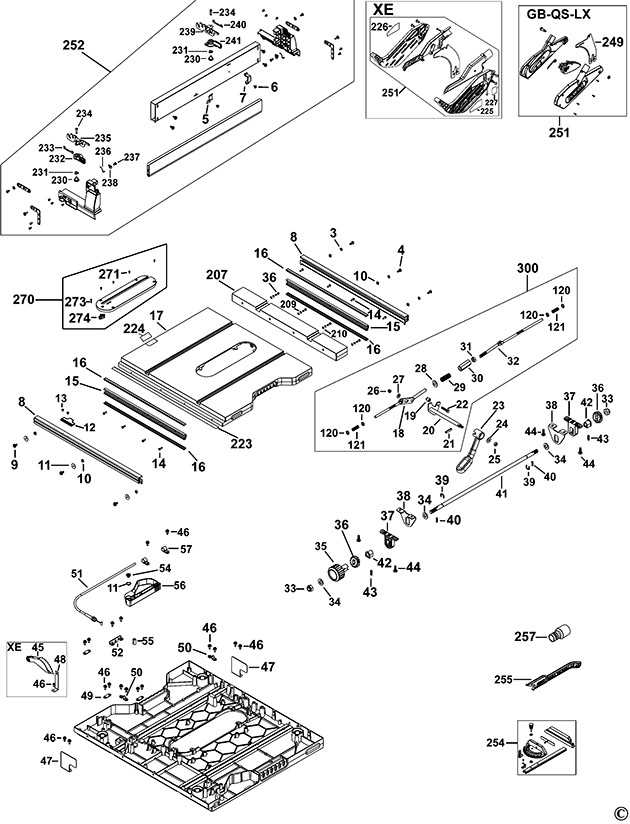

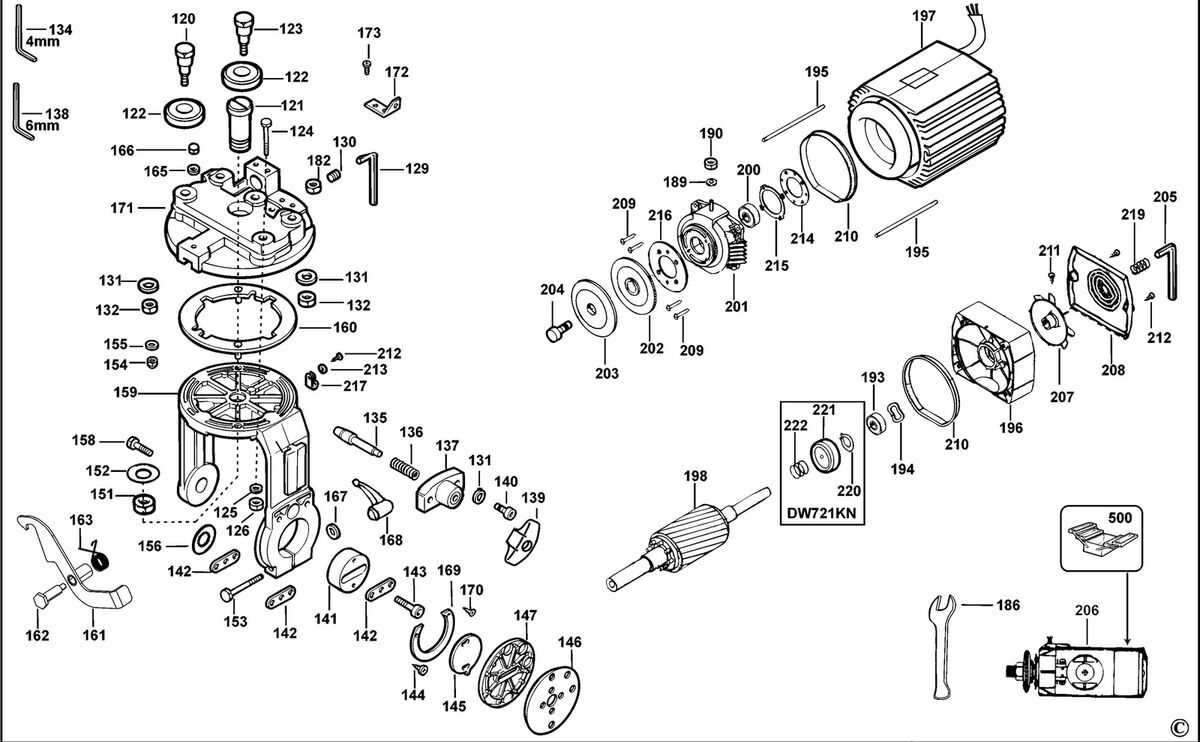

Dewalt DWE7491 Parts Diagram Overview

When exploring the intricacies of power tools, it’s essential to grasp how each component interacts within the overall structure. A clear representation of these elements can enhance both maintenance and repair processes. Knowing the relationships and functions of each part can ultimately improve your tool’s performance.

