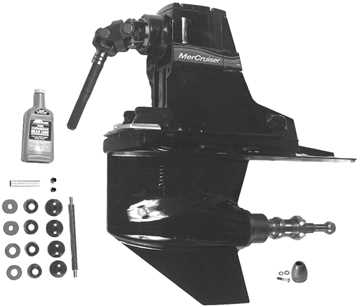

Mercruiser Bravo 3 Outdrive Parts Diagram Overview

When it comes to the intricate world of marine propulsion, having a solid grasp of the various elements involved is crucial. This section aims to illuminate the essential components that contribute to the overall efficiency and performance of marine drive systems. By breaking down each segment, boat owners and enthusiasts can enhance their understanding and maintenance skills.

Every system is a sum of its parts, and this is especially true for marine drives. Each component plays a vital role in ensuring smooth operation, from the transmission elements to the propelling mechanisms. By exploring these parts, individuals can better appreciate the engineering that allows vessels to navigate waters effectively.

Furthermore, the ability to visualize how these elements interact offers an ultimate advantage when troubleshooting or performing maintenance. Whether you are a seasoned sailor or a newcomer to boating, understanding these fundamentals can elevate your experience on the water.

Understanding Mercruiser Bravo 3 Outdrive

The advanced propulsion system discussed here plays a crucial role in enhancing the performance and efficiency of marine vessels. This intricate assembly is designed to transmit power from the engine to the propellers, ensuring smooth navigation and optimal thrust. A comprehensive understanding of its components and functions is essential for maintaining the overall integrity and functionality of the watercraft.

Key Features: This system is characterized by its dual-propeller configuration, which significantly improves grip and reduces cavitation. The innovative design allows for better control and stability, especially during challenging maneuvers.

Maintenance Considerations: Regular inspections and servicing are vital to ensure longevity and prevent potential issues. Understanding the assembly’s various elements helps in identifying wear and tear early, enabling timely interventions.

Conclusion: Familiarity with this propulsion mechanism not only aids in enhancing performance but also fosters a deeper appreciation for marine engineering. Whether for recreational boating or professional applications, knowledge of its operation is invaluable for any vessel owner.

