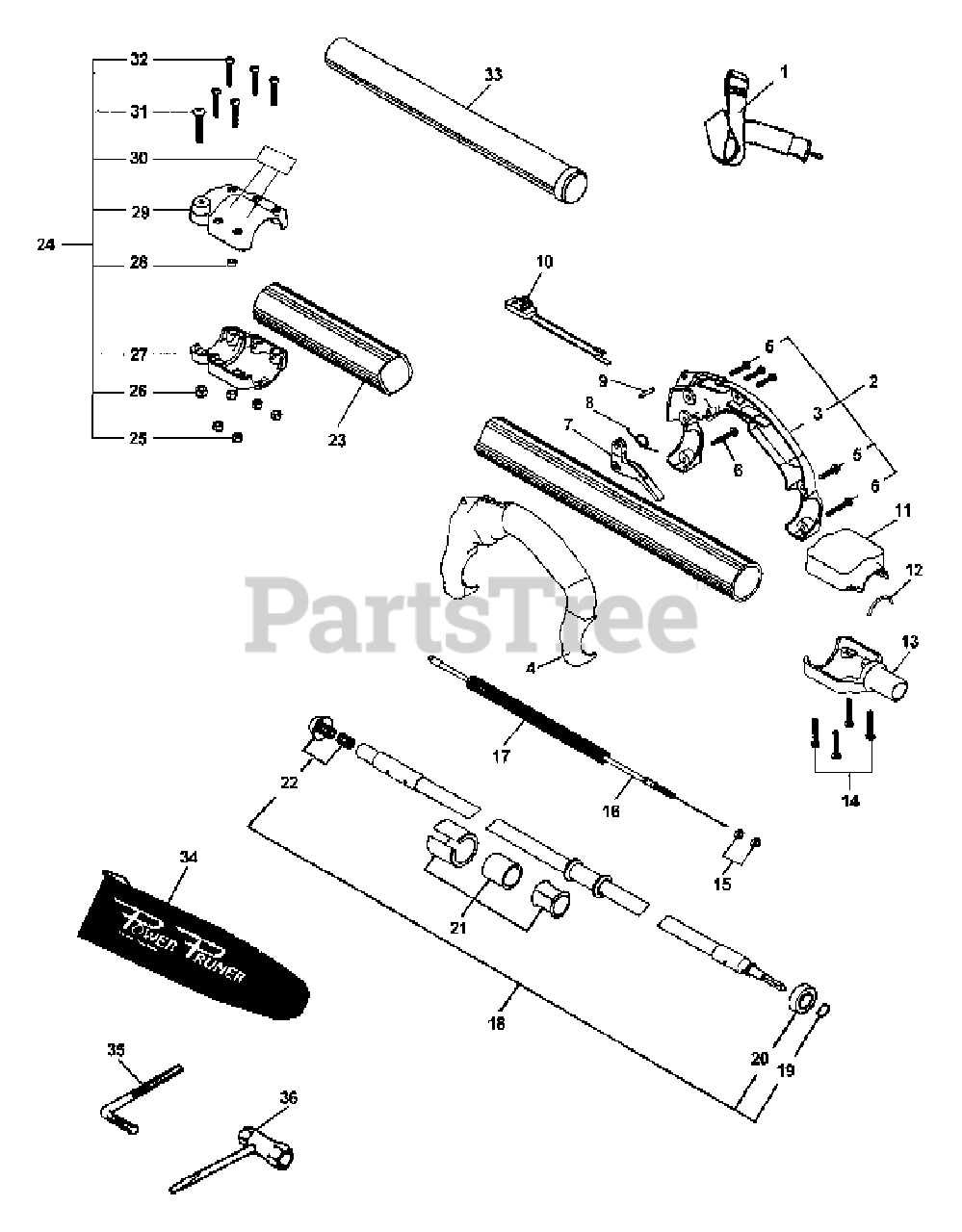

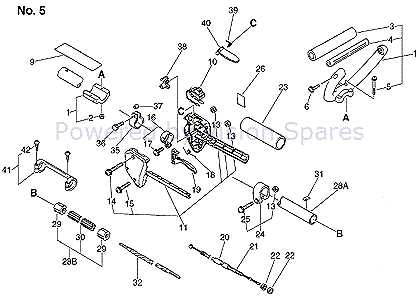

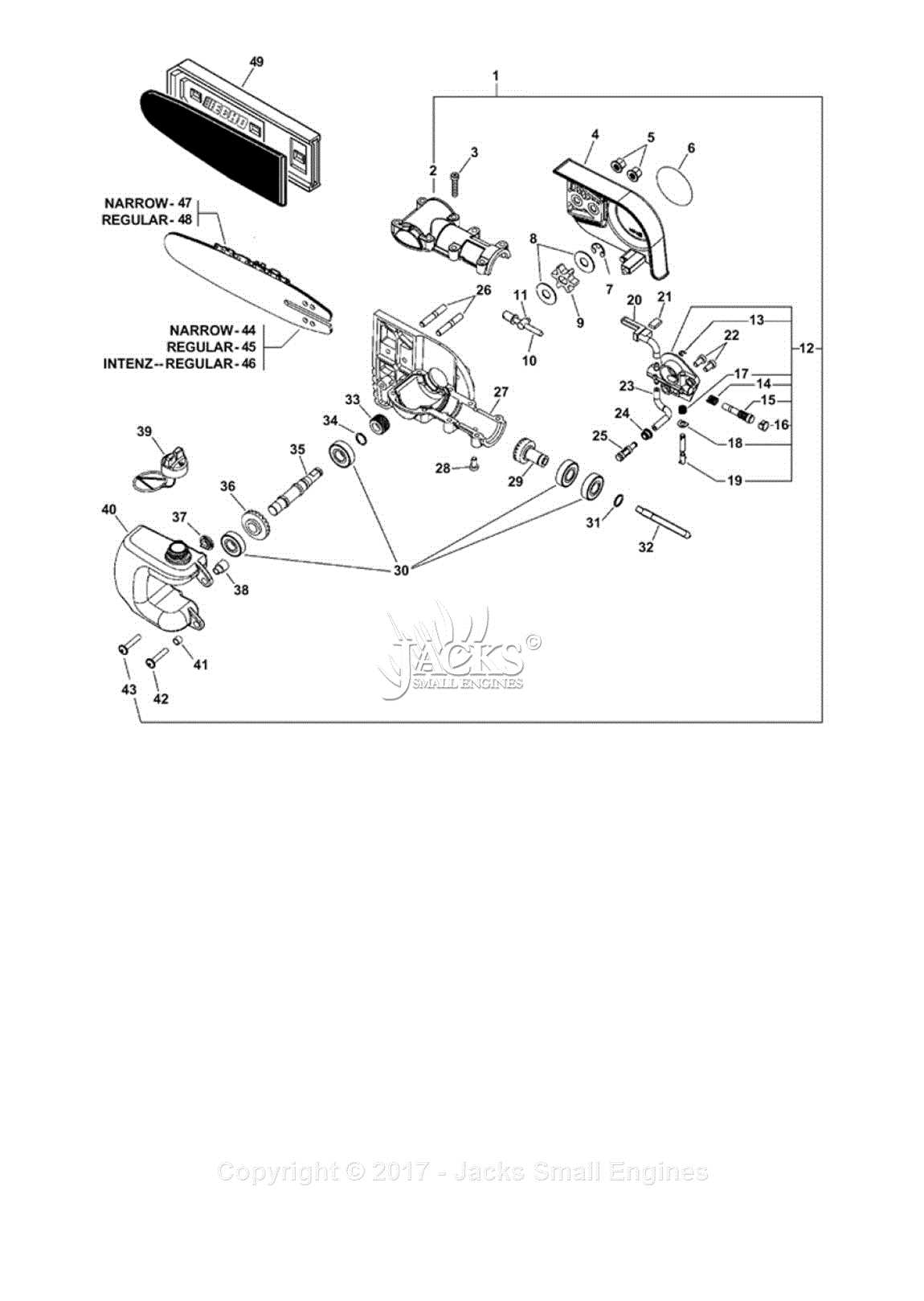

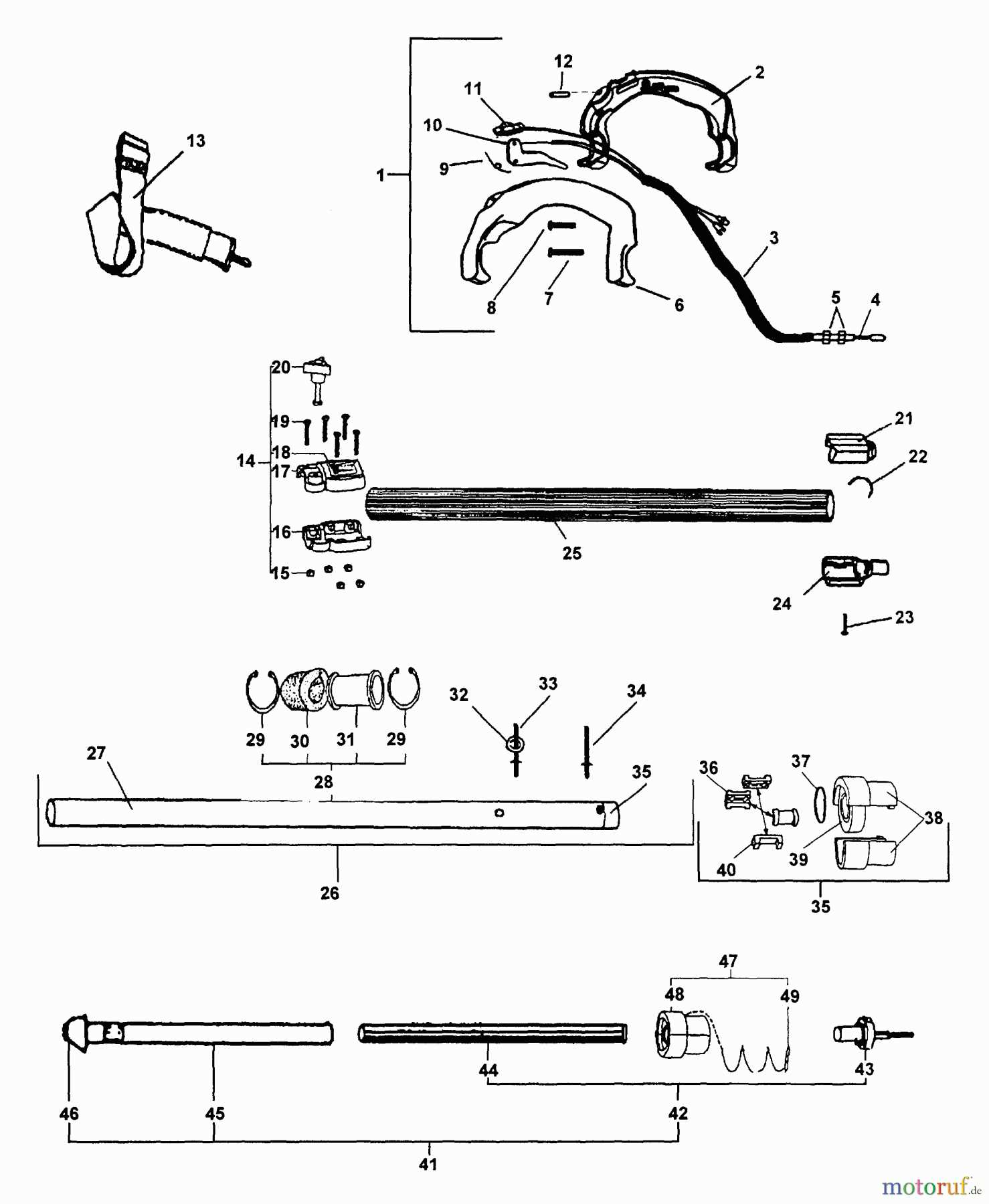

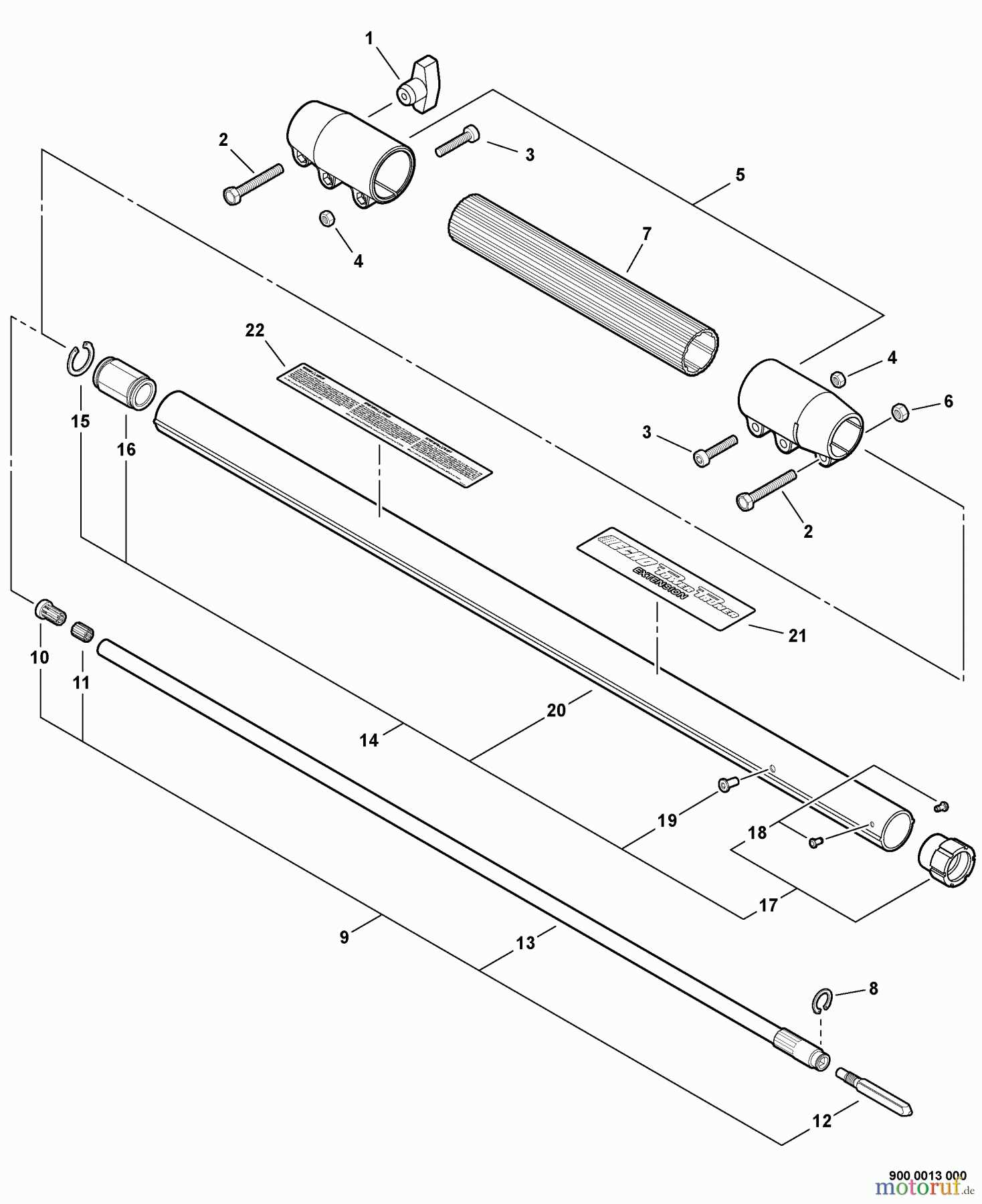

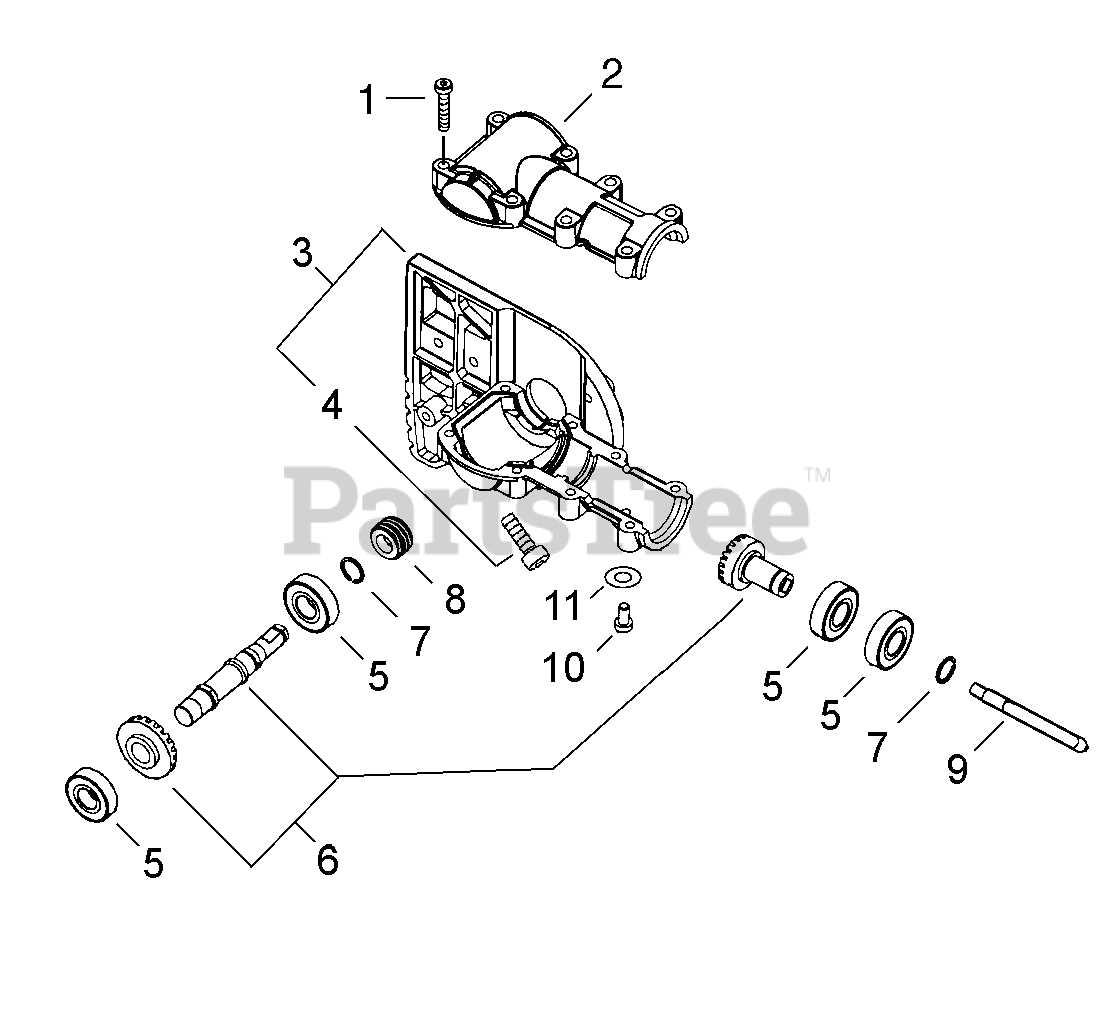

Understanding the Echo PPT-2400 Parts Diagram

When working with complex machinery, a clear visualization of individual elements is essential for effective maintenance and repair. A comprehensive representation of these components helps users identify their roles and interconnections, ultimately leading to a more efficient operation. Such illustrations serve as invaluable tools for both novice and experienced technicians alike.

Delving into the specifics of a particular model reveals a wealth of information that can simplify troubleshooting processes. By examining the intricate layout of various segments, one gains insights into potential failure points and areas that require regular upkeep. This knowledge empowers users to make informed decisions regarding repairs and replacements.

Moreover, understanding the relationship between different elements enhances one’s ability to optimize performance. Familiarity with how each part interacts within the overall system can lead to improved functionality and longevity. Thus, a detailed exploration of these components is not merely academic; it has practical implications for anyone involved in the upkeep of such equipment.

