Understanding the Essential Components of a Car Engine

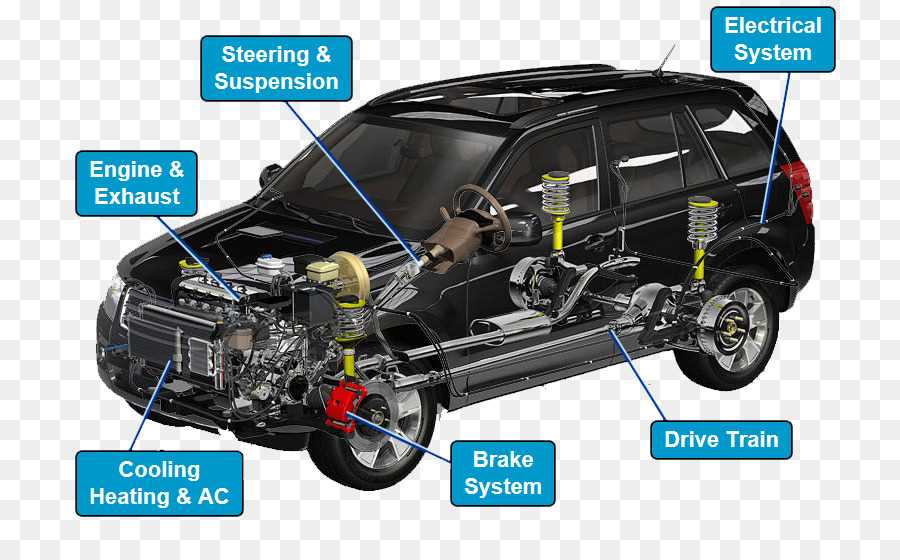

Exploring the intricate mechanisms that drive modern transportation reveals a fascinating interplay of various elements, each contributing to the overall functionality. By delving into these components, one can appreciate how they work in unison to ensure optimal performance and efficiency. A thorough examination of this intricate system unveils the complexities and innovations that underpin contemporary mobility.

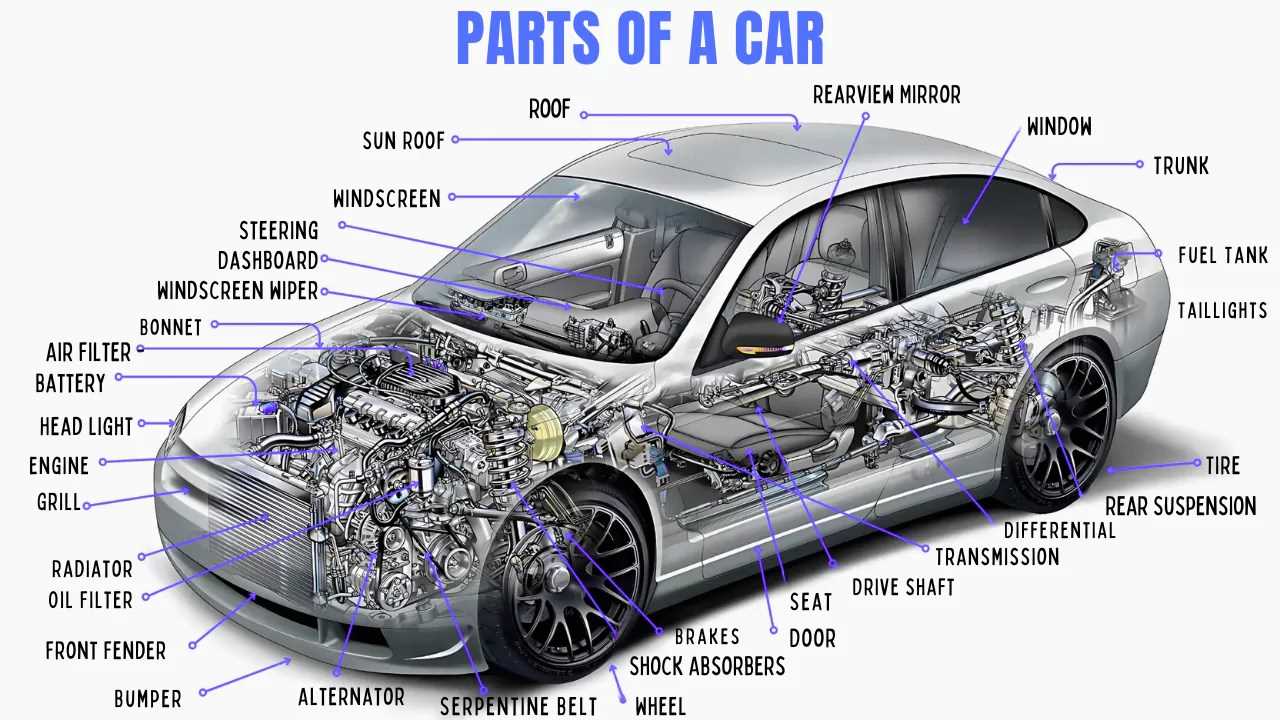

Identifying each crucial element within this system is essential for anyone seeking to grasp the fundamentals of automotive engineering. From the initial force generation to the transmission of power, understanding these individual sections fosters a greater appreciation for the technology involved. Each component, while distinct in its role, is vital to the seamless operation of the whole.

