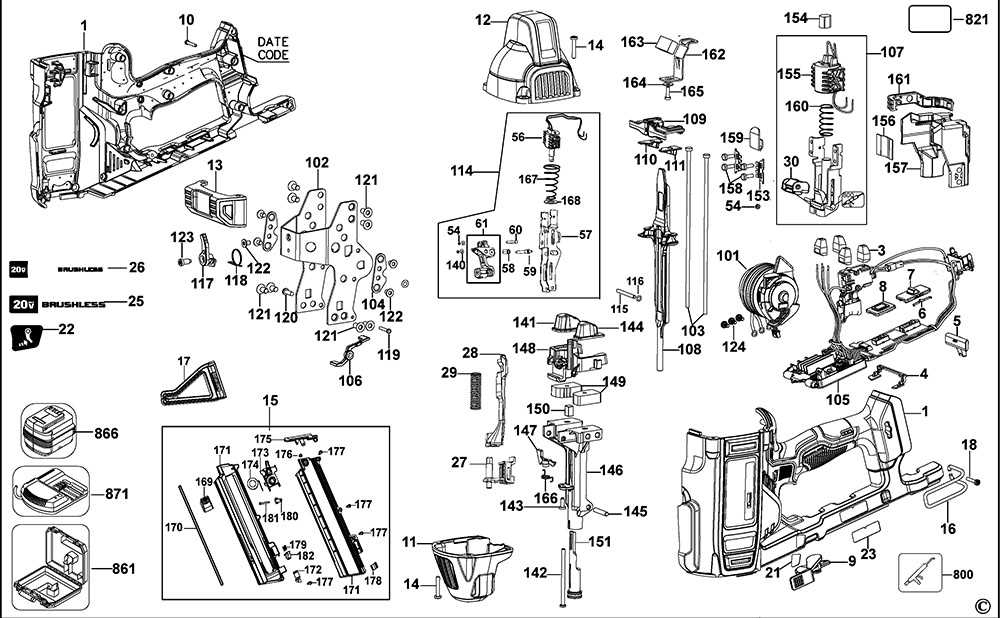

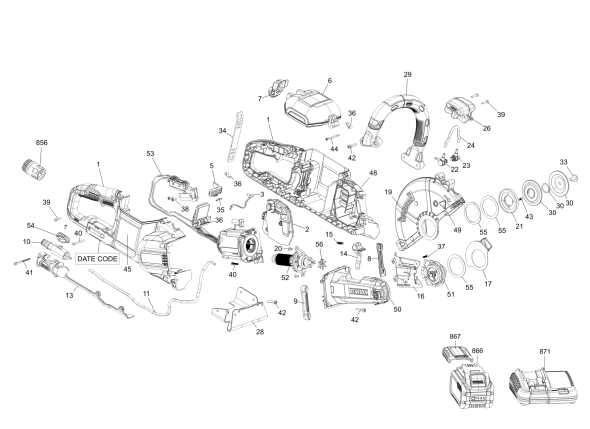

Dewalt DCST970 Parts Diagram Explained

When it comes to maintaining and repairing outdoor power equipment, having a clear visual representation of its individual elements is essential. A comprehensive overview of these components not only aids in identifying specific parts but also enhances overall functionality. This knowledge empowers users to perform troubleshooting and maintenance with confidence.

Detailed illustrations serve as invaluable resources for both novice and experienced users. They simplify the process of disassembly and reassembly, ensuring that each segment is correctly positioned and secured. By utilizing these resources, you can minimize downtime and maximize the efficiency of your equipment.

Furthermore, familiarity with the layout of each component allows for better understanding of the tool’s operation. Recognizing how each piece interconnects enhances the ability to diagnose issues, leading to timely repairs and improved performance. Embracing this knowledge transforms the way users interact with their machinery, fostering a sense of competence and assurance.

