Understanding the Components of a Dewalt 20V Impact Driver

The inner workings of a versatile and powerful tool are often more intricate than they appear at first glance. Each component plays a critical role in ensuring seamless functionality, durability, and efficiency. Whether you’re a professional or a hobbyist, having a clear view of how these elements come together can greatly improve both your understanding and maintenance of the tool in question.

Exploring the core features and layout of this equipment allows users to better identify potential issues and ensure smooth operation over time. By breaking down the individual elements, you’ll gain a clearer picture of how each section contributes to the overall performance and longevity of the device. This knowledge is essential for troubleshooting, repair, and even enhancement of the tool’s capabilities.

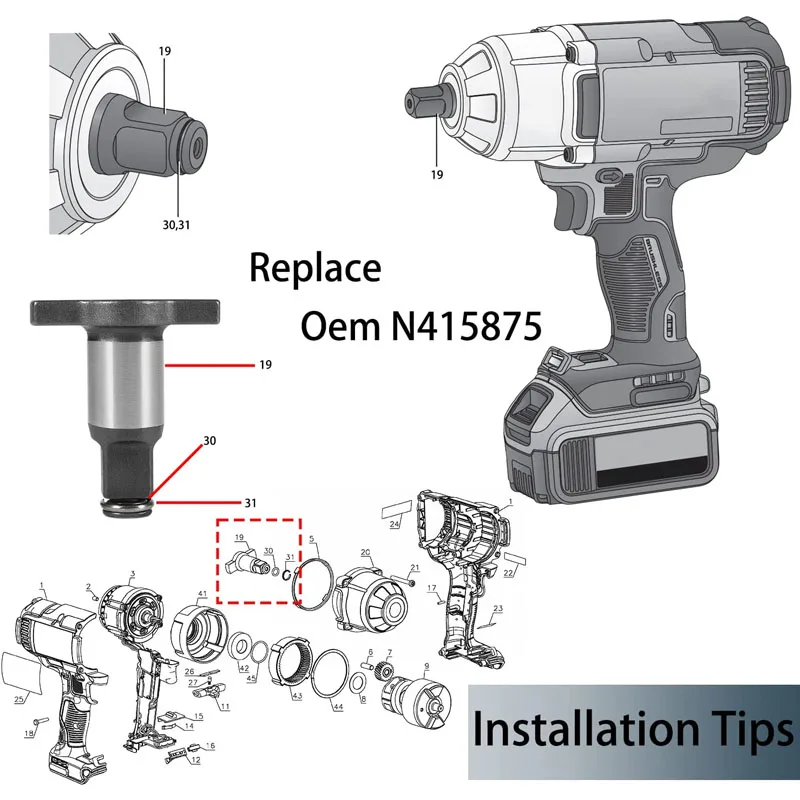

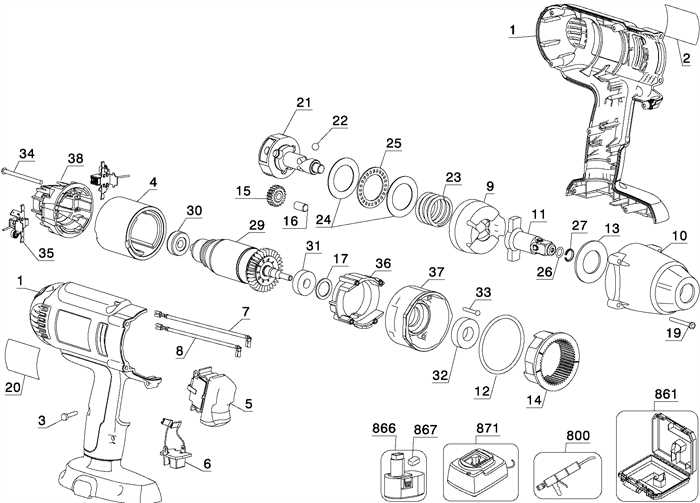

Detailed illustrations and technical breakdowns provide an excellent reference for those looking to fine-tune their equipment or replace specific components. Armed with this insight, you’ll be well-equipped to maintain optimal functionality and get the most out of your device in every project.

