Comprehensive Guide to Freightliner Engine Parts Diagram

In the realm of transportation machinery, the intricate workings of powerful vehicles demand a thorough comprehension of their internal mechanisms. This section delves into the various elements that contribute to the optimal performance of heavy-duty trucks. By exploring the configuration and relationship of these essential components, we can enhance maintenance practices and ensure longevity.

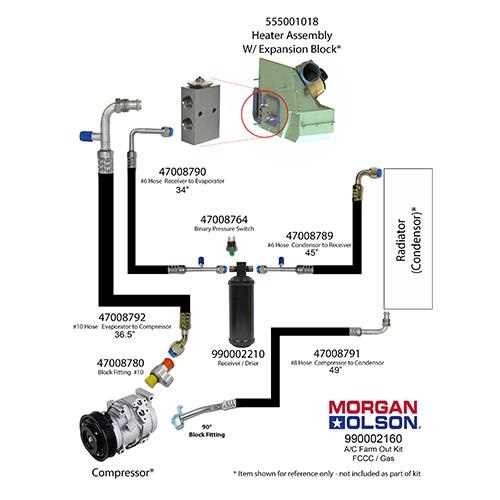

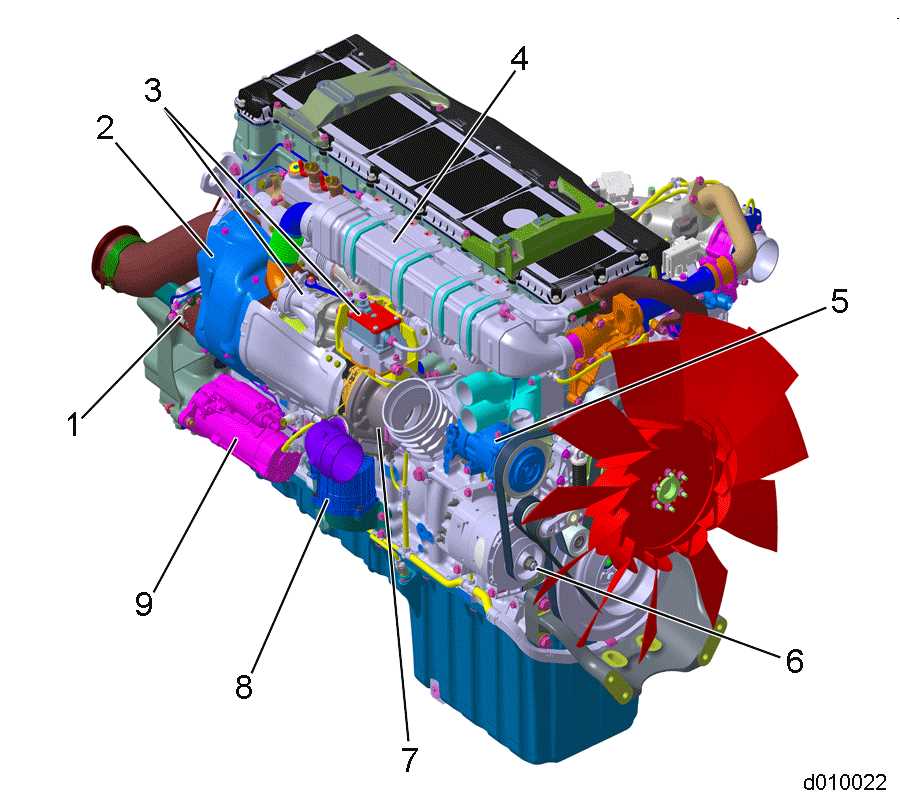

Visual representation of these crucial units serves as a valuable tool for both professionals and enthusiasts. It allows for a clearer understanding of how different sections interact and function cohesively. This knowledge is vital for troubleshooting and efficient repair processes, ultimately leading to improved operational reliability.

Moreover, grasping the layout of these systems empowers operators to make informed decisions regarding upgrades and modifications. As we navigate through the various classifications and specifications, a well-structured overview can facilitate a deeper appreciation for the engineering marvels behind modern transportation.

Understanding Freightliner Engine Components

In the world of heavy-duty transportation, knowledge of various mechanical elements is crucial for efficient operation and maintenance. Each component plays a specific role, contributing to the overall functionality and performance of the vehicle. A solid grasp of these elements helps ensure longevity and reliability, making it essential for operators and technicians alike.

Key components can be categorized into several groups:

- Power Generation: These elements are responsible for producing the necessary force to propel the vehicle.

- Fuel Delivery: This group includes systems that manage the supply and injection of fuel, optimizing efficiency.

