John Deere Sabre GX1438 Parts Diagram Guide

Maintaining agricultural and landscaping equipment requires a clear understanding of its various mechanical elements. A detailed breakdown of each section ensures that users can identify and address issues more efficiently. This allows for better performance and longer service life.

Understanding the individual elements of machinery, from the engine components to the control mechanisms, is crucial for effective repairs. By familiarizing yourself with how each element functions, you’ll be better equipped to handle routine maintenance and potential problems, ultimately ensuring a smoother operation.

Effective maintenance begins with proper identification. Clarity in understanding the layout and design of each element within the machinery will help avoid unnecessary repairs, reducing downtime and improving overall efficiency.

John Deere Sabre GX1438 Overview

The model discussed here is a reliable and versatile lawn care machine, ideal for maintaining medium to large lawns. Its robust construction, combined with efficient performance, ensures a smooth and effective mowing experience. Designed for both residential and light commercial use, this equipment strikes a balance between power and maneuverability.

One of the standout features of this model is its ease of use, making it accessible for users with varying levels of experience. The machine’s intuitive controls and ergonomic design contribute to a comfortable operation, even during extended periods of use.

Durability and reliability are key aspects that have been prioritized in its design. The well-engineered mechanics ensure that it can withstand regular use over long periods, while maintaining consistent performance.

Exploring the Engine Components

The engine is the heart of any machine, ensuring smooth operation and power delivery. Understanding its elements can greatly improve maintenance and troubleshooting. In this section, we’ll take a closer look at the key units that contribute to the efficient functioning of the motor system.

Main Units

The motor is composed of several primary components, each playing a crucial role in performance. These elements work together to convert fuel into mechanical energy, powering the machine’s movement.

- Cylinder Block: Forms the foundation of the motor, housing the pistons and other crucial mechanisms.

- Pistons: These move up and down within the cylinder, compressing the air-fuel mixture to generate power.

- Crankshaft: Converts the linear motion of the pistons into rotational movement, transmitting power to the drivetrain.

- Valves: Regulate the flow of fuel and air into the engine while also managing the exhaust gases.

Supporting Systems

Beyond the main units, there are various support systems that ensure the engine runs efficiently and reliably.

- Cooling System: Prevents overheating by circulating coolant through the engine.

- Lubrication System: Reduces friction and wear by delivering oil to moving parts.

- Fuel System: Manages the delivery of fuel to the combustion chamber in the right amounts.

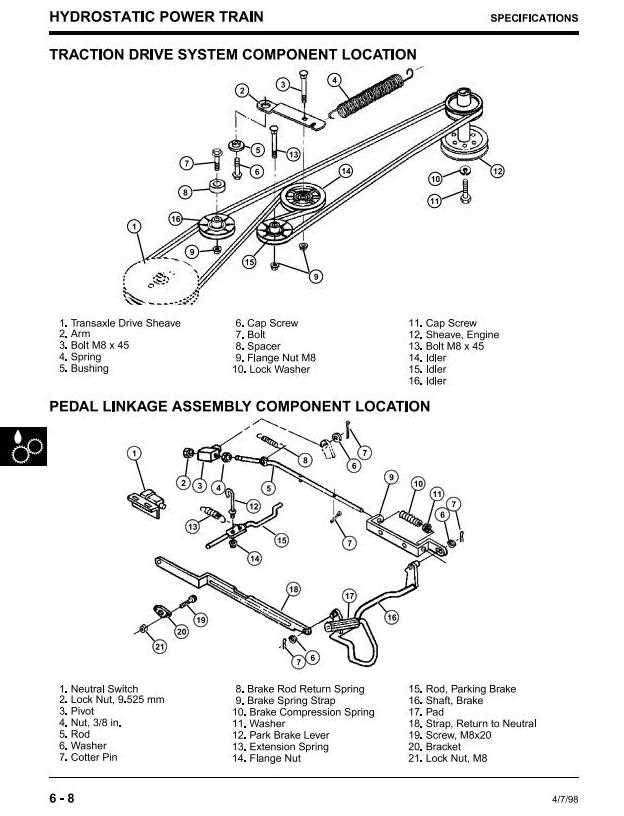

Transmission System Breakdown

The transmission system plays a critical role in transferring power from the engine to the wheels, ensuring smooth operation and efficient performance. This section will explore the essential components of the system and how they work together to manage speed, torque, and direction.