Overview of the Dewalt 20v Impact Driver

This power tool is designed to provide maximum efficiency and durability, making it an essential piece of equipment for both professional and home improvement tasks. With its strong performance and ergonomic design, it is built to handle tough materials and fastenings with ease, ensuring reliable results every time.

- Powerful motor capable of delivering high torque for demanding tasks

- Compact and lightweight design to reduce user fatigue during extended use

- Precision control features that enhance accuracy when working with different materials

- Durable construction ensures long-term reliability, even under heavy-duty conditions

Thanks to its intuitive features and user-friendly build, this tool simplifies the process of fastening, allowing for greater speed and efficiency in a variety of applications.

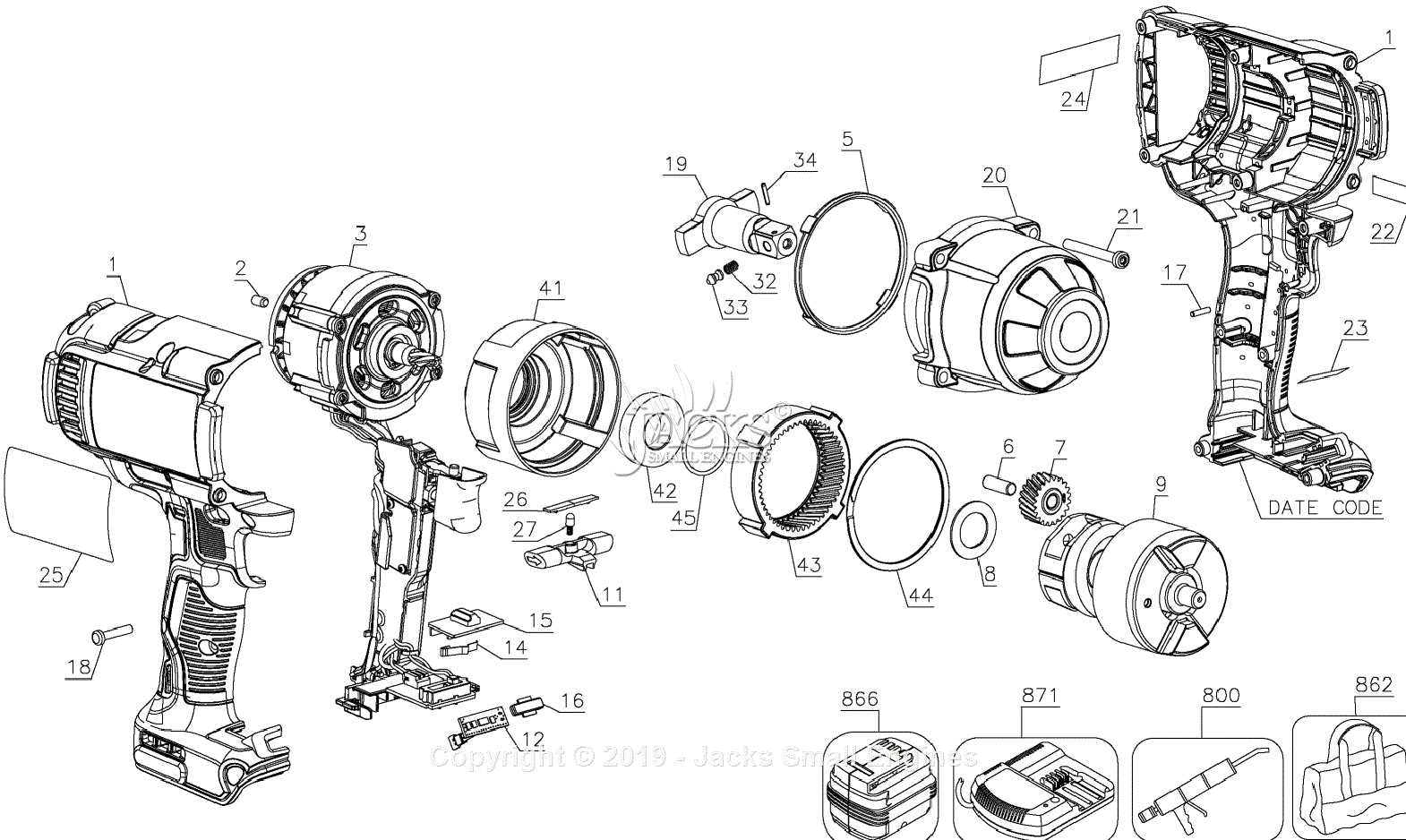

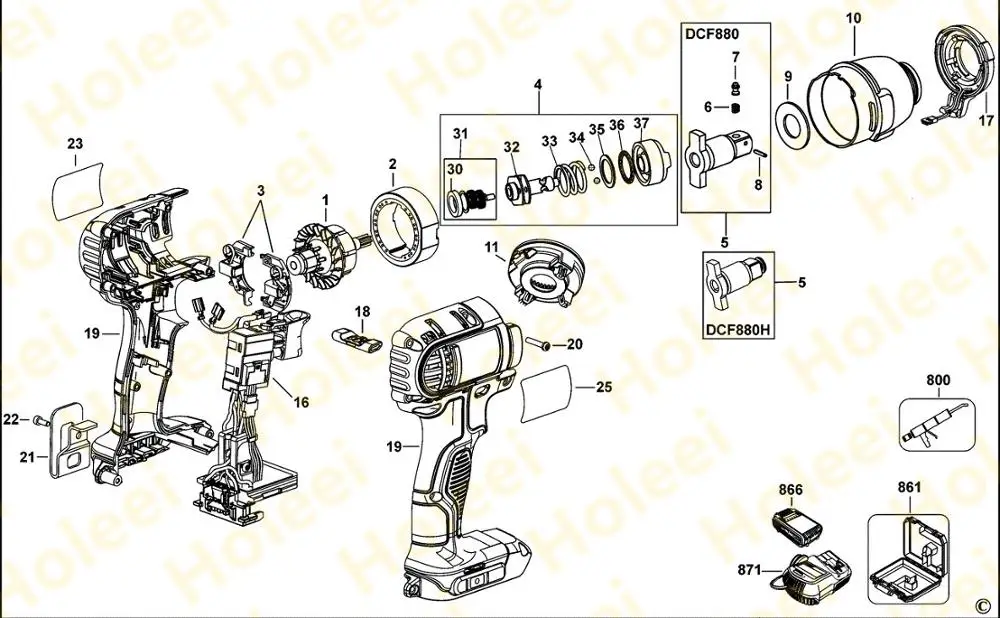

Key Internal Components Breakdown

The inner workings of this power tool consist of several crucial mechanisms that work together to deliver efficient performance. Understanding how these components function provides insight into the overall reliability and effectiveness of the device.

Motor Assembly: At the heart of the tool is a motor that converts electrical energy into mechanical power, driving the system. It is designed for high torque output and durability, ensuring long-lasting performance.