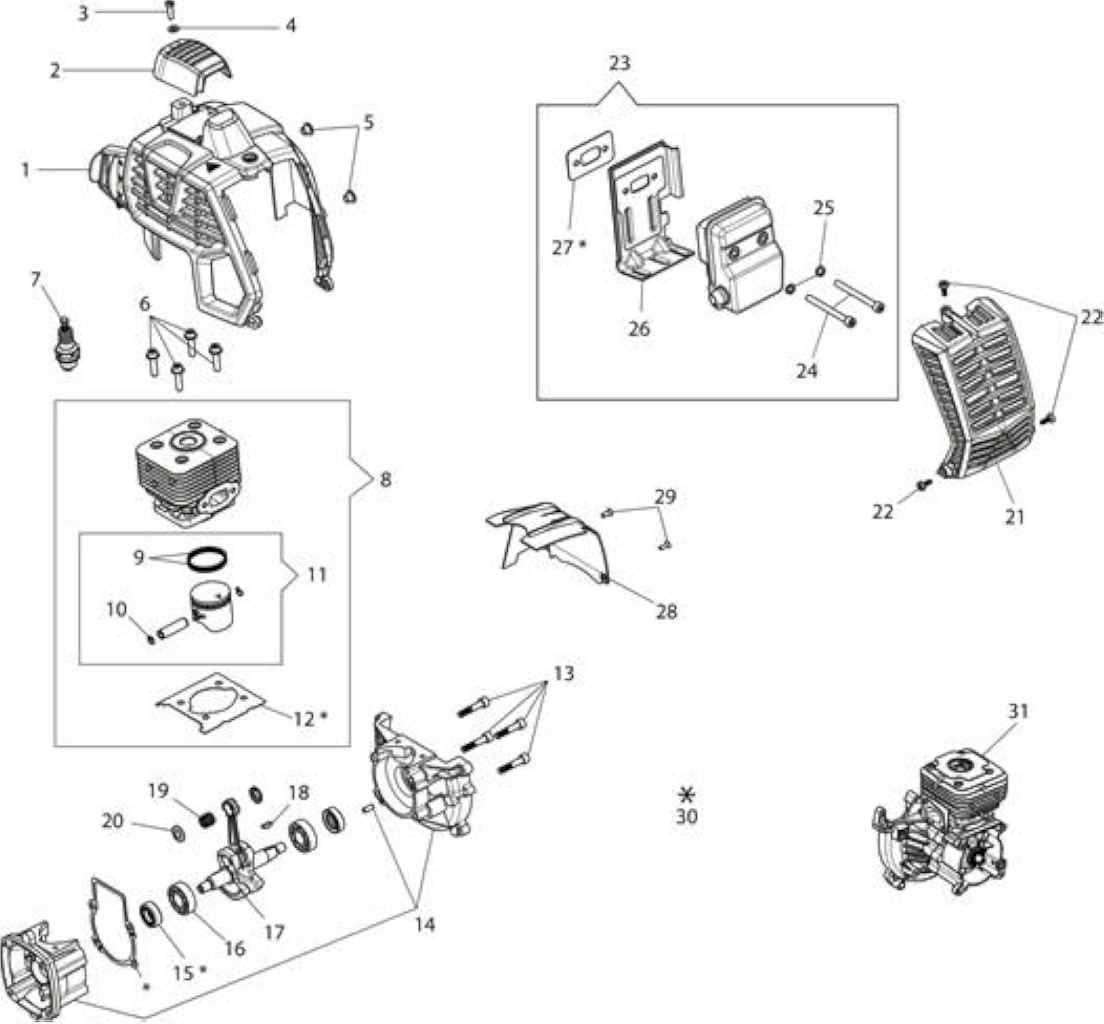

Understanding Echo PPT-2400 Components

In the world of outdoor power equipment, familiarity with various elements is essential for effective operation and maintenance. Each component plays a crucial role in ensuring optimal performance and longevity. This section aims to delve into the essential elements that make up these machines, providing a comprehensive overview of their functions and interrelations.

Key Components and Their Functions

- Engine: The heart of the device, responsible for generating power.

- Fuel System: Manages the supply of fuel, ensuring efficient combustion.

- Ignition System: Initiates the combustion process, critical for starting the engine.

- Cooling Mechanism: Prevents overheating by dissipating heat generated during operation.

- Exhaust System: Channels away harmful gases produced during combustion.

- Chassis: Provides structural support and houses various components.

Importance of Maintenance

Regular upkeep of these individual parts is vital for smooth functionality. Neglecting any element can lead to diminished performance or even complete failure. Here are some maintenance tips:

- Regularly check and replace filters to ensure clean fuel supply.

- Inspect the ignition system for any signs of wear and replace spark plugs as needed.

- Monitor the cooling system to avoid overheating, especially during extensive use.

- Examine the exhaust system for blockages or leaks that could affect performance.

- Ensure the chassis remains free of rust and damage for structural integrity.

By understanding these components and their maintenance needs, users can enhance the reliability and efficiency of their outdoor equipment.

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding and maintaining complex machinery. These illustrations serve as valuable tools for technicians and enthusiasts alike, enabling efficient identification and organization of elements within a device. By breaking down intricate systems into manageable parts, users can more easily grasp the function and interrelationship of each section.

Benefits of Visual Representations

- Enhanced Understanding: Simplifies the comprehension of how different components interact, making it easier to troubleshoot issues.

- Efficient Repair: Streamlines the repair process by providing clear guidance on which parts need attention or replacement.

- Accurate Assembly: Assists in correctly reassembling machinery after maintenance, reducing the risk of errors.

- Inventory Management: Facilitates tracking and ordering of necessary components, ensuring that repairs can be performed promptly.

Applications in Various Fields

- Manufacturing: Vital for assembly lines, where precision and accuracy are paramount.

- Aerospace: Critical for maintaining safety and compliance standards through detailed illustrations.

- Automotive: Essential for mechanics to diagnose and resolve issues efficiently.

In conclusion, visual representations of components are indispensable resources that enhance understanding, streamline repairs, and support efficient maintenance across various industries.