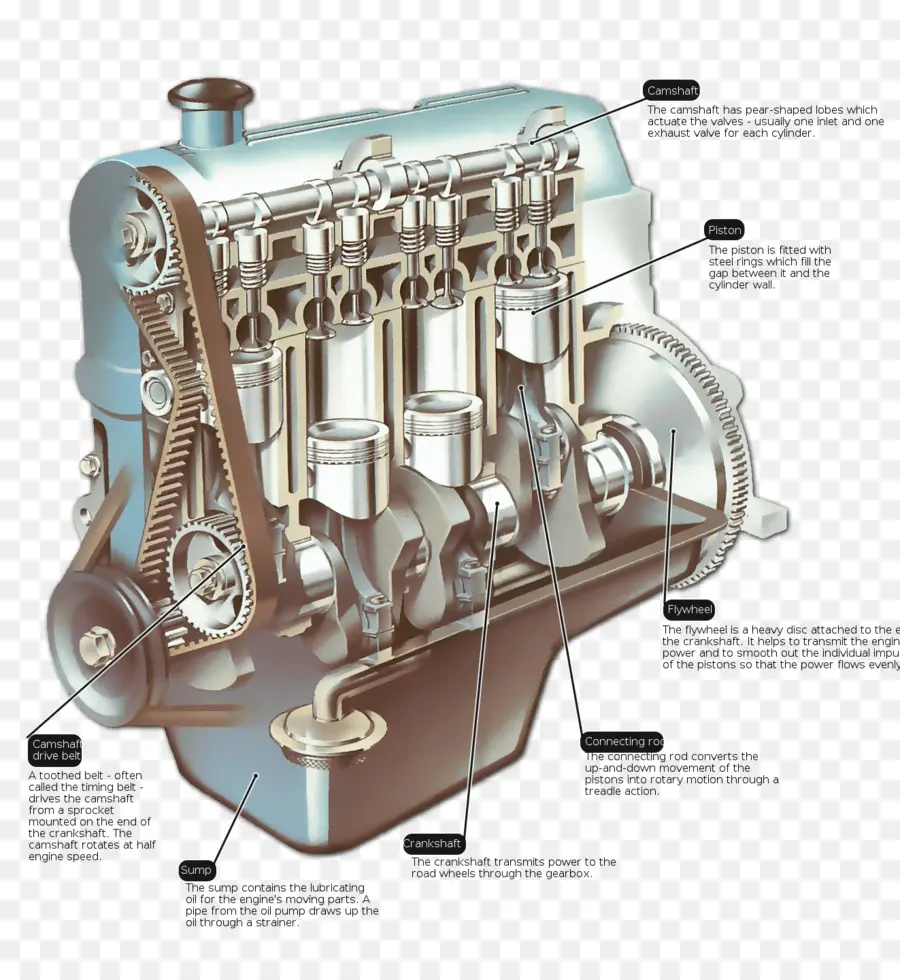

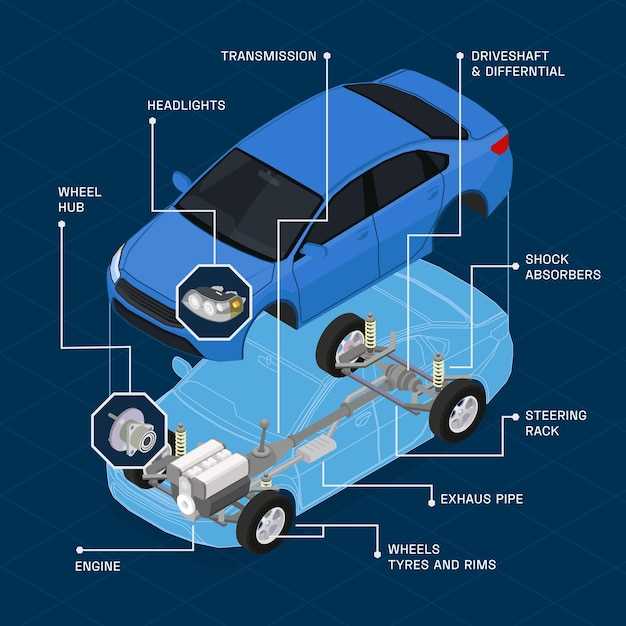

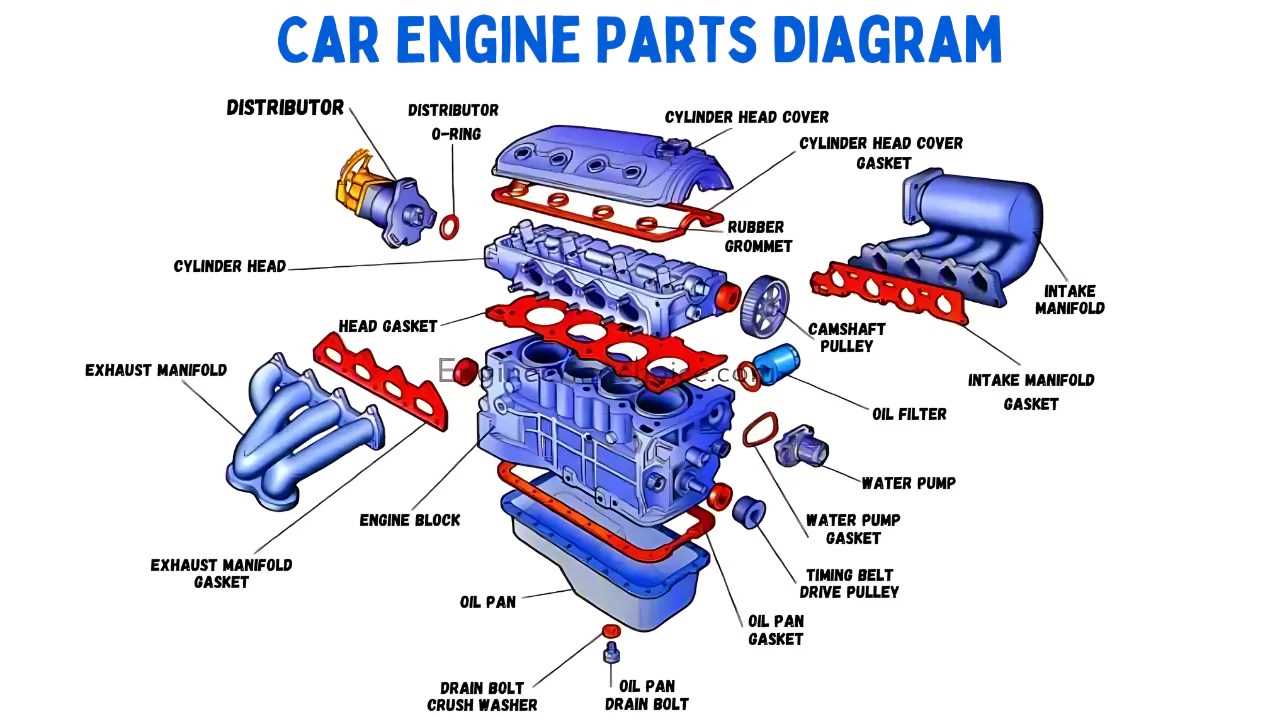

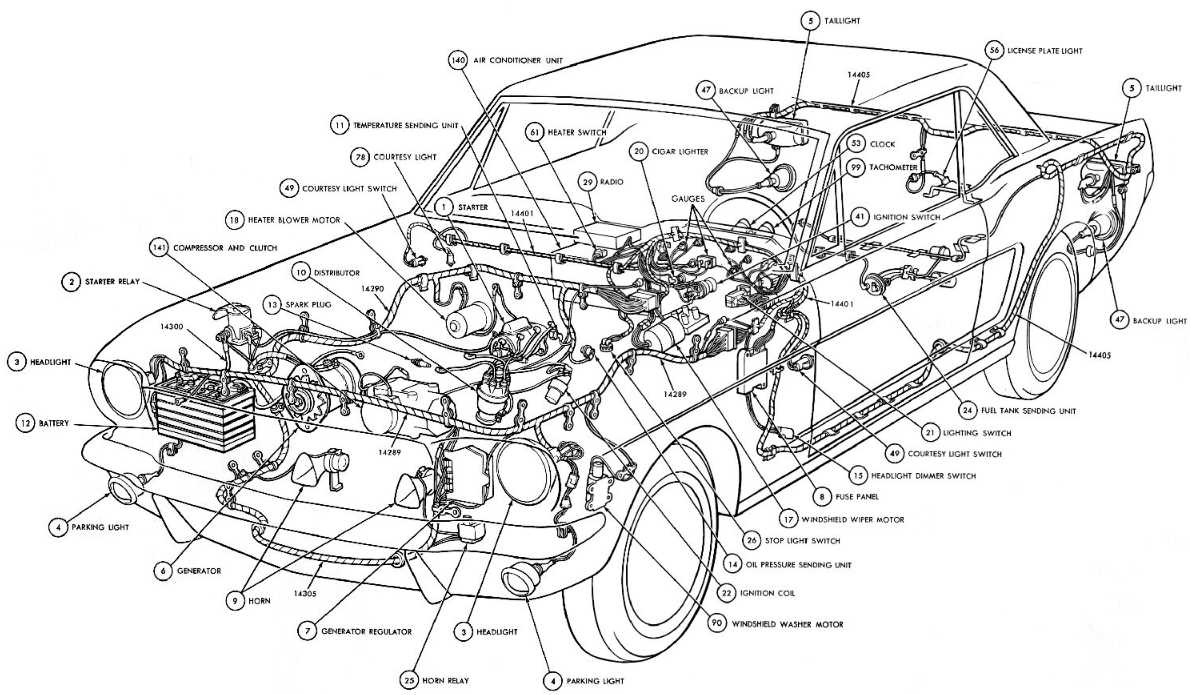

Visual representations of these components serve as invaluable tools for both enthusiasts and professionals alike. They provide clarity, illustrating how each section interrelates and supports the vehicle’s functionality. By familiarizing oneself with these illustrations, one can gain insights into maintenance, troubleshooting, and even enhancement opportunities, paving the way for a deeper engagement with the subject.