Dewalt DCST970 Overview

This powerful tool is designed for efficient trimming and cutting in various outdoor applications. With advanced features and ergonomic design, it ensures user comfort and optimal performance, making it a go-to choice for both professionals and hobbyists.

| Feature | Description |

|---|---|

| Motor | High-efficiency brushless motor for extended runtime and performance. |

| Battery | Compatible with a range of battery systems for versatile usage. |

| Weight | Lightweight design for ease of handling and reduced fatigue. |

| Cutting Width | Generous cutting width for quicker tasks and increased productivity. |

| Ergonomics | Comfort grip handles for enhanced control and maneuverability. |

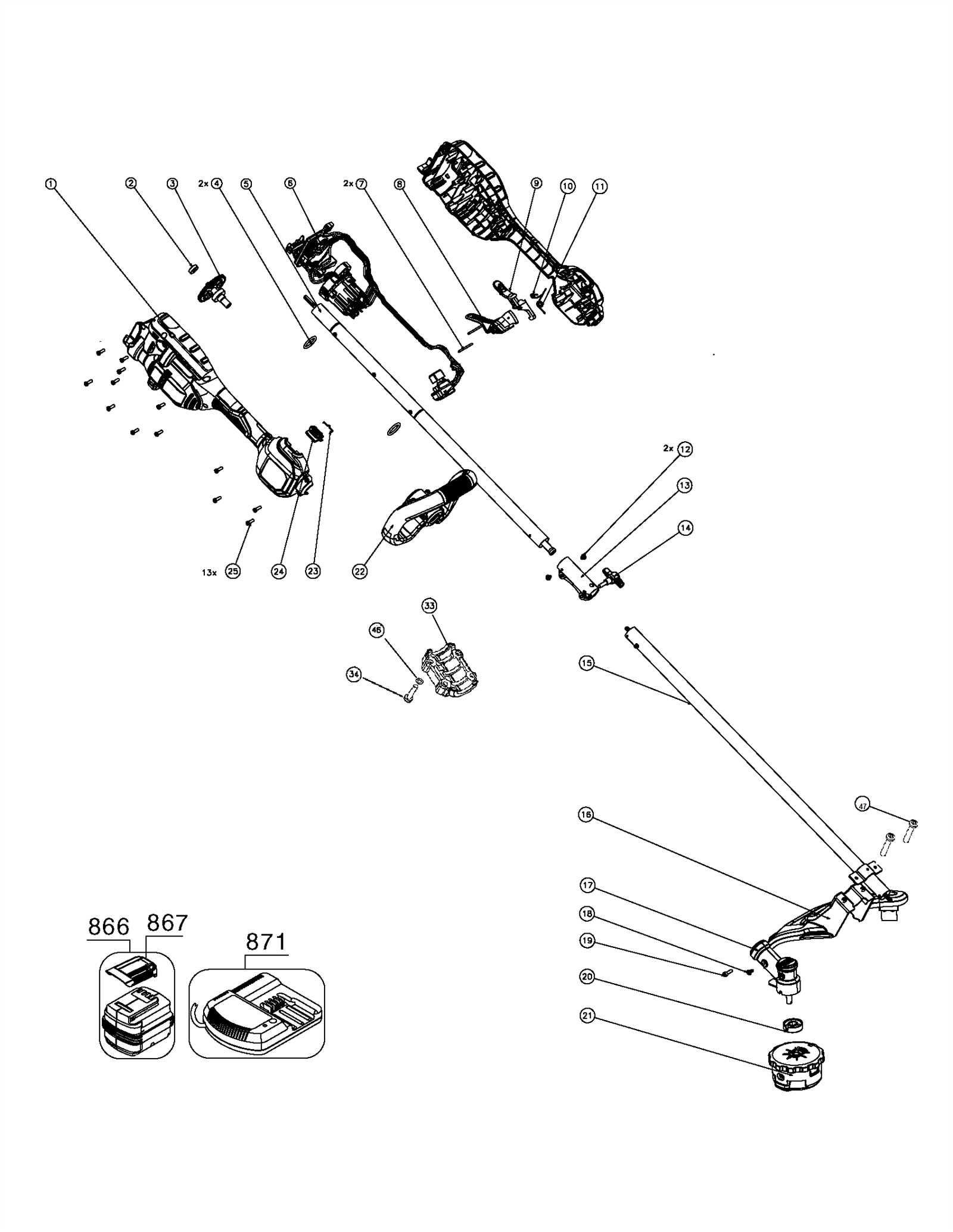

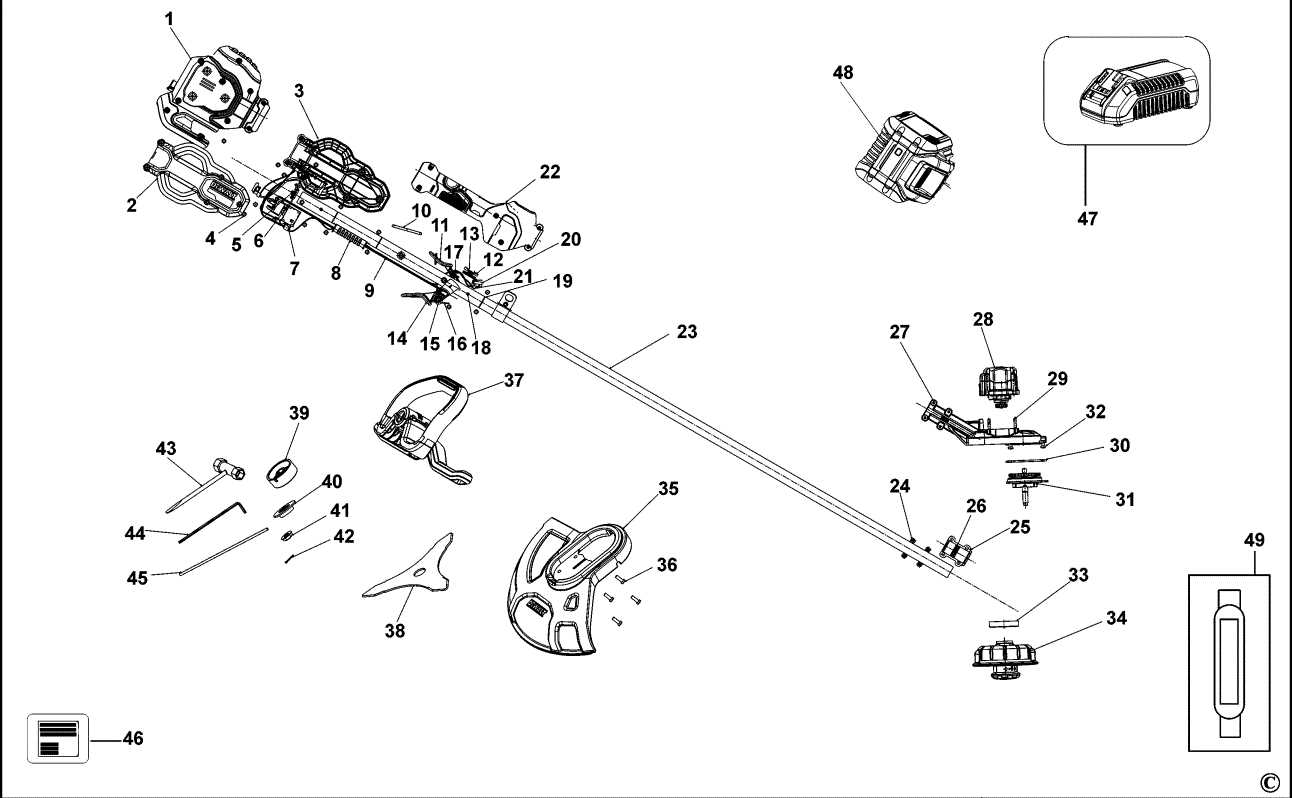

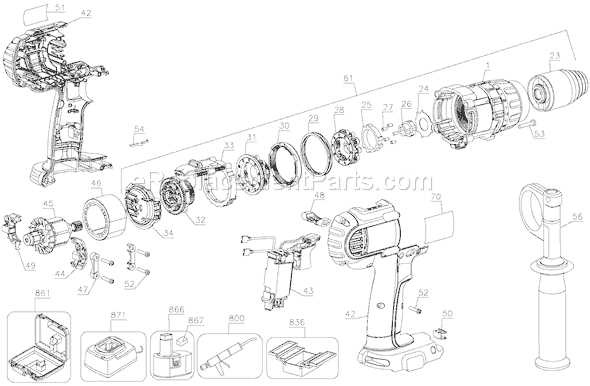

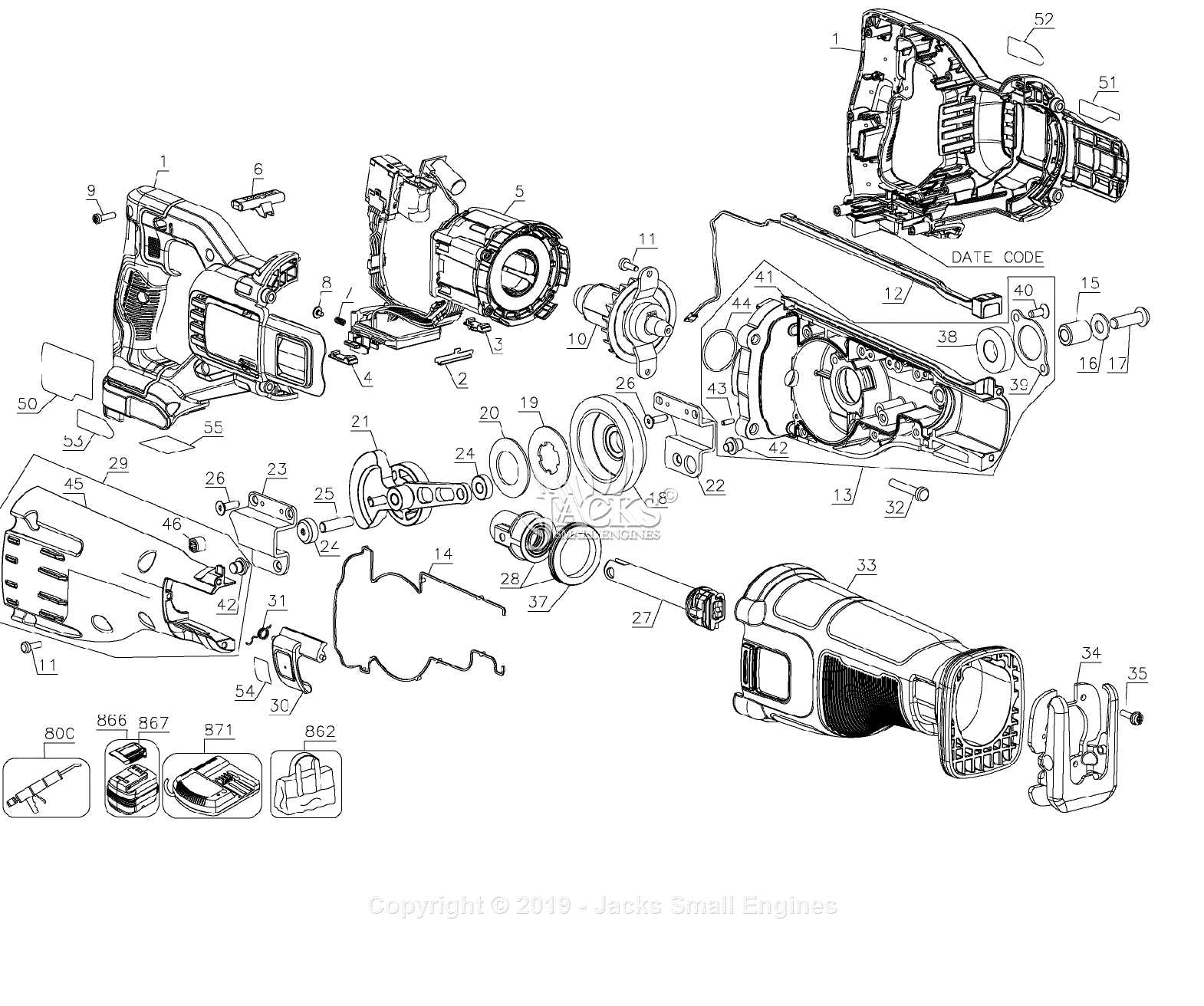

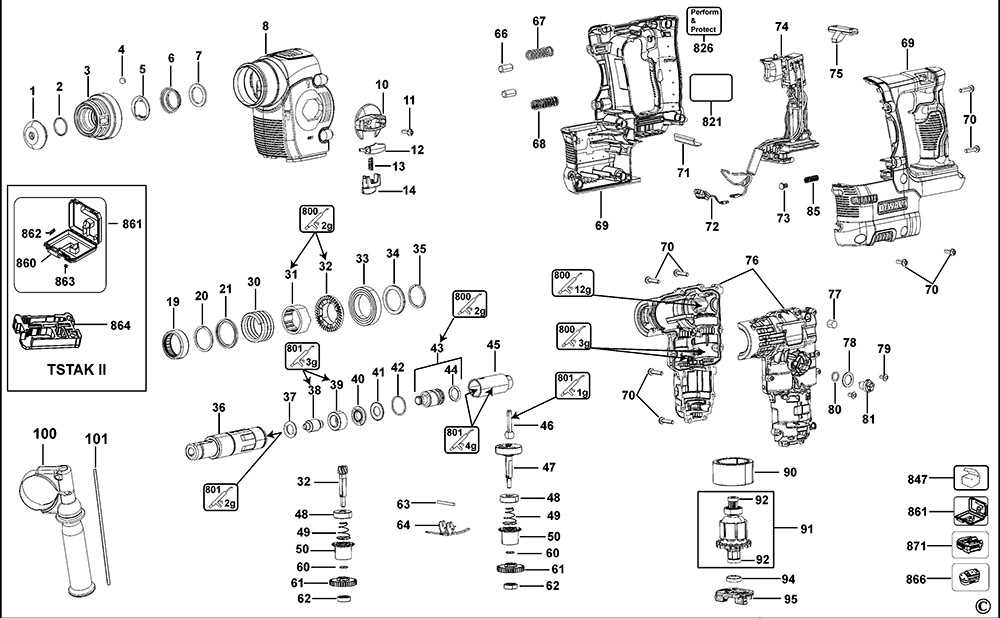

Understanding the Parts Diagram

Familiarizing oneself with the visual representation of components is essential for effective maintenance and repair of any machinery. These illustrations serve as a roadmap, allowing users to identify various elements, their functions, and how they interconnect. By comprehending these representations, users can streamline troubleshooting and enhance their overall efficiency.