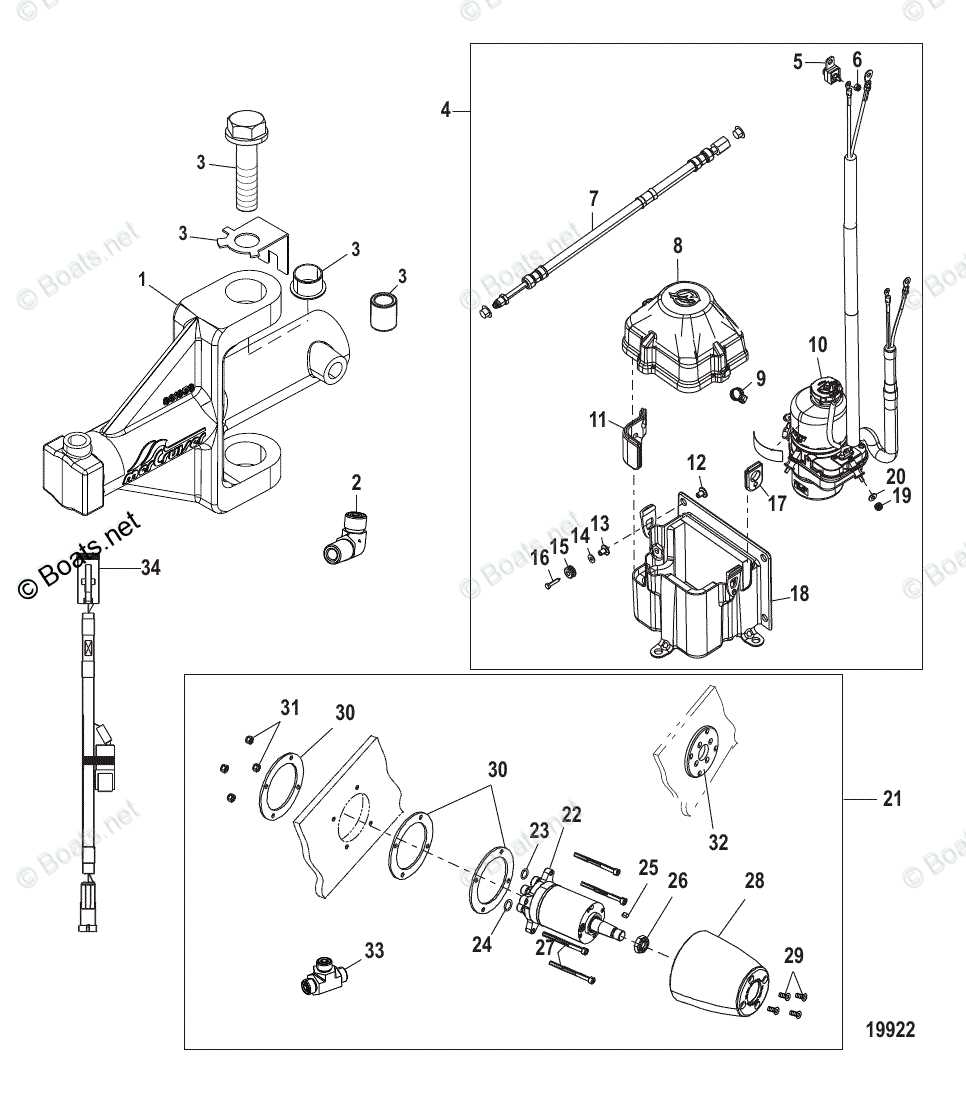

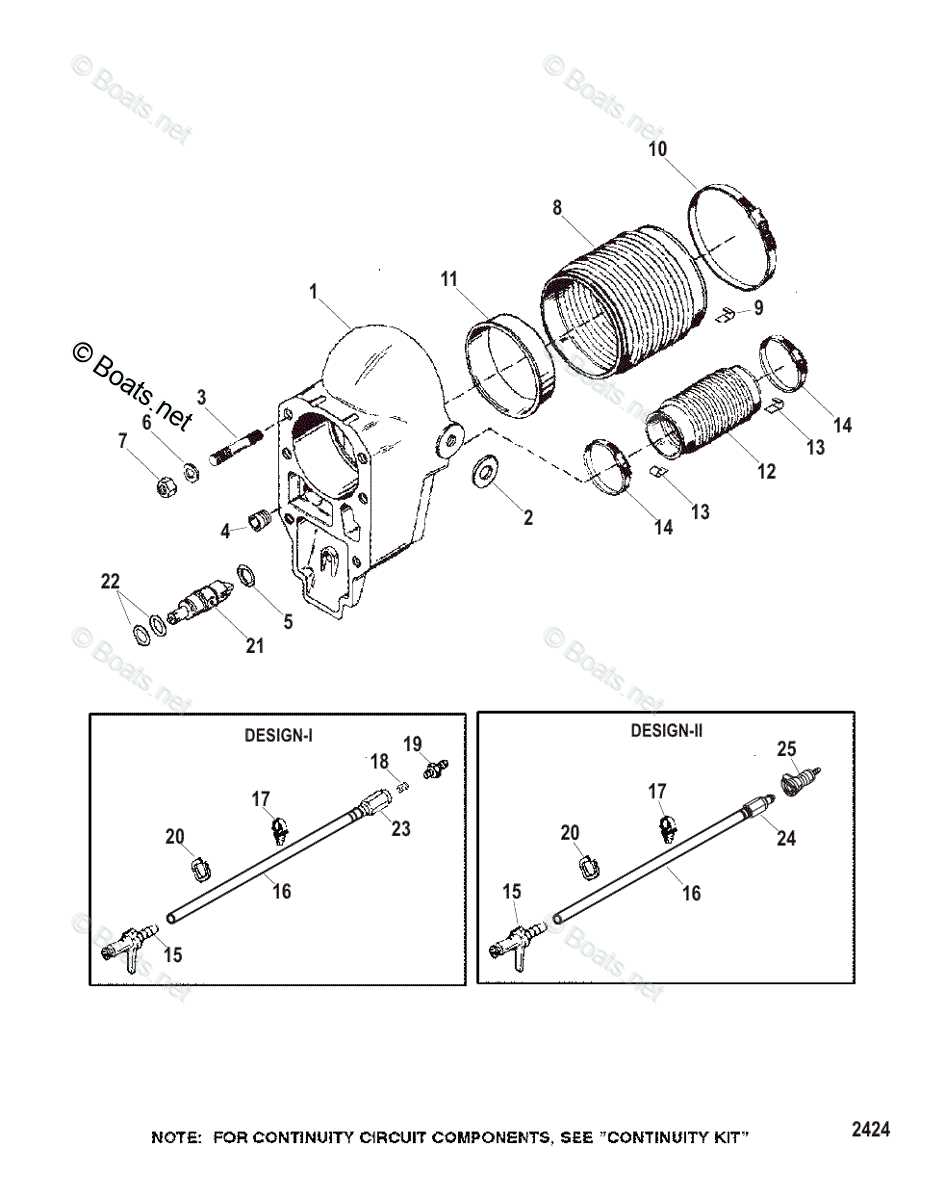

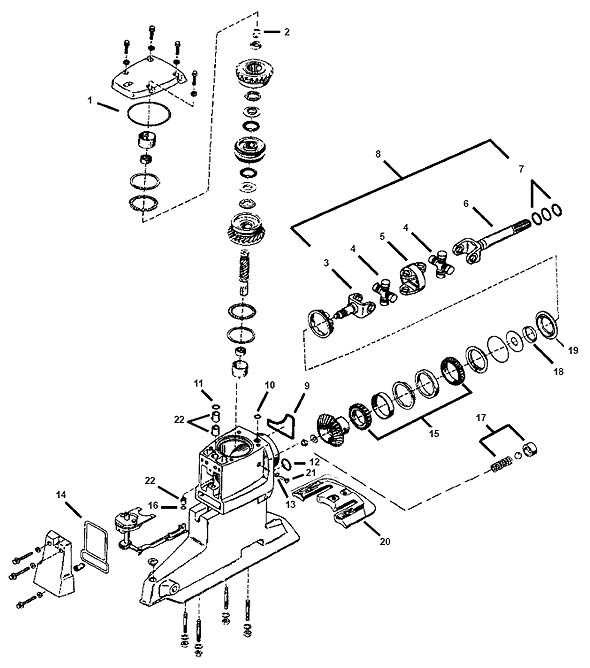

Key Components of Bravo 3 Outdrive

Understanding the essential elements of a propulsion system is crucial for maintenance and performance optimization. Each component plays a significant role in ensuring efficient operation, reliability, and overall effectiveness on the water.

Primary Elements

- Gearcase: The housing that contains the gears responsible for transferring power from the engine to the propellers.

- Propeller: The rotating blades that generate thrust, crucial for maneuverability and speed.

- Drive Shaft: A critical component that transmits power from the engine to the gearcase.

- Universal Joint: Allows for flexibility and movement, accommodating the angle between the engine and the drive unit.

Supporting Components

- Trim Tab: Helps to control the lateral balance and stability of the vessel.

- Seal Kits: Essential for preventing leaks and ensuring proper lubrication within the system.

- Mounting Bracket: Provides secure attachment to the hull, allowing for stability and support during operation.

- Cooling System: Ensures optimal temperature control, preventing overheating during extended use.

Importance of Accurate Parts Diagrams

Having precise illustrations of components is crucial for efficient maintenance and repair. These visuals serve as essential tools for understanding assembly and disassembly processes, ensuring that every element is accounted for. When technicians can easily identify and locate each piece, the risk of errors diminishes significantly, leading to improved functionality and safety.

