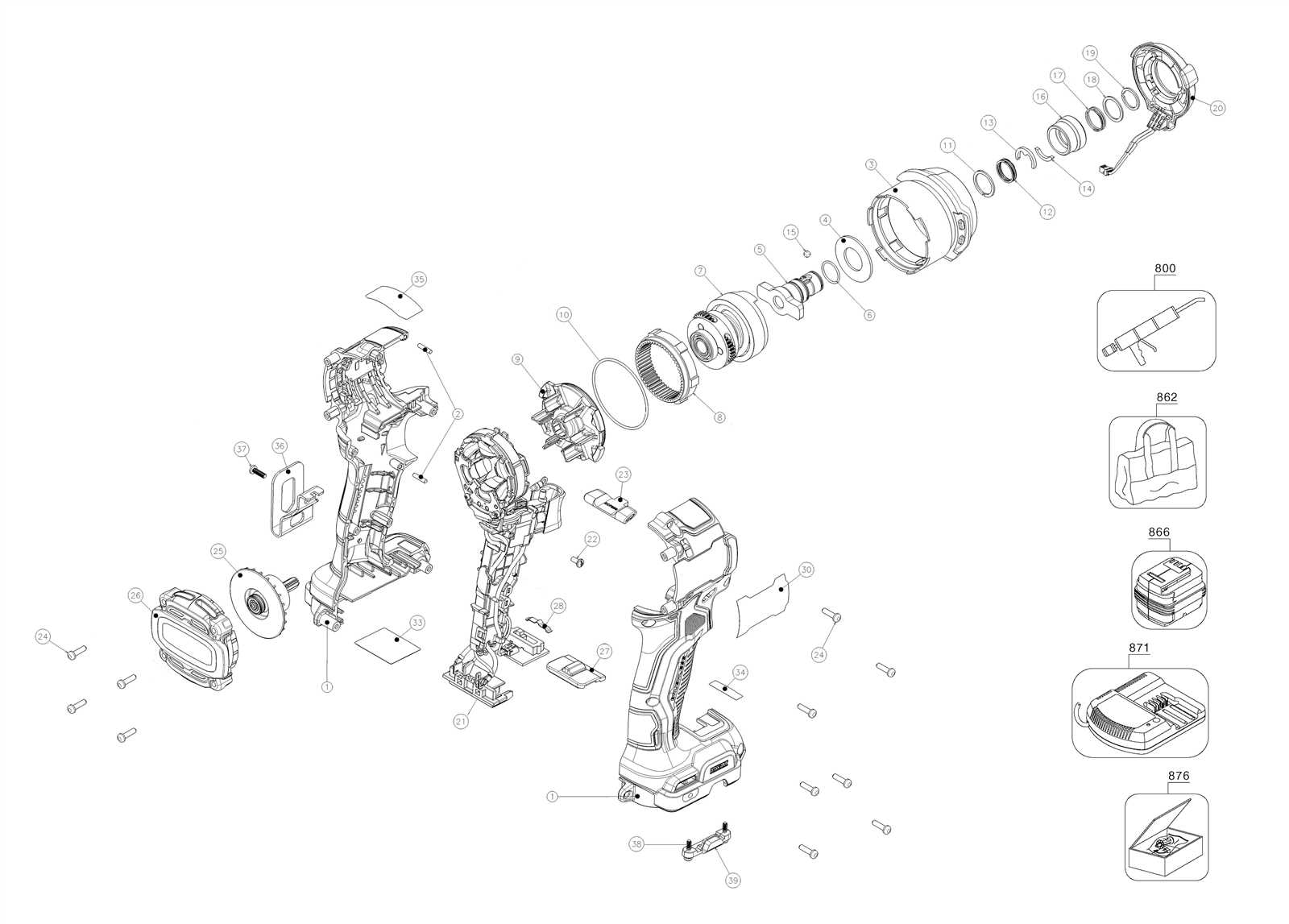

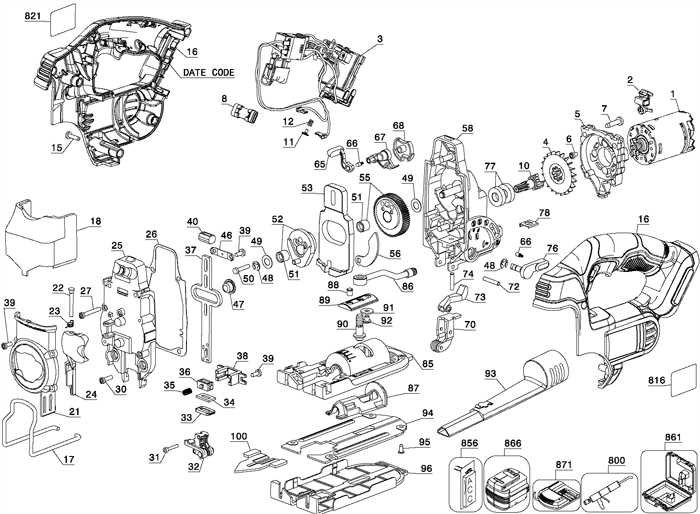

Dewalt DXV10SA Parts Diagram Overview

When working with complex machinery, having a clear understanding of its internal elements is essential for smooth operation and maintenance. Each tool consists of various interconnected components that perform specific tasks, ensuring that the entire system functions efficiently. Whether you are looking to repair, replace, or upgrade, knowledge of these individual parts can significantly enhance your ability to manage the equipment effectively.

Identifying each element helps you quickly assess any potential issues and determine what needs attention. By examining a detailed overview, you can gain insights into how each component fits into the larger mechanism. This understanding can save time and effort when troubleshooting or assembling.

Familiarizing yourself with the structure of your equipment ensures that you make informed decisions about its upkeep and improvements. With accurate knowledge, you can confidently handle any maintenance tasks, from simple repairs to more advanced modifications.