Each section of the illustration typically corresponds to a specific part of the device, providing clear labels and numbers that facilitate quick reference. Understanding these markings can significantly reduce confusion when ordering replacements or performing repairs. This visual guide helps demystify complex assemblies, making it easier to grasp how each component contributes to the machine’s overall performance.

Moreover, recognizing the layout enables users to approach maintenance tasks with confidence. When issues arise, having a solid grasp of the component arrangement can expedite the diagnostic process, ensuring that necessary actions are taken promptly. Overall, a thorough understanding of these representations empowers users to maintain their equipment effectively and prolong its lifespan.

Common Components of the DCST970

This section explores the key elements that contribute to the functionality and efficiency of this particular outdoor power tool. Understanding these components is essential for optimal performance and maintenance.

Power System

The power system is a crucial element, providing the necessary energy to operate the device. It typically consists of a robust motor that ensures high torque and efficiency, enabling seamless cutting through various materials.

Cutting Mechanism

The cutting mechanism plays a pivotal role in achieving precise results. This includes the blade assembly, which is designed for durability and effectiveness, allowing users to tackle tough jobs with ease. Regular maintenance of this part is essential to prolong its lifespan and maintain performance.

Importance of Regular Maintenance

Routine upkeep is crucial for ensuring the longevity and efficiency of any equipment. By adhering to a consistent maintenance schedule, users can prevent unexpected breakdowns and enhance performance. This proactive approach not only saves time but also reduces overall repair costs.

Regular inspections allow for early detection of potential issues, which can be addressed before they escalate. Furthermore, maintaining clean and well-lubricated components ensures optimal functionality, resulting in smoother operation. Investing time in maintenance ultimately leads to better results and a more reliable tool.

How to Read the Parts Diagram

