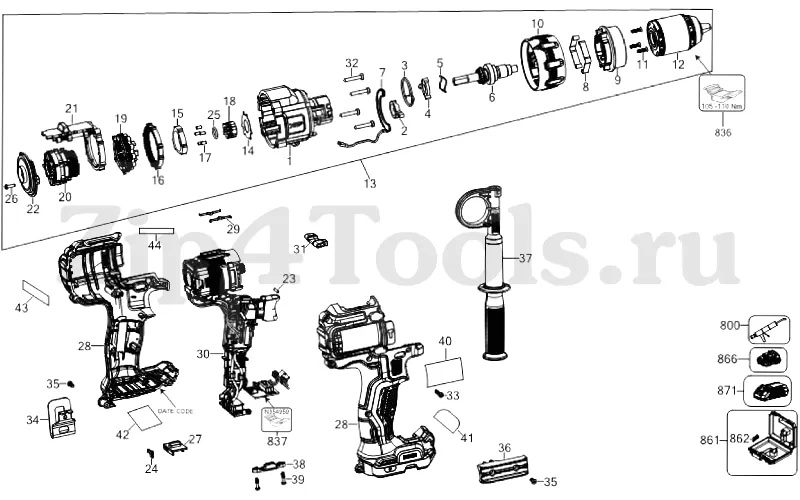

Dewalt DCD999 Parts Diagram Overview

In the realm of power tools, grasping the layout of individual elements is essential for both maintenance and effective usage. Knowing how components interconnect can significantly enhance your understanding of the tool’s functionality and longevity.

With a focus on specific models, users can benefit from visual representations that illustrate the relationships between various parts. This knowledge not only aids in troubleshooting but also empowers operators to carry out repairs with confidence.

Furthermore, detailed schematics serve as invaluable resources for enthusiasts and professionals alike, ensuring that every aspect of their tools is optimized for peak performance. The ultimate goal is to promote efficiency and safety through informed use and care.

Dewalt DCD999 Overview

This section provides an insightful look into a high-performance power tool designed for both professionals and DIY enthusiasts. With its robust features and innovative technology, it caters to a variety of applications, making it a versatile choice for demanding tasks.

Key Features

The tool boasts exceptional torque and speed, ensuring efficiency in every job. Enhanced battery life supports prolonged use, while advanced motor technology delivers reliable performance, even under challenging conditions.

Applications

Ideal for construction, renovation, and maintenance projects, this equipment excels in driving fasteners and drilling into various materials. Its ergonomic design promotes comfort, reducing fatigue during extended operation, ultimately improving productivity.

Importance of Parts Diagrams

Understanding the layout of components is crucial for effective maintenance and repair of tools. These visual aids simplify the identification of each element, ensuring that users can easily locate and understand the function of each section within the equipment. By having access to these resources, individuals can enhance their troubleshooting skills and streamline the repair process.

Facilitating Repairs

Having a clear representation of each component allows users to tackle repairs with confidence. They can efficiently determine which parts may need replacement or servicing, reducing downtime and preventing potential damage to the tool.

Enhancing Safety

Familiarity with the arrangement of components can significantly improve safety during maintenance. Users can better understand how to disassemble and reassemble tools, minimizing the risk of accidents and ensuring that equipment operates correctly after repairs.

Key Components of DCD999

Understanding the essential elements of this powerful tool enhances both its usability and maintenance. Each component plays a vital role in ensuring optimal performance and longevity. Below are some of the key parts that contribute to its effectiveness.

- Motor: The heart of the tool, providing the necessary power for drilling and fastening tasks.

- Gearbox: Responsible for speed control and torque adjustment, enabling versatility in various applications.

- Chuck: This component securely holds drill bits and accessories in place, allowing for quick changes.

