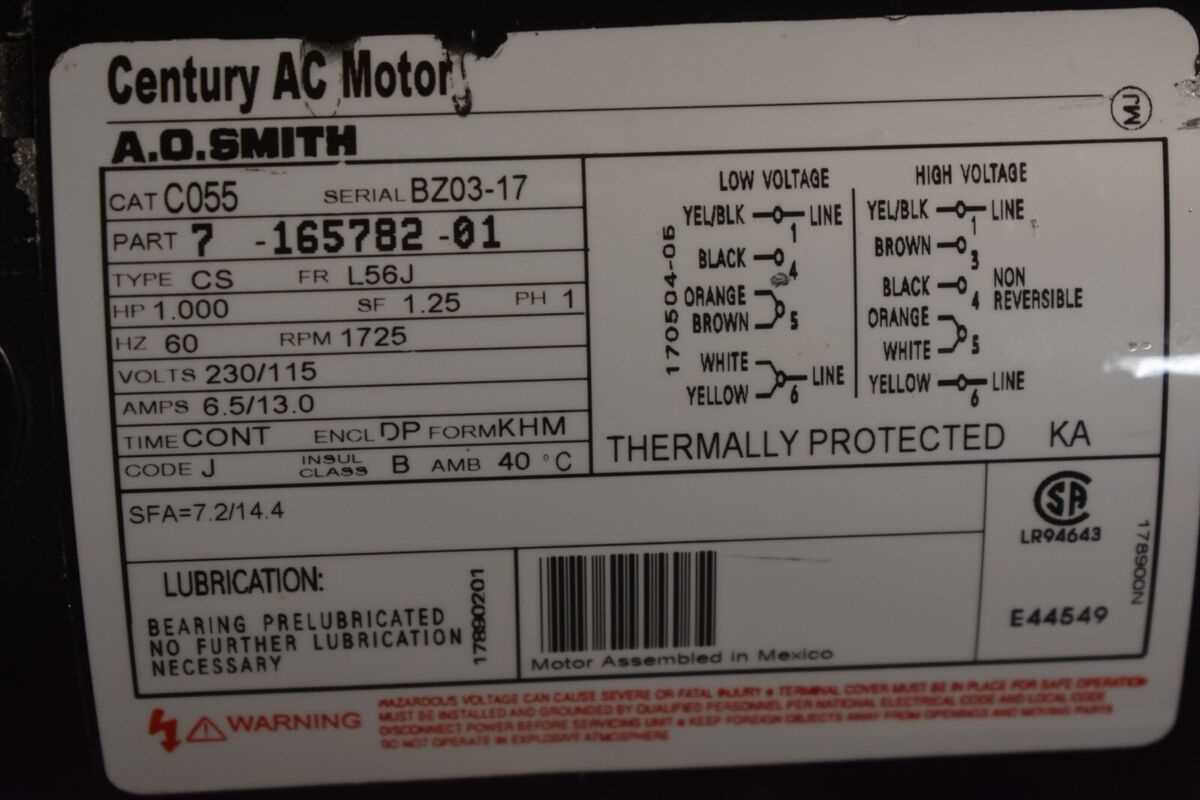

AO Smith Electric Motor Parts Overview

When dealing with mechanical systems, especially those involved in energy conversion, it is crucial to have a clear understanding of the core elements that make up the unit. These components play vital roles in the system’s overall performance, efficiency, and longevity. Familiarity with the construction and function of each part ensures smoother operation and easier maintenance.

Identifying the structure of a device helps in troubleshooting issues, improving functionality, and performing upgrades. Recognizing how the individual parts interact with each other is key to mastering the system’s mechanics.

Whether you are looking to maintain, repair, or replace specific parts, knowing their placement and role within the entire assembly can greatly reduce downtime. This knowledge empowers users to keep their equipment running efficiently and extend its useful life.

Understanding Key Components of Electric Motors

In any mechanical system that relies on rotational movement, several essential elements work in harmony to ensure smooth and efficient operation. These elements, though often unseen, play a critical role in converting energy into motion. By grasping the basic functions of these components, one can better understand the intricate design and performance of various devices that depend on these systems.

