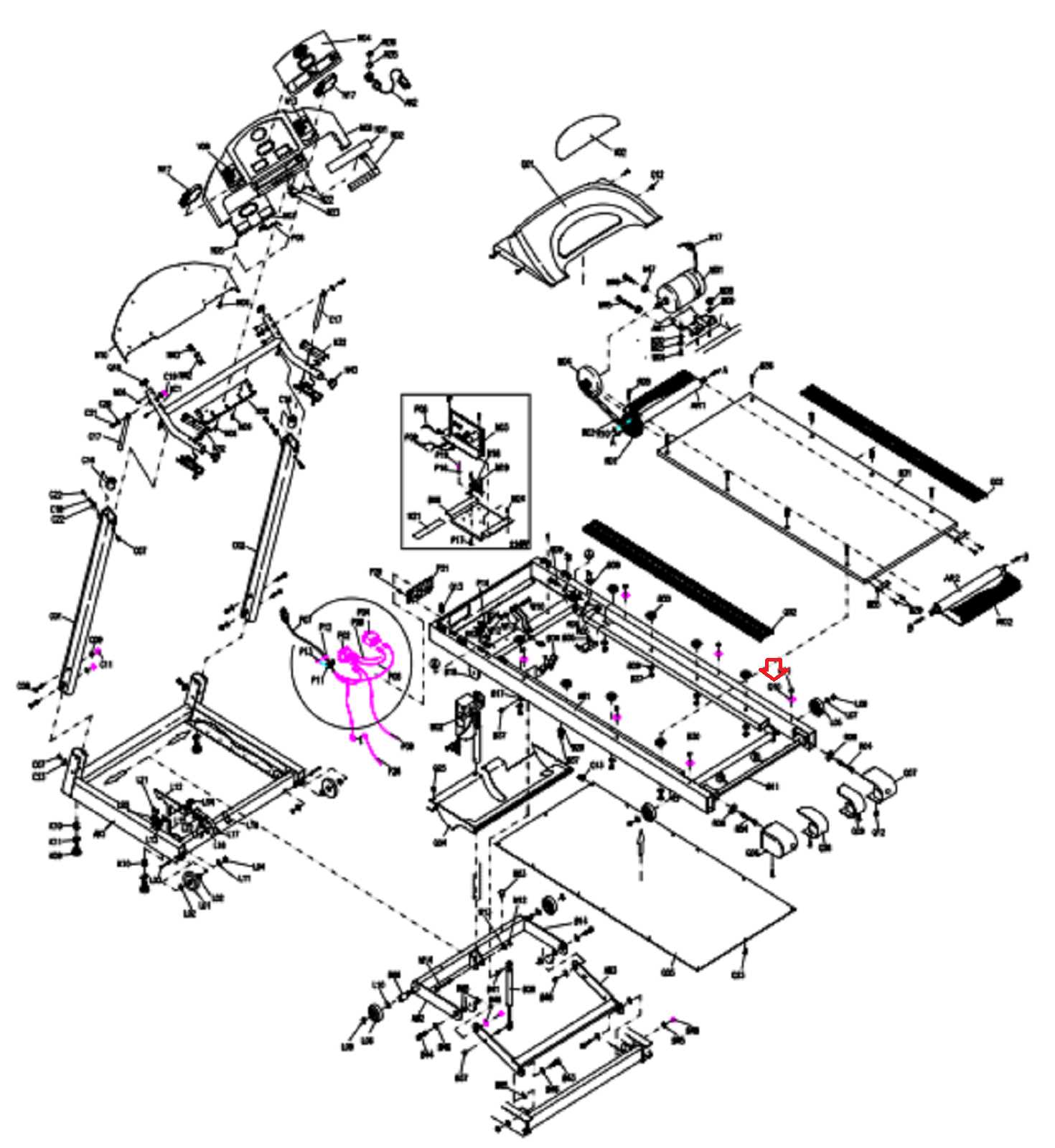

Dewalt DWE7480 Parts Diagram Overview

When working with power equipment, having a clear understanding of each component is crucial for ensuring optimal functionality and longevity. A well-structured overview of various sections not only facilitates repairs but also empowers users to maximize the efficiency of their tools. In this discussion, we will explore how to effectively navigate the intricacies of essential elements.

Recognizing the significance of each part allows for better maintenance practices and informed decision-making during upgrades or replacements. Familiarity with these components can lead to improved performance and enhanced safety, ultimately contributing to a more productive work environment. Whether you’re a seasoned professional or a DIY enthusiast, understanding the layout of your tools is key.

Additionally, visual representations of these assemblies serve as invaluable resources. They provide insight into the arrangement and function of each segment, making troubleshooting and assembly processes more intuitive. With this knowledge, users can tackle challenges with confidence, ensuring their equipment operates smoothly and efficiently.

