Dewalt DWS780 Parts Diagram Overview

This section delves into the intricate layout of a specific tool, offering a comprehensive overview of its essential components and their arrangements. A well-structured assembly is crucial for the effective functioning of any mechanical device, and understanding its configuration can significantly aid users in both troubleshooting and maintenance tasks.

The detailed representation of individual elements provides insight into how they interact and contribute to the overall performance of the equipment. By familiarizing oneself with these components, users can enhance their operational efficiency and ensure longevity through informed care practices.

Furthermore, this exploration serves as a valuable resource for those seeking to replace or upgrade parts. Equipped with the knowledge of how various sections fit together, users can make informed decisions, leading to better tool performance and reliability in various applications.

Dewalt DWS780 Overview

This section provides a comprehensive look at a powerful and versatile tool designed for precision cutting and efficiency. Its robust features make it a preferred choice among professionals and enthusiasts alike, ensuring reliability in various applications.

The tool is equipped with advanced technology, offering enhanced performance that meets the demands of both intricate and large-scale projects. Its design focuses on user convenience, allowing for seamless operation while maintaining safety standards.

With a well-structured build and high-quality components, this device ensures durability and longevity, making it a worthwhile investment for anyone looking to elevate their craftsmanship. Whether tackling construction tasks or detailed woodworking, it serves as an essential ally in achieving outstanding results.

Key Features of the DWS780

This model boasts an impressive array of functionalities that cater to the needs of both professionals and enthusiasts. It is engineered to deliver high precision and reliability, making it an ideal choice for various cutting tasks. From its robust construction to innovative technology, this tool enhances performance and efficiency in any workshop environment.

Enhanced Cutting Capacity

One of the standout attributes is its remarkable cutting capacity. The design allows for larger materials to be processed with ease, facilitating complex projects without compromise. Users can achieve clean and accurate cuts thanks to the advanced blade alignment and support features.

Precision and Accuracy

Equipped with innovative technology, this device ensures utmost precision during operation. The adjustable settings provide customization for different applications, allowing users to achieve their desired results consistently. The intuitive interface further enhances usability, making it accessible for all skill levels.

Identifying Main Components

Understanding the key elements of a tool is essential for effective operation and maintenance. Each part plays a critical role in the overall functionality, contributing to performance and durability. Familiarity with these components can help users troubleshoot issues and ensure proper usage.

Core Elements

- Motor: Powers the machine, providing the necessary energy for cutting tasks.

- Blade: The cutting tool itself, available in various sizes and types depending on the material being worked on.

- Base Plate: Provides stability and support, allowing for accurate cuts.

- Fence: Guides the workpiece, ensuring precision during cutting operations.

Additional Features

- Dust Collection System: Helps maintain a clean workspace by collecting debris and particles.

- Bevel Adjustment: Allows for angled cuts, expanding the versatility of the tool.

- Locking Mechanism: Ensures safety during operation, preventing accidental activation.

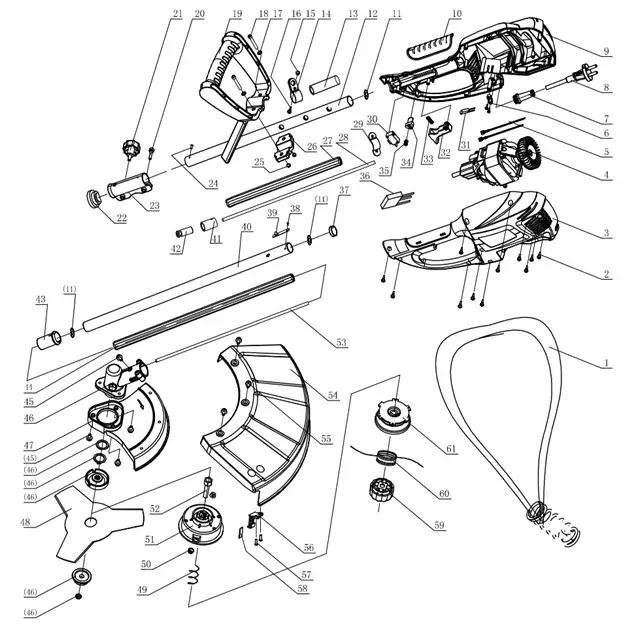

Exploring the Parts Diagram

This section delves into the detailed representation of components for a specific tool, illustrating how each element contributes to its overall functionality. Understanding this illustration can enhance maintenance practices and improve the efficiency of the equipment.

