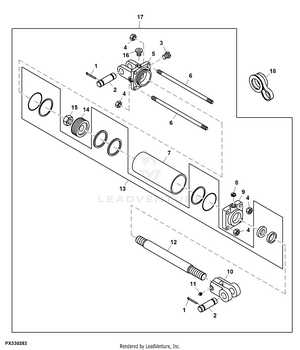

John Deere MX10 Parts Overview

In the realm of agricultural machinery, having a clear visual representation of individual components is essential for maintenance and repair. Such illustrations serve as a valuable resource for operators and technicians alike, enabling them to identify and understand the arrangement of various elements that contribute to the functionality of the equipment.

By exploring a detailed representation of the machinery’s structure, users can gain insights into how each piece interacts within the larger system. This understanding is crucial not only for effective troubleshooting but also for ensuring optimal performance in the field. Furthermore, familiarizing oneself with the layout can streamline repair processes and enhance overall equipment longevity.

Utilizing these comprehensive visuals, individuals can make informed decisions when it comes to ordering replacements or conducting repairs. This knowledge empowers users to maintain their machinery effectively, leading to increased productivity and efficiency in agricultural operations.

This section aims to provide an insightful overview of the essential components associated with the machinery in question. By breaking down the various elements, users can gain a comprehensive understanding of how each part contributes to the overall functionality and efficiency of the equipment. This will not only enhance the operational knowledge but also assist in maintenance and troubleshooting processes.

Key Components Overview

Understanding the critical components is vital for efficient operation. Each part plays a significant role in the machinery’s performance, and familiarity with these elements can aid in effective usage and maintenance.

Table of Essential Elements

| Component Name | Description | Function |

|---|---|---|

| Frame | The main structure supporting all parts. | Provides stability and strength. |

| Gear Assembly | A set of gears that facilitate movement. | Transmits power to various sections. |

| Blades | Sharp cutting edges designed for efficient operation. | Performs the cutting task. |

| Wheels | Round components that allow movement. | Facilitates mobility of the machinery. |

| Hydraulic System | System that utilizes fluid to create motion. | Powers various functions of the equipment. |

Overview of MX10 Components

The components of this agricultural tool play a crucial role in its overall functionality and efficiency. Understanding the various elements helps users appreciate the design and performance of the equipment. Each section is engineered to fulfill specific tasks, ensuring optimal operation in diverse agricultural settings.

The assembly includes a robust frame that supports the entire structure, providing stability and durability during use. Additionally, the cutting apparatus is designed for precision and effectiveness, enabling users to tackle different types of vegetation with ease. The drive system facilitates smooth operation, allowing the implement to navigate various terrains without difficulty.

Moreover, various attachments and accessories enhance the versatility of the equipment, enabling it to adapt to different tasks as required. Regular maintenance of these components ensures longevity and consistent performance, making it a reliable choice for agricultural professionals.

Importance of Parts Diagrams

Understanding the structure and components of machinery is crucial for effective maintenance and repair. Visual representations serve as essential tools, providing a clear overview of individual elements and their interconnections. This clarity helps users to navigate complex systems with ease.

Accurate identification of components is vital for troubleshooting and replacing defective items. By having a visual reference, operators can quickly locate specific parts, ensuring that replacements are accurate and timely. This not only enhances the efficiency of repairs but also minimizes downtime.

Moreover, these illustrations facilitate better communication among technicians and maintenance personnel. When everyone can reference the same visuals, it reduces the likelihood of misunderstandings and errors during repairs. In essence, visual aids enhance teamwork and streamline the repair process.

Additionally, educational purposes benefit from these visual guides. They serve as effective training materials for new technicians, providing them with a solid foundation to understand machinery operations and maintenance protocols. This knowledge fosters confidence and proficiency in handling equipment.

Identifying Major Assemblies

Understanding the key components of agricultural machinery is crucial for effective maintenance and operation. These major sections work together to ensure optimal performance, and recognizing each assembly’s role can greatly enhance the efficiency of the equipment. A comprehensive grasp of these groupings allows operators to perform tasks more effectively and troubleshoot issues as they arise.

Typically, the main assemblies include the transmission system, which is essential for power transfer; the cutting mechanism, responsible for the primary function of the machine; and the frame, providing structural integrity and support. Additionally, the hydraulic system plays a vital role in enabling various operations, allowing for enhanced maneuverability and control. Familiarizing oneself with these fundamental components paves the way for a more productive experience and proactive maintenance strategies.

Commonly Replaced MX10 Parts

Regular maintenance of agricultural machinery involves replacing various components to ensure optimal performance and longevity. Understanding which elements frequently require attention can help users minimize downtime and maintain efficiency.

The following components are often found in need of replacement due to wear and tear:

- Blades: Sharp blades are crucial for effective cutting. Dull or damaged blades can lead to poor performance.

- Belts: These components help transfer power. Worn belts can cause slippage or breakage, impacting overall operation.

- Bearings: Essential for smooth movement, bearings often degrade over time, leading to increased friction and potential failure.

- Gearboxes: These units are vital for power transmission. Malfunctioning gearboxes can significantly affect machinery efficiency.

Keeping an eye on these commonly replaced elements allows for timely maintenance, helping operators avoid unexpected issues and ensuring their equipment remains in optimal working condition.

Tools Needed for Maintenance

To ensure the optimal performance and longevity of your equipment, it is essential to have the right tools for upkeep and repair tasks. Proper maintenance not only enhances functionality but also prevents potential issues from escalating into major problems.

The following is a list of necessary tools that will assist you in performing various maintenance activities effectively:

- Wrenches: Adjustable and socket wrenches are vital for loosening and tightening bolts and nuts.

- Screwdrivers: A set of flathead and Phillips screwdrivers will help you handle screws of different types.

