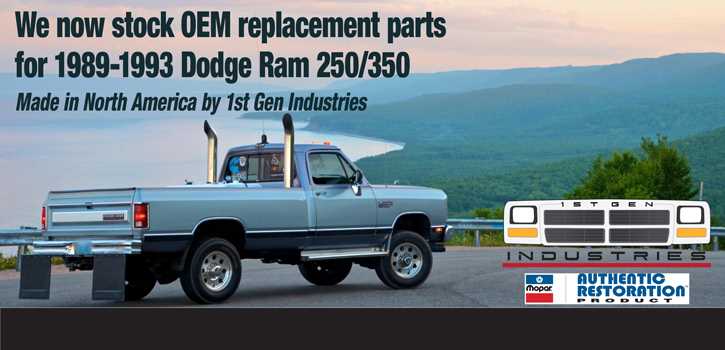

Understanding the OEM Parts Diagram for Dodge Ram Body Components

When it comes to maintaining and repairing your vehicle, having a clear understanding of its structure is essential. Each section plays a crucial role in the overall functionality and safety of the machine. By familiarizing yourself with the various elements and their arrangements, you can better appreciate how they work together to create a seamless driving experience.

The intricate layout of a vehicle includes numerous segments that require careful attention during any service or upgrade. Knowing the position and relationship of each section can significantly ease the process of replacing or modifying specific features. This knowledge empowers owners and enthusiasts alike to approach maintenance tasks with confidence.

In this guide, we will explore the various components and their placements, providing you with valuable insights into their functions and importance. By the end, you will have a clearer vision of how to effectively address any issues that may arise, ensuring your vehicle remains in optimal condition.

This section aims to provide insights into original components that are essential for maintaining vehicle integrity. Understanding the significance of these elements is crucial for enthusiasts and professionals alike, as it can influence performance, safety, and overall functionality.

The Importance of Original Components

Utilizing authentic elements ensures that the vehicle operates as intended by the manufacturer. These components are designed to fit perfectly and meet strict quality standards, contributing to the vehicle’s longevity and reliability. They play a vital role in preserving the value of the vehicle and enhancing its performance on the road.

Key Characteristics of Authentic Components

Identifying genuine elements involves recognizing specific traits that differentiate them from aftermarket alternatives. The following table outlines some distinguishing features:

| Feature | Description |

|---|---|

| Quality Assurance | Manufactured under strict guidelines, ensuring durability and reliability. |

| Perfect Fit | Engineered to match exact specifications, providing seamless installation. |

| Warranty Coverage | Often backed by a warranty, offering peace of mind to the buyer. |

| Enhanced Performance | Designed to work optimally with other components for superior functionality. |

Importance of OEM Components in Vehicles

Utilizing original components in automobiles plays a crucial role in ensuring optimal performance and reliability. These elements are designed specifically for each model, guaranteeing a perfect fit and function. Relying on these specialized parts helps maintain the integrity of the vehicle, allowing for a safer and smoother driving experience.

Here are some key advantages of using these components:

- Quality Assurance: Original components are manufactured to meet stringent industry standards, ensuring durability and longevity.

- Perfect Fit: Each component is tailored to match the specific requirements of the vehicle, reducing the risk of malfunction.

- Manufacturer Support: Original components often come with warranties, providing peace of mind in case of defects.

- Enhanced Performance: Utilizing these specialized components can improve the overall efficiency and functionality of the vehicle.

In conclusion, the use of original components is vital for maintaining a vehicle’s performance, safety, and longevity. Making informed choices regarding the components can lead to significant benefits in the long run.

Common Issues with Aftermarket Parts

Using alternative components for vehicle repair can lead to several challenges that owners should consider. While these replacements often come at a lower cost, they may not always match the quality or performance of original equivalents. This section highlights some frequent complications associated with utilizing such alternatives.

Quality and Fitment Concerns

One of the primary issues with substitute components is inconsistency in quality and fit. Unlike genuine products, which are manufactured to specific standards, replacements may vary greatly. This can lead to difficulties during installation and potential functional problems down the line.