- Gearbox: The gearbox adjusts the speed and torque output, allowing for optimal performance under different load conditions.

- Drive Shaft: This component transmits rotational power from the gearbox to the axles.

- Axles: The axles deliver power directly to the wheels, maintaining the vehicle’s movement.

- Clutch: The clutch engages and disengages the transmission from the engine, allowing for smooth shifting between gears.

- Differential: The differential distributes power to the wheels, adjusting for differences in wheel speed during turns.

Together, these elements ensure efficient power delivery and help the vehicle adapt to various terrains and operating conditions.

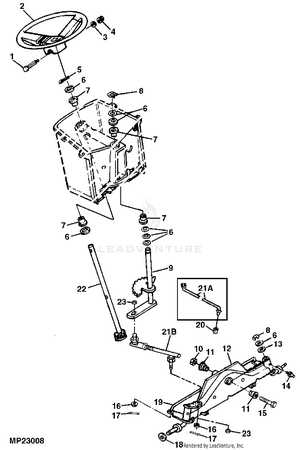

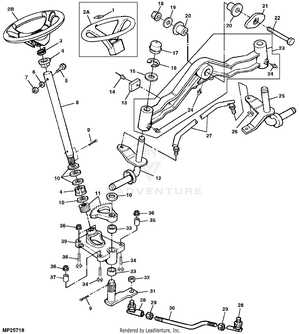

Understanding the Steering Mechanism

The steering system plays a crucial role in providing control and direction to the vehicle. A well-functioning mechanism ensures smooth and precise maneuvering, enabling the operator to handle turns and navigate different terrains with ease. It is a complex assembly that integrates various components working in harmony to transfer the operator’s input into accurate wheel movement.

Main Components of the Steering System

The steering system is composed of several key elements that ensure proper functionality and safety. Below is an overview of the main parts involved:

- Steering Wheel: The component the operator directly interacts with, transferring force into the mechanism.

- Linkages: A series of rods and joints that connect the wheel to the rest of the system, enabling the transfer of motion.

- Steering Shaft: The shaft that transmits the rotational movement of the wheel to the control mechanisms.

- Steering Gear: Converts the rotational motion from the wheel into lateral motion for the wheels.

Steering Mechanism Functionality

The process begins when the operator turns the wheel, which initiates a chain reaction through the linkages and gears, ultimately causing the wheels to pivot in the desired direction. This movement allows the vehicle to navigate turns smoothly. Proper maintenance of the steering system is essential for ensuring both safety and performance during operation.

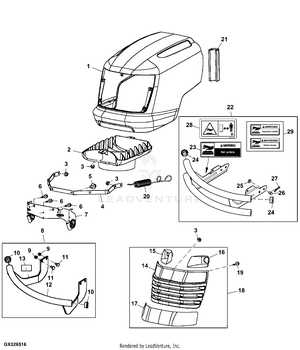

Chassis and Frame Diagram

The chassis and frame provide the structural foundation for the vehicle, ensuring stability and durability during operation. This section will explore the essential components that make up the support system, focusing on how these elements work together to maintain proper function and balance.

Key Structural Components

At the core of the frame system are the reinforced beams, designed to distribute weight evenly across the vehicle. These beams enhance stability by preventing excessive flexing, especially when the vehicle encounters uneven terrain. Additionally, side supports play a crucial role in connecting other elements, ensuring that the entire structure remains rigid under pressure.

Frame Connections

The frame connections are critical for ensuring that all parts of the vehicle are securely attached. Proper alignment and attachment of these components allow for smooth operation, reducing wear and tear over time. Attention to the condition of these connections is important for long-term reliability and efficiency.

Electrical System and Wiring Layout

The electrical system of a lawn mower is crucial for powering various components such as the ignition, lights, and other electrical accessories. It ensures smooth operation by delivering consistent power to the engine and control systems. Proper wiring is essential for the reliable performance of the vehicle, as it connects key components and allows for efficient energy distribution across the system.

