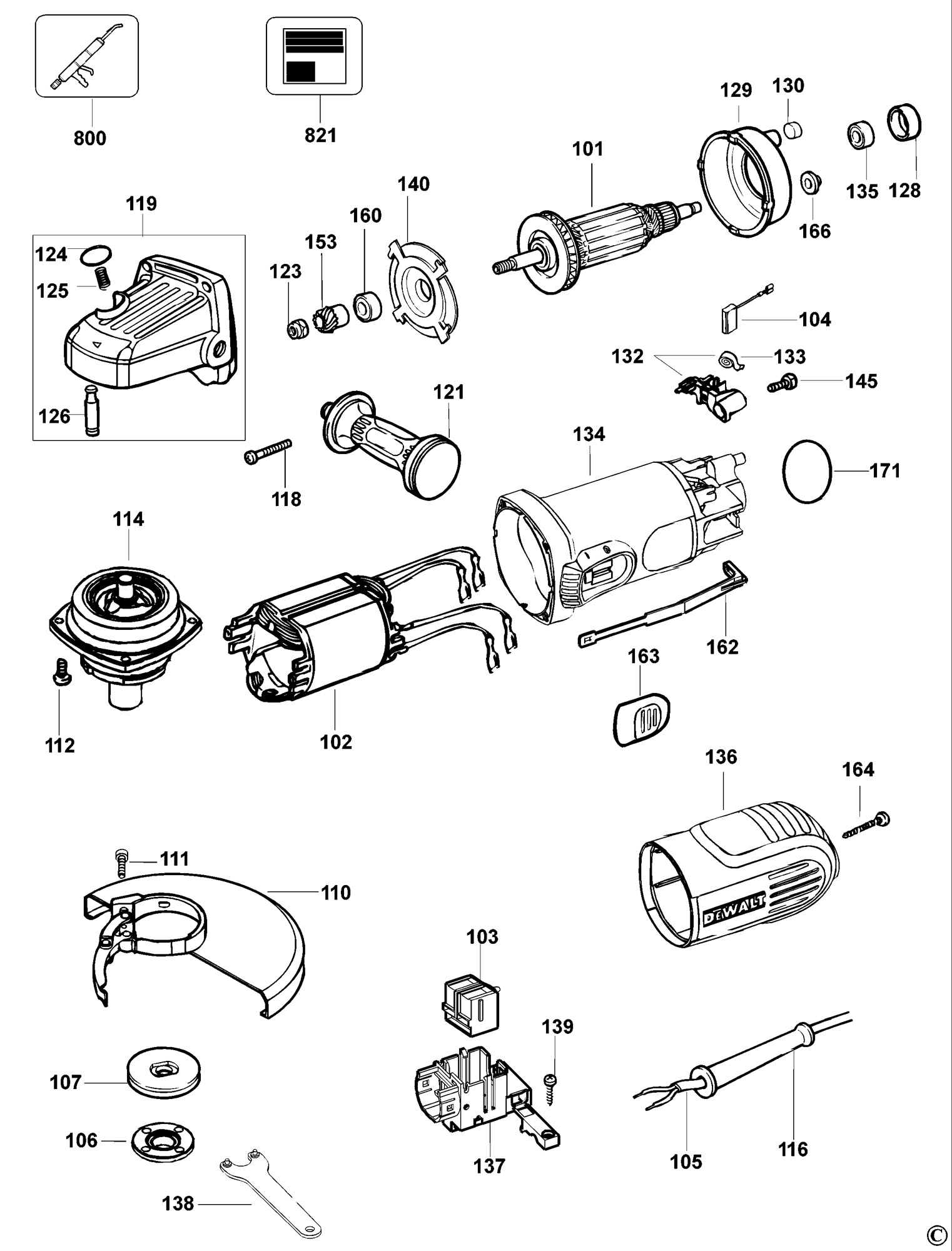

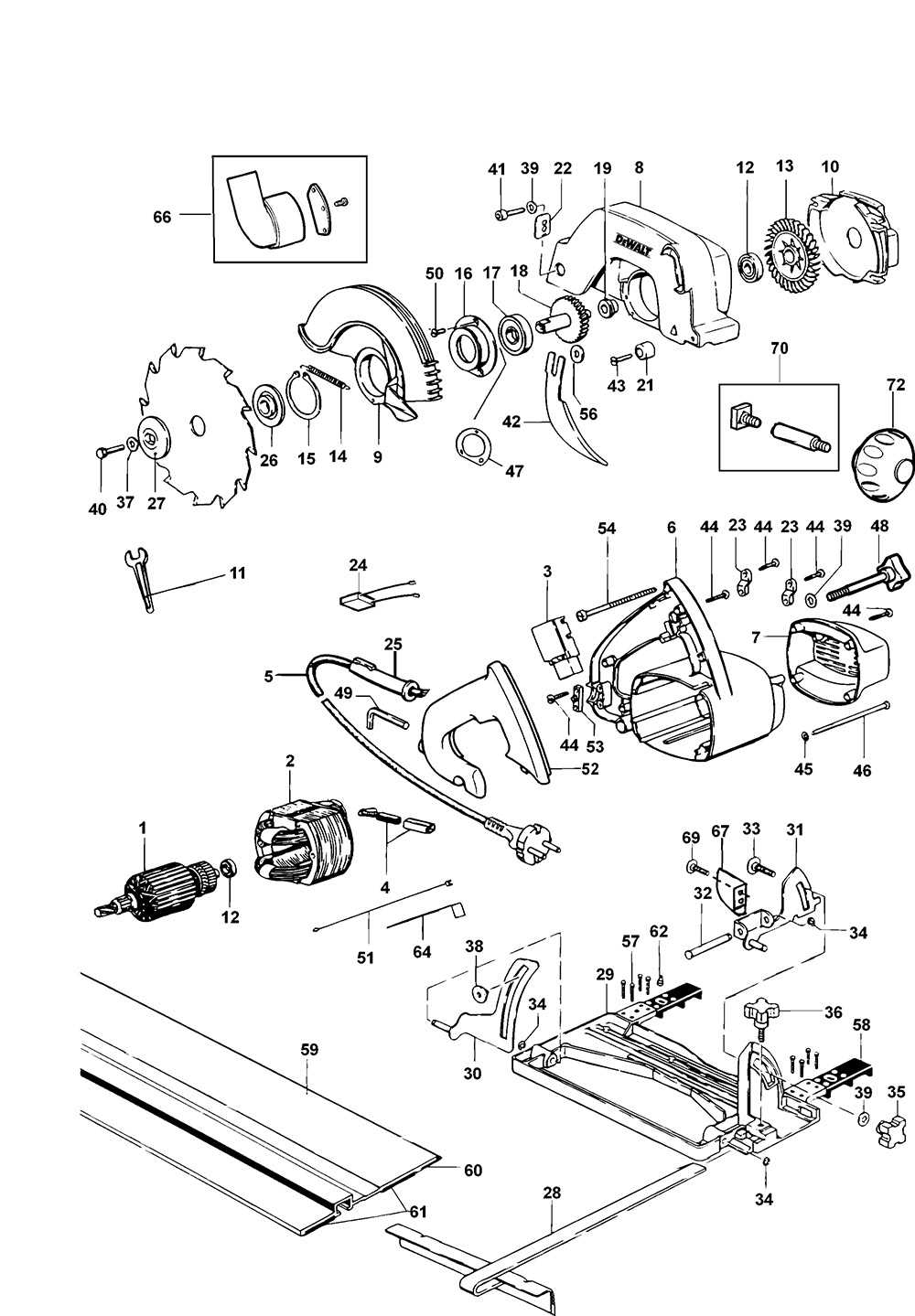

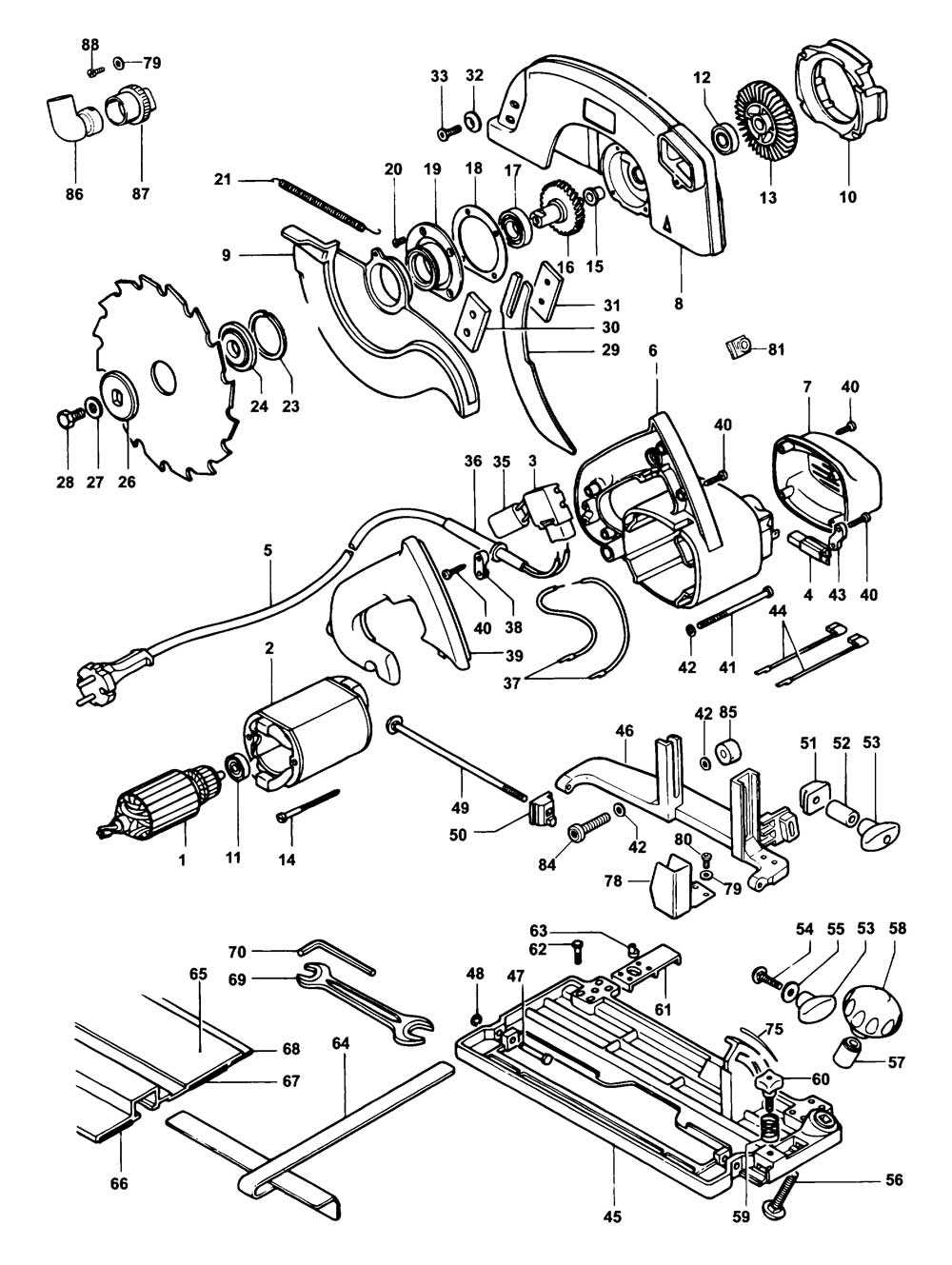

Dewalt DW321 Parts Diagram Overview

In the realm of power tools, comprehending the structure and assembly of equipment is essential for both maintenance and efficient operation. A well-illustrated representation can significantly aid users in identifying the various elements that contribute to the functionality of their devices. Such layouts not only enhance the user experience but also facilitate troubleshooting and repairs.