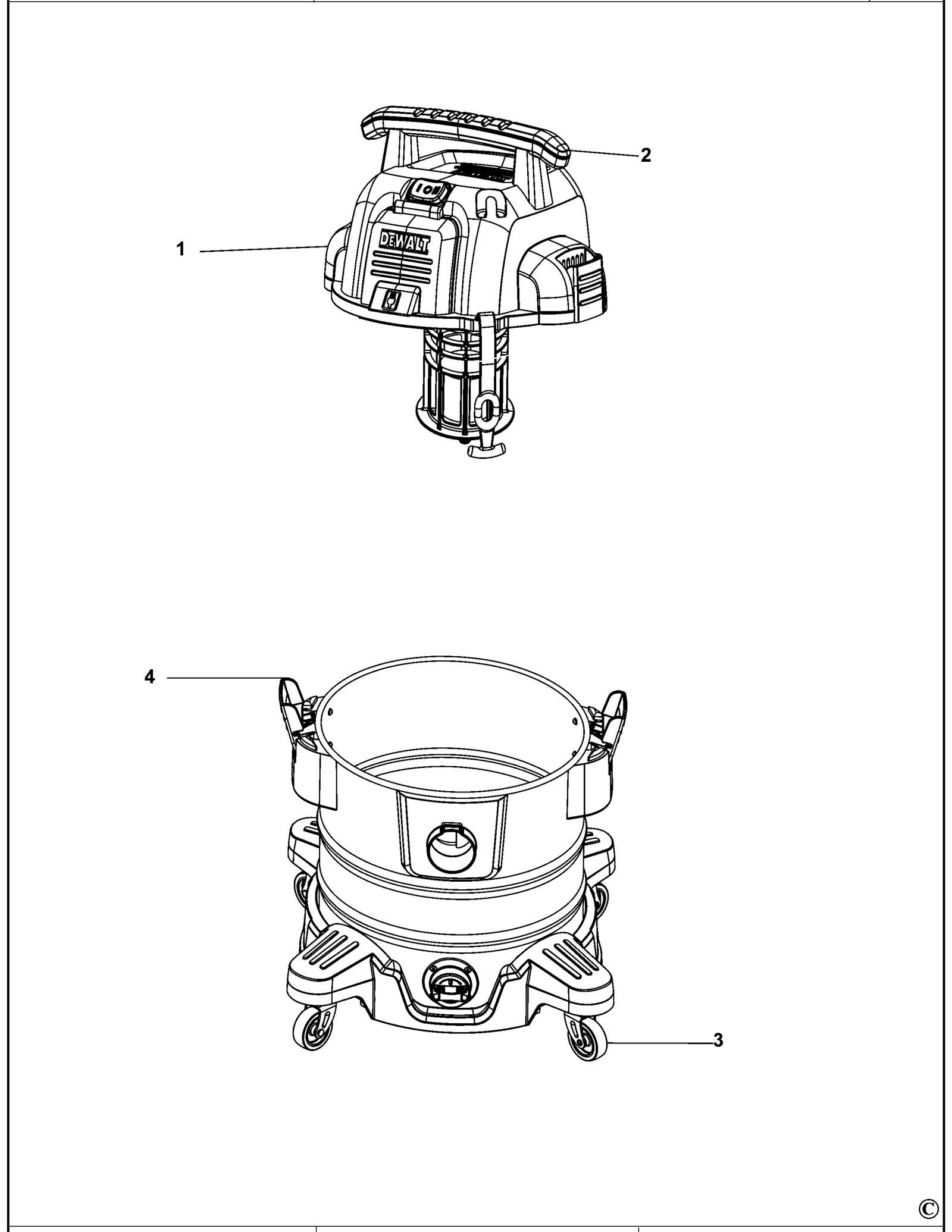

Understanding Dewalt DXV10SA Components

Comprehending the individual elements of a powerful vacuum model enhances both functionality and maintenance. Each component plays a vital role in ensuring efficient operation and longevity, making it crucial to familiarize oneself with their arrangement and purpose.

Key Elements of the Device

The core components include a robust motor, filtration system, and collection tank. The motor drives suction, while the filtration mechanism captures dust and debris effectively. The collection tank is designed for easy disposal, contributing to user convenience.

Maintenance and Care

Regular maintenance of these parts is essential for optimal performance. Checking the filter for clogs and ensuring the tank is emptied regularly will enhance functionality and prolong the life of the equipment.

Key Features of Dewalt DXV10SA

This model stands out in its category due to a combination of advanced engineering and user-friendly design. It is engineered to deliver exceptional performance while ensuring convenience and ease of use for a variety of tasks.