For enthusiasts and professionals alike, having access to a visual layout can simplify troubleshooting and foster a deeper understanding of the tool’s mechanics. This understanding allows for more effective usage and can even prevent costly mistakes during repairs or upgrades.

In this section, we will delve into the various components of a popular cutting machine, highlighting their significance and how they contribute to optimal functionality. By familiarizing yourself with this layout, you can ensure your equipment operates at its peak potential.

Dewalt DWE7491 Overview

This section provides a comprehensive look at a powerful and versatile woodworking tool designed for both professionals and hobbyists. Its robust features and user-friendly design make it an essential addition to any workshop.

Key features include:

- High-performance motor for efficient cutting

- Portable design allowing easy transport

- Expandable table for larger workpieces

- Accurate measurement capabilities

The tool is built with durability in mind, ensuring it withstands rigorous use while maintaining precision. Users appreciate its safety features, which enhance protection during operation.

In summary, this equipment is not only reliable but also enhances productivity, making it a valuable investment for those who demand excellence in their woodworking projects.

Importance of Parts Diagrams

Understanding the components of any machinery is essential for effective maintenance and repair. Visual representations that break down each element help users identify, locate, and troubleshoot issues efficiently. Such illustrations serve as invaluable resources for both professionals and hobbyists alike.

Having a clear overview of the assembly not only simplifies the process of fixing malfunctions but also aids in ensuring that every piece is in its correct place. This reduces the likelihood of errors during reassembly and enhances the overall longevity of the equipment.

Moreover, these visual aids facilitate better communication among technicians and users. When everyone involved has access to a shared reference, it fosters a collaborative approach to problem-solving. This can significantly decrease downtime and increase productivity, making the operation smoother.

In summary, comprehensive visual guides play a critical role in effective equipment management. They not only provide clarity but also empower users with the knowledge needed to maintain their tools in optimal condition.

