Dewalt DW716 Parts Diagram for Easy Repairs

For enthusiasts and professionals alike, mastering the intricacies of power tools is essential for achieving optimal performance and longevity. One critical aspect of this mastery lies in comprehending the arrangement and functionality of various elements within a miter saw. Familiarity with these components not only enhances your ability to troubleshoot issues but also empowers you to perform maintenance and repairs with confidence.

In this guide, we will delve into the essential framework that supports the operation of your cutting machine. By examining the specific elements and their interrelationships, you will gain valuable insights into how to effectively utilize your equipment. Understanding these intricate details can significantly elevate your woodworking or construction projects.

Additionally, a clear visualization of the individual parts will aid in recognizing wear and tear, ensuring that your tool remains in peak condition. As we explore this essential reference, you will be better equipped to maintain your equipment and tackle various tasks with precision and ease.

Dewalt DW716 Overview

This section provides a comprehensive look at a popular power tool designed for precision and efficiency. Engineered for both professional and DIY enthusiasts, it combines advanced features with user-friendly operation, making it an essential addition to any workshop.

The model excels in delivering clean and accurate cuts, ideal for various applications such as framing, molding, and crosscutting. Its robust construction ensures durability, while the thoughtful design enhances ease of use, catering to users of all skill levels.

Key specifications include a powerful motor that facilitates smooth operation even under heavy loads. Additionally, it offers adjustable angles and settings, allowing for versatile applications and customization based on specific project requirements. Safety features are also integrated, providing peace of mind during use.

In summary, this tool stands out for its blend of functionality, reliability, and performance, making it a valuable resource for anyone looking to achieve professional-quality results in their projects.

Importance of Parts Diagrams

Understanding the components of a machine is essential for efficient maintenance and repair. Visual representations of the various elements not only aid in identifying specific sections but also enhance the overall comprehension of the equipment’s structure.

Here are some key benefits of using visual guides:

- Enhanced Clarity: A visual aid makes it easier to pinpoint where each component fits, reducing confusion during disassembly or reassembly.

- Efficient Troubleshooting: Quick identification of faulty parts allows for faster diagnosis and resolution of issues, minimizing downtime.

- Improved Communication: Clear illustrations facilitate discussions among technicians, ensuring everyone is on the same page regarding repairs and maintenance.

- Informed Decision-Making: Users can assess the condition of individual components, helping them decide whether to repair or replace items.

Incorporating visual references into maintenance routines significantly contributes to the longevity and functionality of equipment.

Common Issues with the DW716

Power tools, while essential for various projects, can occasionally experience difficulties that hinder performance. Understanding these common challenges can help users maintain efficiency and extend the lifespan of their equipment. Below are some frequently encountered problems and suggested solutions for resolving them.

| Issue | Description | Solution |

|---|---|---|

| Motor Not Starting | The motor may fail to initiate when the power switch is engaged. | Check the power supply, inspect the cord for damage, and test the switch for continuity. |

| Inaccurate Cuts | Tools may produce uneven or inaccurate cuts due to misalignment. | Adjust the cutting angle and ensure the blade is properly aligned and sharp. |

| Excessive Vibration | Noticeable shaking can indicate a problem with the blade or assembly. | Inspect the blade for damage and ensure all components are securely tightened. |

| Overheating | Tools may become excessively hot during operation. | Allow the motor to cool, check for obstructions, and ensure proper ventilation. |

| Dust Collection Issues | Ineffective dust management can lead to a messy workspace. | Inspect and clean the dust port, and ensure the collection bag is not full or clogged. |

Key Components Explained

This section offers an in-depth look at the essential elements that contribute to the functionality and performance of a particular tool. Understanding these components is vital for effective operation and maintenance.

Motor Assembly

The motor assembly is the powerhouse of the tool, driving its operations with precision. A robust motor not only enhances performance but also ensures longevity, making it a critical aspect to consider during any evaluation.

Cutting Mechanism

The cutting mechanism plays a pivotal role in achieving accurate results. Its design and material selection influence both the quality of the cut and the overall efficiency of the tool. Regular maintenance of this part can lead to optimal performance and durability.