Understanding the wiring layout is vital for troubleshooting electrical issues, performing maintenance, and ensuring that all components function as expected. The layout typically includes the battery, ignition switch, fuses, wiring harnesses, and various relays, all of which must be connected in a specific arrangement to avoid shorts and ensure safety.

| Component | Function |

|---|---|

| Battery | Supplies power to the electrical system, including the engine starter and accessories. |

| Ignition Switch | Controls the flow of power to the engine, enabling startup and operation. |

| Fuses | Protect electrical components from overcurrent by interrupting the circuit if necessary. |

| Wiring Harness | Routes power and signals to various components, ensuring proper electrical connections. |

| Relays | Act as switches to control high-power components by using low-power signals. |

Following the correct wiring layout is essential for the safety and longevity of the mower. It is recommended to regularly inspect the system for any loose connections or damaged wires to prevent electrical failures during operation.

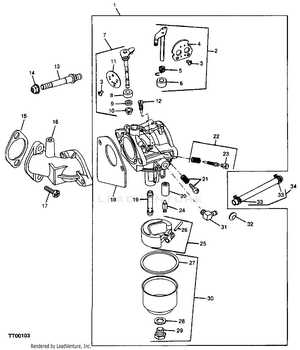

Fuel System Parts and Functions

The fuel system of any engine is responsible for delivering the necessary fuel to the combustion chamber for proper operation. It consists of several components, each playing a specific role in ensuring that the engine runs smoothly and efficiently. From fuel storage to the delivery of the right amount of fuel at the right time, these elements work together to maintain optimal performance.

The main components of the fuel system include the following:

- Fuel Tank: Stores the fuel and ensures its availability for the engine. It is usually located at a convenient point for refueling.

- Fuel Pump: Moves fuel from the tank to the engine, maintaining the required pressure for fuel injection or carburetion.

- Fuel Filter: Ensures that any contaminants in the fuel are removed before it enters the engine, protecting the internal components from damage.

- Fuel Injector: Delivers fuel into the combustion chamber in a precise amount, often in the form of a mist, ensuring efficient combustion.

- Carburetor (if applicable): Mixes air and fuel in the proper ratio before it enters the engine for combustion.

Each of these components plays a critical role in ensuring the engine operates at peak efficiency, reduces emissions, and prevents unnecessary wear or breakdowns. Regular maintenance of these components is essential to prolong the life of the engine and keep it running smoothly.

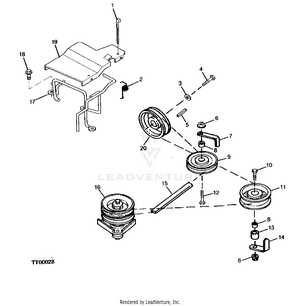

Blade and Mower Deck Assembly

The blade and mower deck assembly is a crucial component in the operation of lawn care equipment, ensuring efficient grass cutting and overall machine performance. This section explains the key parts involved in assembling and maintaining this essential assembly, which directly impacts the effectiveness of the mower.

The mower deck houses the cutting blades and serves as the foundation for the entire cutting mechanism. Proper assembly and maintenance are vital to achieve a smooth and even cut. Below are the key components that make up the blade and mower deck system:

- Cutting Blades: These are the primary parts responsible for trimming the grass. They should be sharpened regularly for optimal performance.

- Deck Housing: The structure that holds the blades in place, providing stability and protection during operation.

- Spindles: These rotate the blades, ensuring they spin at the right speed for effective cutting.

- Blade Adapters: These connect the blades to the spindles, allowing for easy attachment and removal.

- Idler Pulley: This component helps maintain tension in the drive belt, ensuring the blades operate at full capacity.

- Drive Belt: A belt that transfers power from the engine to the spindles, driving the blade’s motion.

Ensuring that each of these components is properly installed and maintained will keep your mower deck functioning efficiently. Regular checks and maintenance can prevent unnecessary wear and tear, ensuring the longevity of the equipment.

Hydraulic System Overview

The hydraulic system is a crucial component designed to transmit power through the use of fluid pressure. It provides the force necessary to operate various mechanical functions, enabling smooth and efficient movement within machinery. This system allows for precise control of different operations, making it an essential part of many modern machines.

Key Functions of the Hydraulic System

- Power transmission through fluid pressure

- Enabling smooth and controlled movement

- Providing force for various mechanical functions

- Ensuring efficient energy use and operation

Main Components

- Hydraulic Pump: Generates the fluid pressure necessary for operation.

