is the arrangement of their transmission system, which allows for smooth power delivery and enhanced control. Familiarity with this configuration can significantly aid in troubleshooting common issues, ensuring that users can keep their vehicles in peak condition.

In this article, we will explore the layout of a specific section of the vehicle, offering a comprehensive overview of its elements. By understanding how these parts interact, operators can make informed decisions about maintenance and upgrades, ultimately prolonging the lifespan of their machines.

Understanding John Deere Gator 825i

This section provides insight into a robust utility vehicle designed for various tasks, from farming to recreational use. It combines functionality with durability, making it a versatile choice for many users.

Key features of this vehicle include:

- Powerful engine that delivers impressive performance.

- All-terrain capabilities for navigating diverse landscapes.

- Spacious cargo area for transporting tools or equipment.

- Comfortable seating arrangements for multiple passengers.

Maintenance and understanding of the vehicle’s components are crucial for longevity. Here are some essential maintenance tips:

- Regularly check fluid levels, including oil and coolant.

- Inspect tires for proper inflation and tread wear.

- Clean and maintain the air filter to ensure optimal performance.

- Schedule routine inspections to identify potential issues early.

Familiarizing yourself with the inner workings can enhance the overall experience. Knowing the critical systems helps in effective troubleshooting and repairs.

Overview of the Gator 825i Model

This versatile utility vehicle is designed to tackle a variety of tasks with ease, making it a popular choice among outdoor enthusiasts and professionals alike. With its robust construction and reliable performance, this machine is well-suited for both recreational and agricultural applications.

Key Features

The vehicle boasts an impressive array of features that enhance its functionality. A powerful engine provides ample torque and speed, allowing users to navigate diverse terrains effortlessly. Additionally, the spacious cargo area is designed to accommodate a range of tools and supplies, making it ideal for transporting equipment or goods.

Durability and Performance

Engineered for resilience, this model can withstand harsh conditions while maintaining optimal performance. The all-wheel drive system ensures superior traction, enabling smooth operation even in challenging environments. Moreover, user-friendly controls and a comfortable seating arrangement contribute to an enjoyable driving experience.

In summary, this utility vehicle stands out for its blend of strength, versatility, and ease of use, making it a top choice for those in need of a reliable companion for various outdoor tasks.

Importance of the Front Differential

The mechanism responsible for the distribution of power to the wheels is crucial for any vehicle’s performance and handling. It plays a vital role in ensuring that the wheels rotate at different speeds, particularly during turns. This function enhances traction, stability, and overall maneuverability, which are essential for effective operation in various terrains.

Benefits of a Well-Functioning Mechanism

- Improved Traction: Ensures that wheels maintain contact with the ground, enhancing grip on uneven surfaces.

- Enhanced Stability: Balances the vehicle, preventing it from tipping over in challenging conditions.

- Better Maneuverability: Facilitates sharper turns without slipping or losing control.

Consequences of Malfunction

When this essential component fails, it can lead to a range of issues that affect performance:

- Increased tire wear due to uneven power distribution.

- Difficulty in navigating sharp corners, leading to potential accidents.

- Loss of power and responsiveness, hindering the vehicle’s ability to perform optimally.

Regular maintenance and timely repairs are crucial to ensure that this mechanism operates efficiently, contributing to the overall longevity and reliability of the vehicle.

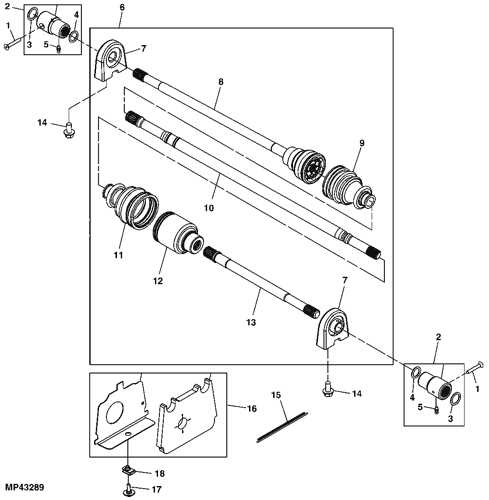

Components of the Differential Assembly

The assembly responsible for distributing power to the wheels consists of several crucial elements that work in harmony. Understanding these components is essential for effective maintenance and repairs, ensuring optimal performance and longevity of the vehicle.

Main Components

- Case: The housing that contains the inner workings and protects them from external debris.

- Ring Gear: A large gear that receives torque from the driveshaft and transmits it to the pinion gear.

- Pinion Gear: A smaller gear that engages with the ring gear, playing a critical role in gear reduction.

- Side Gears: These components connect directly to the axles, allowing for the transfer of torque to the wheels.

- Spider Gears: Also known as differential gears, these allow for wheel speed variation during turns.

Additional Components

- Bearings: Support the rotating elements, reducing friction and wear.

- Seals: Prevent fluid leaks and keep contaminants out of the assembly.

- Shims: Used to adjust clearances for optimal performance.

Each of these elements plays a vital role in the overall functionality, ensuring the vehicle can handle various terrains and driving conditions effectively.

