Comprehensive Guide to Echo CS 400 Parts Diagram

When it comes to maintaining and enhancing the efficiency of your machinery, having a clear understanding of its inner workings is essential. Each element plays a pivotal role in ensuring optimal performance, and familiarizing yourself with them can lead to better maintenance practices.

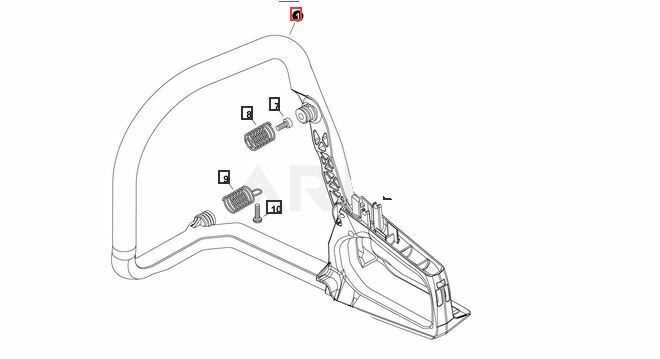

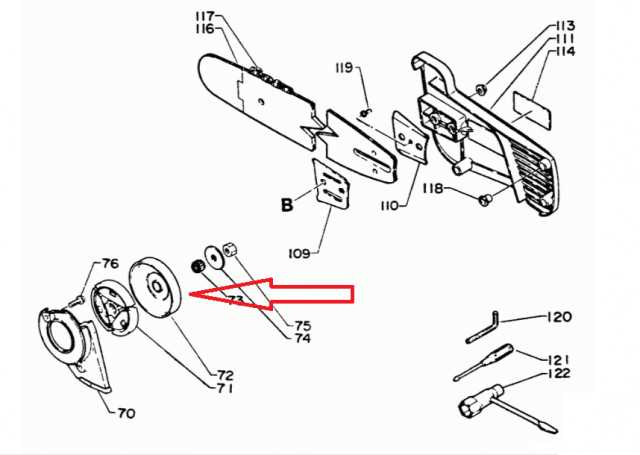

Visual aids can significantly enhance your comprehension of these crucial elements. They allow you to identify and locate various sections and components quickly, facilitating troubleshooting and repair processes.

In this exploration, we will delve into the intricate assembly of your equipment, offering insights into its individual components and their functions. By grasping these details, you can achieve the ultimate efficiency and longevity of your tools.

Understanding Echo CS 400 Components

Exploring the various elements of a chainsaw reveals the intricate design that enhances performance and durability. Each component plays a crucial role in ensuring efficient operation and user safety. Recognizing how these parts work together can significantly improve maintenance and troubleshooting efforts.

- Power Unit: The heart of the machine, responsible for generating the necessary force to drive the cutting mechanism.

- Cutting Bar: This elongated blade is vital for guiding the saw through wood, affecting both precision and speed.

- Chain: A series of sharp links that facilitate the actual cutting process, its tension and sharpness are critical for effective operation.

- Handle Assembly: Designed for comfort and control, it allows the user to maneuver the saw safely during operation.

- Fuel System: Responsible for powering the engine, it includes components for fuel delivery and mixing.

- Safety Features: These include mechanisms such as chain brakes and guards, ensuring user protection against accidents.

Understanding each of these elements not only aids in effective usage but also enhances the longevity of the tool through informed care and maintenance practices.

Importance of Parts Diagrams

Visual representations of component arrangements are crucial in various fields, offering clarity and understanding for maintenance and assembly processes. These illustrations serve as invaluable resources for technicians and enthusiasts alike, facilitating effective repairs and enhancing user comprehension of complex machinery.

Enhanced Understanding: Detailed illustrations allow users to quickly grasp the structure and function of individual components. This understanding is vital for diagnosing issues and ensuring proper reassembly after repairs.

Streamlined Repairs: Access to comprehensive visual guides simplifies the repair process. Users can easily identify specific elements, reducing the risk of mistakes and ensuring that every part is correctly addressed during maintenance.

Time Efficiency: Clear graphical depictions save time by eliminating the need for extensive descriptions. Technicians can reference these visuals quickly, leading to faster troubleshooting and resolution of problems.

Training Aid: For newcomers in the field, these illustrations serve as effective educational tools. They provide a visual framework that complements theoretical knowledge, making it easier to learn about intricate systems.

In conclusion, well-structured visual aids are essential for effective operation, maintenance, and education in technical domains. Their ability to convey information succinctly and clearly enhances both user confidence and overall efficiency.

