Comprehensive Parts Diagram for John Deere Z425 Zero Turn Mower

When it comes to maintaining your outdoor space, having a reliable machine is essential for achieving a well-manicured lawn. This section delves into the intricate design and functionality of a specific model known for its efficiency and precision. By exploring the arrangement of its essential components, users can enhance their operational understanding and maintenance practices.

Each segment of this machinery plays a vital role in its overall performance, influencing how it navigates and performs tasks. Familiarity with the layout of its elements not only facilitates repairs but also empowers owners to make informed decisions regarding upgrades and replacements. The aim is to provide clarity on the interconnectedness of these features, promoting a deeper appreciation for the engineering behind the tool.

Whether you are a seasoned professional or a weekend enthusiast, understanding the specifics of this equipment can significantly improve your experience. This guide offers an insightful look into the configuration of various sections, ensuring you are well-equipped to handle any challenges that may arise during operation or maintenance.

Understanding the John Deere Z425

This section aims to provide a comprehensive overview of a specific model designed for efficient lawn maintenance. By exploring its features and functionality, users can appreciate its unique attributes and operational capabilities.

One of the standout qualities of this machine is its maneuverability. With advanced steering technology, it allows for precise navigation around obstacles, ensuring that every inch of your lawn is attended to with care. The ergonomic design enhances user comfort, making extended sessions more enjoyable.

Moreover, the engine performance plays a crucial role in its effectiveness. Equipped with a robust power unit, it ensures that grass is cut cleanly and efficiently, minimizing the need for repeated passes. This efficiency not only saves time but also contributes to a healthier lawn.

Maintenance is another key aspect to consider. Understanding the maintenance requirements and having access to the right components can significantly prolong the life of the machine. Familiarizing oneself with the essential elements involved in upkeep helps ensure optimal performance year after year.

In summary, this model exemplifies a blend of power, precision, and practicality, making it an ideal choice for homeowners and professionals alike who seek to maintain their green spaces effectively.

Key Features of the Z425 Mower

The machine offers an impressive combination of performance and efficiency, making it ideal for various landscaping tasks. Its innovative design enhances maneuverability and ease of use, ensuring that even challenging areas can be navigated with precision. The robust construction guarantees durability, allowing users to tackle heavy-duty jobs with confidence.

Performance Highlights

Equipped with a powerful engine, this model delivers exceptional cutting performance. The sharp blades are designed to provide a clean finish, while the adjustable cutting height accommodates different grass types and conditions. Users can expect a reliable operation that minimizes downtime.

User-Friendly Features

Featuring an ergonomic seat and intuitive controls, this equipment ensures comfort during extended use. The easy-access maintenance points simplify upkeep, allowing for quick adjustments and repairs. Additionally, the compact design enhances storage capabilities when the task is complete.

| Feature | Description |

|---|---|

| Engine Power | High-performance engine for efficient cutting |

| Cutting Height | Adjustable settings for various grass types |

| Ergonomic Design | Comfortable seating for long durations |

| Maintenance Access | Easy points for quick service and repairs |

Importance of Zero Turn Technology

The advancement of innovative cutting mechanisms has revolutionized the way we approach lawn maintenance. This technology enhances maneuverability, allowing for precise navigation around obstacles and complex landscapes. Such efficiency not only saves time but also improves the quality of the finished area, providing a pristine appearance.

One of the key benefits of this technology is its ability to perform sharp turns without leaving uncut grass. Traditional models often struggle with tight corners, resulting in missed patches. However, with this enhanced design, operators can achieve a professional look with minimal effort.

| Benefits | Description |

|---|---|

| Increased Efficiency | Reduces mowing time significantly due to superior navigation. |

| Precision Cutting | Allows for accurate trimming around obstacles for a polished finish. |

| Enhanced Maneuverability | Facilitates easy handling in tight spaces and complex layouts. |

| Comfort | Improved ergonomics reduce operator fatigue during extended use. |

This cutting-edge approach not only streamlines lawn care but also promotes better results, making it an invaluable asset for both residential and commercial use. As technology continues to evolve, embracing these advancements will lead to superior landscaping practices.

Common Issues with Z425 Mowers

Many individuals encounter a variety of challenges when operating this type of lawn care equipment. Understanding these common problems can help users maintain optimal performance and extend the lifespan of their machines. From mechanical failures to minor adjustments, addressing these issues promptly is crucial for efficiency and reliability.