- Hydraulic Fluid: Transfers energy and lubricates the system.

- Valves: Control the flow and direction of hydraulic fluid.

- Actuators: Convert hydraulic pressure into mechanical movement.

- Reservoir: Holds the hydraulic fluid and ensures its proper circulation.

Brake and Clutch Components

The braking and clutch systems are vital for the safe and efficient operation of any machine. These components ensure proper control of the vehicle’s motion and facilitate smooth transitions during operation. Understanding the function and maintenance of each part can help in maintaining optimal performance and preventing breakdowns.

Key elements of the brake and clutch mechanisms include friction discs, springs, and actuators, each playing a critical role in the overall functionality. Regular inspection and timely replacement of worn-out parts are crucial for the safety and longevity of the equipment.

| Component | Description |

|---|---|

| Brake Pads | Provide friction to slow down or stop the machine’s movement. |

| Clutch Disc | Enables the engagement and disengagement of the engine from the drivetrain. |

| Actuators | Mechanisms that control the operation of both the brake and clutch systems. |

| Springs | Ensure the return of components to their original position after operation. |

Seat and Comfort Features

When operating outdoor machinery, the comfort of the operator is paramount. A well-designed seat and comfort system can significantly enhance the experience, allowing users to focus on their tasks without distraction. Comfort features not only reduce fatigue but also improve productivity, making it easier to work for longer periods with less strain.

Ergonomic Seating

The seat design plays a crucial role in ensuring proper posture and support. Ergonomically engineered seats provide lumbar support, adjustable armrests, and multiple recline settings to suit various body types. These features reduce stress on the back and legs, promoting a more relaxed and efficient operation.

Adjustable Features for Personalized Comfort

For maximum comfort, seats are equipped with various adjustments. These include seat height, tilt, and depth adjustments, which allow the user to customize the seating position. With these personalized settings, operators can find the ideal position, reducing discomfort during extended use and promoting better control over the machine.

Maintenance Parts and Tools

Proper upkeep of your equipment is crucial for its longevity and optimal performance. Ensuring that you have the right tools and replacement components at hand is the first step toward maintaining a smooth operation. This section outlines the essential elements needed for regular maintenance, focusing on key components that require attention and specific tools to facilitate their servicing.

Essential Replacement Components

For routine maintenance, certain elements are prone to wear and tear. Regularly checking and replacing these parts can prevent system failures and ensure your machine operates efficiently. Look for items such as belts, filters, and spark plugs, which play vital roles in the equipment’s functionality and safety. Identifying the correct size and type of these components is essential for maintaining performance standards.

Tools for Effective Servicing

To perform maintenance tasks correctly, a range of specialized tools is required. These tools allow for precise adjustments and safe component replacements. Tools such as wrenches, oil changers, and screwdrivers are necessary for the smooth operation of mechanical and electrical parts. Ensure that all tools are compatible with the equipment specifications to avoid damage and achieve the desired results.

Replacement Parts Availability

Ensuring the continued performance of your lawnmower or garden equipment often relies on the availability of essential components. Finding the right replacements can be crucial to extending the lifespan of the machine and maintaining its efficiency. Whether you need a blade, engine component, or electrical part, it’s important to know where to source these items reliably.

Replacement items for such machines are commonly found in various locations, ensuring ease of access for users. These sources include both physical stores and online platforms. Below are some of the primary options for obtaining replacements:

- Authorized Dealers: These retailers specialize in offering original components designed specifically for your equipment, ensuring compatibility and quality.

- Online Marketplaces: Websites like Amazon, eBay, and other specialty online retailers provide a wide range of aftermarket and OEM options, often with detailed descriptions and user reviews.

- Local Repair Shops: Many repair services offer replacements, often at competitive prices, and they can also assist with installation and maintenance.

- Third-party Manufacturers: Companies that produce non-branded replacements can offer cost-effective alternatives, though checking compatibility is essential before purchasing.

Before purchasing, it’s advised to cross-check part numbers and compatibility to avoid unnecessary returns or delays in repairs. Some manufacturers also offer convenient part lookup tools on their websites, making the process even easier.