By examining the visual representation, users can gain insights into the various elements that make up the tool, such as the motor, blades, and other essential mechanisms. Each part is labeled clearly, providing a reference point for identification and replacement. This understanding is crucial for anyone looking to troubleshoot issues or perform upgrades.

Maintenance becomes more manageable when users can pinpoint specific elements within the assembly. For example, knowing the exact location of a particular gear or bearing allows for quicker repairs and part replacements. Additionally, this familiarity can lead to informed decisions regarding upgrades or enhancements, ensuring optimal performance.

Ultimately, a comprehensive grasp of the illustrated components enables users to maintain their equipment effectively, leading to longer service life and improved operational efficiency.

Replacement Parts Availability

Ensuring the continuous functionality of your equipment is crucial, and having access to suitable components is a key aspect of maintenance. When repairs are needed, the availability of these essential elements can significantly impact the efficiency and longevity of your tools. This section provides insights into sourcing replacement components for optimal performance.

Where to Find Components

Many reliable retailers and online platforms offer a wide selection of replacement items, catering to various models and specifications. It is advisable to purchase from authorized dealers or reputable sources to ensure the authenticity and quality of the products. Additionally, manufacturer websites often have resources for locating certified distributors.

Considerations for Replacement

When seeking new components, it’s important to consider compatibility and specifications. Always verify that the items meet the required standards for your particular equipment to avoid potential issues. Furthermore, checking user reviews can provide valuable insights into the performance and durability of the components.

Common Issues and Solutions

When working with power tools, it’s essential to be aware of potential challenges that may arise during operation. Understanding common problems and their solutions can enhance performance and extend the tool’s lifespan. This section highlights frequent issues users encounter, along with effective remedies to address them.

Frequent Problems

| Issue | Possible Cause | Suggested Solution |

|---|---|---|

| Inconsistent cutting | Dull blade or incorrect alignment | Sharpen or replace the blade; ensure proper alignment |

| Overheating | Continuous use without breaks | Allow the tool to cool down periodically |

| Excessive vibration | Loose components or worn parts | Tighten loose screws and replace worn components |

| Power loss | Faulty electrical connections | Inspect and repair electrical connections |

Maintenance Tips

Regular maintenance is crucial to prevent issues and ensure optimal functionality. Cleaning the tool after each use, lubricating moving parts, and checking for wear can help maintain performance and prevent common problems from arising.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your power tools requires consistent upkeep and attention. Regular maintenance not only enhances performance but also extends the lifespan of the equipment, allowing you to get the most out of your investment.

Start by keeping the tool clean. Dust and debris can accumulate in critical areas, affecting functionality. Use a soft brush or compressed air to remove particles from vents and moving parts. Additionally, inspect the components periodically for wear and tear. Addressing minor issues promptly can prevent them from escalating into significant problems.

Lubrication is essential for maintaining smooth operation. Apply the appropriate lubricant to bearings and pivot points as specified in the user manual. This reduces friction and minimizes the risk of overheating, which can lead to premature failure.

Lastly, store the equipment in a dry, climate-controlled environment. Avoid exposure to extreme temperatures and moisture, which can lead to rust and corrosion. By following these guidelines, you can ensure that your tools remain in peak condition for years to come.

Understanding Warranty Information

When purchasing power tools, it is essential to be aware of the warranty details provided by the manufacturer. This information offers insight into the coverage period, what is included, and the steps necessary to make a claim. A clear understanding of warranty policies can help ensure that users are well-informed about their rights and the manufacturer’s responsibilities.