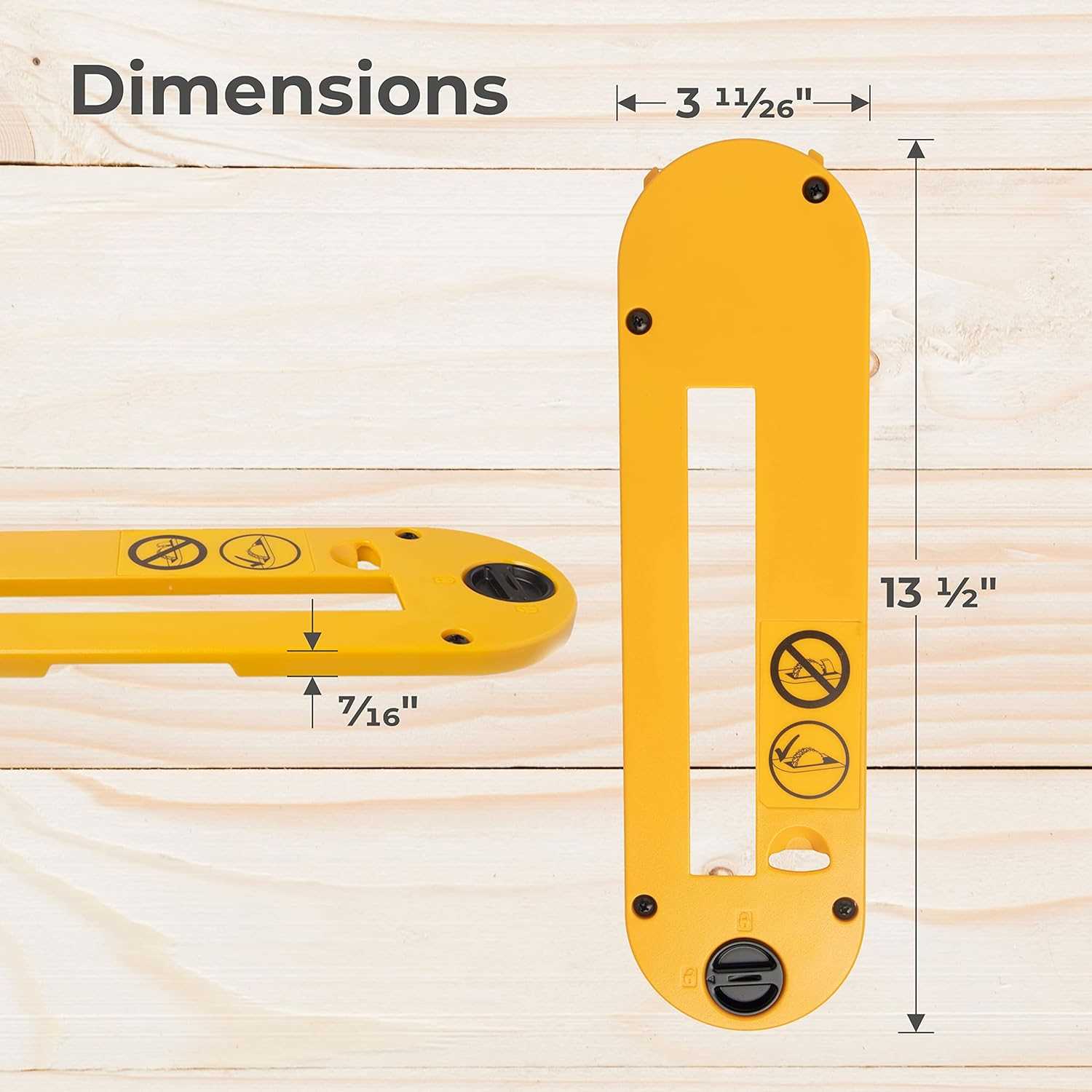

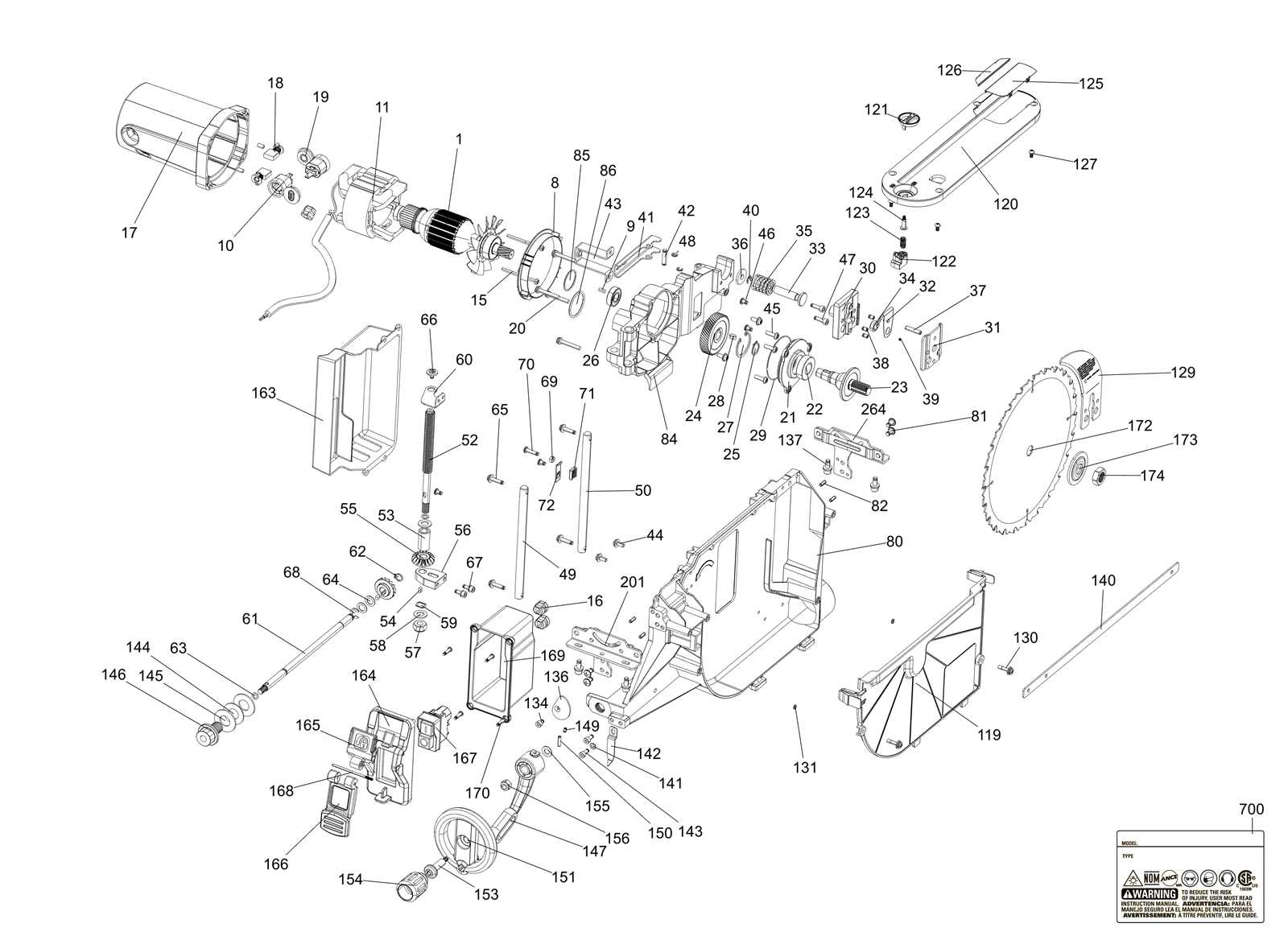

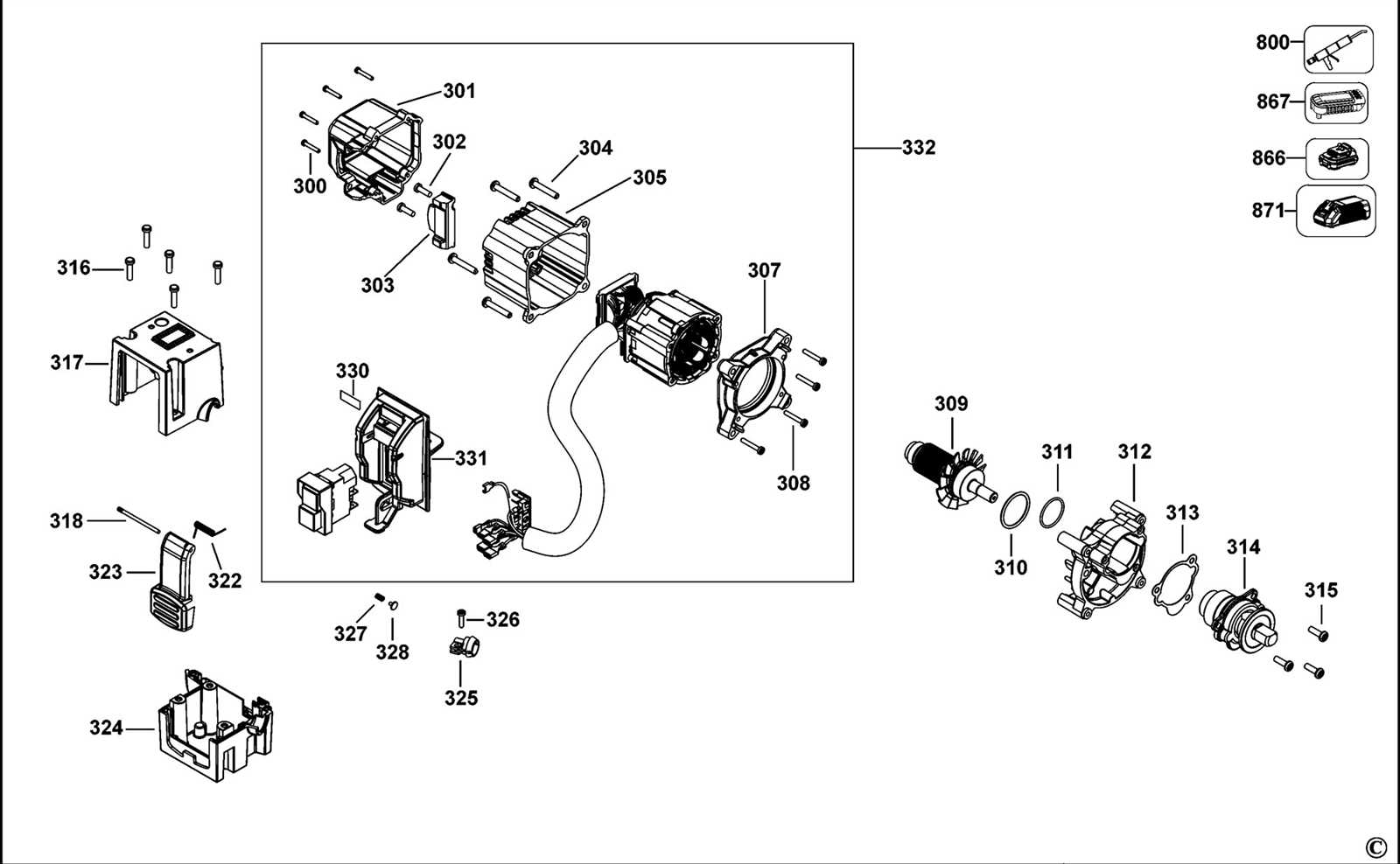

Key Components of the DWE7491

This section explores the essential elements that contribute to the functionality and performance of this powerful tool. Understanding these components enhances your ability to utilize the equipment effectively and maintain it properly.