Key Features of Echo PPT-2400

This model is designed to deliver exceptional performance, combining innovative technology with user-friendly functionality. Its robust construction and advanced features ensure that it meets the needs of both professionals and enthusiasts in various applications.

Power and Efficiency

One of the standout characteristics is its powerful engine, which provides reliable operation even under demanding conditions. The efficient fuel consumption allows for longer working hours, minimizing downtime and enhancing productivity. Users will appreciate the balance between power output and energy efficiency, making it an ideal choice for extensive use.

User-Centric Design

The ergonomic design is tailored for comfort, reducing fatigue during prolonged usage. With intuitive controls and easy handling, operators can achieve precise results with minimal effort. Additionally, the lightweight structure contributes to ease of transportation, making it suitable for various job sites.

In summary, this model integrates performance, efficiency, and user-friendly elements, making it a valuable asset for those seeking reliability and versatility in their tools.

Common Issues with Echo Equipment

Users of outdoor power tools often encounter a range of challenges that can affect performance and reliability. Understanding these issues is crucial for maintaining equipment efficiency and longevity. Common problems typically arise from wear and tear, improper maintenance, or environmental factors that can hinder operation.

One frequent issue is difficulty starting the machine, which may stem from fuel system problems, such as clogged lines or stale fuel. Additionally, users might experience reduced power output, often caused by air filter blockages or spark plug malfunctions. Regular cleaning and timely replacements can mitigate these concerns.

Another common concern is overheating, which can result from extended use or inadequate cooling. Ensuring proper ventilation and allowing the machine to rest between uses can help prevent this situation. Furthermore, issues with cutting performance are often linked to dull blades or improper tension, making regular inspections essential for optimal results.

Lastly, vibrations or unusual noises during operation can indicate underlying mechanical issues. Addressing these symptoms promptly can prevent more severe damage and ensure safe use. By being aware of these typical challenges, users can take proactive steps to maintain their equipment effectively.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your equipment requires consistent care and attention. Regular maintenance practices not only enhance functionality but also extend the lifespan, providing better value over time.

Routine Cleaning

Keeping your machinery clean is essential for its longevity. Dust, debris, and residues can cause wear and tear. Follow these steps:

- Inspect the device regularly for any accumulated dirt.

- Use a soft brush or cloth to remove dust and debris.

- Ensure that air vents and filters are clear for proper airflow.

Regular Inspections

Periodic checks help identify potential issues before they escalate. Implement the following practices:

- Examine all moving parts for signs of wear or damage.

- Check fluid levels and replace any fluids as needed.

- Listen for unusual sounds during operation, which may indicate mechanical problems.

By adhering to these maintenance tips, you can significantly improve the performance and lifespan of your equipment, ensuring it remains reliable for years to come.

Where to Find Replacement Parts

When your equipment requires new components, locating reliable sources becomes crucial. There are various avenues to explore that ensure you obtain the necessary items efficiently and affordably. Below are some common options for sourcing these essential replacements.

| Source | Description |

|---|---|

| Manufacturer’s Website | The official site often provides a dedicated section for ordering direct replacements, ensuring authenticity. |

| Authorized Dealers | Local retailers who are authorized to sell specific brands usually stock a wide range of replacements. |

| Online Marketplaces | Websites like Amazon and eBay feature various vendors, allowing for competitive pricing and user reviews. |

| Repair Shops | Professional repair services often have access to components or can recommend where to purchase them. |

| Second-hand Stores | Thrift shops and salvage yards may offer used components at a fraction of the cost, providing an economical alternative. |

Each of these avenues offers unique benefits, and exploring multiple options can lead to the best deals and quality. Always ensure that the parts you choose meet the required specifications for optimal performance.

Comparing Models: PPT-2400 vs Others

This section delves into the features and specifications of a specific model in comparison to its peers in the market. Understanding the distinctions among different units can help users make informed decisions based on performance, reliability, and usability. By examining various attributes, we can highlight the strengths and weaknesses that set each option apart.

Performance Metrics

When evaluating performance, it’s essential to consider factors such as power output, efficiency, and operational versatility. The examined model showcases a robust power capacity that often surpasses competitors, making it ideal for demanding tasks. Moreover, its design facilitates enhanced fuel efficiency, leading to longer operational periods without the need for frequent refueling.