Understanding Car Engine Components

The inner workings of a vehicle’s power source are intricate, comprising various elements that collaborate to facilitate motion. Grasping the functions and interrelations of these components is essential for appreciating how mobility is achieved. Each element plays a unique role, contributing to the overall efficiency and performance of the mechanism.

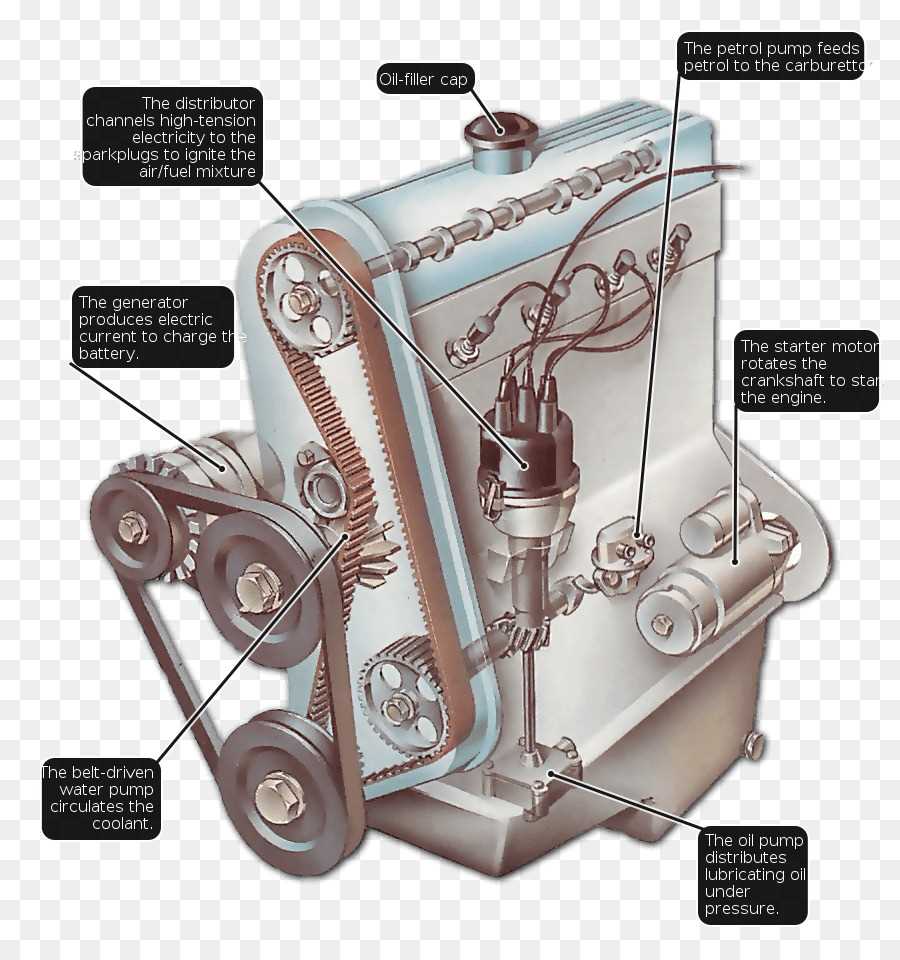

Key elements include those that generate power, regulate flow, and manage temperature. These integral components must operate harmoniously to ensure the system runs smoothly. For instance, the unit responsible for igniting the fuel-air mixture is crucial for generating the force needed for propulsion.

Additionally, systems that handle the movement of gases, as well as those that cool the mechanism, are vital for maintaining optimal performance. Understanding these functions not only enhances knowledge but also informs better maintenance practices, ensuring longevity and reliability.

By familiarizing oneself with these fundamental elements, one can appreciate the engineering marvel that allows for efficient transportation and the continuous innovation within this field.