Warranty Duration: Typically, the warranty lasts for a specific period, which can range from one to three years, depending on the tool type and manufacturer guidelines. Knowing the duration allows users to plan for potential repairs or replacements.

Coverage Scope: Most warranties cover defects in materials and workmanship, but it is crucial to read the fine print to understand any exclusions. Some policies may not cover damage caused by misuse, accidents, or unauthorized repairs.

Claim Process: In case of a defect, it is important to know the steps to initiate a warranty claim. This usually involves contacting customer service, providing proof of purchase, and detailing the issue. Keeping receipts and documentation organized can expedite this process.

Extended Warranties: Many manufacturers also offer extended warranty options for an additional cost. This can provide extra peace of mind for users who rely heavily on their tools, as it may cover repairs or replacements beyond the standard warranty period.

By being well-acquainted with warranty information, users can make informed decisions, ensuring their investments are protected and that they can access support when needed.

Accessories for Enhanced Performance

To optimize the functionality and efficiency of your cutting tool, incorporating various supplementary components can make a significant difference. These enhancements not only improve precision but also extend the lifespan of your equipment, making your projects more productive and enjoyable.

Essential Add-Ons

Investing in high-quality attachments can elevate your experience. Here are some critical accessories that can help you achieve superior results:

| Accessory | Description |

|---|---|

| Laser Guide | Provides enhanced visibility and accuracy during cuts. |

| Replacement Blades | Specialized blades for different materials ensure clean and efficient cuts. |

| Dust Collection System | Helps maintain a clean workspace by efficiently capturing debris and particles. |

Safety Gear

In addition to performance enhancements, using appropriate safety equipment is crucial for protecting yourself during operation. Consider the following:

| Safety Equipment | Description |

|---|---|

| Safety Glasses | Protects eyes from flying debris and dust. |

| Ear Protection | Reduces noise exposure during prolonged use, safeguarding hearing. |

| Work Gloves | Offers grip and protects hands from sharp edges and vibrations. |

Comparing with Similar Models

When evaluating different cutting tools, it is essential to assess their specifications, functionalities, and design features. By examining how various models align with one another, users can make informed decisions that best suit their needs. This comparison not only highlights the strengths and weaknesses of each tool but also helps to identify the most suitable option for specific applications.

Design and Build Quality: The construction of these tools often reflects durability and performance. Some models are designed with lightweight materials for enhanced portability, while others prioritize ruggedness to withstand demanding environments. Understanding these aspects allows users to select a device that aligns with their work conditions.

Performance Features: Different models may offer varying power levels and cutting capabilities. Some tools excel in precision for intricate tasks, while others provide high power for heavy-duty projects. By comparing these performance metrics, users can choose a tool that meets their operational requirements.

Accessory Compatibility: The availability of compatible accessories can significantly influence a tool’s versatility. Models that support a wide range of attachments may enhance productivity by enabling users to perform multiple tasks without switching equipment. This feature is particularly valuable for professionals who seek efficiency in their workflow.

Price and Value: Cost is a crucial factor in any purchasing decision. While some models may be more expensive, they often justify the price through superior performance and features. Conversely, budget-friendly options can still deliver satisfactory results for less intensive tasks. Comparing price-to-performance ratios can help users find the best value for their investment.

User Manual Insights

This section delves into the essential aspects of the user guide, providing valuable information for effective utilization and maintenance of the tool. Understanding the contents of the manual can enhance user experience and ensure safety while operating the device.

Key Features Highlighted

- Comprehensive instructions for setup and operation.

- Safety precautions to prevent accidents.

- Maintenance tips for optimal performance.

- Common troubleshooting steps for issues encountered during use.

Benefits of Following the Manual

- Enhances familiarity with tool functionalities.

- Promotes safe usage and handling techniques.

- Encourages regular maintenance to prolong tool lifespan.

- Provides insights into warranty coverage and support options.