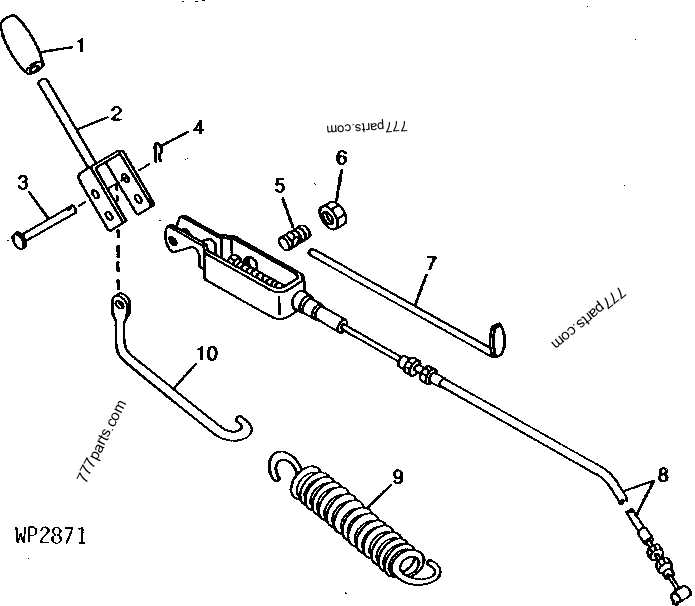

Parts Diagram Explanation

This section delves into the visual representation of components that make up the vehicle’s system. By understanding the layout and function of each element, users can enhance their knowledge of maintenance and repair procedures. These illustrations serve as invaluable tools for identifying specific elements and their relationships within the overall assembly.

Understanding Component Relationships

Each illustration not only highlights individual elements but also demonstrates how they interact within the system. Recognizing these connections is crucial for troubleshooting issues and performing effective repairs. Familiarity with this schematic representation empowers users to approach tasks with confidence and clarity.

Utilizing the Visual Guide

To effectively use the visual guide, one should start by identifying the components relevant to their specific needs. A clear comprehension of each part’s location and role aids in systematic disassembly and reassembly. Moreover, this knowledge minimizes the risk of overlooking essential elements during maintenance, ensuring optimal functionality.

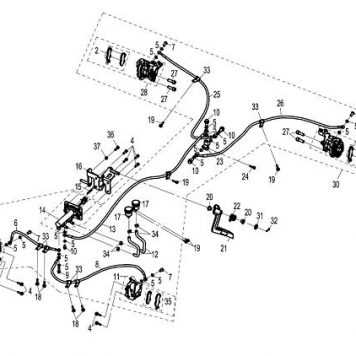

Common Issues with the Front Differential

The mechanism responsible for power distribution in various all-terrain vehicles often encounters a range of complications that can impact performance and efficiency. Understanding these typical problems is essential for effective maintenance and timely repairs, ensuring optimal functionality and longevity.

One prevalent issue is the wear and tear of internal components due to prolonged use. Friction can lead to degradation of gears and bearings, resulting in noise and reduced efficiency. Regular inspection can help identify signs of wear early, allowing for preventive measures.

Another concern involves fluid leaks, which may arise from faulty seals or gaskets. Insufficient lubricant levels can lead to overheating and increased friction, ultimately damaging the internal workings. Monitoring fluid levels and addressing leaks promptly is crucial for maintaining the system’s health.

Moreover, misalignment can cause uneven wear and stress on components. This misalignment may stem from improper installation or damage to the frame, necessitating careful alignment checks and adjustments to restore balance.

Finally, abnormal sounds during operation often indicate underlying problems. Grinding, clunking, or whining noises may suggest issues with gears or bearings that require immediate attention to prevent further damage.

Maintenance Tips for Optimal Performance

Ensuring peak functionality of your utility vehicle requires regular upkeep and attention to detail. Proper maintenance not only enhances efficiency but also extends the lifespan of various components, ultimately saving time and resources in the long run.

Start with routine inspections to identify any wear or damage early on. Check fluid levels and replace them according to the manufacturer’s recommendations, as clean lubricants play a crucial role in reducing friction and preventing overheating. Additionally, clean or replace air and fuel filters regularly to maintain optimal engine performance.

Pay attention to tire pressure and tread wear, as they directly impact handling and safety. Regularly clean the vehicle to remove dirt and debris that can lead to corrosion or other issues. Finally, consult the service manual for any specific maintenance schedules and adhere to them to ensure your machine runs smoothly and efficiently.

How to Replace Differential Parts

Replacing essential components in the drivetrain system can significantly enhance the performance and longevity of your vehicle. This process requires attention to detail and a solid understanding of the assembly. By following a methodical approach, you can ensure that everything functions smoothly once reassembled.

Preparation and Tools

Before beginning, gather all necessary tools and replacement components. A well-organized workspace is crucial for efficiency. Common tools include wrenches, sockets, and screwdrivers. Additionally, having a service manual can provide valuable insights into specifications and assembly sequences.