Overview of Engine Anatomy

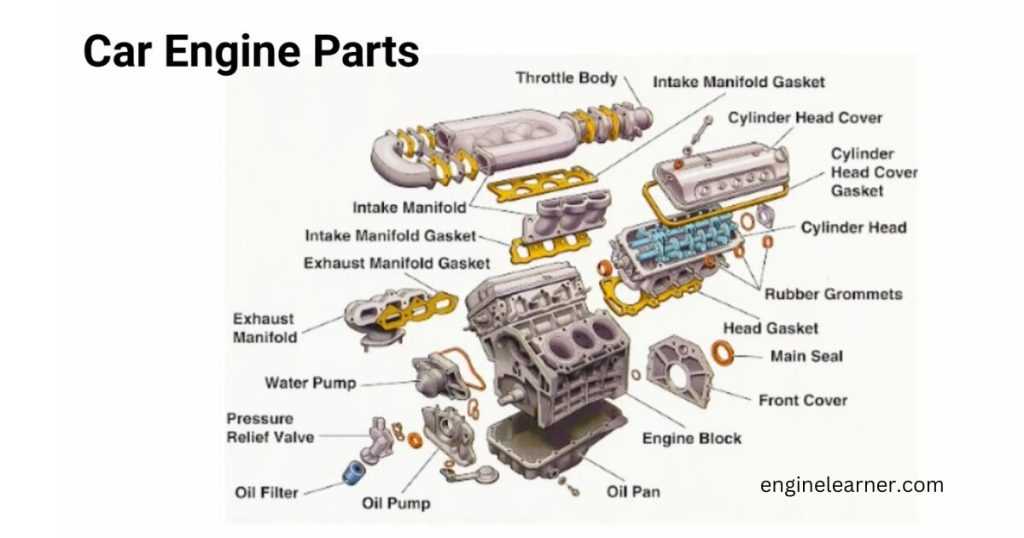

The internal workings of a vehicle’s propulsion system are complex and fascinating, comprising various interconnected components that work in harmony to ensure optimal performance. Understanding the fundamental structure and functions of these elements is crucial for diagnosing issues and enhancing efficiency.

Core Components

At the heart of this mechanism lies the primary assembly that transforms fuel into motion. This crucial unit is supported by various auxiliary structures that contribute to the overall functionality. Each segment plays a significant role, from generating power to regulating temperature and maintaining fluid dynamics.

Functionality and Interaction

All segments within this assembly are designed to operate in unison, ensuring that energy conversion occurs smoothly. The interplay between these elements dictates the effectiveness of the entire system, making it essential to grasp how they interact. Knowledge of this intricate framework aids in comprehending maintenance requirements and potential enhancements.

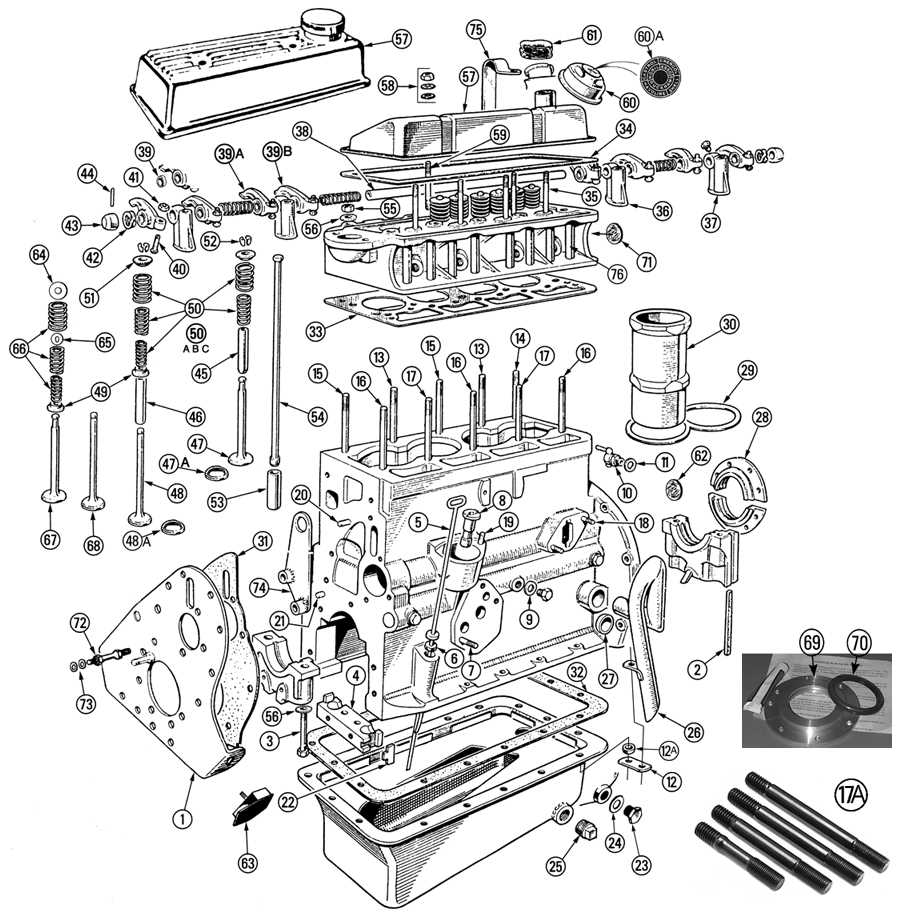

Key Parts of an Internal Combustion Engine

The internal combustion system operates through the interaction of several essential components that work together to convert fuel into mechanical power. Each element plays a critical role in ensuring efficient operation, balancing precision, and performance. Understanding these primary elements helps in grasping the complex process behind energy conversion in this type of machinery.