Understanding the schematic representation of components is essential for efficient maintenance and repair. This visual guide provides a clear overview of each individual piece and its relationship to others, allowing for a better grasp of how everything fits together.

Identifying Components

Each element is typically labeled with a unique identifier, making it easier to locate specific parts when seeking replacements or upgrades. Pay attention to the numbering system, as it often corresponds with a parts list, aiding in quick identification.

Understanding Relationships

The layout not only shows individual items but also illustrates how they interact within the overall assembly. By examining the connections and placements, one can better understand the assembly’s functionality and troubleshoot any issues that may arise.

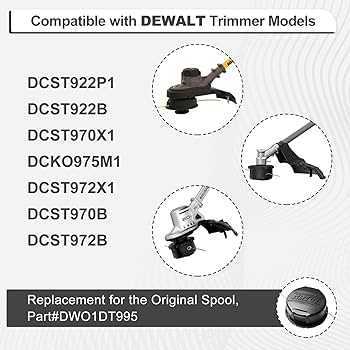

Replacement Parts Availability

Access to essential components is crucial for maintaining the efficiency and longevity of any power tool. Ensuring that users can easily find the necessary replacements contributes significantly to their satisfaction and productivity. Various suppliers and platforms offer a range of options, making it straightforward to acquire the needed items.

