Comprehensive Guide to John Deere JS60 Parts Diagram

In the realm of machinery maintenance, having a comprehensive grasp of the configuration of various elements is crucial for effective repairs and upgrades. This knowledge not only enhances efficiency but also ensures longevity of the equipment in question. By familiarizing oneself with these layouts, operators can navigate their maintenance tasks with greater confidence.

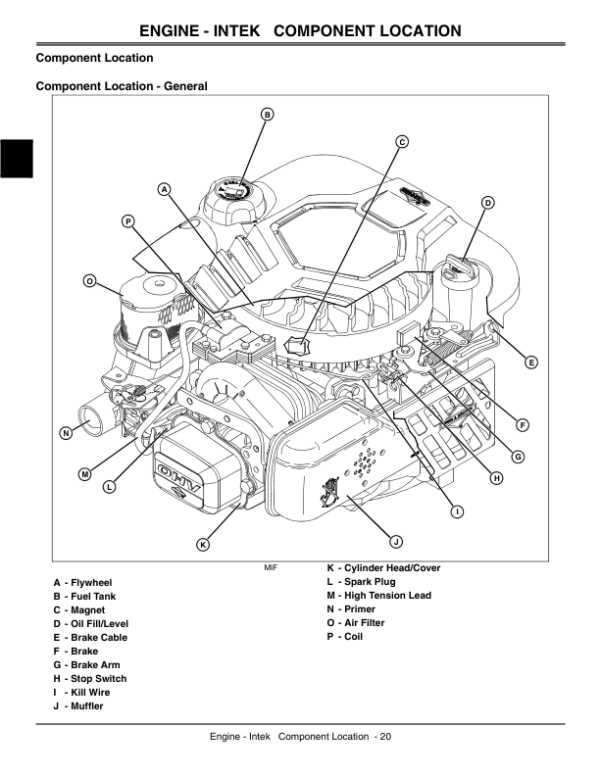

Detailed illustrations serve as invaluable resources, allowing users to visualize the intricate relationships between different components. They provide insights into how parts interact and where potential issues may arise. Understanding these relationships is essential for both novice and experienced technicians alike.

By exploring the specifics of these configurations, one can ultimately enhance their ability to troubleshoot and optimize equipment performance. This section aims to delve into the intricacies of component arrangements, offering guidance for anyone looking to improve their mechanical knowledge and skills.

Understanding John Deere JS60

This section delves into the intricacies of a specific model known for its efficiency and reliability in lawn care. Designed for both homeowners and professionals, this equipment exemplifies a blend of advanced engineering and user-friendly features, making it a popular choice among enthusiasts and landscapers alike.

One of the key aspects to appreciate about this model is its robust construction, which ensures durability over time. Users often highlight the ease of maintenance, allowing for smooth operation and longevity. Familiarity with the components and their functions can significantly enhance the overall experience.

| Component | Function |

|---|---|

| Engine | Drives the cutting blades and powers the unit |

| Cutting Deck | Houses the blades and determines the width of the cut |

| Wheels | Facilitate movement across various terrains |

| Handle | Provides control and maneuverability during operation |

Understanding these elements is crucial for optimal usage and can lead to more efficient lawn care practices. Regular inspections and knowledge of each part’s role contribute to effective maintenance and enhanced performance.

Overview of JS60 Model Features

This section provides a comprehensive look at the key characteristics and functionalities of a popular machine designed for efficiency and performance. The model stands out in its class, catering to a range of tasks while ensuring ease of use and reliability for operators.

Performance and Efficiency

The machine is engineered for optimal power output, allowing it to handle demanding jobs with ease. Its innovative design minimizes fuel consumption while maximizing productivity, making it an economical choice for various applications.

User-Friendly Design

Ergonomics play a significant role in the model’s appeal, with intuitive controls and a comfortable operating environment. The layout is designed to enhance accessibility, ensuring that operators can perform their tasks with minimal strain and maximum effectiveness.

Importance of Parts Diagrams

Understanding the structure and components of machinery is crucial for maintenance and repair. Visual representations serve as essential tools for identifying each element and its function within the assembly. This clarity not only streamlines the repair process but also enhances overall efficiency.