Engine Troubles

One frequent complication involves the engine not starting or stalling during operation. This can be attributed to several factors, including a faulty ignition system, clogged fuel lines, or a dead battery. Regular maintenance and inspection can help identify these issues early, ensuring smoother operation.

Cutting Quality Concerns

Users often report unsatisfactory cutting results, which may stem from dull blades or improper height settings. Regular sharpening of the cutting edges and adjusting the cutting height can significantly improve performance. Additionally, debris accumulation around the blades can hinder efficiency, making periodic cleaning essential.

By being aware of these common challenges and addressing them proactively, operators can enjoy a more reliable and effective lawn care experience.

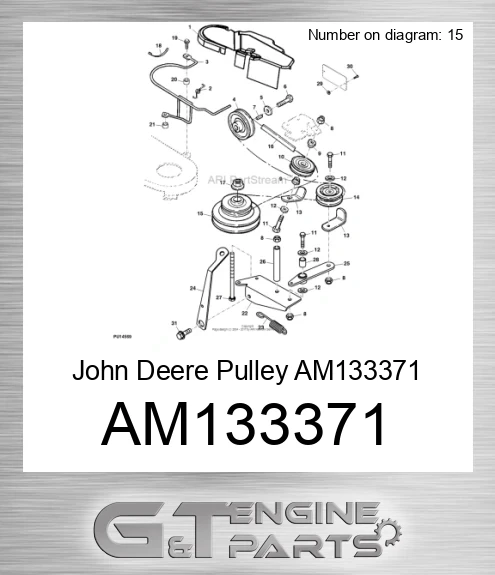

Parts List for Z425 Model

This section provides a comprehensive overview of the various components associated with the specified model, ensuring that users have access to essential information for maintenance and repairs. Understanding the different elements can greatly assist in enhancing the performance and longevity of the equipment.

| Component Name | Description | Part Number |

|---|---|---|

| Engine | Power unit for operation | AM123456 |

| Blades | Cutting tools for grass | AM654321 |

| Transmission | Drive mechanism | AM987654 |

| Deck | Main body housing blades | AM112233 |

| Wheels | Support and movement | AM445566 |

| Battery | Power supply | AM778899 |

Where to Find Replacement Parts

Locating high-quality components for your equipment can greatly enhance its performance and longevity. Whether you’re in need of specific elements for repairs or general maintenance, there are various reliable sources to consider. Understanding where to look can save you time and ensure you acquire the right items.

Authorized Retailers

One of the most dependable options is to visit authorized dealers. These retailers typically carry a comprehensive inventory of genuine components designed specifically for your model. Purchasing from them not only guarantees compatibility but also provides assurance of quality and support.

Online Marketplaces

The internet offers a vast array of platforms where you can find both new and refurbished items. Websites such as e-commerce giants or specialized forums can connect you with sellers who offer various components. Be sure to read reviews and check seller ratings to ensure you’re making a wise investment.

Additionally, exploring community groups and social media can lead to valuable recommendations and resources for obtaining the necessary equipment for your maintenance needs.

Maintenance Tips for Longevity

Ensuring the extended life of your equipment requires consistent care and attention. By following a few essential practices, you can significantly enhance performance and durability. Regular maintenance not only helps in avoiding costly repairs but also keeps your machinery operating efficiently for years to come.

Regular Inspection

Conducting frequent checks on various components is crucial. Look for signs of wear and tear, such as frayed belts or loose connections. Addressing these issues early can prevent more significant problems later. Ensure that all moving parts are well-lubricated to reduce friction and wear.

Cleaning and Storage

Keep your equipment clean to prevent the buildup of dirt and debris, which can hinder performance. After each use, take a few minutes to remove any grass clippings or dust. When not in use, store your machinery in a dry, sheltered area to protect it from the elements. This simple step can drastically prolong its lifespan.