Step-by-Step Replacement Process

Start by safely lifting the vehicle and securing it on jack stands. Remove the cover to access the components you intend to replace. Carefully detach the existing elements, taking note of their arrangement for reinstallation. Once removed, clean the area to ensure no debris interferes with the new components. Install the new parts, ensuring proper alignment and secure fastening. Finally, replace the cover, double-checking all connections before lowering the vehicle and conducting a test run to confirm functionality.

Tools Needed for Repairs

When undertaking maintenance or repairs on your utility vehicle, having the right tools is essential for efficient and effective work. A well-equipped toolkit can make a significant difference in both the ease of the repair process and the overall outcome. Below are some of the key tools that you should have on hand to tackle various tasks.

Wrenches and Sockets: A set of both metric and standard wrenches will allow you to handle a variety of bolts and nuts. Socket sets, particularly those with deep sockets, can provide better access to hard-to-reach areas.

Screwdrivers: Flathead and Phillips screwdrivers are indispensable for removing and securing various components. Having a range of sizes will ensure that you can tackle any screws you encounter.

Pliers: A good pair of pliers is useful for gripping, twisting, and cutting wires or small components. Needle-nose pliers can also help in tight spaces.

Torque Wrench: To ensure that fasteners are tightened to the manufacturer’s specifications, a torque wrench is crucial. This tool helps prevent over-tightening, which can lead to damage.

Jack and Stands: For any undercarriage work, a reliable jack and jack stands are necessary for safely elevating the vehicle. This provides the necessary clearance to access components easily.

Multimeter: For electrical diagnostics, a multimeter can help you troubleshoot wiring issues and check for continuity.

Having these essential tools readily available will streamline the repair process and enhance your ability to perform quality maintenance on your vehicle.

Signs of Differential Wear

Identifying the signs of deterioration in crucial drivetrain components is essential for maintaining optimal performance. Awareness of these indicators can prevent further damage and ensure longevity. Here are some common symptoms to look out for:

- Unusual Noises: Grinding, whining, or clunking sounds while turning can indicate internal wear.

- Vibration: Excessive shaking or vibrations during operation may signal misalignment or wear.

- Fluid Leaks: Puddles or spots of lubricant under the vehicle could suggest a seal failure.

- Overheating: Increased operating temperature can result from insufficient lubrication or internal friction.

- Difficulty Turning: Struggling to steer or excessive resistance may indicate issues with the system.

Regular inspection and maintenance can help mitigate these issues, ensuring reliable operation and extending the lifespan of your machinery.

Upgrading Differential Components

Enhancing the components of a vehicle’s power distribution system can significantly improve performance and durability. By selecting higher-quality or advanced materials, users can optimize traction, reduce wear, and enhance overall efficiency. This section will explore various options for upgrading these essential components.

Benefits of Upgrading

- Improved traction and handling

- Increased durability and lifespan

- Enhanced performance in challenging terrains

- Better heat dissipation and lubrication

Key Components to Consider

- Bearings: Upgrade to high-performance bearings for smoother operation and increased load capacity.

- Gears: Consider stronger gear materials to withstand higher torque and prevent breakage.

- Seals: Utilize advanced seals to reduce leakage and protect internal components from contaminants.

- Lubricants: Opt for specialized lubricants designed for extreme conditions to enhance protection and performance.

Comparing Gator Models and Differentials

When evaluating various utility vehicles, it is essential to understand the differences in their performance and design. Each model offers unique features and capabilities that cater to diverse needs. A critical aspect of these vehicles is their drivetrain systems, which significantly influence handling, traction, and overall efficiency.

Different models often incorporate varied configurations that affect how power is distributed to the wheels. This affects not only the vehicle’s ability to navigate challenging terrain but also its durability and maintenance requirements. Some variants may prioritize off-road performance, while others are designed for smoother, more urban environments.

Moreover, understanding the mechanics behind these systems can provide insights into their longevity and reliability. For instance, certain configurations may require more frequent servicing or may be better suited for specific tasks. By analyzing the technical specifications and user experiences, potential buyers can make informed decisions that align with their operational needs.

Ultimately, the choice between models should consider not just the immediate requirements but also long-term performance and adaptability in various conditions.

Resources for Parts and Service Manuals

When it comes to maintaining and repairing utility vehicles, having access to reliable documentation is crucial. Service manuals and component guides provide essential information, ensuring that users can effectively troubleshoot issues and perform necessary upkeep. Here are some valuable resources for obtaining these important materials.

- Manufacturer’s Website: Most manufacturers offer downloadable manuals on their official sites. These documents are often comprehensive and include detailed diagrams and specifications.

- Online Retailers: Websites specializing in vehicle parts frequently provide access to service manuals for various models. They can be a convenient source for both manuals and replacement components.

- Forums and Online Communities: Enthusiast forums often have sections dedicated to technical resources. Users share manuals, diagrams, and personal experiences, which can be invaluable for troubleshooting.

- Local Dealerships: Authorized dealerships can provide printed versions of service manuals. They may also offer advice and additional resources specific to your vehicle’s model.

- Library Resources: Many public libraries offer access to technical manuals through their online databases. This can be a great way to find hard-to-locate documentation.

Utilizing these resources can greatly enhance your ability to maintain and repair your utility vehicle, ensuring it operates at peak performance.