Powerful Performance

Equipped with a robust motor, this unit offers impressive suction capabilities, making it ideal for both professional and home environments. Its efficient operation ensures that debris and liquids are effectively managed, allowing for a cleaner workspace.

User-Centric Design

The thoughtful design incorporates features such as an ergonomic handle and large wheels, providing enhanced mobility. Additionally, its compact size allows for easy storage, while various attachment options ensure versatility for different cleaning needs.

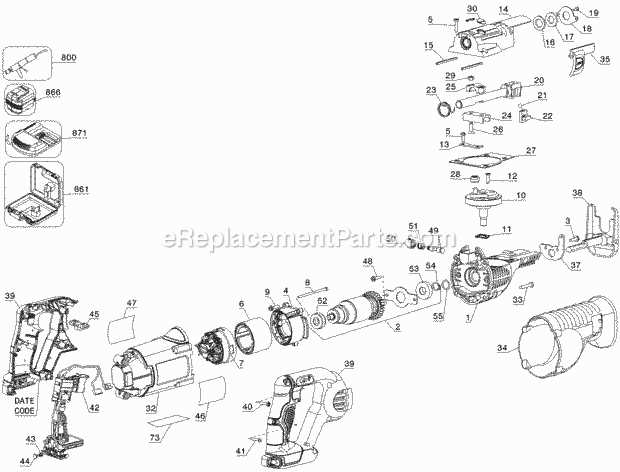

Exploring the Main Assembly Parts

Understanding the components that make up a robust assembly is essential for effective maintenance and repair. Each element plays a critical role in ensuring optimal performance and longevity. In this section, we will delve into the key components that contribute to the overall functionality of the unit.