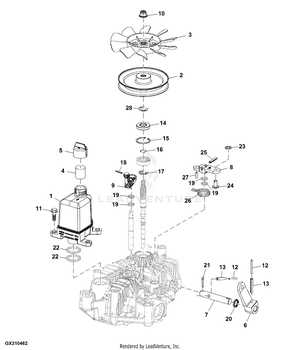

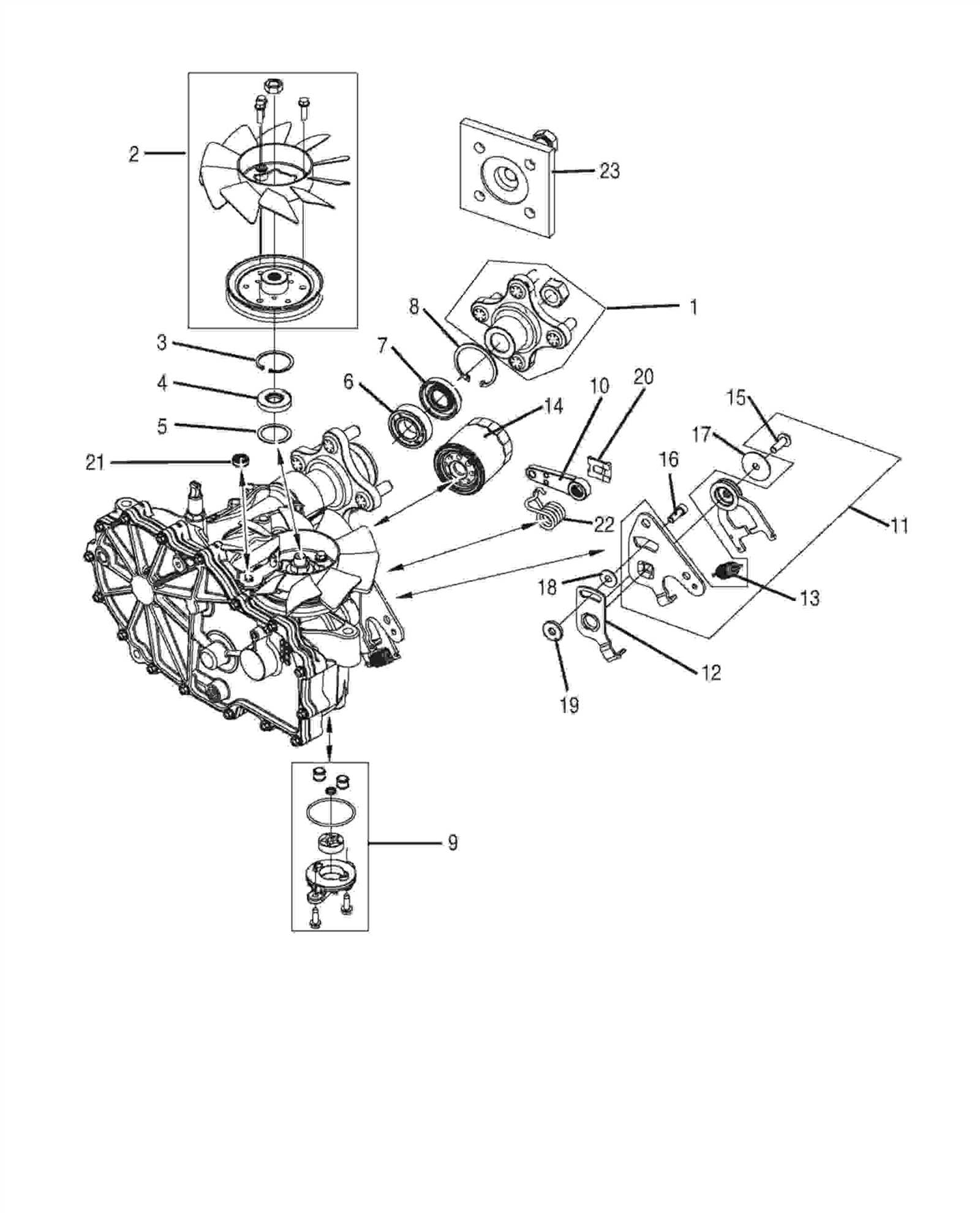

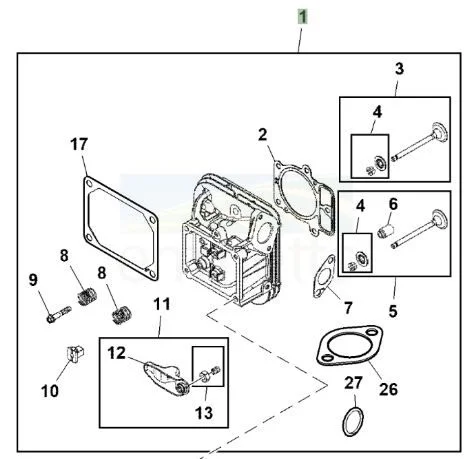

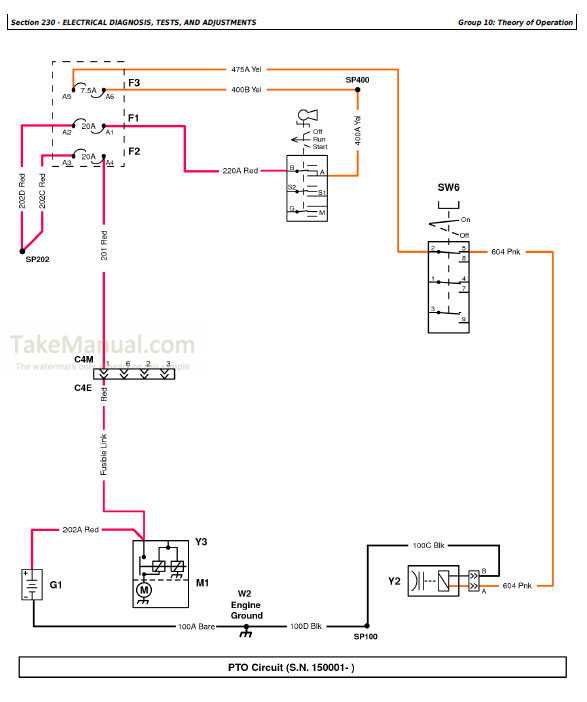

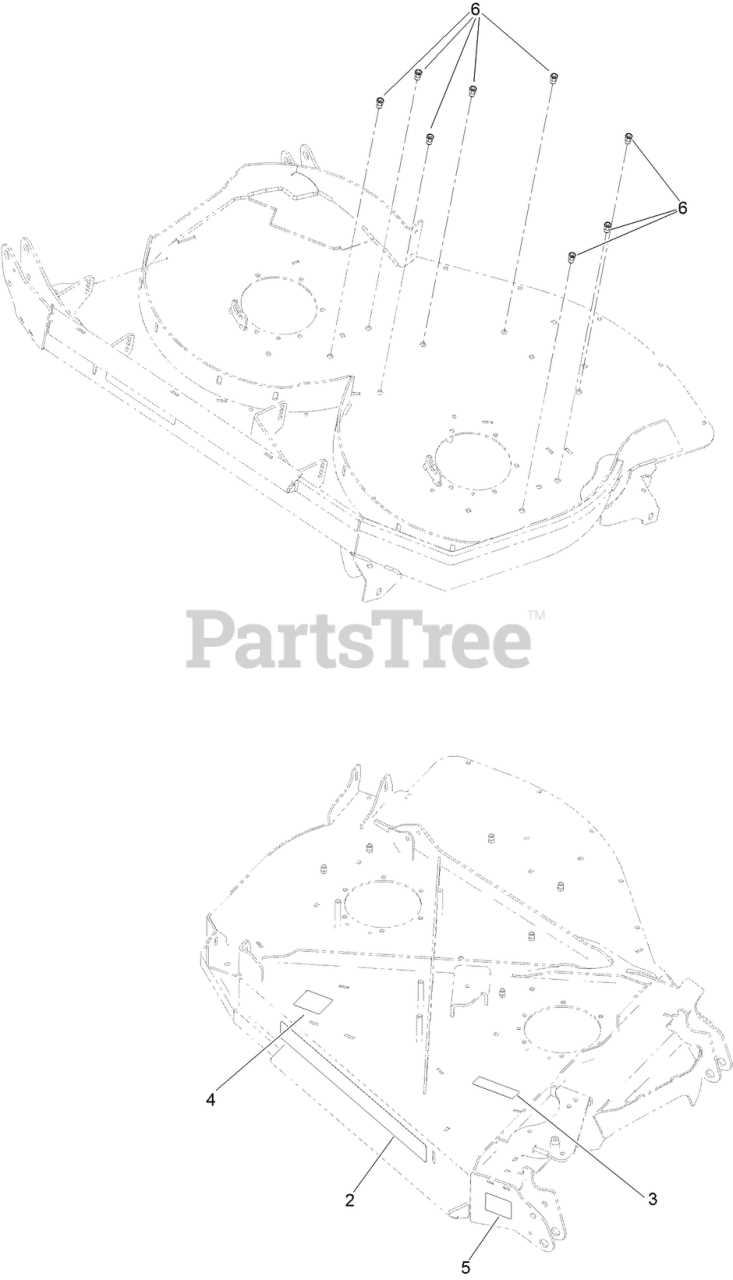

How to Read Parts Diagrams

Understanding visual representations of components is crucial for effective maintenance and repairs. These illustrations provide essential insights into the relationships between various elements, helping users identify what is needed for efficient operation.