Main Features

- Robust motor for reliable power delivery

- Adjustable fence for precise measurements

- Stable tabletop for improved work stability

Safety Mechanisms

- Blade guard to prevent accidental contact

- Emergency stop feature for immediate shutdown

- Anti-kickback pawls to enhance user safety

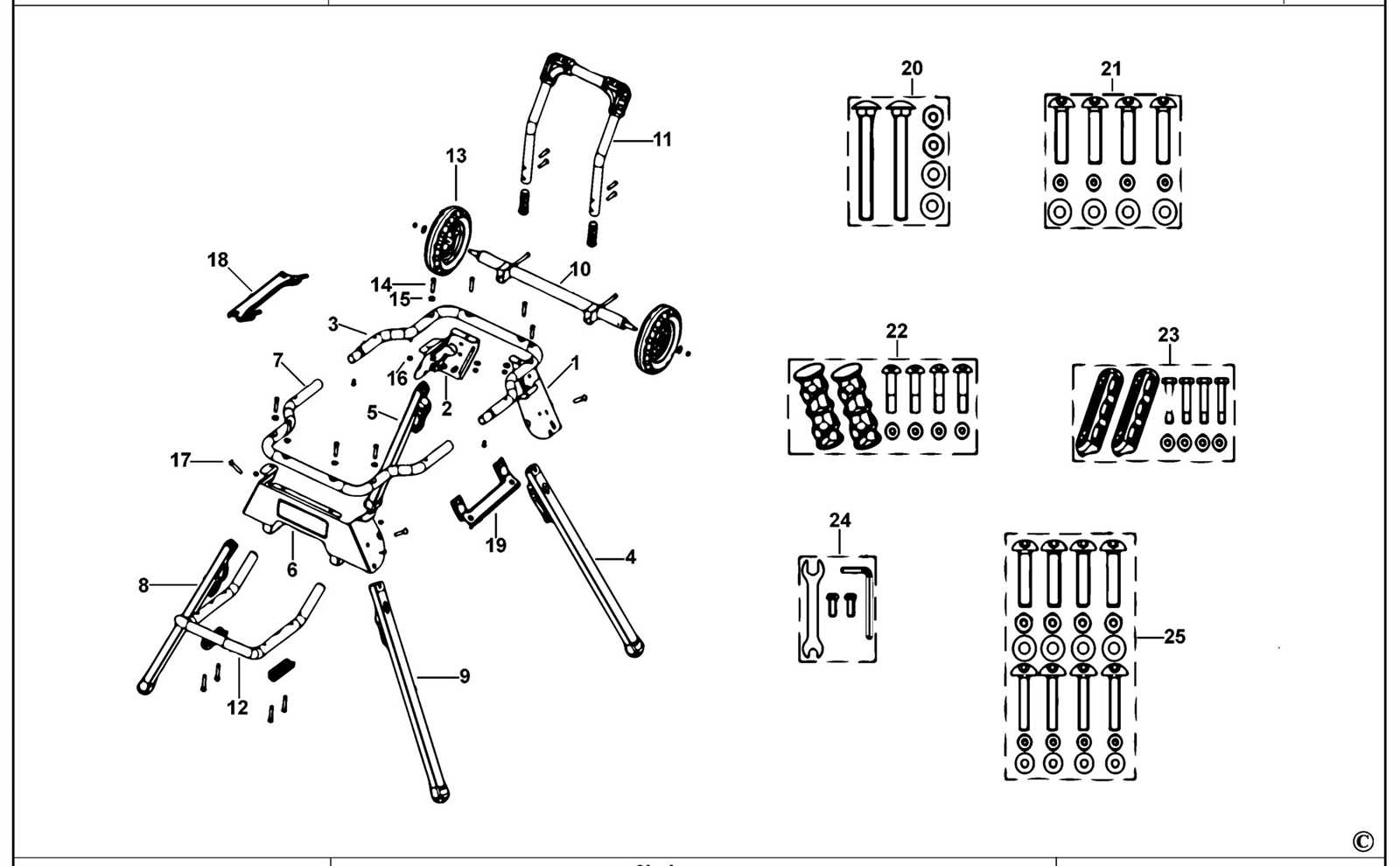

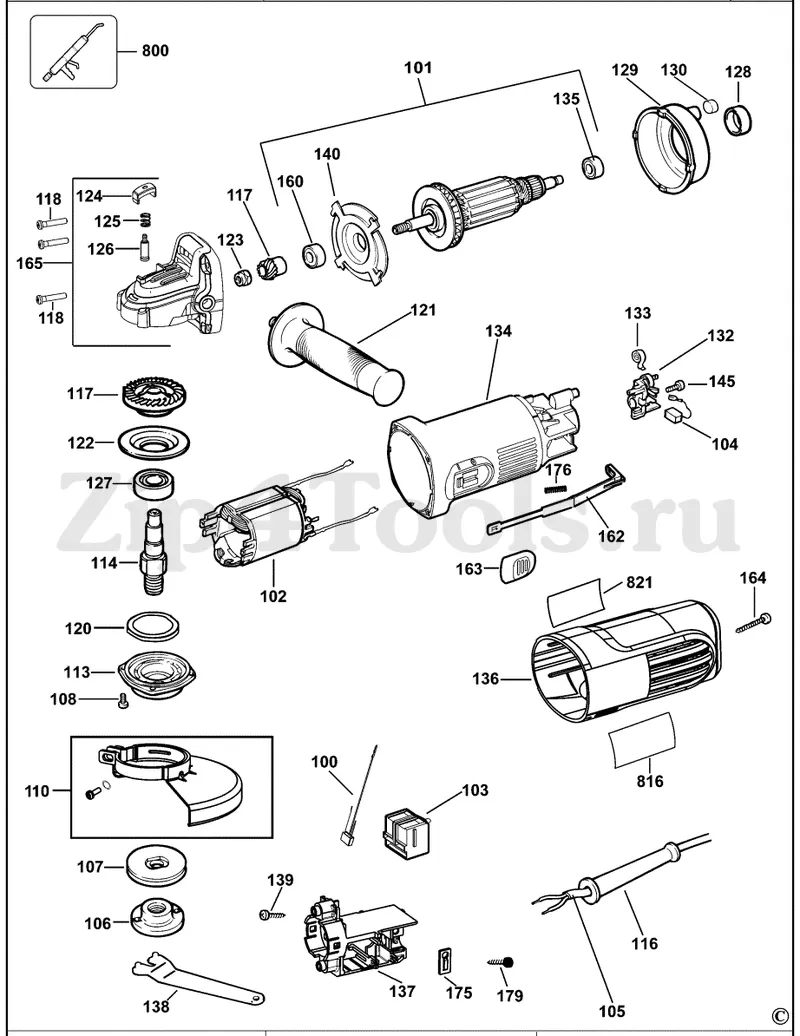