Durability and Longevity

Another significant drawback is the longevity of these alternatives. Many substitutes are made from inferior materials, which can result in quicker wear and tear. This not only affects the reliability of the vehicle but may also lead to increased repair costs over time.

| Issue | Description |

|---|---|

| Quality Variability | Substitute components may not meet the same standards as original ones, affecting performance. |

| Poor Fit | Incompatibility can lead to installation difficulties and require modifications. |

| Shortened Lifespan | Inferior materials often lead to quicker degradation and the need for premature replacement. |

| Increased Repair Costs | Potential for higher long-term expenses due to frequent replacements and repairs. |

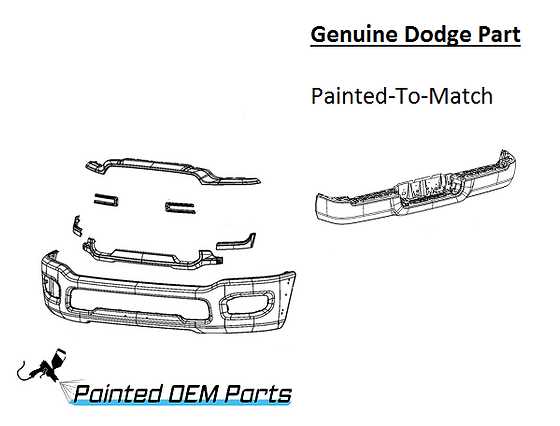

Benefits of Using Genuine Dodge Parts

Utilizing authentic components for vehicle repairs offers numerous advantages that enhance performance and longevity. These elements are designed specifically for particular models, ensuring optimal functionality and compatibility. This commitment to quality translates into a smoother driving experience and increased reliability on the road.

Quality Assurance

When opting for genuine components, you are guaranteed to receive high-quality materials that meet stringent manufacturing standards. This commitment to excellence minimizes the likelihood of premature wear and tear, ensuring that your vehicle operates efficiently over time.

Perfect Fit and Compatibility

Authentic components are engineered to fit seamlessly within your vehicle’s systems, reducing the chances of installation errors. This compatibility not only streamlines the repair process but also ensures that all parts work harmoniously, enhancing overall performance.

| Benefit | Description |

|---|---|

| Durability | Genuine components are built to last, reducing the need for frequent replacements. |

| Warranty | Most authentic components come with a manufacturer warranty, offering peace of mind. |

| Resale Value | Vehicles maintained with authentic components often retain a higher resale value. |