User Experience and Maintenance

Another critical aspect to consider is user experience, including ease of use and maintenance requirements. The model in question is renowned for its user-friendly interface, allowing operators to quickly familiarize themselves with its functions. Additionally, maintenance protocols are streamlined, requiring minimal effort to keep the unit in optimal condition. In contrast, several rival products may present challenges in terms of upkeep and user navigation.

Ultimately, understanding these differences equips potential buyers with the knowledge necessary to select the most suitable equipment for their specific needs.

Assembly Instructions for Users

This section provides essential guidelines for users to effectively assemble the components of their equipment. Proper assembly is crucial for optimal performance and longevity, ensuring that each part fits together seamlessly.

Before starting the assembly process, it is important to gather all necessary tools and components. Follow these steps to achieve a successful assembly:

- Review the list of components to ensure you have everything needed.

- Prepare a clean workspace to avoid losing small pieces.

- Start by laying out all parts in an organized manner.

When assembling, adhere to the following instructions:

- Begin with the main body, ensuring all screws and fasteners are correctly aligned.

- Attach any additional parts sequentially, verifying that each piece locks into place securely.

- Periodically check the assembly for stability and alignment to prevent issues later.

After completing the assembly, it is advisable to conduct a final inspection. This ensures that all components are properly installed and ready for use. Following these steps will help guarantee a smooth assembly experience and enhance the functionality of your device.

Safety Precautions When Operating

Ensuring safety while using equipment is crucial for preventing accidents and injuries. Adhering to specific guidelines not only protects the operator but also extends the lifespan of the machinery. Proper knowledge and precautions create a secure working environment.

Before starting any operation, it is essential to familiarize oneself with the user manual and safety features of the device. Regular maintenance and inspections can identify potential issues before they escalate. Here are some fundamental precautions to keep in mind:

| Precaution | Description |

|---|---|

| Wear Protective Gear | Always use safety glasses, gloves, and ear protection to safeguard against potential hazards. |

| Check for Damage | Inspect the equipment for any signs of wear or damage before use, ensuring all parts are functioning correctly. |

| Maintain Clear Area | Keep the operating area free from obstructions and debris to avoid accidents during operation. |

| Follow Operating Procedures | Adhere strictly to the established guidelines for operation to minimize risks. |

| Stay Alert | Remain focused and avoid distractions while operating the equipment to ensure safety and efficiency. |

By following these essential safety measures, operators can significantly reduce the risk of accidents and enhance the overall efficiency of the machinery. Prioritizing safety creates a responsible working atmosphere for everyone involved.

Upgrading Your Echo Equipment

Enhancing your outdoor tools can significantly improve their performance and longevity. Upgrades can range from simple modifications to comprehensive overhauls, providing better efficiency and functionality. This section will guide you through various options for enhancing your equipment.

Benefits of Upgrading

- Improved Performance: Upgrading components can lead to better speed and efficiency.

- Increased Durability: High-quality parts can extend the life of your tools.

- Enhanced User Experience: Modern upgrades often include ergonomic designs for easier handling.

- Cost Efficiency: Investing in upgrades can reduce the need for frequent replacements.

Popular Upgrade Options

- Engine Modifications: Boost horsepower and torque for better operation.

- Fuel System Enhancements: Improve fuel efficiency and reduce emissions.

- Blade and Attachment Upgrades: Select attachments that match specific tasks for optimized performance.

- Safety Features: Integrate new safety systems to protect both the user and the machine.

By exploring these upgrade options, you can ensure that your outdoor tools remain reliable and effective for years to come. Regular maintenance combined with thoughtful enhancements will keep your equipment in peak condition.

User Experiences and Reviews

This section delves into the insights and feedback from individuals who have engaged with the product. Their experiences highlight both the strengths and weaknesses, providing valuable information for potential users.

Positive Feedback

Many users appreciate several aspects, including:

- Performance: Users frequently commend the efficiency and reliability, noting that it meets their expectations in various tasks.

- Ease of Use: The straightforward operation is often highlighted, making it accessible for beginners and experienced users alike.

- Durability: Reviews commonly mention the robust build quality, indicating a long lifespan under regular use.

Areas for Improvement

However, some users have pointed out certain limitations:

- Weight: A few find the device heavier than anticipated, which can affect portability.

- Noise Level: Some reviews mention that the operational noise is higher than expected, which could be a consideration for use in quieter environments.

- Customer Support: There are occasional reports of delays in response from customer service, suggesting a need for improvement in this area.

Overall, user feedback provides a comprehensive overview, helping others make informed decisions based on real-world experiences.