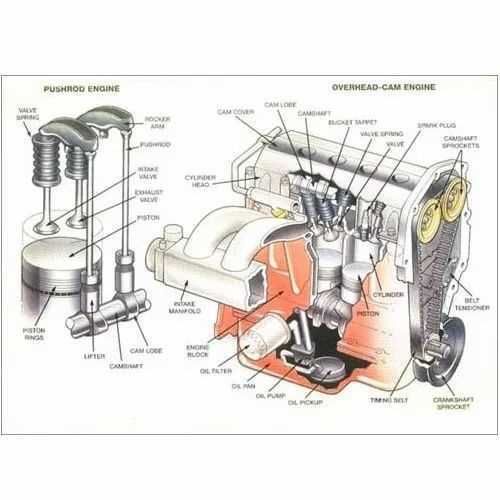

Cylinders and Pistons

Cylinders form the central chamber where controlled explosions occur, driving the movement of the pistons. The piston moves up and down within the cylinder, creating the necessary pressure to initiate the energy transformation. The movement is cyclical, repeating with every combustion cycle.

Crankshaft and Connecting Rods

The crankshaft converts the vertical motion of the pistons into rotational force. This motion is transferred through the connecting rods, which link the

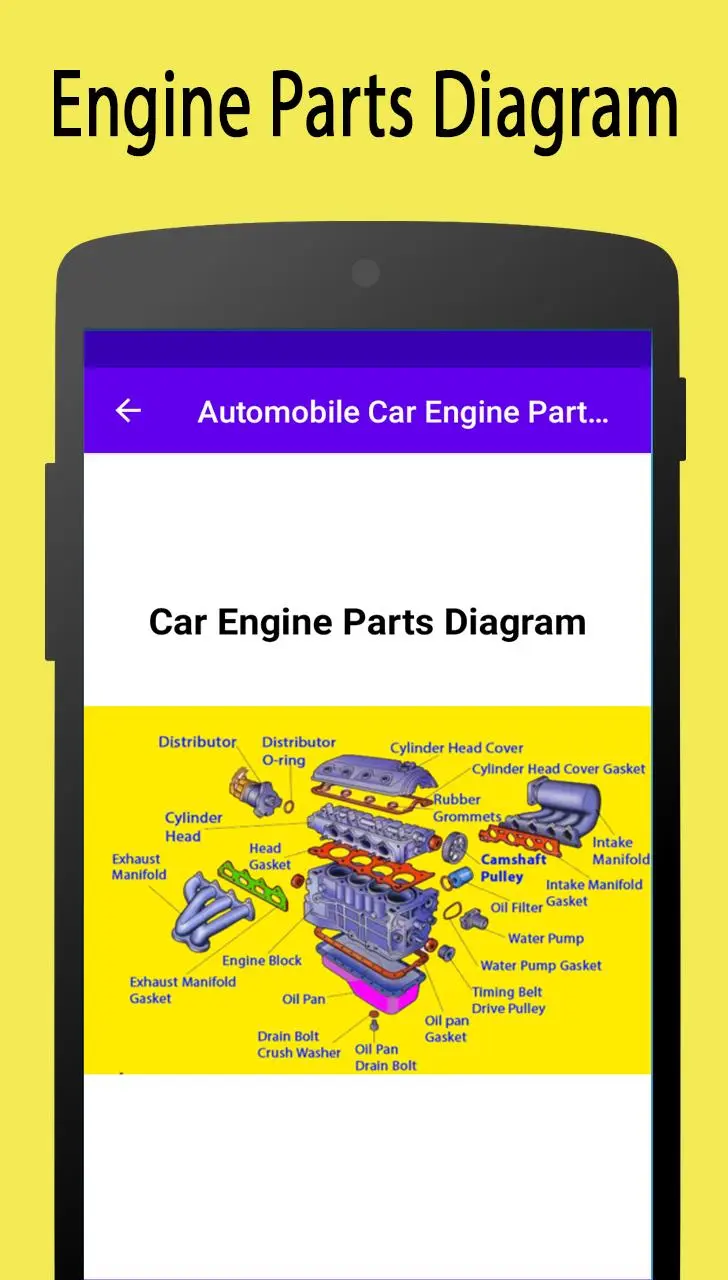

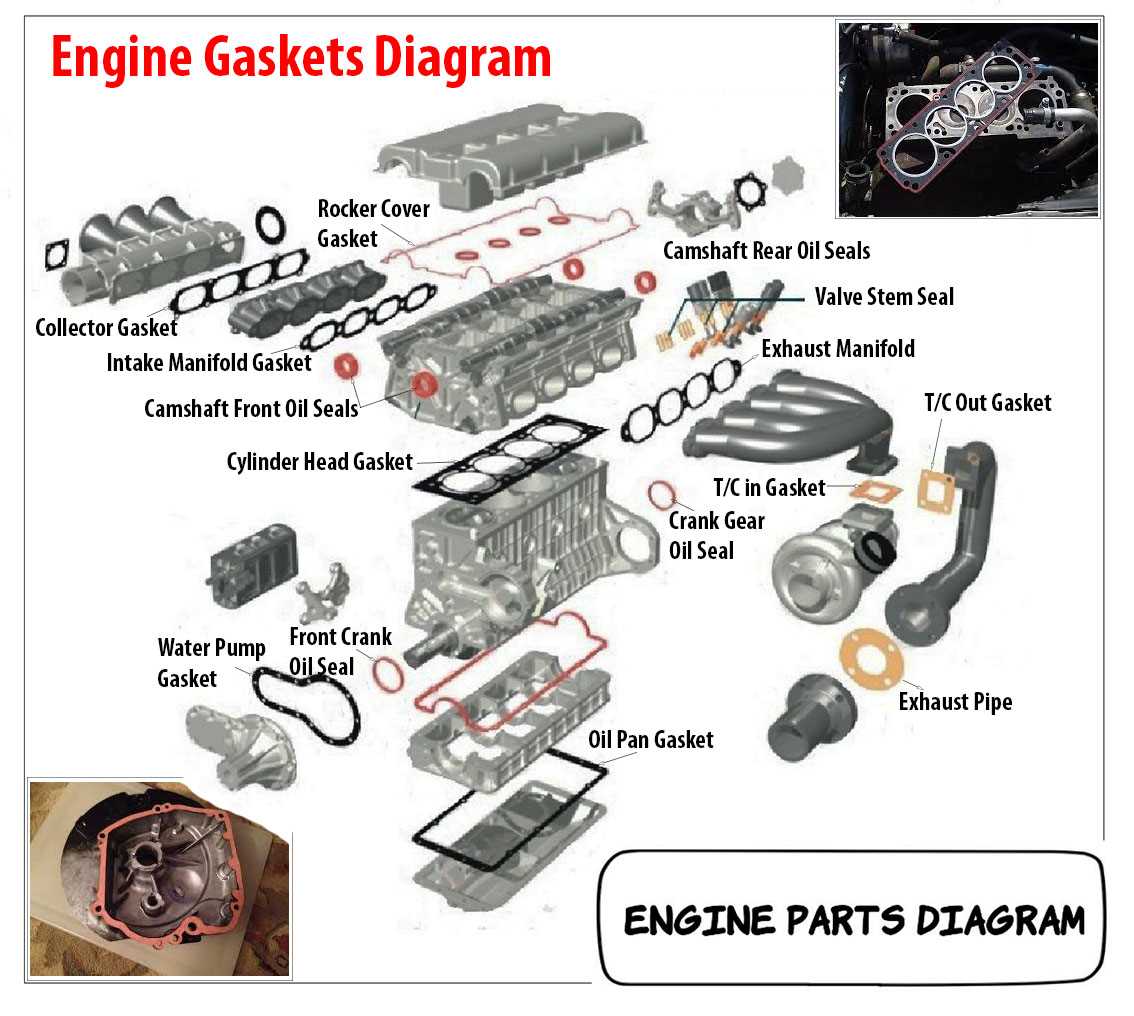

Functionality of the Cylinder Head

The cylinder head plays a critical role in the operation of an internal combustion system, contributing to both performance and efficiency. It serves as a crucial component that controls the movement of air and fuel, while also managing the release of exhaust gases. This section explores its key features and how they affect overall performance.

Control of Air and Fuel Flow

A key aspect of the cylinder head’s function is the regulation of air and fuel entering the combustion chambers. Through precise valve timing, the head ensures that the correct mixture reaches each chamber, enhancing the combustion process. Proper air-fuel management is essential for optimizing energy production and minimizing waste.

Heat Dissipation and Structural Integrity

The cylinder head is also responsible for managing high temperatures generated during the combustion process. By facilitating heat dissipation, it protects vital components from damage and maintains structural stability under extreme conditions. This ensures that the system operates efficiently over time.

The Role of the Crankshaft

The crankshaft is a vital component that ensures the conversion of linear motion into rotational movement. This process is essential for maintaining the functionality and efficiency of the system, as it transforms energy produced by other components into usable mechanical power.

Main Functions

- Energy Conversion: The crankshaft transforms the force generated by other parts into rotational force, allowing further components to operate smoothly.

- Movement Coordination: It ensures synchronized motion within the mechanical assembly, ensuring precise timing and balance.

- Structural Stability: The crankshaft supports the overall framework by distributing forces evenly, preventing imbalances that could lead to damage.

Key Interactions

- The crankshaft works closely with multiple mechanical elements, transferring motion to facilitate continuous operations.