Gearbox System: The gearbox transfers the energy from the motor to the tool’s active elements, optimizing speed and force. Built with precision gears, it allows for smooth transitions between different levels of force, essential for varied applications.

Trigger Mechanism: This component regulates the flow of power, giving the user control over the operation. The trigger’s sensitivity and design allow for precision, responding quickly to user input for improved accuracy.

Battery Interface: The power source is connected through a secure interface, ensuring a stable flow of electricity. This component is engineered for fast attachment and detachment, enhancing convenience during use.

Cooling System: To maintain optimal performance, a cooling system is integrated to dissipate heat generated by the motor and other moving parts. This helps prevent overheating and extends the tool’s lifespan.

Understanding the Motor Assembly

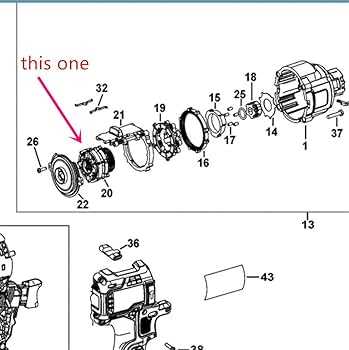

The heart of any power tool lies in its motor assembly, which is responsible for converting electrical energy into the mechanical force needed for operation. A solid understanding of the internal components and how they interact ensures better performance and maintenance. This section will break down the essential parts that work together to create the tool’s driving force.