Core Components

The heart of any assembly is its core components, which include the motor and housing. The motor is responsible for powering the device, while the housing provides protection and structural integrity. Together, they form the backbone of the equipment, allowing it to operate smoothly under various conditions.

Supplementary Elements

In addition to the main components, there are several supplementary elements that enhance functionality. These may include seals, gaskets, and connectors, which ensure that the device operates efficiently and without leaks. Understanding these additional features is crucial for troubleshooting and performing regular upkeep.

By familiarizing yourself with these essential components and their functions, you can ensure that your equipment remains in top-notch condition for years to come.

Power and Performance Insights

Understanding the capabilities and efficiency of a tool is crucial for maximizing its potential. Insights into power output and operational effectiveness can guide users in selecting the right equipment for their tasks. A detailed examination reveals how design and technology contribute to performance metrics.

| Feature | Description |

|---|---|

| Motor Strength | High-torque motors enable heavy-duty tasks with ease. |

| Airflow Efficiency | Optimized airflow improves suction and overall effectiveness. |

| Durability | Robust construction ensures long-lasting performance in various environments. |

| Noise Level | Designed for reduced noise without compromising power. |

Detailed Breakdown of Motor Components

This section provides a comprehensive analysis of the essential elements that make up the motor assembly. Understanding these components is crucial for maintenance and troubleshooting, ensuring optimal performance and longevity of the device.

Stator: The stationary part of the motor, it creates a magnetic field when electric current flows through it. This component is vital for initiating the motor’s operation.

Rotor: Positioned inside the stator, the rotor is the rotating element that converts electrical energy into mechanical energy. Its design and materials significantly affect efficiency.

Bearings: These components support the rotor and reduce friction during rotation. Quality bearings ensure smooth operation and minimize wear over time.

Commutator: A crucial part of the direct current motors, it reverses the current direction, allowing the rotor to turn continuously. This component is essential for maintaining motor rotation.

Windings: The coils of wire wrapped around the stator and rotor, they play a key role in generating magnetic fields. The configuration of these windings can influence the motor’s torque and speed.

Cooling System: Effective heat dissipation is vital to prevent overheating. This system typically includes fans or vents designed to maintain optimal operating temperatures.

By delving into each of these components, one can appreciate their roles and interconnections, ultimately enhancing understanding of motor functionality.