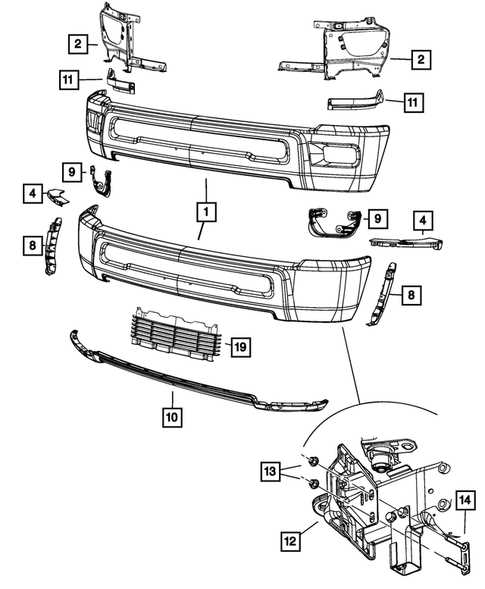

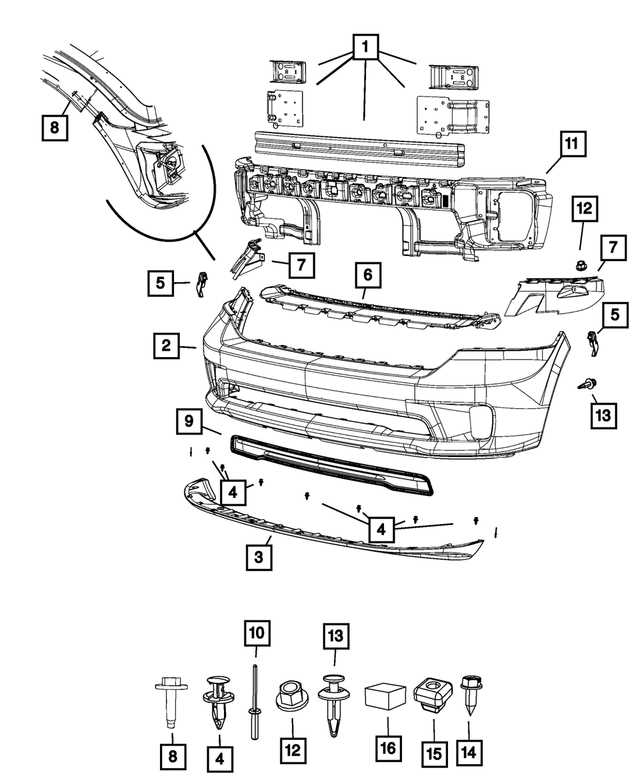

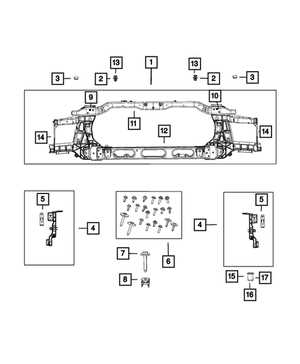

Key Components in Dodge Ram Body

This section explores the essential elements that contribute to the overall structure and functionality of the vehicle’s exterior. Understanding these crucial components can aid in maintenance and repair, enhancing performance and safety.

Main Structural Elements

- Chassis: The main framework that supports the entire structure and houses various components.

- Fenders: These protect the wheels and enhance the vehicle’s aerodynamics.

- Hood: Provides access to the engine compartment while contributing to the aesthetic appeal.

- Doors: Facilitate entry and exit while providing insulation and protection.

- Roof: Offers structural integrity and shelter from environmental elements.

Functional Components

- Bumpers: Designed to absorb impact and protect the vehicle during minor collisions.

- Grilles: Allow airflow to the engine while adding to the vehicle’s styling.

- Windows: Provide visibility and protection from the elements.

- Lighting Systems: Enhance visibility during low-light conditions, improving safety.

- Side Mirrors: Offer essential rear visibility, crucial for safe maneuvers.

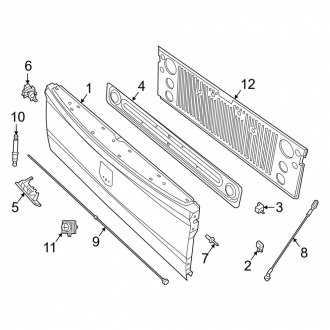

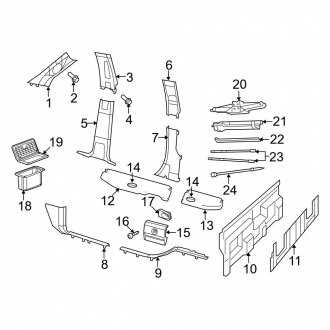

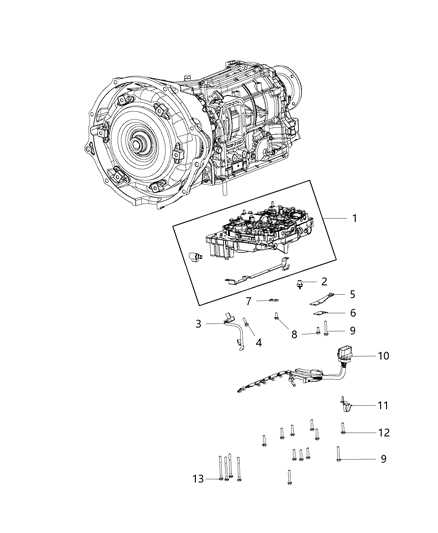

How to Read OEM Diagrams Effectively

Understanding technical illustrations can significantly enhance your ability to identify components and their functions within a complex system. These visual guides provide a clear representation of various elements, allowing for easier navigation and comprehension of intricate layouts. By mastering the art of interpreting these visuals, you can streamline the maintenance and repair processes.

To maximize your understanding of these illustrations, consider the following strategies:

| Tip | Description |

|---|---|

| Familiarize Yourself with Symbols | Many illustrations utilize standard symbols to represent specific components. Learning these can help you quickly identify parts. |

| Follow the Legend | Legends typically accompany these visuals, providing essential information about the symbols and lines used. Always reference this guide to clarify any confusion. |

| Examine Connections | Pay attention to how components are connected. This will help you understand their relationships and functionalities within the overall system. |

| Use a Reference Tool | Having a reliable reference tool, such as a service manual, can provide additional context and details about each component depicted in the illustration. |

| Practice Regularly | Regularly reviewing and analyzing these visuals will improve your skills over time, making it easier to interpret them in the future. |

Identifying Parts Using Diagram References

Understanding how to locate components through visual guides is essential for efficient maintenance and repairs. These references provide a clear representation of the assembly, allowing users to navigate and recognize each element’s specific location and function.