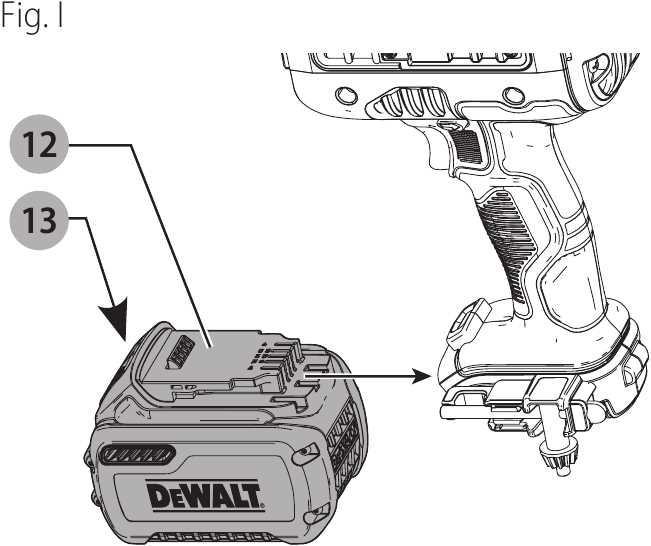

- Battery: A critical part for cordless models, ensuring portability and efficiency without the need for power outlets.

- Handle: Designed for comfort and grip, it aids in precision and reduces user fatigue during extended use.

- Trigger: The user interface that controls the tool’s operation, allowing for variable speed and control.

- LED Light: Illuminates the work area, enhancing visibility in low-light conditions.

Familiarity with these components can significantly improve your experience and effectiveness when using this robust device.

Common Issues with Dewalt Tools

Power tools, while essential for many projects, can sometimes experience challenges that hinder performance. Understanding these common problems can help users troubleshoot effectively and maintain their equipment in optimal condition.

Battery Failure: One prevalent issue involves the battery, which may lose charge capacity over time. Regular usage and exposure to extreme temperatures can accelerate this decline. Ensuring proper storage and maintenance can prolong battery life.

Motor Overheating: Overworking the tool or using it for tasks beyond its capacity can lead to overheating. This not only affects performance but can also cause long-term damage. It’s important to allow the tool to rest periodically during extended use.

Wear and Tear: Components such as brushes and gears may wear out with frequent use. Signs of wear can manifest as reduced power or unusual noises. Regular inspection and timely replacement of worn parts are crucial for maintaining functionality.

Jamming: Tools can become jammed due to debris or improper usage. Regular cleaning and ensuring the correct attachment is in place can help prevent this issue. When jamming occurs, careful disassembly and inspection are recommended.

By being aware of these common challenges, users can take proactive steps to ensure their tools remain reliable and efficient for all their projects.

How to Read a Parts Diagram

Understanding an assembly illustration is crucial for effective maintenance and repair tasks. These visual representations serve as guides, helping users identify components and their relationships within a tool or machine. By mastering how to interpret these illustrations, you can streamline your troubleshooting and replacement processes.

First, familiarize yourself with the layout. Typically, the image will display various elements in a systematic arrangement, often numbered or labeled for easy reference. Pay attention to these annotations, as they indicate specific pieces and their respective positions.

Next, notice the key or legend, which explains the symbols or color codes used. This section is essential for understanding the nuances of the illustration. Make sure to consult it whenever you’re unsure about a particular symbol or notation.

Finally, correlate the illustration with the physical unit. By comparing the visual guide to the actual equipment, you can better grasp how parts interact and identify any missing or damaged components. This practical approach will enhance your repair capabilities significantly.

Finding Replacement Parts Easily

Locating components for your tools can often seem daunting, but with the right approach, it becomes a straightforward process. Knowing where to look and how to identify what you need is key to ensuring your equipment remains in optimal condition.

Where to Search

- Official Websites

- Authorized Retailers

- Online Marketplaces

- Local Hardware Stores

Tips for Identification

- Refer to the user manual for specifics.

- Take note of model numbers and specifications.

- Utilize online forums for advice from other users.

- Consult customer service for expert guidance.