These visual guides serve as a roadmap, providing clarity on how different components interact and function together. By familiarizing oneself with these intricate designs, users can better appreciate the engineering behind their tools. Moreover, this knowledge empowers them to perform essential upkeep, ensuring longevity and reliability.

Whether for a novice or an experienced craftsman, the value of having a detailed reference cannot be overstated. It demystifies the inner workings of the machinery, allowing for informed decisions regarding repairs and replacements. As a result, this understanding fosters a deeper connection with the tools, enhancing both confidence and capability in their use.

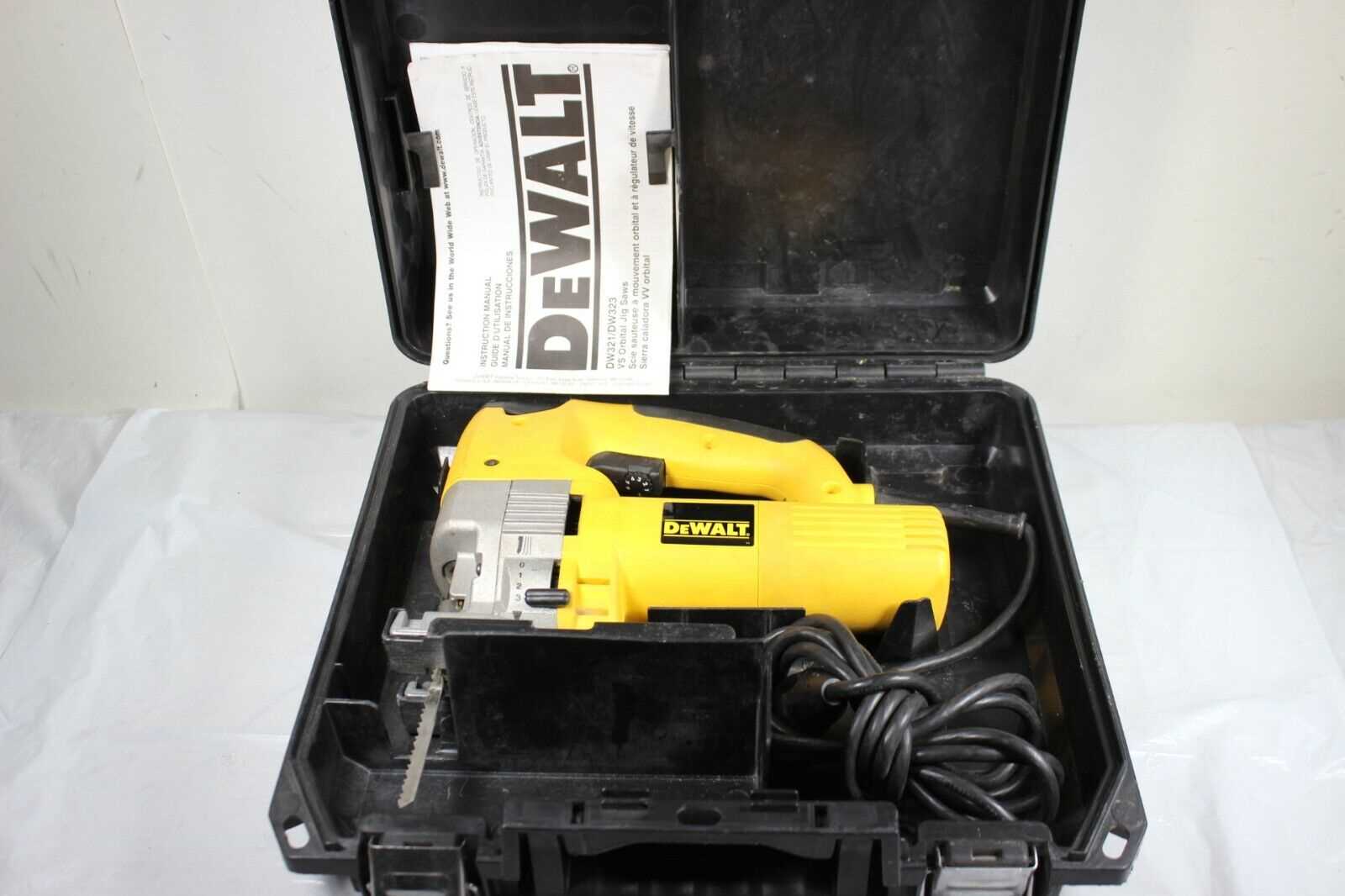

Dewalt DW321 Overview

This section provides a comprehensive look at a powerful tool designed for efficiency and precision. It combines robust engineering with user-friendly features, making it a valuable asset for both professionals and DIY enthusiasts. The tool stands out for its versatility and reliability, ensuring it can handle various tasks with ease.

Key Features

Among its many attributes, this model boasts a lightweight design that facilitates easy maneuverability. Its advanced motor technology delivers consistent performance, allowing for smooth operation in diverse applications. The inclusion of ergonomic handles enhances user comfort, reducing fatigue during extended use.

Applications

This equipment is suitable for a wide range of tasks, from woodworking to intricate craft projects. Whether cutting through tough materials or making precise adjustments, it excels in delivering high-quality results. Its adaptability makes it an essential tool for anyone looking to achieve professional-grade work.

Understanding the Parts Diagram

The visual representation of components in a tool is essential for effective maintenance and repair. By examining this schematic, users can identify each element and its function within the device. This knowledge fosters a deeper appreciation for the intricacies of the equipment and enhances troubleshooting skills.

Such illustrations typically label each section, allowing for quick reference during disassembly or reassembly. Familiarity with the arrangement of various elements aids in recognizing potential issues, ensuring efficient problem-solving. Additionally, understanding the layout can streamline the ordering of replacements when necessary.