When searching for specific components, consider the following sources:

| Source | Advantages | Considerations |

|---|---|---|

| Authorized Retailers | Genuine quality, warranty support | Potentially higher prices |

| Online Marketplaces | Convenient, wide selection | Variable quality, need to verify sellers |

| Local Repair Shops | Expert advice, immediate access | Limited stock, may vary by location |

| Manufacturer’s Website | Direct sourcing, official updates | Shipping times may vary |

By exploring these avenues, users can ensure they have the right components on hand to keep their tools functioning optimally. A proactive approach to sourcing replacements can save time and enhance the overall experience of using equipment.

Tools Needed for Repairs

When undertaking maintenance or fixing equipment, having the right tools at hand is essential for ensuring a smooth and efficient process. The appropriate instruments not only simplify the tasks but also enhance safety and precision in your work.

Essential Hand Tools: A variety of hand tools such as wrenches, screwdrivers, and pliers are fundamental for tackling common issues. These instruments provide the leverage and grip needed to manipulate components effectively.

Power Tools: Depending on the extent of repairs, electric drills and impact drivers may be necessary. These tools allow for quicker and more efficient disassembly and assembly, especially when dealing with tightly secured parts.

Safety Equipment: Don’t overlook the importance of personal protective gear. Safety goggles, gloves, and masks are vital for protecting yourself from debris and hazardous materials during repairs.

Measuring Instruments: Accurate measurements are crucial in ensuring proper fit and alignment. A tape measure, calipers, and levels can help guarantee that all adjustments are precise.

Equipping yourself with these tools will not only facilitate effective repairs but also instill confidence in your ability to maintain and restore equipment to optimal performance.

Step-by-Step Repair Guide

This section provides a comprehensive approach to fixing issues with your equipment. By following each step carefully, you can ensure that your tool is restored to optimal working condition. Understanding the components and their functions will simplify the repair process.

Assessing the Problem

Begin by identifying the specific malfunction. Is it failing to start, making unusual noises, or showing signs of wear? Take notes on your observations, as this will help you in troubleshooting and acquiring necessary replacements.

Disassembly and Inspection

Once the issue is pinpointed, proceed to carefully disassemble the tool. Use the appropriate tools to avoid damaging any parts. Inspect each component for signs of damage or wear. Document your findings to assist in the reassembly process.

Identifying Worn-Out Parts

Recognizing components that have reached the end of their useful life is crucial for maintaining optimal performance and safety. Regular inspections can help in pinpointing issues before they escalate, ensuring that your equipment remains reliable.

Signs of wear can include unusual noises, decreased efficiency, or physical damage. Cracks, fraying, and discoloration are visual indicators that should not be overlooked. If a part begins to show these symptoms, it’s often best to replace it promptly to avoid further complications.

Moreover, scheduled maintenance plays a key role in prolonging the lifespan of your equipment. Keeping a close eye on critical components will help in making informed decisions about replacements, ultimately enhancing performance and reliability.

Safety Tips for DIY Repairs

Engaging in home repairs can be rewarding, but safety should always be a priority. Following essential precautions ensures a smooth and secure experience, preventing accidents and injuries.

- Always wear appropriate personal protective equipment, such as gloves and safety goggles.

- Ensure your workspace is well-lit and organized to avoid unnecessary hazards.

- Disconnect power sources before starting any electrical work to prevent shocks.

- Use tools properly and keep them maintained to avoid malfunctions.

By adhering to these guidelines, you can tackle your projects with confidence and minimize risks effectively.

Warranty and Support Options

When investing in power tools, understanding the available warranty and support options is crucial for ensuring a satisfactory ownership experience. Manufacturers often provide various guarantees that protect against defects and malfunctions, allowing users to seek assistance when needed. This section outlines the typical support avenues and warranty terms that enhance customer satisfaction.