Here are some key steps to effectively interpret these visuals:

- Familiarize Yourself with Symbols:

- Learn common icons used to represent different parts.

- Understand the color coding, if applicable.

- Identify the Sections:

- Locate the main areas highlighted in the illustration.

- Recognize how different segments interact.

- Refer to the Key:

- Utilize any accompanying legend or key that explains specific markings.

- This will clarify any ambiguities in the visual.

- Check the Reference Numbers:

- Look for numerical identifiers linked to each component.

- These numbers can guide you to detailed descriptions or part listings.

- Cross-Reference with Manuals:

- Consult maintenance manuals or catalogs for additional information.

- These resources often provide insights that enhance understanding.

By following these steps, you can navigate through the intricate details of component illustrations, making the process of repair and maintenance much more manageable.

Identifying Essential Components

Understanding the key elements of a landscaping machine is crucial for effective maintenance and operation. Familiarity with these components not only enhances performance but also extends the lifespan of the equipment. Recognizing each part’s function helps ensure that everything operates smoothly and efficiently.

Main Elements

The primary structure includes the chassis, which serves as the foundation for other components. Additionally, the engine plays a vital role, providing the necessary power for movement and operation. The cutting system, comprising blades and associated hardware, is essential for achieving a clean and precise finish on lawns.

Auxiliary Features

Beyond the basics, there are several auxiliary features that enhance functionality. Control mechanisms allow the operator to steer and manage speed effectively. Fuel systems ensure that the engine receives the right amount of energy, while transmission components facilitate smooth movement across various terrains. Regular inspection of these features is key to maintaining overall efficiency.

DIY Repairs for Z425 Owners

For enthusiasts seeking to maintain their equipment effectively, tackling repairs independently can be both rewarding and cost-effective. Understanding the basic components and their functions allows for a more hands-on approach to maintenance, ensuring that your machine operates smoothly for years to come.

Basic Tools and Safety

Before embarking on any repair tasks, it’s essential to gather the right tools. A good set of wrenches, screwdrivers, and pliers will cover most needs. Additionally, always prioritize safety by wearing gloves and eye protection during any maintenance activities.

Common Issues and Solutions

One frequent problem is with the cutting mechanism. If you notice uneven cuts, check the blade sharpness and alignment. Sharpening or replacing blades can significantly enhance performance. Another area to inspect is the drive system. If the movement feels sluggish, examine the belts for wear and ensure they are properly tensioned.

Routine Maintenance Tips

Regular upkeep is vital for longevity. Clean the undercarriage after each use to prevent grass buildup, which can cause rust and corrosion. Additionally, check the oil and fuel levels periodically, and replace filters as necessary to maintain optimal engine performance.

Resources for Assistance

For those looking for visual guidance, many online resources offer video tutorials and community forums where fellow owners share their experiences. Engaging with these platforms can provide valuable insights and troubleshooting tips that enhance your repair skills.

Benefits of Original Parts vs. Aftermarket

When it comes to maintaining machinery, the choice between authentic components and those from third-party manufacturers can significantly impact performance and longevity. Understanding the advantages of using original equipment can help ensure that your equipment operates efficiently and reliably.

Quality Assurance: Original components are designed and tested to meet the specific standards set by the manufacturer. This guarantees a level of quality that often surpasses aftermarket alternatives. The precision engineering of these parts minimizes the risk of malfunction, leading to better overall performance.

Compatibility: Authentic components are crafted to fit perfectly within the system they are intended for. This ensures seamless integration, reducing the likelihood of issues that can arise from improper fitment associated with non-original options.

Warranty Protection: Using original components often preserves warranty coverage. Many manufacturers stipulate that utilizing third-party parts can void the warranty, which may lead to costly repairs if issues arise later on.

Long-Term Savings: While the upfront cost of original components may be higher, their durability and reliability can lead to lower maintenance costs over time. Investing in quality often results in fewer replacements and repairs, ultimately saving money in the long run.

Resale Value: Equipment maintained with authentic parts typically retains a higher resale value. Prospective buyers often prefer machinery that has been serviced with original components, as it reflects a commitment to quality and care.

In summary, while aftermarket options may seem appealing due to their lower price, the benefits of using original components far outweigh the initial savings. Prioritizing quality and compatibility can lead to enhanced performance, reliability, and value for your machinery.