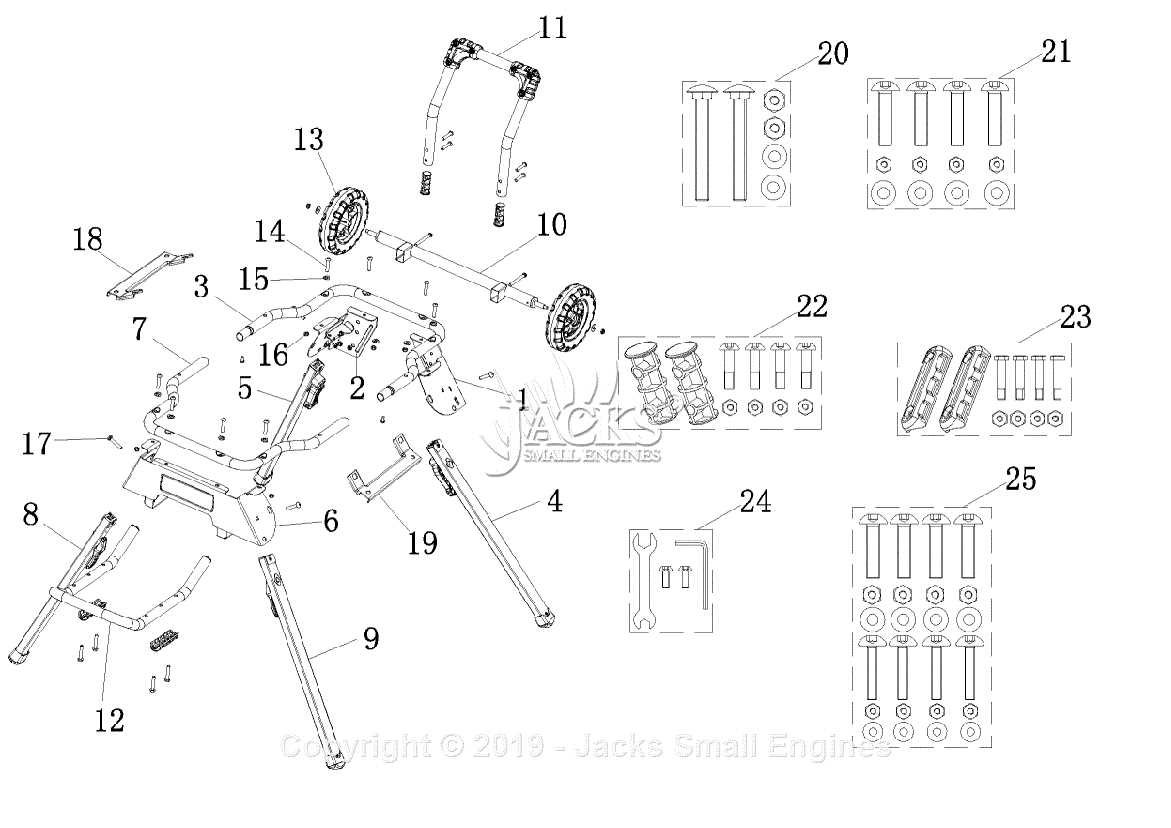

Understanding the Assembly Process

The assembly process of complex machinery requires a clear understanding of each component and how they interact. This involves not only identifying individual elements but also grasping the overall workflow. Each part plays a crucial role, contributing to the functionality and efficiency of the device.