Common Issues with Echo CS 400

Power tools are essential for various outdoor tasks, but they can sometimes present challenges that users need to address. Understanding frequent problems can enhance maintenance and prolong the lifespan of the equipment. This section highlights some prevalent concerns that users might encounter with their equipment.

Starting Difficulties: One of the most common issues is trouble starting the machine. This can stem from various factors such as fuel quality, spark plug condition, or air filter blockages. Regular checks and maintenance can prevent these issues.

Overheating: Another frequent problem is overheating, which can occur due to improper fuel mixtures or obstructed cooling vents. Ensuring proper airflow and using the correct fuel mixture is crucial for optimal performance.

Performance Degradation: Users often report a decrease in cutting efficiency. This may be linked to dull blades, incorrect tension, or even issues within the engine. Regular sharpening and maintenance of components can mitigate this problem.

Vibration and Noise: Excessive vibration and unusual noise can indicate loose parts or internal wear. It’s essential to inspect bolts and screws regularly to ensure everything is securely fastened.

By being aware of these issues, users can take proactive measures to maintain their equipment, ensuring it remains reliable and effective for all outdoor projects.

Where to Find Diagrams Online

In the digital age, accessing technical illustrations has become remarkably easy. Numerous platforms provide detailed schematics and layouts for various equipment, allowing users to efficiently identify components and understand assembly processes. These resources are invaluable for both professionals and hobbyists who seek to maintain or repair their machinery.

One of the most reliable sources for such resources is manufacturer websites, which often host a wealth of information about their products. Additionally, online forums and community groups dedicated to specific machinery types frequently share user-generated content, including helpful visuals. Another option includes specialized online retailers that offer maintenance guides and technical drawings alongside their product listings.

Moreover, video platforms can serve as a rich source of practical demonstrations, often accompanied by visual aids that enhance understanding. Lastly, digital libraries and educational websites may also feature a range of technical documents, making them excellent places to explore various schematics and layouts.

Identifying Replacement Parts Easily

Understanding how to recognize and locate components for your equipment is essential for maintenance and repair tasks. When you know the various elements involved, you can ensure optimal performance and longevity of your tools. This section provides guidance on simplifying the identification process.

Utilizing Reference Guides

One effective approach is to consult reference manuals or online resources that detail the different elements. These guides typically offer illustrations and descriptions, making it easier to match the required component with its corresponding label. Visual aids can significantly enhance your ability to identify the necessary items.

Organizing Your Tools

Another useful strategy involves keeping your tools organized and categorized. By grouping similar components together, you can quickly locate what you need during repairs. Additionally, using labeled storage can streamline your workflow and minimize downtime, allowing for a more efficient maintenance routine. Effective organization leads to a smoother identification process.

Step-by-Step Repair Guide

This guide provides a systematic approach to troubleshoot and fix common issues encountered with outdoor power equipment. By following each step carefully, you can ensure optimal performance and longevity of your device.

Preparation

- Gather necessary tools: screwdrivers, wrenches, and safety equipment.

- Ensure a clean, well-lit workspace to avoid losing small components.

- Read the manufacturer’s manual for specific instructions and safety guidelines.

Troubleshooting Steps

- Identify the issue by observing the equipment’s performance.

- Disconnect power sources to prevent accidents.

- Examine external components for damage or wear.

- Remove housing to access internal parts if needed.

- Check connections and wiring for signs of failure.

- Replace or repair faulty components, using original or compatible parts.

- Reassemble the device, ensuring all screws and fasteners are secure.

- Test the equipment to confirm the issue has been resolved.

Maintenance Tips for Longevity

Regular upkeep is essential for maximizing the lifespan and performance of your equipment. By implementing simple practices, you can ensure that it operates efficiently and remains in optimal condition over time.

Firstly, always clean the machinery after each use. This helps to prevent dirt and debris from accumulating, which can lead to operational issues. Additionally, regularly check and replace any worn-out components to avoid more significant damage later.

Furthermore, ensure that lubrication is applied where necessary. This reduces friction and wear, contributing to smoother operation. Keeping fuel and oil levels in check is equally vital; use high-quality products to enhance efficiency and performance.

Finally, store your equipment in a dry, sheltered environment to protect it from the elements. A proactive approach to maintenance will not only prolong its life but also improve your overall experience during use.

Tools Needed for Repairs

When undertaking maintenance tasks, having the right instruments is essential for achieving optimal results. The appropriate tools not only facilitate the repair process but also ensure safety and efficiency. Whether you’re performing routine checks or tackling more complex issues, a well-prepared toolkit can make a significant difference.