For anyone working with machinery, grasping the details presented in these visuals is crucial. It not only facilitates repairs but also empowers users to perform regular upkeep, thereby prolonging the life of the tool and optimizing its performance.

Importance of Genuine Parts

Utilizing authentic components in machinery and tools is crucial for maintaining optimal performance and longevity. When replacing elements, the quality and compatibility of the replacements can significantly impact the functionality and reliability of the equipment. Choosing original items ensures that the integrity of the system is preserved, preventing potential issues that could arise from using inferior alternatives.

Benefits of Using Authentic Components

- Enhanced Durability: Genuine items are engineered to meet specific standards, resulting in improved lifespan and resilience.

- Optimal Performance: Original components are designed to work seamlessly with the equipment, ensuring peak efficiency.

- Safety Assurance: Using authentic replacements minimizes the risk of malfunctions that could lead to accidents or injuries.

Risks of Using Imitation Items

- Compatibility Issues: Non-genuine replacements may not fit correctly, causing operational problems.

- Increased Wear: Inferior materials can lead to faster degradation of the entire system.

- Voided Warranty: Many manufacturers’ warranties require the use of original components; failure to comply can result in loss of coverage.

Common Issues with the DW321

Power tools, while incredibly useful, can occasionally encounter various challenges that impact their performance and reliability. Understanding these common problems is essential for maintaining efficiency and prolonging the lifespan of the equipment. Below are some frequently observed issues that users may face with this particular model.

Overheating is a prevalent concern. This can result from prolonged use without adequate breaks or from a buildup of debris in the motor area. Regular cleaning and allowing the tool to cool down can help mitigate this issue.

Another common issue is inconsistent power delivery. Users might notice fluctuations in performance, which can stem from faulty wiring or a malfunctioning switch. Checking the electrical connections and ensuring the tool is properly maintained can alleviate this problem.