Enhancing Repair Efficiency

Accurate representations streamline the repair process, allowing professionals to quickly diagnose issues and find solutions. With clear visuals, they can effectively plan their actions, minimizing downtime and enhancing overall productivity. This efficiency not only saves time but also reduces costs associated with prolonged repairs.

Ensuring Component Compatibility

Correct illustrations aid in verifying the compatibility of different elements. This is vital in preventing mismatched parts that could lead to operational failures. By consulting reliable visuals, users can make informed decisions, ensuring that each component fits seamlessly within the larger system.

Common Issues with Bravo 3 Outdrive

Understanding the typical challenges faced by marine propulsion systems is essential for maintaining optimal performance. Many users experience specific complications that can hinder efficiency and lead to costly repairs. Identifying these issues early can prevent further damage and ensure a smoother experience on the water.

One prevalent problem is corrosion, which can affect various components, especially in saltwater environments. Regular inspections and protective coatings can mitigate this risk.

Another frequent concern involves gear shifting difficulties. This may stem from misalignment or low fluid levels, which require immediate attention to maintain functionality.

Overheating is also a critical issue, often caused by clogged cooling passages or insufficient fluid circulation. Ensuring clean and clear systems is vital for preventing severe engine damage.

Lastly, vibration issues can indicate problems with propeller balance or shaft alignment, necessitating professional evaluation to restore smooth operation.

Maintenance Tips for Outdrive Longevity

Ensuring the durability of marine propulsion systems requires consistent care and attention. Regular maintenance not only enhances performance but also extends the lifespan of vital components. By implementing a few essential practices, boat owners can significantly reduce the likelihood of costly repairs and downtime.

Regular Inspections: Conduct thorough assessments of the system before and after each season. Look for signs of wear, corrosion, or damage. Early detection of issues can prevent more extensive problems down the line.

Fluid Changes: Keep the hydraulic fluids clean and replace them according to the manufacturer’s guidelines. Contaminated fluids can lead to inefficient operation and potential failure.

Seal Checks: Inspect seals and gaskets for leaks and deterioration. Replacing these components promptly can prevent water ingress, which is crucial for maintaining functionality.

Cleaning: Regularly clean the exterior surfaces to remove salt, grime, and debris. A clean system not only looks better but also helps in identifying any potential issues more easily.

Storage Practices: When not in use, ensure that the unit is stored in a dry, protected environment. Utilizing proper covers can shield against environmental elements, which can cause damage over time.

Professional Servicing: Schedule routine professional inspections. Experienced technicians can identify potential problems that may not be evident to the untrained eye, ensuring your system remains in peak condition.

By following these guidelines, boat owners can enjoy smoother operations and enhance the reliability of their marine equipment for years to come.

How to Identify Outdrive Parts

Understanding the components of a marine propulsion system is essential for maintenance and repair. Each element plays a crucial role in the overall functionality and performance, and recognizing them can greatly enhance troubleshooting efforts.

Visual Inspection Techniques

Start by examining the exterior for any visible markings or serial numbers. These identifiers can often lead you to specific details about the component’s model and compatibility. Pay attention to wear signs, as they can indicate the need for replacement or servicing.

Consulting Reference Materials

Utilize manuals and online resources that provide comprehensive illustrations and descriptions. Such references can help you match visual cues to their respective components, ensuring you have the ultimate understanding necessary for effective repairs.

Where to Find Parts Diagrams

Locating detailed schematics for various marine equipment is essential for effective maintenance and repair. These illustrations help users understand component relationships and functions, ensuring accurate replacements and assembly.

Online Resources

Numerous websites offer extensive libraries of technical drawings. Searching specific brands or models on these platforms can yield valuable information for both novice and experienced users.

Local Dealers and Repair Shops

Authorized retailers and service centers often provide access to manufacturer resources. Consulting with professionals can also lead to recommendations for reliable sources.

| Source Type | Description |

|---|---|

| Manufacturer Websites | Official sites usually host downloadable resources. |

| Online Forums | Communities can share diagrams and tips. |

| Repair Manuals | Printed or digital manuals contain essential information. |

Benefits of Using OEM Parts

Utilizing original equipment manufacturer components offers numerous advantages that enhance both performance and longevity of marine systems. These components are specifically designed to meet the exact specifications of the equipment, ensuring optimal compatibility and functionality.