Essential Instruments

Here are some fundamental instruments you should have on hand:

| Tool | Purpose |

|---|---|

| Screwdriver Set | For loosening or tightening various screws. |

| Wrench Set | To adjust nuts and bolts effectively. |

| Pliers | Useful for gripping and manipulating small components. |

| Socket Set | Ideal for working with fasteners in tighter spaces. |

Safety Gear

Safety should always be a priority when performing repairs. Ensure you have the following gear:

| Gear | Importance |

|---|---|

| Safety Glasses | Protect your eyes from debris and chemicals. |

| Gloves | Shield your hands from sharp objects and chemicals. |

| Mask | Prevent inhalation of harmful dust and fumes. |

Comparing Echo CS 400 Models

This section explores the differences and similarities among various models in a specific series of powerful outdoor tools, focusing on their features, performance, and suitability for different tasks.

- Engine Specifications:

- Power output variations

- Fuel efficiency rates

- Weight and Balance:

- Lightweight options for ease of use

- Weight distribution for optimal handling

- Bar Length:

- Standard sizes available

- Extended versions for larger tasks

- Maintenance Requirements:

- Frequency of tune-ups

- Ease of part replacement

- Accessories Compatibility:

- Available attachments for versatility

- Customization options

By examining these aspects, users can make informed decisions tailored to their specific needs and preferences.

Customer Reviews and Experiences

Understanding user feedback is crucial for anyone considering the purchase of outdoor power tools. Customers often share their insights and stories, providing a comprehensive view of the product’s performance and reliability. These reviews can guide potential buyers in making informed decisions based on real-life experiences.

Many users appreciate the efficiency and effectiveness of these tools in handling various tasks. They often highlight features that enhance usability, such as ergonomic designs and easy-start mechanisms. Feedback frequently emphasizes how these elements contribute to a more enjoyable working experience, allowing users to complete their jobs with less fatigue.

On the other hand, some reviews address common challenges encountered during usage. Issues such as maintenance requirements or occasional mechanical difficulties can surface in discussions. However, many users express satisfaction with customer support, noting how quickly issues are resolved and how helpful the representatives are.

Ultimately, the shared experiences of customers serve as a valuable resource for anyone interested in these products. By weighing the pros and cons highlighted in reviews, potential buyers can gain a clearer perspective on what to expect, ensuring that their investment aligns with their needs and expectations.

Upgrades for Enhanced Performance

Improving the efficiency and power of your equipment can significantly enhance its overall functionality. By focusing on strategic enhancements, you can unlock greater potential and achieve superior results in your tasks. These modifications not only increase performance but also extend the lifespan of your machine.

One of the most effective upgrades involves upgrading the air filtration system. A high-quality filter allows for better airflow and reduces engine strain, ultimately leading to improved power output. Additionally, consider optimizing the spark plug; a premium plug ensures better combustion, contributing to smoother operation and increased fuel efficiency.

Another area for enhancement is the fuel system. Utilizing higher-grade fuel or a fuel additive can provide better performance and cleaner combustion. Furthermore, tuning the carburetor for optimal air-fuel mixture can dramatically impact responsiveness and power delivery.

Finally, don’t overlook the importance of regular maintenance and upgrades to components such as the exhaust system. A more efficient exhaust can reduce back pressure, enhancing engine performance and efficiency. Investing in these upgrades will ultimately lead to a more powerful and reliable machine.

FAQs About Echo CS 400 Parts

This section aims to address common inquiries related to components of a specific model of a chainsaw, helping users understand the essentials for maintenance and repair.

- What should I do if I need to replace a component?

Identify the specific item you need and consult a reliable supplier. Make sure to have your model details ready for accurate assistance.

- How can I tell if a component is worn out?

Look for signs of damage, excessive wear, or decreased performance. Regular inspections can help catch issues early.

- Where can I find a comprehensive list of components?

Check the manufacturer’s website or authorized dealers for detailed inventories. Many resources are available online for specific models.

- Are there compatible alternatives to original components?

Yes, aftermarket options may be available. However, verify compatibility to ensure optimal performance and safety.

- How often should I perform maintenance on these components?

Routine checks are advisable, ideally before each use. Follow the manufacturer’s recommendations for detailed intervals.

- Can I perform repairs myself?

Basic repairs can often be done with the right tools and knowledge. For complex issues, consulting a professional is recommended.