Maintenance Tips for Longevity

Proper upkeep is essential for extending the life of your power tools. Regular care not only enhances performance but also prevents costly repairs and downtime. By following a few simple practices, you can ensure that your equipment remains in optimal condition for years to come.

| Tip | Description |

|---|---|

| Regular Cleaning | Remove dust and debris after each use to prevent buildup. |

| Lubrication | Apply appropriate lubricants to moving parts to reduce friction. |

| Battery Care | Charge batteries properly and store them in a cool, dry place. |

| Inspection | Regularly check for wear and tear, replacing any damaged components. |

| Follow Guidelines | Refer to the manufacturer’s recommendations for maintenance schedules. |

Where to Buy Authentic Parts

Finding genuine components for your tools is essential for maintaining their performance and longevity. Whether you are a professional or a DIY enthusiast, sourcing high-quality replacements ensures your equipment operates at its best.

Here are some reliable sources to consider:

- Manufacturer’s Website: Always check the official site for the most accurate information and authenticity.

- Authorized Retailers: Look for stores or online platforms that are recognized by the manufacturer.

- Specialty Tool Shops: Local or online shops that specialize in tools often carry original components.

- Trade Shows: Attend events where manufacturers showcase their products; these can be great places to find genuine items.

Ensuring you purchase from reputable sources will help you avoid counterfeit products and ensure the ultimate reliability of your equipment.