Vibrations during operation can also be problematic. Excessive shaking may indicate worn bearings or loose components. Ensuring all parts are secure and in good condition is vital to maintain stability and control while using the tool.

Finally, blade dullness can significantly affect cutting efficiency. Regularly inspecting and replacing blades when necessary ensures optimal performance and precision. By addressing these common issues proactively, users can enhance the longevity and functionality of their equipment.

How to Read a Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and repair. This type of illustration provides a detailed overview of the individual elements of a tool, showcasing their arrangement and function within the assembly. By interpreting this guide, users can identify specific pieces needed for replacement or repair, facilitating a more straightforward approach to troubleshooting.

Begin by familiarizing yourself with the overall layout. Look for a legend or key that correlates numbers or letters to specific components. Each item is usually labeled, allowing for easy reference. Take note of the connections between parts; this can reveal how they interact and affect the overall operation.

Next, focus on the sequence of assembly. Many illustrations show how parts fit together, which can be crucial for disassembly and reassembly. Understanding this sequence can help prevent errors and ensure that all components are securely in place.

Lastly, pay attention to any additional notes or specifications that might accompany the visual guide. These often include maintenance tips or warnings that can enhance your understanding and ensure the longevity of the equipment. With practice, interpreting these visuals will become a valuable skill in managing your tools effectively.

Where to Find Replacement Parts

When equipment requires specific components for maintenance or repair, locating the right sources is crucial for ensuring optimal performance. Various options exist to help you acquire the necessary items without hassle. Understanding where to look can save time and ensure you get quality replacements.

Authorized Retailers

Official dealers provide an extensive selection of genuine components. Shopping through these outlets guarantees compatibility and reliability. They often have knowledgeable staff who can assist in identifying the correct items for your needs.

Online Marketplaces

Many online platforms offer a vast range of components for various tools. Searching through these websites can yield both new and refurbished options at competitive prices. Make sure to read reviews and check seller ratings to ensure quality before making a purchase.

Comparing DW321 with Similar Models

When evaluating power tools in the same category, it’s crucial to identify how various models stack up against one another. Understanding the differences in performance, features, and user experience can significantly influence purchasing decisions. This section highlights key comparisons with similar tools, providing insights into their unique attributes and functionalities.

Here are some important factors to consider when comparing these models:

- Power and Performance: Examine the motor specifications and overall power output. This affects the efficiency of the tool in handling various tasks.

- Weight and Ergonomics: Assess how the weight distribution and design contribute to user comfort, especially during prolonged use.

- Speed Settings: Consider the range of speed options available, which can enhance versatility for different applications.

- Durability: Look into the materials used in construction and the tool’s overall build quality to gauge long-term reliability.

- Accessories and Compatibility: Check what additional attachments are available and how they enhance the tool’s functionality.

In addition to these factors, user reviews and expert opinions can provide valuable insights into the real-world performance of these tools. By taking a comprehensive approach to comparing models, consumers can make informed choices that best meet their needs.

Tools Needed for Repairs

When undertaking maintenance or fixing machinery, having the right equipment at your disposal is crucial for ensuring efficiency and safety. A well-equipped toolkit not only simplifies the process but also enhances the quality of the repairs. Understanding the essential tools can make a significant difference in achieving successful outcomes.

Essential Hand Tools

Basic hand tools are fundamental for any repair task. Items such as screwdrivers, wrenches, and pliers are indispensable for loosening or tightening components. Additionally, a reliable set of sockets can provide versatility for various fasteners. Ensuring these tools are of good quality will contribute to the durability and effectiveness of your repairs.

Power Tools and Accessories

Power tools can greatly expedite the repair process. Drills, saws, and sanders allow for more complex tasks to be completed with precision. When using these tools, having the appropriate bits and blades is essential for optimal performance. Safety gear, including goggles and gloves, should not be overlooked, as they protect against potential hazards during operation.

Step-by-Step Repair Guide

This guide provides a comprehensive approach to troubleshooting and fixing common issues associated with your tool. Following these structured steps can help ensure effective repairs and maintain optimal performance.