During assembly, following a structured approach ensures that all pieces fit together seamlessly. This includes verifying that each component is in the correct position and properly secured. Attention to detail is vital, as even minor misalignments can lead to operational issues or decreased performance.

Additionally, it is essential to utilize the right tools and techniques throughout the assembly. Familiarity with the required equipment enhances precision and reduces the risk of damage to components. Knowledge of the assembly sequence can also streamline the process, making it more efficient and effective.

Ultimately, a thorough understanding of the assembly process not only aids in proper construction but also enhances maintenance and troubleshooting efforts in the future. This foundational knowledge is key for anyone looking to work with or repair similar equipment.

Common Issues and Solutions

When operating a power tool, users often encounter a range of challenges that can affect performance and efficiency. Understanding these common problems and knowing how to address them can significantly enhance the overall experience and longevity of the equipment.

Frequent Problems

- Motor Failure: Inability to start or inconsistent operation can indicate motor issues.

- Blade Misalignment: An improperly aligned blade can lead to uneven cuts and potential safety hazards.

- Overheating: Excessive heat can be caused by prolonged use or obstructed ventilation.

- Power Supply Issues: Inconsistent power can lead to interruptions in operation.

Effective Solutions

- Regular Maintenance: Ensure the motor is clean and free from debris; check electrical connections regularly.

- Blade Adjustment: Use alignment tools to ensure blades are properly set; consult the manual for specifications.

- Cooling Management: Allow for breaks during extended use; keep vents unobstructed for optimal airflow.

- Check Power Source: Verify the outlet and extension cords for any faults; replace damaged components as necessary.

Replacement Parts Availability

When it comes to maintaining and repairing power tools, the accessibility of components is crucial for ensuring optimal performance and longevity. Having the right elements on hand can significantly reduce downtime and improve efficiency. Understanding where to find these essential items is key for both professionals and DIY enthusiasts alike.

Manufacturers and Authorized Retailers often stock a comprehensive selection of necessary components. These sources typically guarantee the quality and compatibility of the items they offer. By consulting their catalogs, users can quickly locate what they need to restore their equipment to working order.

Online Marketplaces have also become popular avenues for acquiring replacements. Various platforms allow customers to browse extensive inventories, often providing competitive pricing and convenient delivery options. However, it is vital to verify the credibility of sellers to avoid counterfeit or substandard goods.

Additionally, local repair shops may have a range of essential components available. Establishing a relationship with a nearby service provider can be beneficial, as they often possess valuable knowledge about specific requirements and can assist in sourcing hard-to-find items.

Ultimately, having reliable access to components is vital for anyone looking to keep their equipment in top condition, ensuring that projects can be completed without unnecessary interruptions.

How to Read a Parts Diagram

Understanding an assembly illustration is crucial for effective maintenance and repair tasks. These visual guides provide an organized representation of components, enabling users to identify, locate, and replace parts as needed. Familiarity with these resources can enhance your ability to work on equipment efficiently.

Key Elements to Identify

- Component Labels: Each element typically features a label or number that corresponds to a list of items. This makes it easier to find specific parts.

- Assembly Order: Often, illustrations depict the sequence in which parts are assembled. This helps in understanding how components fit together.

- Groupings: Components are often grouped based on functionality or location, simplifying navigation through the illustration.

Steps to Interpret the Illustration

- Locate the Legend: Most visuals include a legend that explains symbols or color codes used throughout.

- Identify the Components: Cross-reference the labels on the illustration with the list of parts to understand what each piece represents.

- Follow the Assembly Path: Observe how each component connects to others, noting any special instructions or warnings.

- Take Notes: As you analyze, jot down any observations or questions for later reference.

By mastering the interpretation of these visual tools, you can significantly improve your repair and maintenance proficiency.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your equipment requires regular care and attention. By following a few essential maintenance practices, you can extend the lifespan of your tools and enhance their performance. Consistent upkeep not only prevents unexpected breakdowns but also optimizes functionality during operation.

Regular Cleaning

One of the simplest yet most effective maintenance tasks is regular cleaning. After each use, remove dust, debris, and any residue that may have accumulated. This prevents buildup that can lead to overheating and malfunctions. Utilize a soft brush or compressed air to reach hard-to-access areas, ensuring that all components remain free of obstruction.