One of the most fundamental elements is the core that facilitates the transformation of energy into movement. This component interacts with magnetic fields to generate the force necessary for motion. Coupled with other key components, it ensures that the system remains operational under different conditions. Additionally, the way these parts are arranged and the materials used in their construction significantly impact the overall performance of the system.

Another critical component is the system that controls the flow of current, which regulates the movement and stability of the entire mechanism. This control is necessary to maintain consistent speeds and prevent malfunctions. Together, these components create a synergy that allows the system to function smoothly and efficiently.

Motor Housing and Its Functions

The housing of a mechanical unit plays a crucial role in ensuring smooth operation and protection. It serves as the outer shell that encases the internal components, providing necessary support and shielding from external elements. Without proper housing, the unit’s efficiency and durability would be compromised, leading to premature wear or damage.

Key Functions of the Housing

- Protection: The casing shields internal elements from dust, debris, and moisture, which could lead to rust or other forms of damage.

- Heat Dissipation: The housing facilitates the release of heat generated during operation, preventing overheating and maintaining optimal performance.

- Structural Support: It provides stability, keeping the internal parts securely in place while the unit is in use.

- Noise Reduction: The casing helps in minimizing noise, ensuring quieter operation during function.

Design Considerations

- Material Selection: The choice of materials, such as aluminum or steel, ensures durability while balancing weight and strength.

- Ventilation: Proper ventilation features, like vents or fan blades, are integrated into the design to manage heat effectively.

- Sealing: Effective seals are employed to prevent the entry of contaminants and ensure longevity.

Key Electrical Parts of an Electric Motor

When exploring the internal mechanisms of a rotational device, it’s important to understand the electrical components that enable its functionality. These elements play a crucial role in transferring and controlling energy, ensuring that the unit operates efficiently and effectively. Each component works in harmony with others to convert electrical energy into mechanical power.

Winding and Coils

One of the fundamental elements involved in energy transfer within the system is the arrangement of wire loops or coils. These are typically made of copper or aluminum, and they create magnetic fields when electricity passes through them. The configuration and design of these windings influence the overall efficiency and performance of the system.