Here are several key benefits of utilizing such visual aids:

- Improved Clarity: Visual guides break down complex systems into manageable sections, making it easier to comprehend how components interact.

- Efficient Troubleshooting: By quickly locating issues, operators can address problems more swiftly, minimizing downtime.

- Accurate Assembly: Clear representations ensure that reassembly is conducted correctly, reducing the risk of errors.

- Enhanced Communication: These visuals facilitate better communication among team members, ensuring everyone understands the assembly’s layout.

- Facilitated Training: New employees can learn faster with visual aids, as they provide a clear reference for understanding machinery.

Incorporating such visuals into maintenance practices is an investment in efficiency and reliability.

Common Parts for John Deere Mowers

When maintaining lawn care equipment, understanding essential components is crucial for optimal performance and longevity. Familiarity with these elements can significantly enhance user experience and efficiency.

- Blades

- Engines

- Filters

- Belts

- Wheels

Regularly inspecting and replacing worn items ensures smooth operation and effective grass cutting.

- Check blades for sharpness and damage.

- Inspect the engine for any signs of wear.

- Change filters periodically for better airflow.

- Replace belts to prevent slippage.

- Ensure wheels are aligned and functional.

By focusing on these fundamental components, users can maintain their machinery effectively and enjoy a well-kept lawn.

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for effective maintenance and repairs. These visual guides provide crucial information about the arrangement and interconnection of various elements within a machine, making it easier to identify and source the necessary replacements.

Here are some key steps to effectively interpret a schematic:

- Familiarize Yourself with Symbols: Different elements are represented by specific symbols. Knowing what each symbol stands for will help you navigate the schematic with ease.

- Identify Key Sections: Schematics are often divided into sections based on functionality. Recognizing these areas can streamline your understanding of the overall layout.

- Locate Part Numbers: Each component typically has an associated number. Make a note of these identifiers as they will be essential when ordering replacements.

- Follow the Connections: Arrows or lines indicate how components connect and interact. Tracing these connections can reveal how the entire system functions.

- Consult the Legend: A legend usually accompanies the schematic, providing explanations for symbols and numbers. Refer to it frequently for clarity.

By following these steps, you can enhance your ability to interpret visual guides, leading to more efficient repairs and maintenance tasks.

Identifying Replacement Parts Easily

Finding the right components for your machinery can be straightforward with the right approach. Utilizing resources and visual aids can streamline the process, ensuring you select the correct items without unnecessary hassle.

Utilizing Visual Guides

Visual aids are invaluable when seeking to identify necessary components. They allow users to compare and contrast different elements, making it easier to pinpoint what is needed for replacement.

Cross-Referencing Numbers

Always cross-reference identification numbers from your equipment’s manual with available resources. This practice minimizes errors and ensures compatibility, leading to a more efficient replacement experience.

Where to Find Parts Diagrams

Locating schematics for equipment can enhance maintenance and repair efforts. Understanding where to seek these resources ensures that users can effectively manage their machinery.

- Manufacturer’s Official Website

- Authorized Dealers and Service Centers

- Online Forums and Communities

- Specialized Parts Retailers

- Technical Manuals and Guides

Utilizing these sources can provide valuable insights and support for efficient equipment upkeep.

Benefits of Using Genuine Parts

Utilizing authentic components is essential for maintaining optimal performance and longevity of your machinery. These items are specifically designed to fit seamlessly and operate efficiently, ensuring your equipment runs smoothly.

Quality Assurance: Genuine components undergo rigorous testing to meet strict standards, providing reliability that aftermarket alternatives often lack.

Longevity: Investing in authentic items can extend the lifespan of your machinery, reducing the need for frequent replacements and repairs.

Warranty Protection: Many manufacturers offer warranties on their machinery when original components are used, safeguarding your investment against unexpected failures.

Peace of Mind: Using certified parts ensures compatibility and performance, allowing operators to focus on their tasks without concerns about potential breakdowns.

In summary, choosing genuine components leads to enhanced efficiency, reliability, and overall satisfaction in the operation of your equipment.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the durability and efficiency of your equipment. By following a few key practices, you can significantly extend its lifespan and maintain optimal performance.