| Component | Description | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Rotor | This rotating element works with the stator to generate movement through electromagnetic induction, powering the tool’s primary function. | ||||||||

| Stator | A stationary part that surrounds the rotor, the stator creates a magnetic field essential for rotation and consistent torque. | ||||||||

| Bearings | Bearings support the rotation of the rotor, ensuring smooth and efficient movement with minimal friction and wear. | ||||||||

| Brushes | Located in direct contact with the rotor, these components deliver electrical current, which is necessary for maintaining the flow of power during operation. | ||||||||

| Housing | This protective casing keeps

Trigger Mechanism and How It Works

The control system for activating the device’s rotation relies on a carefully designed trigger that initiates power flow. This component allows the user to manage speed and intensity by adjusting the pressure applied to it. Its role is essential for providing precision and responsiveness during operation. At the heart of this mechanism lies a connection between the electrical contacts and the motor. When the trigger is pressed, it closes the circuit, enabling the motor to start. The more the trigger is squeezed, the higher the power output, allowing for variable control over the tool’s performance. This ensures that users can adjust the device’s speed according to the task at hand, providing both finesse and force when needed. Another key element of this system is the electronic control that governs the power supply. By modulating the flow of electricity, the trigger mechanism helps maintain consistent speed even under varying loads. This feature allows for smoother operation, reducing the risk of motor strain and improving overall efficiency. Battery Connection and Compatibility

The connection between the power source and the tool is a critical aspect of ensuring reliable performance. A well-designed system guarantees a secure and efficient transfer of energy, providing consistent operation during even the most demanding tasks. Understanding how different power units integrate with the tool’s internal components is essential for optimal use. Ensuring a Secure ConnectionThe integration point between the energy cell and the tool must be robust and reliable. This connection often involves multiple contact points, designed to minimize resistance and maintain a steady flow of power. Any misalignment or wear in this area can lead to reduced efficiency or interruptions during operation, making it important to ensure all contacts are clean and properly aligned. Compatibility with Various Power Units

When selecting a power source, it is important to ensure compatibility across different models. Some energy cells are designed to work across a range of tools, offering flexibility and convenience. Checking the specifications of both the tool and the energy unit ensures that they are well-matched, preventing potential damage or performance issues. Exploring the Chuck and Bit Holder

The central mechanism that connects and secures various tools in a power device plays a key role in ensuring its functionality. This section focuses on the components responsible for holding and releasing accessories, highlighting their design and practical features. These parts are essential for smooth operation, allowing users to quickly switch between different attachments while maintaining a secure grip on the working piece. Key Components of the MechanismThe main section responsible for securing the accessory is composed of several interconnected elements. Each part plays its role in enabling easy attachment and removal. Whether you need to fasten or loosen, the structure is designed to offer a seamless experience.

Advantages of Quick Attachment SystemsThese modern solutions offer increased efficiency and flexibility. Users benefit from rapid transitions between tasks, minimizing downtime and enhancing overall productivity. The system’s ergonomic design ensures ease of use, making it a reliable choice for various tasks. Gears and Torque Transmission System

The efficiency of power tools heavily relies on the intricate mechanisms that govern energy transfer and force amplification. At the core of these systems are various gears designed to optimize performance, ensuring that rotational force is effectively translated into the desired output. Understanding the design and functionality of these components is crucial for appreciating how they enhance the tool’s overall capabilities. Functionality of Gear AssembliesGear assemblies play a pivotal role in modifying speed and torque output, allowing for versatile operation across different tasks. The arrangement of gears can significantly affect the tool’s performance, with specific configurations enabling higher torque for demanding applications or increased speed for lighter tasks. Each gear’s size and tooth configuration are meticulously engineered to ensure smooth operation and minimal energy loss. Torque Transmission Mechanisms

Torque transmission mechanisms are essential for converting the motor’s rotational energy into usable force. These systems often employ a combination of gears and clutches to manage the power output effectively. By adjusting the gear ratio, tools can provide the necessary torque required for various applications, enhancing both efficiency and user control. This precise transmission not only improves performance but also extends the lifespan of the tool by reducing wear and tear on internal components. Housing and External Protection PartsThis section delves into the components that provide structural integrity and safeguarding for power tools. These elements are essential for ensuring durability and reliability during usage, allowing the device to withstand various environmental conditions and mechanical stresses. Understanding these components is crucial for maintenance and repair, as they play a vital role in the overall functionality of the equipment. Protective CasingsThe outer shell of the tool serves as the primary defense against physical impacts and external debris. These casings are typically constructed from high-quality materials designed to absorb shocks and resist wear. Their design not only enhances durability but also contributes to the ergonomic aspects, ensuring a comfortable grip for users. Ventilation and Cooling Systems