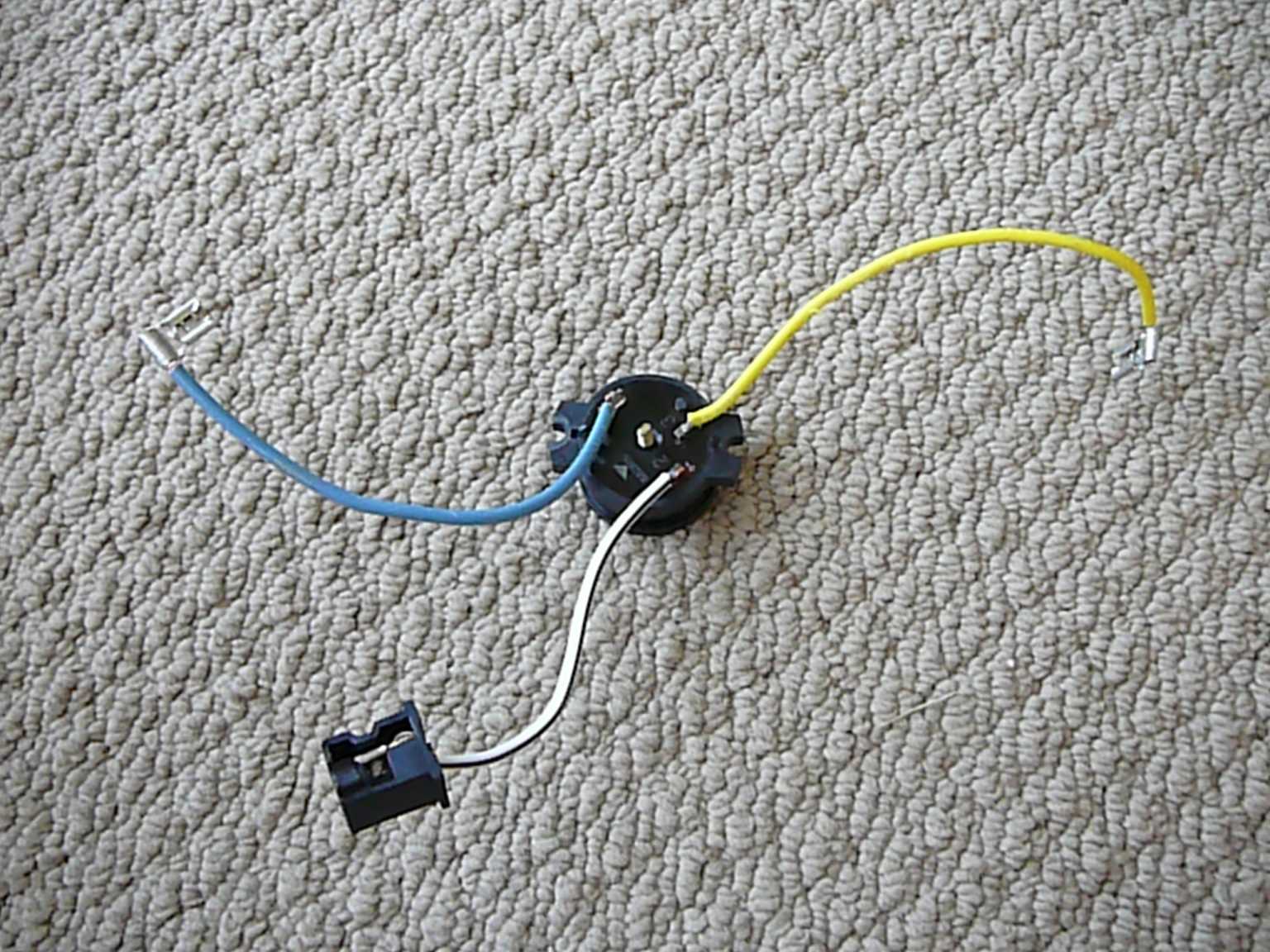

Capacitors and Switches

Capacitors are essential for storing and releasing electrical energy, assisting in the smooth start and operation of the device. Switches control the flow of current, allowing the unit to be turned on or off as needed. Both components are critical for controlling voltage and ensuring that the system functions without interruptions or failures.

| Component | Function |

|---|---|

| Winding | Transfers electrical energy into a magnetic field |

| Capacitor | Stores and releases energy to stabilize voltage |

| Switch | Controls the flow of electrical current |

Role of Bearings in Motor Performance

Bearings are essential components in machinery, facilitating smooth rotation and minimizing friction between moving parts. They play a critical role in ensuring the efficient and reliable operation of various systems, contributing to their longevity and performance. Properly functioning bearings help in maintaining the alignment and reducing the wear and tear on other components, thereby enhancing the overall effectiveness of the system.

In the context of mechanical systems, bearings support rotating elements, allowing them to move freely and with minimal resistance. The quality of these components directly impacts the operational efficiency, noise levels, and heat generation. Without properly functioning bearings, systems would experience excessive friction, resulting in increased energy consumption and potential damage to other parts.

| Bearing Type | Function | Impact on Performance |

|---|---|---|

| Ball Bearings | Reduces friction and supports axial and radial loads. | Enhances speed and reduces heat generation. |

| Cylindrical Roller Bearings | Supports heavy radial loads and minimizes friction. | Improves overall efficiency and prolongs lifespan. |

| Needle Bearings | Optimizes space while supporting heavy loads. | Increases operational stability and reduces vibration. |

How the Shaft Operates in Motors

The shaft plays a critical role in the functionality of a rotating device. It acts as the central component that transfers power from one part of the system to another, allowing energy to be efficiently distributed. This component connects various mechanisms within the machine and converts the electrical or mechanical energy into rotational movement.

In many devices, the shaft’s motion is initiated by an external source, such as a current or pressure, and is then distributed through gears, belts, or other couplings. The design and construction of the shaft are critical in ensuring the smooth and consistent operation of the entire system. Key functions include:

- Transferring mechanical energy from the source to the load.

- Providing stability and support to rotating elements.

- Minimizing friction and wear between moving parts.

The way the shaft interacts with other components determines the efficiency and longevity of the device. Proper alignment, material strength, and balancing are essential for maintaining optimal performance.

Cooling Systems for Electric Motors

The proper management of heat is essential to ensure the long-term reliability and performance of machines. Without an efficient cooling mechanism, internal components can overheat, leading to premature failure and reduced efficiency. Effective cooling techniques help maintain optimal operating temperatures, prevent damage, and enhance overall performance.