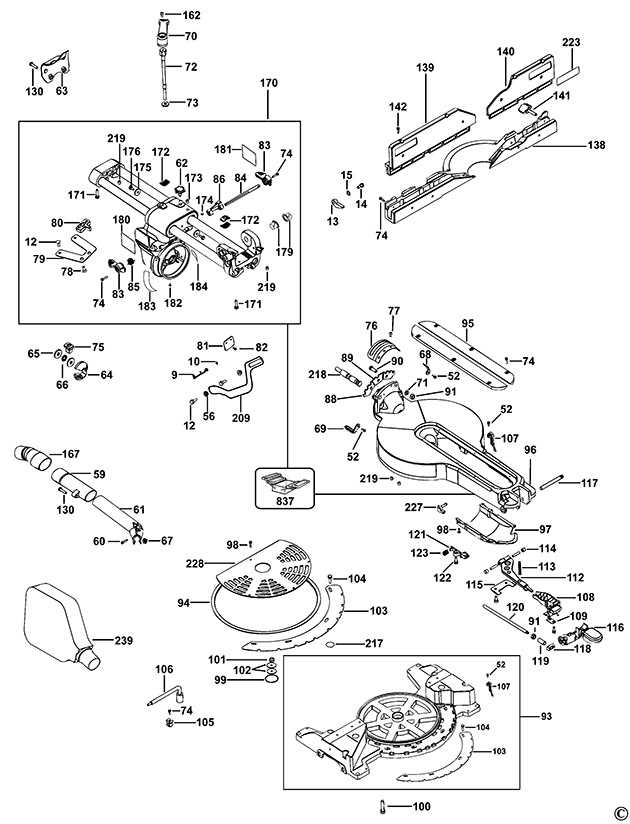

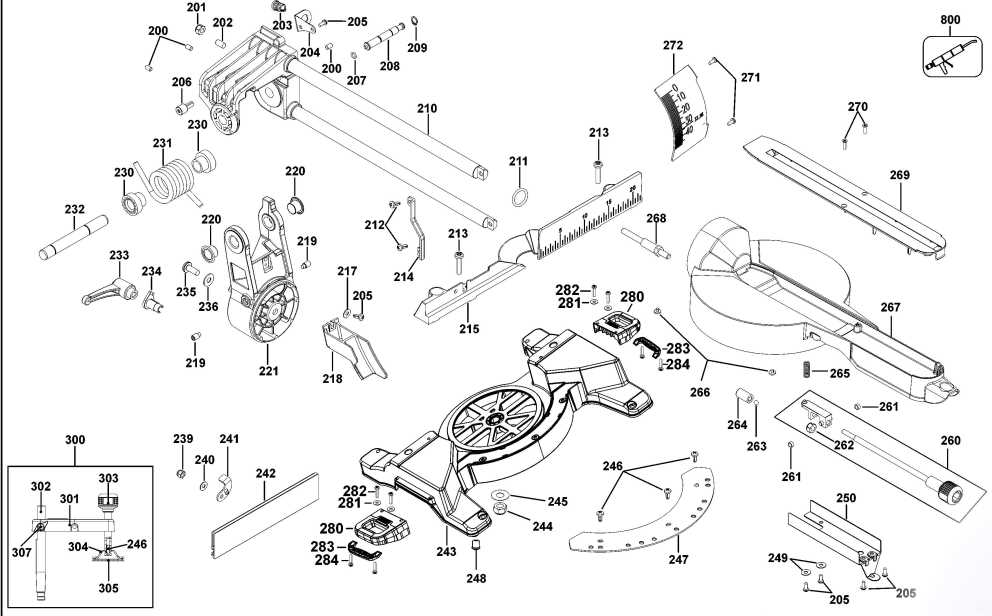

How to Read the Diagram

Understanding a schematic representation of tools is essential for effective maintenance and repair. By familiarizing yourself with this visual guide, you can easily identify components and their relationships, which ultimately enhances your ability to troubleshoot issues.

Identifying Key Elements

Begin by locating the legend, which explains the symbols used throughout the representation. Each part is typically labeled with a reference number that corresponds to the list of components, making it easier to find replacements or understand assembly.

Understanding Connections

Pay attention to the lines connecting various elements, as they illustrate how parts interact and function together. Recognizing these connections is crucial for diagnosing problems and ensuring proper assembly during repairs.

Finding Replacement Parts

When it comes to maintaining your tools, sourcing the right components can be crucial for ensuring optimal performance. Knowing where to look and how to identify suitable replacements can save both time and money. This section will guide you through the process of locating high-quality substitutes for your equipment.

Online Retailers: A variety of online platforms specialize in selling tool components. These websites often provide detailed descriptions and specifications, making it easier to find what you need. Be sure to check user reviews to ensure reliability.

Manufacturer’s Website: Visiting the official site of the manufacturer can offer direct access to the original components. This ensures compatibility and may provide additional resources, such as installation guides or customer support.