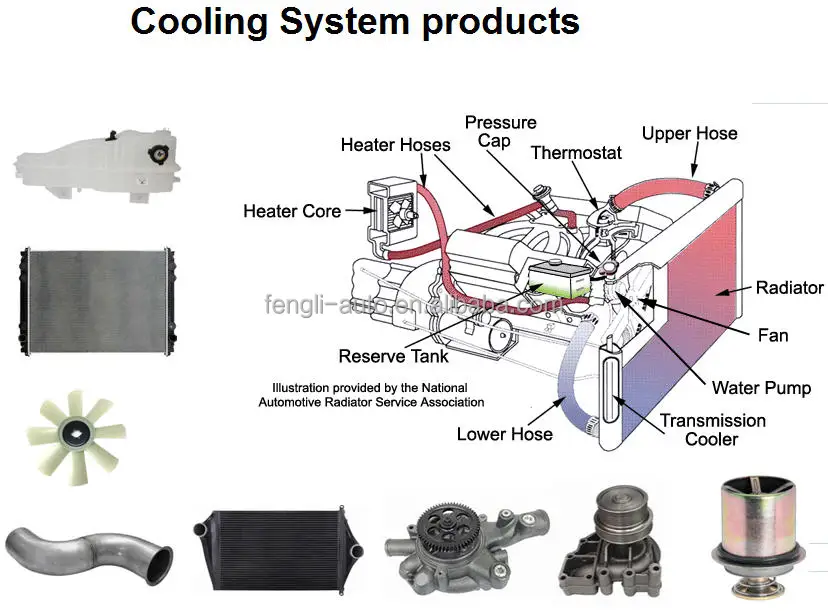

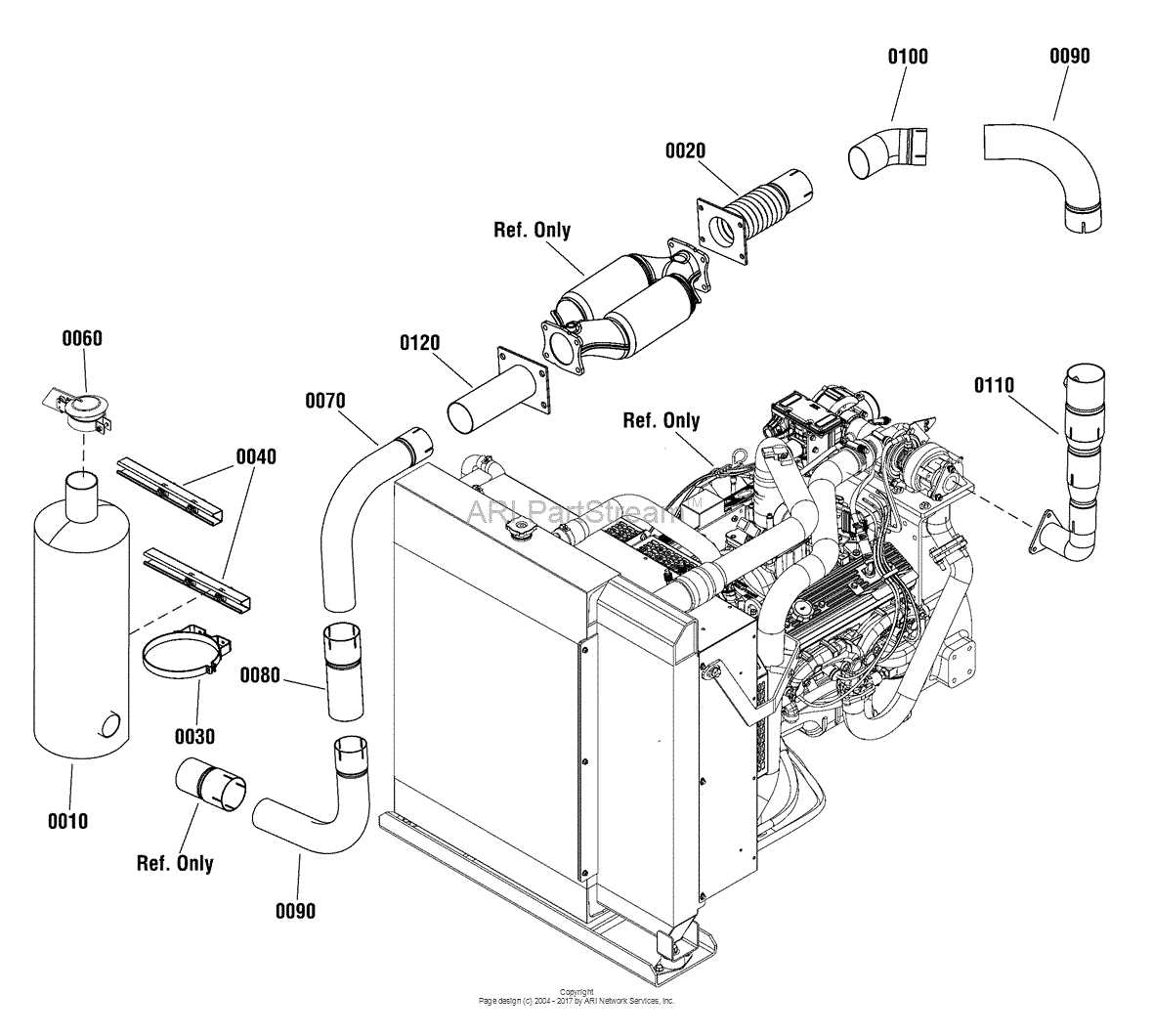

- Cooling Systems: Essential for regulating temperature, these parts prevent overheating and maintain optimal operating conditions.

- Exhaust Management: Components in this category handle the byproducts of combustion, ensuring compliance with environmental standards.

- Lubrication Systems: These elements minimize friction between moving parts, extending the lifespan of critical components.

Understanding the function and interaction of these groups is vital for troubleshooting and performing maintenance tasks effectively. Each part contributes to the intricate dance of mechanics that keeps the vehicle moving smoothly on the road.

- Identify key elements in the power generation group.

- Examine how fuel delivery systems impact performance.

- Assess the role of cooling mechanisms in preventing breakdowns.

- Explore the importance of managing exhaust emissions.

- Evaluate lubrication methods and their effect on wear and tear.

By gaining a comprehensive understanding of these mechanical elements, individuals can make informed decisions that enhance performance and reliability, ultimately leading to safer and more efficient transportation solutions.

Types of Freightliner Engines Explained

This section delves into the various types of power units utilized in heavy-duty vehicles. Understanding the different classifications helps in recognizing their unique characteristics and applications in the transportation industry.

Common Classifications

The primary categories of these power units can be broken down based on their design, performance, and fuel type. Each type serves distinct roles, catering to specific operational needs.

| Type | Description | Applications |

|---|---|---|

| Diesel | Known for durability and fuel efficiency, this type is widely used in commercial vehicles. | Long-haul trucking, construction |

| Natural Gas | Emphasizes lower emissions and is gaining popularity in urban transport. | City logistics, waste management |

| Hybrid | Combines traditional and electric power sources to enhance efficiency and reduce environmental impact. | Local deliveries, short-distance routes |

Performance Metrics

Evaluating these units involves considering horsepower, torque, and fuel consumption. These metrics play a crucial role in determining the suitability of each type for specific tasks and conditions.