One common method of cooling involves the circulation of air around the device. This can be achieved through fans or other ventilation systems that direct airflow toward heated areas. Forced air cooling is particularly useful in systems with high power demands where natural convection might not be sufficient.

In more demanding applications, liquid cooling systems are often employed. These systems use liquids such as water or specialized coolants to absorb and carry away heat from critical components. This method is highly effective in maintaining consistent performance in environments where high temperatures are common.

In addition to air and liquid cooling, some designs incorporate heat sinks to dissipate excess heat. These components increase the surface area of the heated parts, allowing for more efficient heat transfer. Heat dissipation can also be enhanced with the use of heat exchangers, which help regulate temperature by transferring heat to a cooler medium.

Exploring the Motor Windings and Coils

The winding system inside a mechanical rotor plays a crucial role in transforming energy. By understanding the arrangement of the conductive threads and the coils, it becomes easier to grasp how electrical power is converted into rotational force. The interaction between these components is key to efficient operation and performance.

Types of Windings

There are several distinct configurations of windings that influence how the machine functions. Each type is designed for specific purposes, allowing for variations in speed, efficiency, and energy consumption.

- Single-phase windings: These are commonly used for smaller applications and have a simple setup.

- Ensure regular maintenance of brushes fo

How the Rotor and Stator Work Together

The collaboration between two core components plays a pivotal role in ensuring the system functions efficiently. Their relationship is essential in generating the necessary movement that drives performance.

The Interaction of Key Components

- The first element remains stationary, serving as the foundation for the system.

- The second element rotates, responding to the forces generated within the system.

- Both are designed to complement each other, ensuring smooth operation and energy transfer.

The Process of Energy Conversion

- The stationary component creates a

Common Motor Problems and Their Causes

Devices powered by rotational systems are often prone to various issues that can affect their efficiency and longevity. Recognizing the root of these malfunctions can help prevent costly repairs and downtime. Below are some of the frequent challenges faced and their potential origins.

Overheating

One of the most widespread issues is excessive heat generation during operation. This can be caused by inadequate ventilation, an overworked device, or insufficient lubrication. Addressing these factors early can prevent permanent damage to critical components.

Excessive Noise

Loud or unusual sounds may indicate underlying issues such as worn bearings, unbalanced

Maintenance Tips for Extending Motor Life

To ensure long-lasting performance and reliability, consistent upkeep is essential for any rotating equipment. Regular inspections and small adjustments can significantly enhance its lifespan, helping to avoid unexpected failures and costly repairs.

- Clean the unit regularly to prevent the accumulation of dust and debris, which can hinder cooling and efficiency.

- Lubricate moving parts as per manufacturer recommendations to reduce friction and wear over time.

- Check for any loose connections or unusual sounds that may indicate early signs of wear or misalignment.

- Ensure proper ventilation around the equipment to prevent overheating and ensure optimal cooling.

- Schedule reg

Motor Capacitors: Types and Functions

Capacitors play an essential role in the operation of various devices by storing and releasing electrical energy. Their application enhances performance and efficiency in different systems, depending on the design and requirements. Understanding the diverse kinds of capacitors and how they function is key to selecting the right one for specific applications.

Start Capacitors are used to provide an initial boost to get systems moving. They are designed for short-term use and help with initial acceleration. Once the system reaches a certain level of performance, these components disengage, allowing continuous operation.

Run Capacitors are more suited for ongoing support, helping maintain optimal function during regular use. They remain engaged throughout the process, ensuring stable and

Understanding the Commutator and Brushes

The commutator and brushes play a key role in ensuring smooth rotation and effective performance. These components work together to maintain the connection between the rotating part and the stationary power source, enabling energy flow and functionality.

Role of the Commutator

The commutator is responsible for converting current direction, which is essential for consistent movement. It ensures that the rotating segment continues moving in the desired direction by alternating the electrical input at the right moments.

Function of Brushes

Brushes are designed to make continuous contact with the commutator. They transfer electrical current from the power source to the rotating part, allowing the system to function efficiently. Properly functioning brushes reduce wear and tear, contributing to longevity.