Local Supply Stores: Many local hardware stores stock various items for tool repair. Visiting in person allows you to speak with knowledgeable staff who can assist in finding the right piece.

Forums and Community Groups: Engaging with online communities focused on tool maintenance can yield valuable insights. Members often share experiences and recommendations for sourcing replacement items.

In summary, whether you prefer online shopping or local resources, numerous avenues exist for acquiring essential components. Proper research and connections can lead you to the best options available.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended lifespan of any power tool. Regular maintenance not only enhances performance but also prevents potential issues that could arise from neglect. By following a few simple guidelines, users can keep their equipment running smoothly and efficiently for years to come.

Start with routine cleaning to remove dust and debris, as these can accumulate and interfere with functionality. Utilize a soft brush or compressed air to clear away particles from critical components. This practice will help maintain optimal performance and reduce wear on moving parts.

Periodic lubrication of necessary components is crucial for minimizing friction and preventing rust. Use manufacturer-recommended lubricants and apply them sparingly to avoid attracting more dirt. Checking and replacing worn-out parts in a timely manner can significantly extend the tool’s operational life.

Lastly, storing the tool in a dry, cool environment will help protect it from environmental factors that may cause damage. Consider using a protective cover to shield it from dust and moisture. By following these maintenance tips, users can ensure their equipment remains reliable and effective for many projects ahead.

Repairing the DW716 Yourself

When tools start to show signs of wear or malfunction, many enthusiasts consider tackling the repairs themselves. This not only saves money but also provides a valuable learning experience. With the right knowledge and approach, restoring your equipment can be a rewarding endeavor.

Before beginning any repair, it’s essential to gather the necessary tools and materials. Here’s a list of what you might need:

- Screwdrivers (flathead and Phillips)

- Wrenches and pliers

- Replacement parts

- Cleaning supplies

- Lubricants

Follow these steps to ensure a smooth repair process:

- Assess the Problem: Identify the issue by inspecting the tool carefully. Look for visible signs of damage or wear.

- Consult Resources: Utilize manuals, online forums, and videos for guidance specific to your equipment.

- Disassemble with Care: Take apart the unit methodically, keeping track of each component and its placement.

- Replace or Repair Parts: Depending on your assessment, either replace damaged components or make necessary adjustments.

- Reassemble: Carefully put the tool back together, ensuring that all parts are aligned correctly.

- Test Thoroughly: Once reassembled, perform a thorough test to ensure everything functions properly before returning it to regular use.

By taking the initiative to repair your equipment, you not only extend its lifespan but also enhance your skills and confidence in handling tools.