Effective heat dissipation is crucial for maintaining optimal performance. The ventilation features incorporated into the housing allow for airflow, which helps cool the internal mechanisms during operation. This prevents overheating and extends the life of the internal components, making proper maintenance of these ventilation pathways essential for the longevity of the equipment. Cooling System and Heat DissipationEfficient thermal management is essential for the optimal performance and longevity of power tools. The mechanism utilized to regulate temperature plays a crucial role in maintaining functionality during operation. Proper heat dissipation mechanisms are integral to preventing overheating and ensuring that the device operates smoothly, even under demanding conditions. One of the primary methods for managing heat involves the use of airflow to dissipate excess warmth generated during usage. This can be achieved through various design elements:

Additionally, the materials used in construction can significantly impact thermal performance:

Implementing an effective cooling system not only safeguards the integrity of internal components but also enhances user comfort by reducing the risk of the tool becoming too hot to handle. Overall, the design and functionality of the thermal management features are pivotal in ensuring reliable performance and durability. Common Replacement Parts for MaintenanceMaintaining tools is essential for optimal performance and longevity. Regular inspection and timely replacement of worn components can prevent costly repairs and ensure that the equipment operates efficiently. This section highlights key elements that are often replaced during maintenance routines. Battery: One of the most critical components, batteries provide the necessary power for operation. Over time, batteries may lose their capacity, leading to reduced performance. Regularly checking the condition of the power source is vital to ensure reliability. Brushes: These components are essential for transferring electrical energy to the motor. Worn brushes can lead to decreased efficiency and increased wear on the motor. Inspecting and replacing brushes as needed can help maintain optimal function. Chuck: The chuck is responsible for holding the bit securely in place. If it becomes damaged or worn, it may not grip bits properly, affecting the tool’s performance. Regular checks and replacements can prevent potential accidents and ensure precise operation. Motor: The motor is the heart of the tool, converting electrical energy into mechanical power. If performance declines, it may indicate a need for motor replacement. Keeping an eye on performance indicators can help catch issues early. Gearbox: The gearbox transfers power from the motor to the chuck. Wear and tear can lead to grinding noises or slipping, which signifies a need for inspection and potential replacement. Proper maintenance of the gearbox can extend the lifespan of the tool. By regularly checking these components and replacing them as necessary, users can maintain their tools in top condition, ensuring reliability and efficiency during use. Troubleshooting Common Component Issues

When using power tools, users may encounter various issues related to their internal mechanisms. Understanding these common problems can help in diagnosing and resolving malfunctions effectively. This section provides insights into frequent component-related challenges and offers practical solutions to restore optimal functionality. 1. Motor Overheating: One of the most prevalent concerns is motor overheating. This can result from prolonged use or excessive load. To alleviate this issue, allow the tool to cool down during breaks, and ensure it is not overloaded during operation. Regularly inspect the ventilation slots to keep them clear of debris. 2. Battery Performance: A decline in battery efficiency can lead to reduced tool performance. If the tool struggles to maintain power, consider checking the battery’s charge level and connections. For lithium-ion batteries, ensure they are stored in a cool, dry place and avoid deep discharges to prolong their lifespan. 3. Torque Settings: Improper torque settings can lead to inadequate fastening or stripping screws. Always refer to the manufacturer’s guidelines for the recommended settings based on the material being worked on. Adjusting the torque can help in achieving the desired results without damaging the fasteners. 4. Chuck Issues: Difficulty in securing or releasing bits can indicate problems with the chuck mechanism. Regularly lubricate the chuck to prevent sticking and ensure a firm grip on bits. If the chuck is damaged, replacement may be necessary to maintain efficient operation. 5. Electrical Faults: If the tool fails to operate, it may indicate an electrical issue. Inspect the power cord and connections for any signs of damage. Additionally, checking the internal wiring for loose connections can help in diagnosing the problem. Seek professional assistance for repairs involving electrical components. |