- Its design and placement play a crucial role in determining the efficiency and durability of the entire system.

Importance of the Camshaft

The camshaft plays a pivotal role in ensuring the proper timing of critical mechanical processes. Its operation directly influences how smoothly these processes occur and ensures that everything happens in a coordinated manner. Without this key component, the system would struggle to function efficiently.

Precision and synchronization are essential when it comes to the performance of various mechanical actions. The camshaft ensures that the movement of interconnected systems is properly timed, allowing each to perform its role effectively. The precise function of this element is what guarantees a balance between different moving parts.

Over time, the wear and tear on this component can affect overall functionality. Regular inspection and maintenance are crucial for preserving the integrity of the system. Any misalignment or damage can lead to significant performance issues, underlining the critical importance of the camshaft in the broader mechanical structure.

Exploring the Pistons and Rings

In this section, we will delve into the core components responsible for converting energy into motion. These elements play a crucial role in maintaining pressure, ensuring smooth operation, and contributing to overall performance. Their interaction and design are fundamental to the dynamics and efficiency of the mechanical system.

| Component | Function |

|---|---|

| Pistons | Move within the chambers to transmit force, transforming power into mechanical movement. |

| Rings | Create a seal between the moving element and its surroundings, preventing leaks and maintaining pressure balance. |

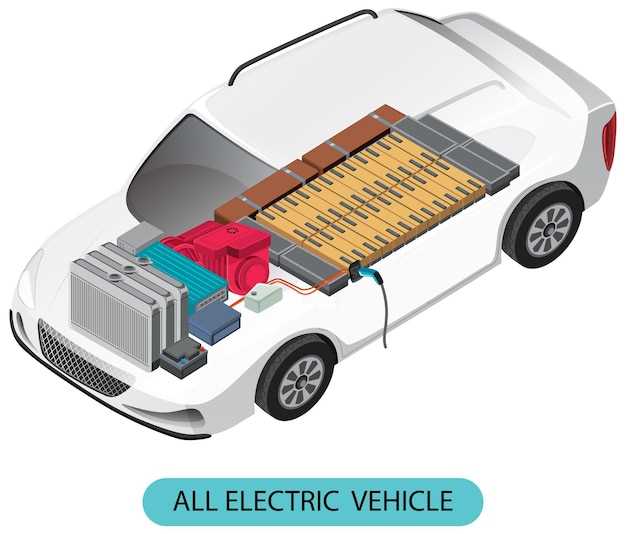

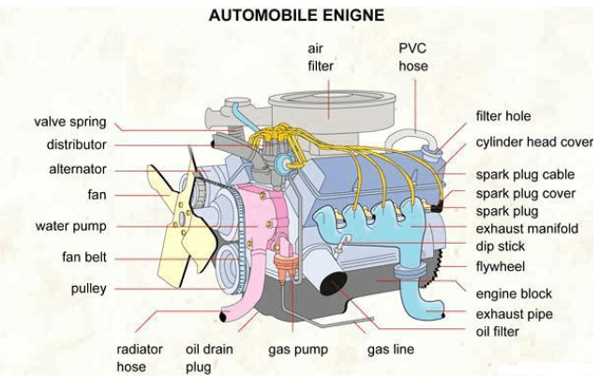

Cooling System and Its Components

The cooling system is essential for maintaining optimal temperature during operation. It prevents overheating and ensures that various mechanisms work efficiently under varying conditions. By regulating thermal energy, this system plays a vital role in ensuring the longevity and performance of the entire structure.

Main Components of the Cooling System

- Radiator: A heat exchanger responsible for dissipating excess heat through a series of fins and tubes.

- Water Pump: Ensures the circulation of coolant, pushing it through the system for consistent cooling.

- Thermostat: Regulates the flow of coolant based on temperature levels, ensuring that the system stays within optimal parameters.

- Coolant Reservoir: A storage container that holds excess coolant and prevents the system from running dry.

- Cooling Fan: An additional component that increases air circulation over the radiator, especially when external airflow is limited.

Fuel Delivery System Explained

The fuel delivery system is responsible for transporting the necessary fuel to the combustion chamber in a precise and controlled manner. It ensures the appropriate amount of fuel is delivered to maintain optimal performance under varying conditions, contributing to smooth and efficient operation.

Key Components of the Fuel Delivery System

This system consists of several critical elements that work together to transfer fuel from the tank to the combustion area. Below is a table outlining these components and their primary functions.

| Component | Function |

|---|---|

| Fuel Pump | Draws fuel from the tank and sends it under pressure through the system. |

| Fuel Lines | Transport fuel between the tank, pump, and injectors. |

| Fuel Injectors | Precisely spray fuel into the combustion area for mixing with air. |

| Component | Function |

|---|---|

| Spark Plug | Produces a spark to ignite the air-fuel mixture. |

| Ignition Coil | Transforms low voltage from the battery into high voltage required for sparking. |

| Distributor |