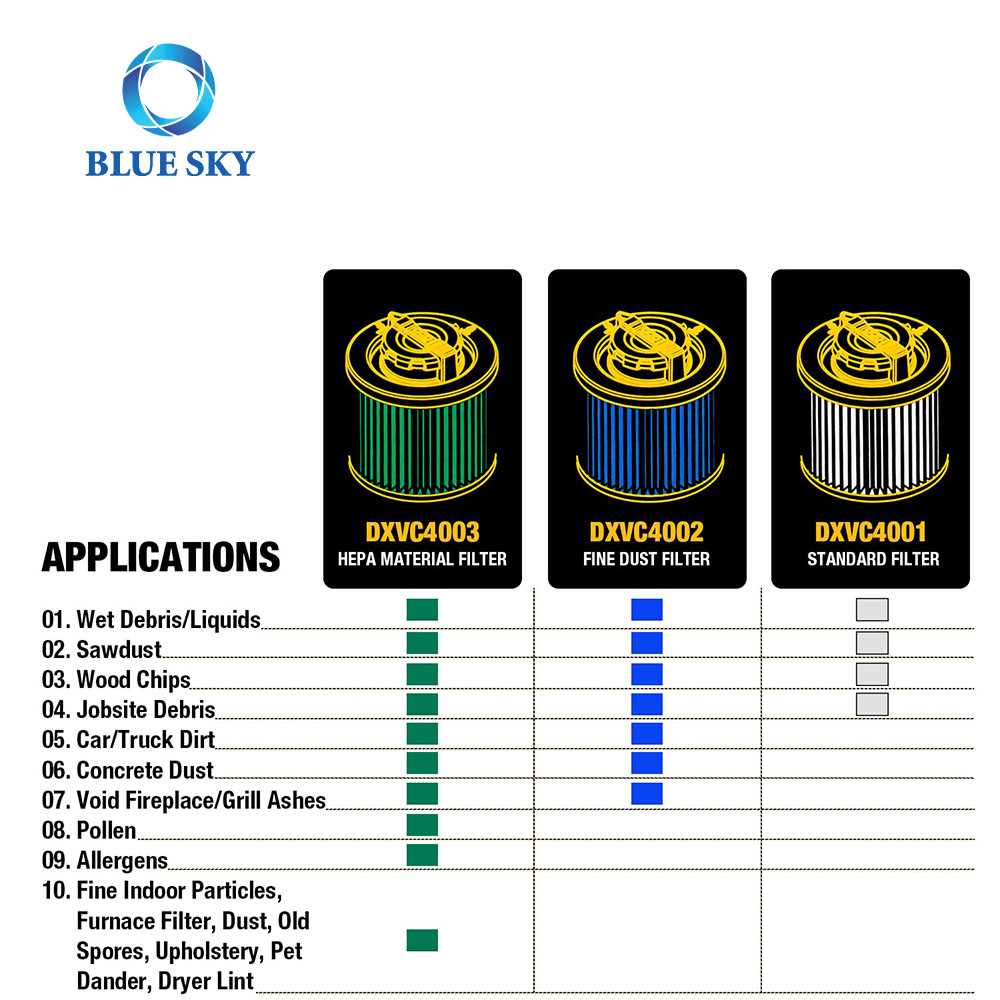

Dissecting the Filtration System

The filtration mechanism of a vacuum unit is crucial for maintaining efficiency and ensuring clean air output. Understanding its components and how they function together can enhance performance and prolong the life of the device.

Key Components

At the heart of the filtration system are the various elements that capture debris and particles. Filters serve as the primary barrier against dust, while pre-filters help extend the life of these main filters by trapping larger particles. HEPA filters, known for their fine filtration capabilities, play a vital role in minimizing allergens and fine dust emissions.

Maintenance and Efficiency

Regular maintenance of the filtration system is essential for optimal operation. Cleaning or replacing filters as needed not only improves suction power but also enhances air quality. A well-maintained system ensures the ultimate efficiency and longevity of the equipment.

How the Wheels and Casters Function

The functionality of wheels and casters is crucial for enhancing mobility and ease of use in various equipment. These components allow for smooth movement across different surfaces, providing stability and support. By understanding their design and operation, one can appreciate their role in improving efficiency and reducing effort during transport.

Wheels are typically designed to roll smoothly, minimizing friction and allowing for effortless movement. Their size, shape, and material significantly affect performance, influencing factors like load-bearing capacity and maneuverability. Casters, on the other hand, combine wheels with a pivoting mechanism, enabling enhanced directional control. This dual functionality is essential in settings where agility and quick adjustments are necessary.

The interaction between wheels and casters also plays a vital role in load distribution. Properly designed components can ensure that weight is evenly spread, reducing wear and tear while promoting longevity. Additionally, features such as brakes and locking mechanisms provide safety and stability when the equipment is stationary, further enhancing the overall user experience.