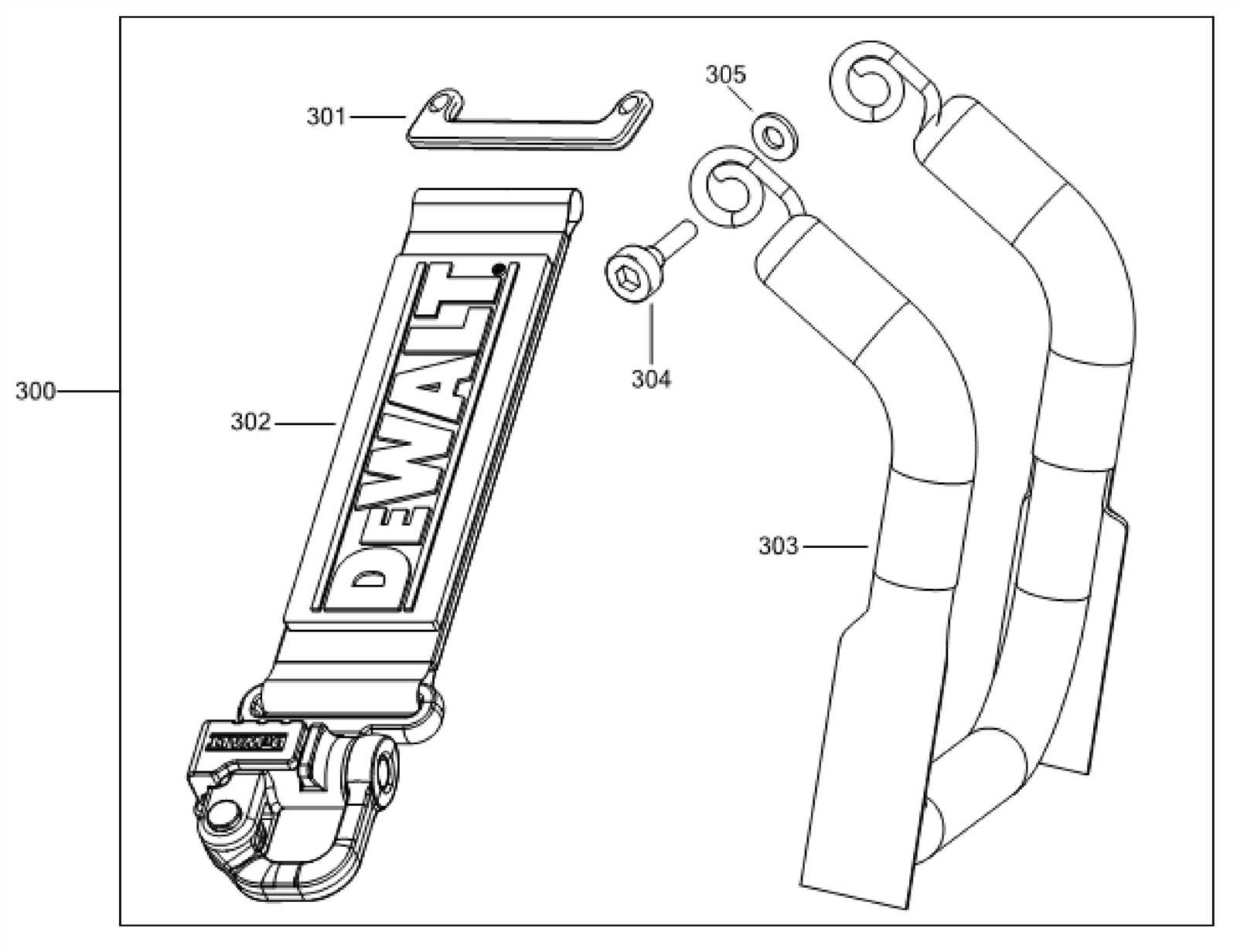

Upgrading Your Dewalt DCD999

Enhancing the performance and capabilities of your power tool can significantly improve your efficiency and effectiveness in various projects. By implementing strategic upgrades, you can transform a reliable device into a more powerful and versatile asset in your toolkit.

Power Source Optimization is a critical aspect to consider. Upgrading to high-capacity batteries can provide longer runtime and enhanced performance, allowing you to tackle more demanding tasks without interruption.

Another key upgrade involves accessory enhancements. By selecting specialized bits and attachments, you can expand the range of applications for your tool, making it suitable for diverse materials and environments.

Additionally, ergonomic improvements can greatly influence your comfort during extended use. Consider adding grips or handle modifications that reduce fatigue, enabling you to work efficiently for longer periods.

Finally, investing in protective upgrades like custom cases or guards can ensure the longevity of your tool while keeping it safe from damage. This not only preserves its functionality but also maintains its resale value.

By thoughtfully considering these upgrades, you can maximize the potential of your power tool, making it a more valuable component of your project arsenal.

Expert Repair Techniques

Mastering the art of tool maintenance requires a deep understanding of their internal mechanisms and components. By employing advanced methods, one can enhance the longevity and performance of equipment, ensuring they operate at peak efficiency. This section will delve into essential strategies that can transform a novice into a proficient technician.

First and foremost, it’s crucial to familiarize oneself with the assembly of the equipment. Thoroughly studying the internal layout allows for quicker identification of issues. Utilizing specialized tools, such as torque wrenches and circuit testers, can streamline the repair process, minimizing the risk of damage during disassembly.

Another vital technique involves systematic troubleshooting. By adopting a methodical approach–starting from the power source and working through each component–one can isolate faults effectively. Keeping detailed notes throughout the repair can provide valuable insights for future maintenance tasks.

Furthermore, sourcing high-quality replacement parts is essential. Utilizing original or trusted aftermarket components ensures compatibility and reliability. Always verify that any replacements meet the manufacturer’s specifications to avoid complications.

Finally, regular calibration and testing post-repair cannot be overstated. Conducting thorough checks helps confirm that the tool operates correctly and safely, allowing for immediate adjustments if necessary. With these expert techniques, anyone can achieve professional-level repairs and keep their tools in optimal condition.

Customer Reviews and Feedback

Understanding user experiences is crucial when evaluating any tool. Feedback from those who have used a particular model provides valuable insights into its performance, reliability, and overall satisfaction. This section highlights various perspectives from customers, showcasing both positive remarks and constructive criticism.

Positive Experiences

Many users have praised the durability and efficiency of the tool. Its robust construction and powerful functionality have made it a favorite among professionals and DIY enthusiasts alike. Customers often highlight its ease of use and versatility, making it suitable for a wide range of applications.

Areas for Improvement

While the overall reception is largely favorable, some users have noted specific areas for enhancement. Common feedback includes suggestions for better battery life and ergonomic design adjustments. These insights help manufacturers identify potential improvements for future iterations.

| Customer Rating | Comment |

|---|---|

| 5/5 | Excellent performance and highly reliable! |

| 4/5 | Great tool, but I wish the battery lasted longer. |

| 3/5 | Good overall, but the weight can be a bit cumbersome. |