To begin with, familiarizing oneself with the layout of the visual guide is crucial. Each section typically includes labeled areas that correspond to different functionalities or segments of the system. By studying these sections, one can quickly pinpoint where specific elements are situated, enhancing the overall efficiency of the identification process.

Moreover, cross-referencing the visual guide with a comprehensive list of specifications can provide deeper insights into the characteristics and compatibility of the components. This approach ensures that users can make informed decisions when selecting replacements or upgrades, ultimately leading to a more seamless repair experience.

In addition, employing this method can also aid in troubleshooting issues. By understanding where each element resides within the assembly, identifying potential points of failure becomes more straightforward. This knowledge empowers users to approach repairs methodically, reducing the likelihood of errors and ensuring optimal performance.

Maintenance Tips for Dodge Ram Owners

Proper upkeep is essential for ensuring longevity and reliability of your vehicle. Regular care not only enhances performance but also helps in identifying potential issues before they escalate into costly repairs. Here are some valuable suggestions for maintaining your truck in optimal condition.

Regular Inspections

Conducting routine checks on various components of your vehicle can prevent unexpected breakdowns. Focus on crucial areas such as fluid levels, tire pressure, and brake functionality. Early detection of wear can save time and money in the long run.

Scheduled Maintenance

Adhering to a scheduled maintenance plan is vital for vehicle performance. Follow the manufacturer’s recommendations for oil changes, filter replacements, and other necessary services. Keeping accurate records of maintenance performed can also help in assessing the overall health of your vehicle.

| Service Item | Frequency | Notes |

|---|---|---|

| Oil Change | Every 5,000 miles | Use recommended oil type |

| Tire Rotation | Every 6,000 miles | Check for uneven wear |

| Brake Inspection | Every 10,000 miles | Replace pads as needed |

Where to Find OEM Parts Diagrams

Locating detailed schematics for vehicle components is essential for accurate repairs and maintenance. Understanding how various elements fit together can simplify the process of finding suitable replacements. Here are some reliable sources for obtaining these vital illustrations.

- Manufacturer Websites: Many automotive manufacturers provide online resources where users can access detailed illustrations of various components specific to their vehicle models.

- Authorized Dealers: Visiting or contacting a certified dealer can yield access to official documentation, including comprehensive drawings and specifications.

- Online Forums: Enthusiast communities often share valuable resources, including links to helpful schematics and personal insights on where to find them.

- Repair Manuals: Purchasing or downloading repair manuals, such as those from reputable publishers, can provide detailed visuals along with step-by-step instructions.

- Parts Retailers: Many online retailers specializing in vehicle components offer detailed images and diagrams alongside their product listings, assisting in proper identification.

Utilizing these resources can streamline the process of sourcing the correct components and ensure successful repairs.

Cost Comparison: OEM vs. Aftermarket

When it comes to vehicle components, consumers often face a decision between original manufacturer offerings and alternatives from other suppliers. Understanding the financial implications of these choices is crucial for informed purchasing. This section explores the cost differences and potential long-term value between these two categories of offerings.

| Category | Average Cost | Warranty | Availability |

|---|---|---|---|

| Original Manufacturer | $100 – $500 | 1-3 years | Limited |

| Alternative Supplier | $50 – $300 | Varies | Widely Available |

The table above highlights typical pricing, warranty options, and availability for each type. While original offerings may come with higher costs and limited accessibility, they often provide assurance regarding compatibility and quality. In contrast, alternative components can be more affordable and easier to find but may vary significantly in terms of durability and support. Balancing immediate expenses against potential future repairs is essential for making

Ensuring Proper Installation of Parts

Achieving a successful assembly process is crucial for the functionality and longevity of any vehicle. This section will explore key considerations to guarantee that every component is correctly positioned and secured, which ultimately enhances performance and safety.

Verification of Compatibility

Before proceeding with the installation, it is essential to confirm that each item is suitable for the specific model. Checking specifications and utilizing compatible alternatives can prevent issues that arise from mismatched elements. Always refer to the manufacturer’s guidelines for recommendations.

Follow Proper Techniques

Utilizing appropriate methods during the assembly phase is vital. Ensure that all connections are firm but not excessively tight, as this can cause damage. Employ tools that are designed for the task at hand to facilitate a seamless integration process. Regularly inspect the assembly to identify any potential discrepancies that may require adjustments.