In summary, the wheels and casters work together harmoniously to facilitate movement, balance, and safety, making them indispensable in various applications.

Exploring the Vacuum Hose and Attachments

The effectiveness of any cleaning apparatus largely depends on the quality and versatility of its hose and attachments. These components play a crucial role in optimizing suction power and ensuring a thorough clean across various surfaces. By examining their features and compatibility, users can enhance their experience and achieve superior results.

Understanding Hose Features

A well-designed hose should offer flexibility and durability. Materials that resist wear and tear contribute to the longevity of the device, while a lightweight construction allows for easy maneuverability. Additionally, features such as anti-kink technology help maintain consistent airflow, preventing obstructions during use.

Maximizing Attachments

Attachments are essential for tailoring the cleaning experience to specific tasks. Tools like crevice nozzles and brush heads can enhance versatility, allowing users to tackle everything from tight corners to delicate surfaces. Selecting the right attachment not only improves efficiency but also ensures optimal performance across different cleaning scenarios.

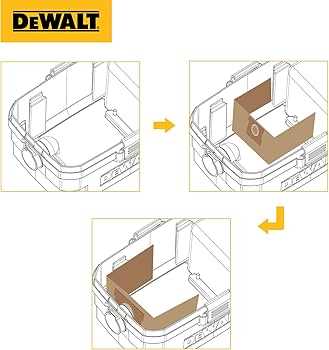

Assembly and Disassembly Guide

This section provides a comprehensive approach to the process of putting together and taking apart equipment safely and efficiently. Mastering these techniques ensures optimal performance and longevity of the machinery while minimizing the risk of damage.

Disassembly Steps

Begin by gathering necessary tools and ensuring the workspace is clear. Carefully detach any electrical connections and fasteners. As you proceed, keep track of components and their arrangement to facilitate reassembly. Documenting the process can be beneficial for future reference.

Assembly Steps

To reassemble, start with the main structure and work your way through the components in the reverse order of disassembly. Ensure all parts are clean and undamaged before reattaching. Tighten connections securely, but avoid overtightening, which can lead to damage. Final checks are crucial to ensure everything is in place before use.

Replacement Parts and Their Availability

Maintaining equipment in optimal condition often requires access to specific components that can be easily replaced. Understanding where to find these essential items ensures that users can swiftly restore functionality and prolong the life of their tools. This section explores the options available for sourcing these crucial elements.

Where to Find Components

Numerous retailers and online platforms offer a wide selection of replacements. Users can choose from authorized dealers, independent hardware stores, or various e-commerce websites. Each option has its own benefits, such as competitive pricing or immediate availability, making it important to evaluate based on individual needs.

Availability Overview

| Source | Pros | Cons |

|---|---|---|

| Authorized Dealers | Genuine items, expert advice | Higher prices |

| Independent Hardware Stores | Local support, potential for quick access | Limited selection |

| Online Retailers | Wide variety, competitive pricing | Shipping time, risk of counterfeit |

Maintenance Tips for Longevity

Proper upkeep is essential for extending the lifespan of your equipment and ensuring optimal performance. Regular maintenance not only prevents unexpected breakdowns but also enhances efficiency and reliability. By following a few simple practices, you can keep your tools in top condition for years to come.

| Tip | Description |

|---|---|

| Regular Cleaning | Remove dust and debris after each use to prevent buildup that can affect performance. |

| Lubrication | Apply appropriate lubricants to moving parts to reduce friction and wear. |

| Check for Wear | Inspect components regularly for signs of damage or wear and replace them as needed. |

| Storage | Store equipment in a dry, cool place to prevent corrosion and deterioration. |

| Follow Manufacturer Guidelines | Refer to the manufacturer’s recommendations for maintenance schedules and procedures. |

By implementing these practices, you can ensure your tools remain functional and reliable, minimizing costly repairs and maximizing efficiency in your projects.