One significant benefit is the assurance of quality. OEM components are produced under stringent quality control measures, guaranteeing that each piece meets high standards. This reliability helps to minimize the risk of failures and reduces the need for frequent replacements.

Additionally, using original components often results in better overall performance. Because they are engineered to fit seamlessly with existing systems, they contribute to improved efficiency and effectiveness. This can lead to enhanced fuel economy and superior handling on the water.

Another important aspect is the warranty and support that typically accompany OEM items. Manufacturers often provide warranties that cover defects, offering peace of mind to users. In case of any issues, customers can easily access manufacturer support, ensuring prompt resolutions.

Lastly, investing in original components can enhance resale value. Equipment maintained with genuine parts tends to attract buyers looking for reliability and quality, making it a smart choice for those considering future sales.

Upgrading Your Bravo 3 Outdrive

Enhancing your marine propulsion system can lead to improved performance, efficiency, and longevity. This section will explore various strategies to elevate your equipment, ensuring optimal operation on the water.

Key Benefits of Upgrading

- Increased speed and acceleration

- Enhanced fuel efficiency

- Improved handling and stability

- Greater durability and reduced wear

Considerations for Improvement

- Evaluate your current setup and identify weaknesses.

- Research compatible enhancements that align with your goals.

- Consult with professionals for expert recommendations.

- Prioritize quality components for lasting results.

Tools Needed for Outdrive Repairs

Effective maintenance and repair of marine propulsion systems require a well-equipped toolkit. Having the right instruments not only ensures a smoother repair process but also enhances safety and efficiency. Understanding which tools are essential can make a significant difference in the quality of the work performed.

Essential Hand Tools

Start with basic hand tools, such as wrenches, screwdrivers, and pliers. These are vital for disassembling and reassembling various components. Additionally, a torque wrench is crucial for applying the correct amount of force when securing bolts, preventing potential damage from over-tightening.

Specialized Equipment

For more advanced tasks, specialized equipment is necessary. A gear puller is essential for removing stubborn components without causing damage. A seal installer can ensure that new seals are fitted correctly, preventing leaks. Furthermore, having a multimeter can help diagnose electrical issues efficiently.

Cost Factors for Replacement Parts

When it comes to acquiring components for marine propulsion systems, several key elements influence pricing. Understanding these factors can help in budgeting and making informed decisions regarding replacements.

| Factor | Description |

|---|---|

| Material Quality | Higher-grade materials typically increase durability but come at a premium cost. |

| Brand Reputation | Renowned manufacturers often charge more due to their established reliability and performance. |

| Market Demand | Fluctuations in supply and demand can lead to price variations over time. |

| Compatibility | Specific designs for particular vessels may command higher prices due to limited availability. |

| Distribution Costs | Shipping and handling fees can contribute significantly to the overall expense of components. |

FAQs About Bravo 3 Outdrive Maintenance

This section addresses common inquiries related to the upkeep of marine propulsion systems, aiming to enhance understanding and ensure optimal performance. Proper maintenance is crucial for longevity and efficiency, making it essential for boat owners to stay informed.

| Question | Answer |

|---|---|

| How often should I change the lubricant? | It is recommended to change the lubricant at least once a season or every 100 hours of operation. |

| What are signs of wear on components? | Look for unusual noises, vibrations, or fluid leaks as indicators of potential issues. |

| Can I perform maintenance myself? | Yes, many tasks can be done by owners, but consulting a professional for complex repairs is advisable. |

| How do I winterize my system? | Drain fluids, add antifreeze, and check for any corrosion or damage to protect your system during cold months. |

| What is the ultimate way to extend the lifespan? | Regular inspections, timely repairs, and adhering to manufacturer guidelines will significantly extend the lifespan. |