Dewalt DWE7480 Overview

This section provides an in-depth look at a highly regarded portable cutting tool, designed for versatility and efficiency. Ideal for both professional tradespeople and DIY enthusiasts, it combines robust features with user-friendly operation, making it a top choice in its category.

| Feature | Description |

|---|---|

| Power | Equipped with a high-performance motor for optimal cutting strength. |

| Portability | Lightweight design for easy transport and setup on job sites. |

| Cutting Capacity | Generous cutting dimensions suitable for various materials. |

| Safety Features | Includes multiple safety enhancements to protect users during operation. |

Key Features of DWE7480

This portable saw offers a range of characteristics that enhance its usability and performance for both professionals and DIY enthusiasts. Its design prioritizes convenience while ensuring robust functionality, making it a reliable choice for various cutting tasks.

One notable aspect is its powerful motor, which delivers consistent performance across different materials, ensuring clean and precise cuts. The adjustable table allows for versatile setups, accommodating various workpieces with ease.

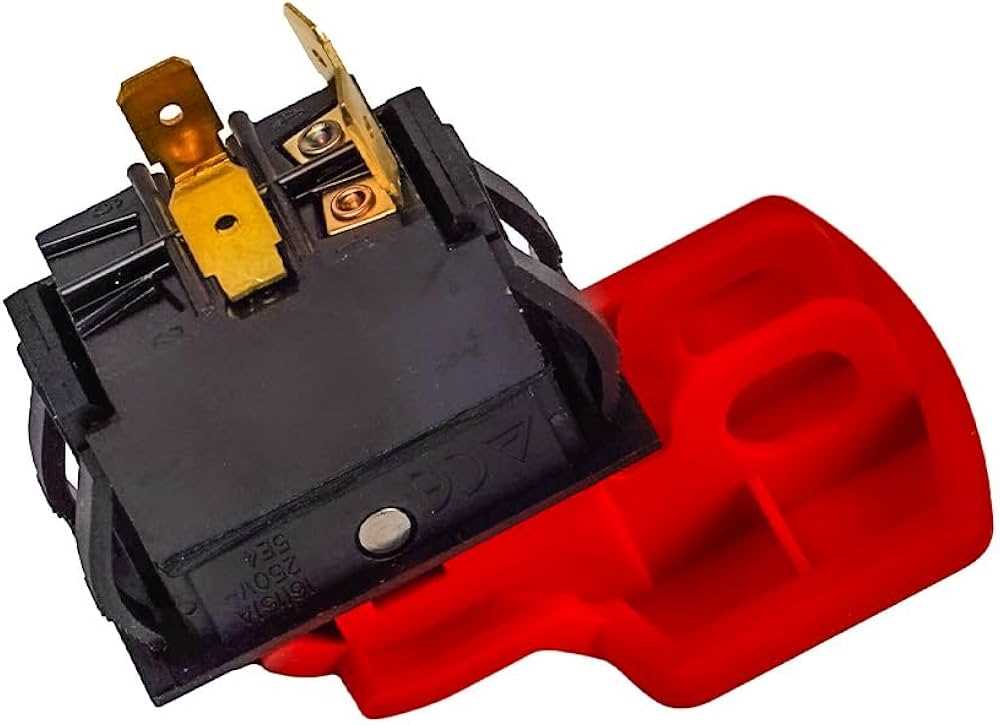

Moreover, the lightweight construction enhances mobility, enabling users to transport it effortlessly to different job sites. Safety features, including blade guards and emergency shut-off, add an extra layer of protection during operation.

Another advantage is the compatibility with a range of accessories, expanding its capabilities beyond standard cutting tasks. Users appreciate the easy assembly and user-friendly controls, contributing to a seamless experience.

Understanding Parts and Components

Comprehending the individual elements of a tool is essential for effective usage and maintenance. Each component plays a significant role in the overall functionality, contributing to both performance and durability. By exploring these elements, users can enhance their understanding and ensure longevity in their equipment.

Key Elements

Familiarity with the primary components enables users to troubleshoot issues and optimize their performance. Major sections often include the motor, base, and cutting mechanisms, each designed to work harmoniously. Recognizing how these elements interact is crucial for maximizing efficiency.

Maintenance Tips

Regular upkeep of these components can prevent wear and tear, extending the life of the tool. Simple practices such as cleaning, lubrication, and timely replacements can significantly enhance operational reliability. Staying informed about the intricacies of each part empowers users to take proactive measures in their maintenance routine.

Common Issues and Solutions

When operating power tools, users may encounter various challenges that can hinder performance. Understanding these common issues and their corresponding solutions can enhance the longevity and efficiency of your equipment.

Motor Overheating

Problem: Excessive heat can lead to decreased performance and potential damage. Solution: Ensure proper ventilation and avoid prolonged use without breaks. Regularly inspect the motor for dust buildup and clean as necessary.