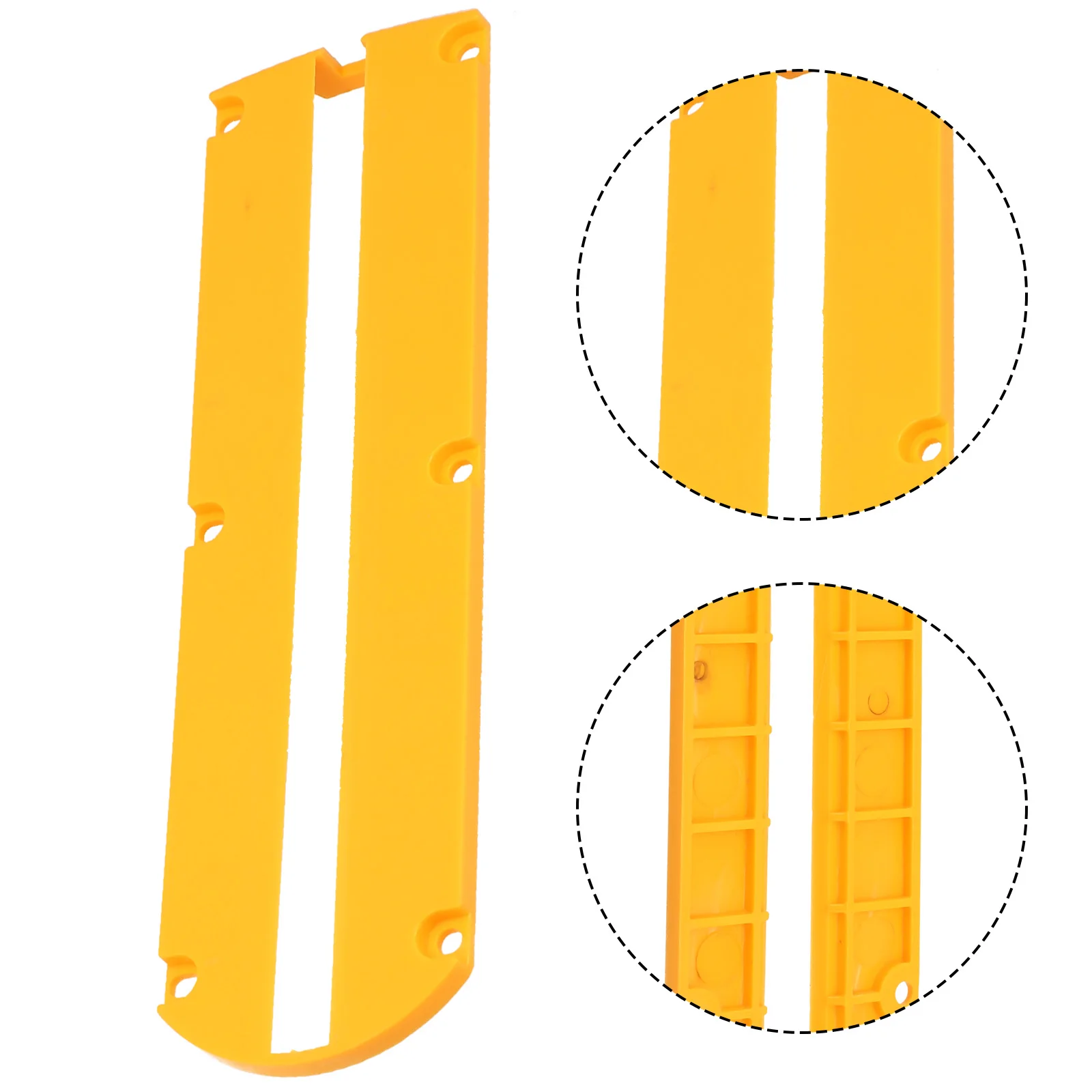

Upgrading Parts for Performance

Enhancing the functionality of your machinery can significantly boost its efficiency and longevity. By selecting higher-quality components, users can experience improved precision, smoother operation, and reduced downtime. This process involves identifying critical areas where upgrades can make a tangible difference, leading to optimal performance in various tasks.

Identifying Key Components

When considering enhancements, it’s essential to focus on specific elements that directly impact the overall operation. Blades, for instance, play a vital role in achieving clean cuts and reducing strain on the motor. Upgrading to specialized cutting tools can yield better results and extend the life of your equipment.

Material and Design Considerations

Beyond the basic parts, the choice of materials and design can also influence performance. Durable alloys and advanced engineering designs contribute to greater resilience against wear and tear. Investing in these superior components not only elevates functionality but can also provide enhanced safety features, making your equipment more reliable during use.

Customer Reviews and Feedback

Understanding user experiences and insights can significantly influence potential buyers’ decisions. Reviews often provide a wealth of information about product performance, durability, and overall satisfaction. This section aims to highlight common themes found in customer feedback, offering a clearer picture of what to expect from the tool.

Performance: Many users praise the efficiency and power of the device, noting that it excels in various tasks. Users frequently mention its ability to handle demanding projects with ease, making it a reliable choice for both professionals and hobbyists.

Durability: Several reviewers highlight the robust construction and long-lasting nature of the equipment. Customers often express satisfaction with its ability to withstand heavy usage over time, reinforcing its value as a long-term investment.

User Experience: Feedback commonly reflects on the ease of use and intuitive design. Many individuals appreciate the straightforward setup process and user-friendly controls, which contribute to a smooth working experience.

Overall Satisfaction: The consensus among users tends to lean toward a high level of satisfaction, with many recommending the tool to others. Positive remarks regarding its features and overall quality frequently emerge, indicating a strong reputation within the community.

Resources for Further Assistance

When seeking help with your tools and machinery, it’s essential to access reliable resources that provide in-depth information and support. Whether you’re looking for user manuals, troubleshooting guides, or community forums, various options are available to ensure you can effectively maintain and repair your equipment.

Official Support Channels

Utilizing official support channels is a great first step. Manufacturers typically offer comprehensive resources, including online manuals, FAQs, and customer service contact options. These platforms often provide detailed instructions and specifications that can help you understand your equipment better.

Online Communities and Forums

Engaging with online communities can be incredibly beneficial. Many enthusiasts and professionals share their experiences and solutions in forums dedicated to tools and equipment. Participating in these discussions allows you to gain insights from others who have faced similar challenges and can offer practical advice.

In summary, leveraging both official resources and community knowledge will enhance your understanding and ability to troubleshoot effectively.