Routine Inspections

Conduct frequent checks for wear and tear. Look for any signs of damage or degradation that may require immediate attention. Addressing issues promptly can prevent further complications and costly repairs.

Proper Cleaning

Keep your machinery clean to prevent buildup that can affect functionality. Use appropriate cleaning agents and techniques to ensure all components remain in peak condition. Regular cleaning not only enhances performance but also contributes to overall longevity.

Common Issues and Solutions

When operating machinery, users may encounter a variety of common challenges that can affect performance and efficiency. Understanding these issues and their resolutions can significantly enhance the overall experience and prolong the lifespan of the equipment.

1. Engine Difficulties: One frequent problem is engine stalling or failure to start. This can often be traced back to issues such as insufficient fuel supply or battery problems. Regular maintenance checks can mitigate these concerns.

2. Blades Not Functioning Properly: If the cutting elements are not performing as expected, it may be due to dullness or misalignment. Ensuring proper sharpening and alignment can restore optimal function.

3. Electrical Failures: Electrical components may occasionally malfunction. Inspecting connections and fuses can often reveal and resolve underlying issues.

4. Excessive Vibration: Unusual vibrations can indicate loose parts or imbalances. Tightening bolts and ensuring correct assembly can alleviate this problem.

5. Overheating: If the machinery becomes excessively hot, it may signal cooling system failures or blockages. Regular cleaning and coolant checks are essential preventive measures.

Upgrading Components for Better Performance

Enhancing the functionality of your machinery can significantly boost its efficiency and longevity. By focusing on key elements that contribute to overall performance, operators can achieve smoother operation and reduced downtime. Identifying which components to upgrade is crucial for maximizing productivity.

Improving the Engine is often the first step in achieving better performance. Upgrading to a higher-efficiency model can lead to increased power output and fuel savings. Consider components like air filters and exhaust systems, which can improve airflow and optimize combustion.

Transmission and Drive Systems are critical for effective power transfer. Replacing outdated gears or bearings with high-quality alternatives can enhance responsiveness and reduce wear. Look for options that provide better torque management and smoother engagement.

Hydraulic Components play a vital role in machinery efficiency. Upgrading pumps and cylinders can improve lifting capacity and response times. Additionally, using high-grade hydraulic fluid can enhance performance and reduce heat generation.

Electrical Systems should not be overlooked. Upgrading wiring, connectors, and battery systems can lead to improved reliability and reduced electrical losses. High-performance batteries can provide better power delivery, ensuring all systems function optimally.

Ultimately, strategic upgrades to various components can result in a marked improvement in performance. Careful consideration of each system will allow operators to tailor enhancements to their specific needs, leading to a more efficient and effective operation.

FAQs about JS60 Parts and Maintenance

This section addresses common inquiries regarding components and upkeep for a specific model. Understanding these aspects can significantly enhance performance and longevity, ensuring optimal functionality.

| Question | Answer |

|---|---|

| What are the most common replacements needed? | Typically, the blades, belts, and filters require frequent attention. |

| How often should maintenance be performed? | Regular checks every 25 hours of use are recommended to ensure efficiency. |

| Where can I find high-quality components? | Authorized dealers and reputable online retailers offer reliable options. |

| Is it necessary to follow the manual? | Yes, the manual provides crucial information for proper care and servicing. |

Resources for John Deere Owners

For enthusiasts and operators of agricultural machinery, accessing quality information and resources is essential for maintaining optimal performance and longevity of their equipment. Whether you’re looking for manuals, community forums, or trusted suppliers, a variety of options are available to support you in your journey.

Here are some valuable resources to consider:

- Manufacturer Manuals: Official guides provide detailed information on maintenance, troubleshooting, and operations.

- Online Communities: Forums and social media groups where owners share experiences, tips, and advice.

- Local Dealers: Authorized dealers often offer expertise, parts, and support specific to your machinery.

- Educational Videos: Platforms like YouTube feature tutorials and demonstrations that can be incredibly helpful.

- Specialized Websites: Numerous websites focus on machinery reviews, comparisons, and insights to help owners make informed decisions.

Leveraging these resources can enhance your understanding and help you keep your equipment in top condition for years to come.