Routine Inspections

Conducting periodic inspections is vital for identifying wear and tear before it becomes a significant issue. Examine all moving parts for signs of damage or excessive wear. Pay close attention to electrical connections and ensure that all screws and bolts are tight. Addressing minor issues promptly can prevent more severe problems and costly repairs down the line.

Upgrades for Enhanced Performance

Enhancing the efficiency and capability of your woodworking equipment can significantly improve your overall experience and output. With the right modifications and additions, you can unlock greater potential and achieve better results in your projects. This section explores various enhancements that can elevate the functionality of your tools, ensuring they meet your evolving needs.

Motor Upgrades

Upgrading the motor can lead to improved power and efficiency. A higher torque motor allows for smoother operation and better performance under heavy loads. This modification is especially beneficial for those tackling demanding tasks or working with dense materials. Consider selecting a motor with a higher amp rating to increase cutting speed and overall effectiveness.

Table and Blade Enhancements

Investing in a high-quality blade can dramatically affect cutting precision and finish quality. Blades designed for specific materials or purposes can minimize tear-out and provide cleaner cuts. Additionally, upgrading the table to a sturdier, more stable version can enhance support and reduce vibrations, leading to more accurate results. Combining these upgrades ensures that your equipment performs optimally and meets professional standards.

Safety Features of the DWE7491

When working with powerful machinery, prioritizing safety is essential. Advanced tools are designed with various protective features to enhance user security and minimize risks. These features not only safeguard the operator but also contribute to a safer working environment.

Blade Guard System

The integrated blade guard system is a critical safety measure. It effectively covers the cutting blade when not in use, preventing accidental contact. This feature retracts automatically when the material is fed into the saw, ensuring visibility and control during operation while maintaining protection when the tool is idle.

Overload Protection

Another significant safety enhancement is the overload protection mechanism. This system monitors the motor’s performance, automatically shutting down the tool in case of excessive strain. This prevents overheating and potential damage, allowing the user to work confidently without worrying about equipment failure.

Incorporating these features makes the tool safer and enhances overall efficiency, enabling users to focus on their projects with peace of mind.

Comparative Analysis with Other Models

This section delves into a comparative study of various power tools within the same category, focusing on key features, performance metrics, and user preferences. By evaluating these alternatives, we can gain insights into how one particular model stands against its peers in terms of functionality and value for money.

| Feature | Model A | Model B | Model C |

|---|---|---|---|

| Power Output | 1800W | 1600W | 2000W |

| Cutting Capacity | 24 inches | 22 inches | 26 inches |

| Weight | 90 lbs | 85 lbs | 95 lbs |

| Price | $599 | $499 | $649 |

| User Rating | 4.5/5 | 4.0/5 | 4.7/5 |

The above comparison highlights the strengths and weaknesses of each tool. Model A, while slightly heavier, offers a balanced combination of power and cutting capacity, making it suitable for heavy-duty tasks. Conversely, Model B is more lightweight and budget-friendly, ideal for casual users. Model C excels in power but comes with a higher price tag, catering to professionals seeking robust performance.

User Reviews and Experiences

This section delves into the feedback and insights shared by users who have interacted with the tool in question. Their opinions provide valuable information regarding performance, durability, and overall satisfaction, allowing potential buyers to make informed decisions.

Positive Feedback

- Many users appreciate the robust construction, noting its resilience under demanding conditions.

- Several reviews highlight the ease of setup, with most indicating a straightforward assembly process.

- The versatility of the tool receives high praise, with users reporting its effectiveness for a range of projects.

Constructive Criticism

- Some reviewers mention that the weight can be a concern, making it less portable for some tasks.

- A few users suggest improvements in the user manual, indicating that clearer instructions would enhance the experience.

- Some feedback points to the need for additional accessories to maximize functionality.

Where to Buy Genuine Parts

Finding authentic components for your tools is crucial for maintaining their performance and longevity. Using original elements ensures compatibility and reliability, which is vital for optimal operation. Here are some reliable sources where you can procure genuine items for your equipment.

Authorized Retailers

One of the best options is to purchase from authorized dealers. These retailers are recognized by the manufacturer and typically offer a comprehensive range of original components. Shopping at these locations not only guarantees the authenticity of the products but also provides expert advice and support.

Online Marketplaces

In addition to physical stores, numerous online platforms specialize in selling original equipment. These websites often have detailed catalogs and user reviews to help you make informed decisions. Ensure that you verify the seller’s credentials to avoid counterfeit products.

| Source | Benefits |

|---|---|

| Authorized Dealers | Guaranteed authenticity, expert assistance |

| Official Websites | Wide selection, often exclusive offers |

| Reputable Online Marketplaces | Convenience, user reviews, price comparisons |