- Pliers: Needle-nose and regular pliers are useful for gripping and bending components.

- Lubricants: Appropriate lubricants ensure smooth operation of moving parts and reduce friction.

- Cleaning Supplies: Brushes and cloths are necessary for removing dirt and debris from surfaces.

- Diagnostic Tools: Multimeters and other testing devices can assist in troubleshooting electrical issues.

Having these tools readily available will facilitate routine checks and repairs, making maintenance tasks more efficient and straightforward.

Parts Identification Techniques

Understanding the various components of machinery is essential for effective maintenance and repair. This process involves recognizing and categorizing elements based on their features and functions. Employing systematic methods allows operators and technicians to ensure that every component is correctly identified, promoting efficiency in servicing and replacements.

Visual Inspection Methods

Visual examination is a straightforward yet effective approach to component identification. This technique involves closely observing the shapes, colors, and markings of different elements. By comparing these features with reference materials or manuals, one can accurately determine the specifications and functions of each item.

Utilizing Reference Materials

Another useful strategy is consulting reference guides, manuals, or online databases. These resources often contain detailed illustrations and descriptions that aid in recognizing components. Cross-referencing actual parts with the provided information can significantly enhance identification accuracy and assist in procurement when replacements are needed.

Where to Find Replacement Parts

Locating suitable components for your machinery is essential for maintaining its performance and longevity. Various sources offer a range of options, ensuring you can find what you need efficiently and effectively.

Authorized Dealers

Visiting certified retailers guarantees that you acquire genuine components designed specifically for your equipment. These establishments provide:

- Expert assistance in identifying the correct components

- Access to the latest inventory and updates

- Warranty options for purchased items

Online Marketplaces

Numerous online platforms specialize in providing an extensive selection of components. When using these resources, consider the following:

- Check customer reviews for quality assurance

- Compare prices across different websites to secure the best deal

- Verify the return policy before purchasing

Manufacturer Specifications and Standards

This section outlines the essential requirements and guidelines established by the manufacturer to ensure optimal performance and reliability of agricultural machinery. Adhering to these standards is crucial for maintaining the efficiency and safety of equipment, as well as extending its lifespan.

The specifications typically include detailed information on material quality, design parameters, and operational capacities. These criteria are crucial for users to select compatible components and to understand the operational limits of their machinery. Following these guidelines contributes to better functionality and minimizes the risk of malfunctions during usage.

Furthermore, manufacturers often provide documentation that includes recommendations for maintenance and service intervals. Regular adherence to these practices ensures that equipment operates at peak efficiency, ultimately leading to improved productivity in agricultural tasks.

Maintenance Tips for MX10

Regular upkeep is essential for ensuring the longevity and efficiency of any agricultural implement. Implementing a systematic maintenance routine can prevent unexpected breakdowns and optimize performance. This section outlines key recommendations for maintaining your equipment effectively.

Routine Inspections

Conducting periodic inspections helps identify wear and tear before it becomes a major issue. Look for signs of damage on all components, and pay close attention to any areas that experience high levels of stress. Ensure that all fasteners are tight and in good condition.

Lubrication Practices

Proper lubrication is vital for reducing friction and extending the lifespan of moving parts. Use high-quality lubricants recommended by the manufacturer and apply them according to the specified intervals. Regularly check grease fittings and replenish as needed to maintain smooth operation.

By following these maintenance tips, you can enhance the functionality of your equipment and reduce the likelihood of costly repairs.

DIY Repair vs. Professional Help

When faced with equipment issues, many owners contemplate whether to tackle the repairs themselves or seek assistance from a specialist. Each approach has its advantages and drawbacks, which can influence the decision-making process.

Do-it-yourself repairs can offer a sense of accomplishment and save money on labor costs. With the right tools and resources, individuals can learn to fix common problems and maintain their machinery efficiently. However, this route may require a significant time investment and a certain level of technical knowledge.

On the other hand, professional assistance ensures that repairs are conducted by trained experts with experience in handling various types of machinery. This option often leads to quicker resolutions and peace of mind, knowing that the work is done correctly. Nonetheless, hiring a professional can be costly and may lead to delays based on their availability.

Ultimately, the choice between DIY repairs and hiring an expert depends on personal skills, available time, and the complexity of the issue at hand. Weighing these factors can help individuals make the best decision for their specific situation.

Understanding Warranty Information

When purchasing machinery, it’s essential to be informed about the warranty coverage provided by the manufacturer. This section aims to clarify the fundamental aspects of warranty details, ensuring users have a comprehensive understanding of what is included and the conditions that may apply.

Key Components of Warranty Coverage

The warranty typically encompasses various elements, including the duration of protection, the specific parts or components covered, and any limitations that may exist. Familiarizing oneself with these components can help in making informed decisions regarding maintenance and repairs.

Importance of Warranty Documentation

Having proper warranty documentation is crucial for claiming repairs or replacements. This documentation often outlines the steps needed to initiate a claim, including necessary paperwork and the contact information for customer support. It is advisable to keep this information readily accessible to avoid any complications in the event of a warranty claim.

Frequently Asked Questions

This section addresses common inquiries regarding equipment components and their functionality. Understanding these elements can greatly enhance the user experience and maintenance of machinery.

What should I do if I can’t find the component I need?

If you are having difficulty locating a specific item, consider consulting your local dealer or authorized service provider. They can assist in identifying the right replacement or accessory for your machinery.

How often should I check the components?

Regular inspections are crucial for ensuring optimal performance. It is advisable to examine the various parts periodically, especially before and after intensive usage.

Are there universal components compatible with my machinery?

While many components are designed for specific models, some universal parts may be available. Always verify compatibility with your particular equipment to avoid issues.