Blade Misalignment

Problem: Misaligned blades can cause uneven cuts and increase wear. Solution: Periodically check and adjust the blade alignment according to the manufacturer’s guidelines, ensuring optimal performance.

Importance of Accurate Diagrams

Clear and precise representations play a crucial role in understanding complex machinery and tools. They serve as essential guides, allowing users to identify components and comprehend assembly processes effectively. When these illustrations are accurate, they minimize confusion and enhance efficiency, ensuring that users can perform repairs or maintenance with confidence.

Enhancing User Experience

Well-crafted visuals improve the overall experience by simplifying complex instructions. When users can easily interpret these resources, they are more likely to successfully navigate challenges and complete tasks without unnecessary frustration. This accessibility fosters a sense of empowerment and proficiency.

Reducing Errors and Increasing Safety

Accurate illustrations are vital for minimizing mistakes during assembly or repair work. Misinterpretations can lead to improper installations, potentially resulting in accidents or equipment failures. By providing a reliable reference, these visuals significantly enhance safety for users, ensuring that operations proceed smoothly.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your equipment requires regular attention and care. By following a few straightforward maintenance practices, you can significantly extend the lifespan of your tools, keeping them in optimal working condition for years to come.

Regular Cleaning

Keeping your tools clean is essential for their performance. After each use, wipe down surfaces to remove dust and debris. Pay special attention to moving parts, as build-up can lead to wear and tear. Utilize compressed air to blow out any hard-to-reach areas, ensuring that all components function smoothly.

Routine Inspections

Conducting regular inspections helps identify potential issues before they escalate. Check for signs of wear, such as frayed cords or loose screws. Make it a habit to examine all parts periodically, and replace any damaged components promptly. This proactive approach will not only enhance performance but also promote safety during operation.

Finding Replacement Parts Online

Locating suitable components for your tools can be a straightforward process if you know where to look. The internet offers various resources that can simplify your search, providing options for both original and aftermarket replacements.

Where to Start

- Manufacturer Websites: Official sites often have dedicated sections for replacement items.

- Retailers: Major online stores frequently stock a variety of components.

- Forums and Community Groups: These can provide recommendations and tips from other users.

Tips for Successful Searches

- Use specific keywords related to the item you need.

- Check multiple sources to compare prices and availability.

- Read reviews to ensure quality before making a purchase.

Comparing DWE7480 with Other Models

When selecting a table saw, it’s essential to evaluate various options available in the market. Each model comes with its own set of features, strengths, and weaknesses, making direct comparisons crucial for informed decision-making. This section delves into how this particular model stacks up against its competitors, highlighting key aspects that set it apart.

Performance and Efficiency

One of the primary considerations when assessing different table saws is performance. This model is known for its powerful motor, which delivers consistent cutting capabilities. In comparison, some alternatives may offer lower horsepower, affecting their efficiency and ability to handle tougher materials. Additionally, factors like blade speed and cutting depth can significantly influence performance, making them critical points of comparison.

Portability and Design

Another vital aspect to examine is portability. This specific model is designed with user convenience in mind, often featuring lightweight construction and foldable stands. In contrast, other models may prioritize sturdiness over mobility, resulting in a bulkier design. Users seeking a balance between stability and portability will find these differences particularly relevant when choosing the right tool for their needs.

Assembly Instructions for New Users

Starting your journey with a new tool can be exciting yet challenging. Proper assembly is crucial to ensure optimal performance and safety. Follow these guidelines to facilitate a smooth setup process.

- Gather all components included in the package.

- Review the user manual for specific assembly steps.

- Identify the main parts and any necessary tools required for assembly.

To achieve the best results, adhere to the following steps:

- Begin by laying out all pieces in an organized manner.

- Attach the base securely to the main body.

- Ensure all screws and fasteners are tightened properly.

- Check alignment to avoid operational issues.

Once assembled, inspect for any loose parts before initial use. This attention to detail will enhance both functionality and safety.

User Reviews and Feedback

Customer experiences play a vital role in understanding the quality and performance of tools in the market. Reviews often provide insights into usability, reliability, and overall satisfaction, helping potential buyers make informed decisions. The feedback gathered from users can highlight both strengths and weaknesses, offering a comprehensive view of the product’s functionality.

Many users appreciate the efficiency and ease of use, noting how intuitive the design is for both novices and seasoned professionals. One reviewer stated, “The setup was straightforward, and I was able to get to work within minutes.” Others have praised its robust construction, emphasizing durability even with regular use.

However, some feedback also points out areas for improvement. Several customers have mentioned occasional issues with specific components, suggesting that certain parts could benefit from enhanced quality control. As one user put it, “While it performs well, I did encounter a couple of hiccups that required attention.” Overall, the blend of positive and constructive criticism provides a balanced perspective for anyone considering this tool.