Tools and Materials Needed

Before starting the repair process, gather the necessary tools and materials. Having everything at hand will streamline the procedure and prevent interruptions.

| Tool/Material | Purpose |

|---|---|

| Screwdriver Set | To remove and install screws |

| Replacement Parts | To replace any damaged components |

| Wrench | To tighten or loosen bolts |

| Cleaning Cloth | For maintenance and cleaning |

Repair Steps

Follow these systematic steps to ensure a successful repair:

- Ensure the tool is unplugged and cool to the touch.

- Examine the exterior for visible signs of damage or wear.

- Disassemble the unit carefully, keeping track of all screws and components.

- Inspect internal parts for defects and replace any that are damaged.

- Reassemble the tool in the reverse order of disassembly.

- Test the tool to confirm that the repair was successful.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your tools requires regular upkeep and attention to detail. Implementing effective maintenance practices can prevent wear and tear, enhancing both performance and reliability. A proactive approach not only safeguards your investment but also optimizes efficiency during use.

Start by regularly cleaning the equipment after each use. Remove any debris, dust, or residues that could interfere with operation. Utilize appropriate cleaning solutions and tools to maintain the surfaces without causing damage.

Lubrication is essential for moving parts. Apply suitable lubricants to joints and bearings to minimize friction, which can lead to premature wear. Follow the manufacturer’s recommendations for the best types of lubricants to use.

Inspect components periodically for signs of wear or damage. Pay attention to any irregularities in performance and address issues promptly to avoid further complications. Replace worn parts as needed to maintain optimal functioning.

Store your tools in a clean, dry environment, protected from moisture and extreme temperatures. Proper storage prevents rust and corrosion, ensuring that your equipment remains in peak condition when needed.

Lastly, adhere to any recommended service intervals and guidelines provided in the user manual. Regular professional servicing can catch potential problems early and extend the lifespan of your equipment significantly.

Customer Reviews and Experiences

This section aims to provide insights into user feedback and testimonials regarding a popular power tool model. Customers often share their hands-on experiences, offering valuable information about performance, durability, and overall satisfaction. This collective feedback can guide potential buyers in making informed decisions.

Positive Feedback

- Users frequently commend the tool’s reliability and ease of use.

- Many appreciate the robust construction that withstands demanding tasks.

- Several reviewers highlight the effective customer support provided by the manufacturer.

Areas for Improvement

- Some customers mention the need for clearer assembly instructions.

- A few users suggest enhancements in weight distribution for better handling.

- Several reviews note that replacement components could be more accessible.

Overall, user experiences reflect a blend of satisfaction and constructive criticism, contributing to a well-rounded understanding of this tool’s performance in real-world applications.

Frequently Asked Questions

This section addresses common inquiries related to tool components and their maintenance. Here, you’ll find essential information to help you understand various aspects of tool functionality and part replacements.

Common Inquiries

- What are the signs that my tool needs repairs?

- How can I identify the right components for my model?

- Where can I purchase quality replacement parts?

- Is there a warranty on the replacement items?

Maintenance Tips

- Regularly clean your tool to prevent dirt buildup.

- Check for any signs of wear or damage.

- Follow the manufacturer’s guidelines for maintenance schedules.

- Store your tool in a dry, safe place to avoid damage.

Resources for Further Learning

Enhancing your knowledge and skills in the field of tools and equipment maintenance is crucial for both professionals and enthusiasts. A variety of resources are available to help deepen your understanding and proficiency. Below are some valuable options to explore.

- Online Tutorials: Websites offer step-by-step guides and videos that cover a wide range of topics.

- Technical Manuals: Accessing official documentation can provide insights into specific models and their components.

- Forums and Community Groups: Engaging with like-minded individuals can facilitate knowledge exchange and troubleshooting tips.

- Workshops and Classes: Local institutions often conduct hands-on sessions to improve practical skills.

Utilizing these resources can significantly enhance your understanding and ability to work with various tools effectively.