Types of Warranty Coverage

Most brands offer different levels of warranty coverage, which can include limited warranties, full warranties, or extended service plans. It’s essential to familiarize yourself with the specific terms of each type to make informed decisions regarding repairs or replacements.

| Warranty Type | Coverage Duration | Typical Features |

|---|---|---|

| Limited Warranty | 1-3 years | Defects in materials and workmanship |

| Full Warranty | Varies | Comprehensive coverage including parts and labor |

| Extended Service Plan | Additional 1-3 years | Includes regular maintenance and accidental damage |

Customer Support Resources

In addition to warranty coverage, effective customer support is essential. Users can access assistance through various channels, such as online resources, helplines, and authorized service centers. Utilizing these options can significantly enhance the experience and resolve any issues efficiently.

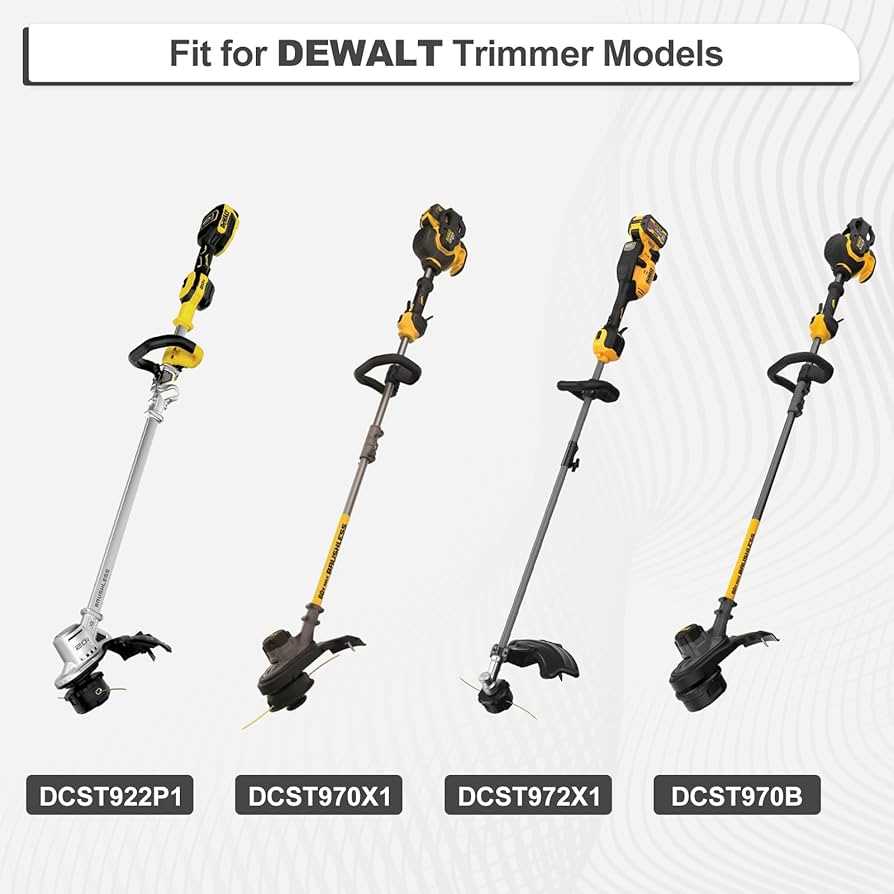

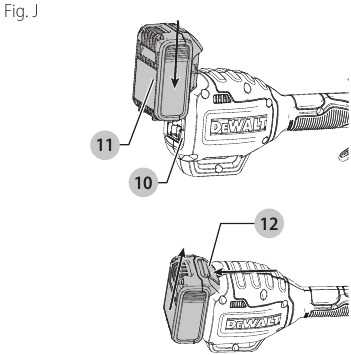

Upgrades and Accessories for the DCST970

Enhancing your tool’s performance and versatility can significantly improve your experience and efficiency in various tasks. A range of upgrades and additional components are available to elevate functionality, making your equipment more adaptable to different projects and conditions.

Consider investing in advanced batteries for extended runtime, enabling longer working periods without interruptions. Upgraded cutting blades can also enhance precision and durability, ensuring cleaner cuts through various materials. Ergonomic handles and grips provide added comfort during prolonged use, reducing fatigue and improving control.

Additionally, attachments like debris guards and brushless motors can optimize your tool’s effectiveness in specific environments. Accessories such as replacement spools and protective cases ensure your equipment remains in top condition and is easy to transport. Exploring these enhancements will help you achieve the ultimate performance from your equipment.