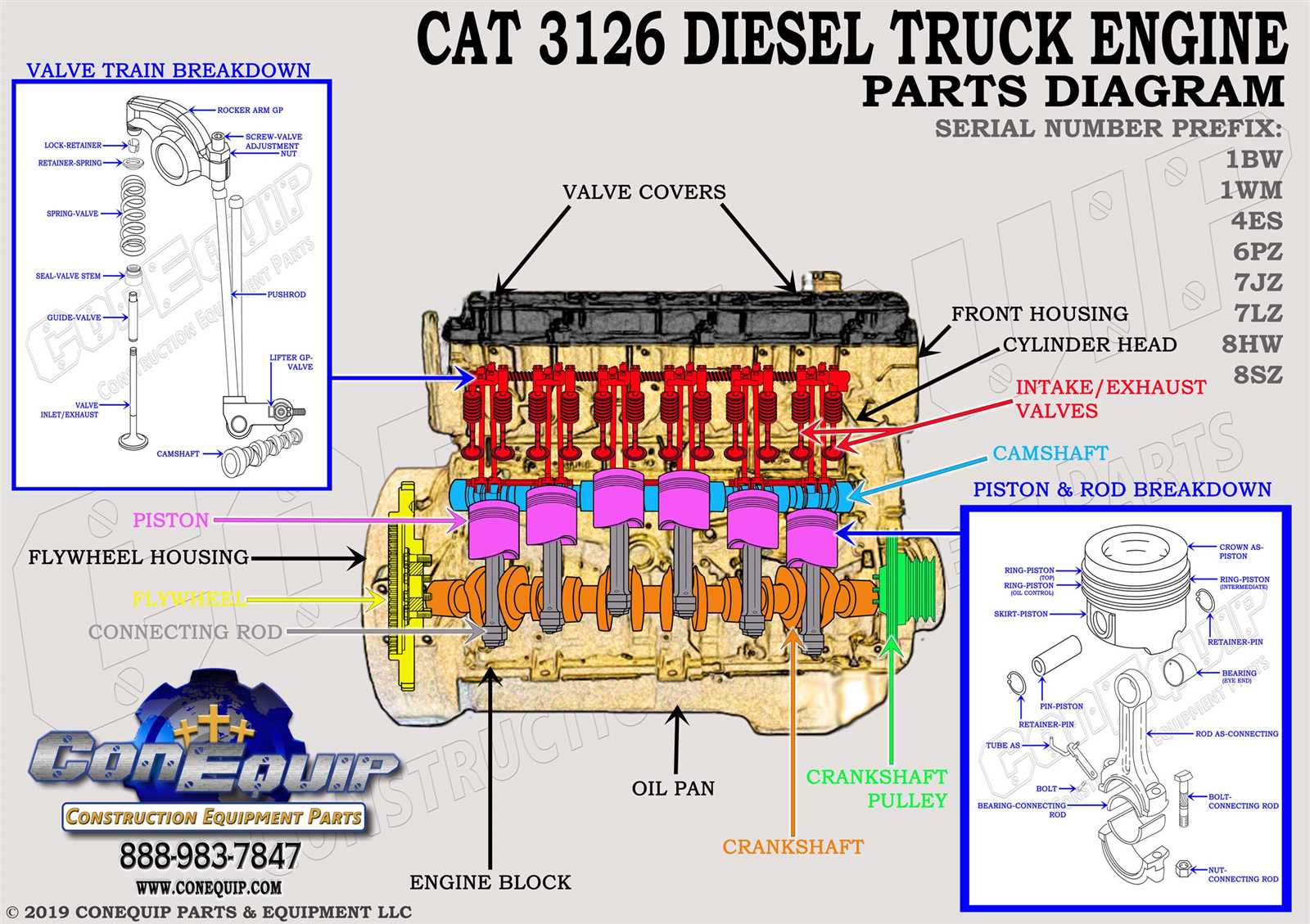

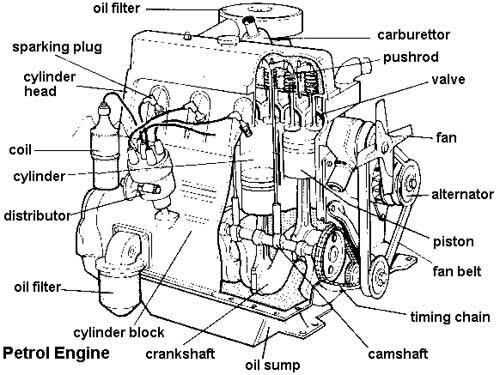

Key Parts in Engine Functionality

Understanding the essential components that contribute to the overall performance of a power unit is crucial for ensuring optimal operation. Each element plays a significant role in converting fuel into energy, enabling seamless movement and functionality of the vehicle. Recognizing these integral pieces helps in maintaining efficiency and preventing potential issues.

Pistons are vital in the process of combustion, as they compress the fuel-air mixture, allowing for powerful explosions that drive the crankshaft. Their movement translates directly into mechanical energy, making them indispensable for power generation.

Crankshafts are another crucial component, responsible for converting the linear motion of the pistons into rotational force. This transformation is key for driving the wheels and supporting various functions within the vehicle.

Camshafts control the opening and closing of valves, regulating the flow of air and fuel into the combustion chamber. This precise timing is essential for maintaining efficiency and power output, ensuring the optimal performance of the entire system.

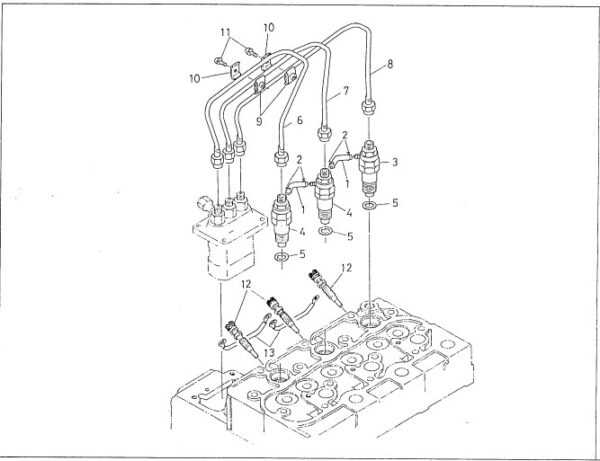

Fuel injectors play a critical role in delivering the right amount of fuel at the right time, enhancing combustion efficiency and overall power. Properly functioning injectors are vital for smooth operation and reduced emissions.

Valves are responsible for the intake and exhaust of gases, allowing for a continuous cycle of combustion. Their correct operation is fundamental to maintaining the rhythm of the combustion process and ensuring maximum efficiency.

In summary, the collaboration of these components is essential for the effective operation of the power unit. Regular maintenance and understanding of their functions can significantly enhance longevity and performance.

Importance of Accurate Diagrams

Precise visual representations are crucial in any technical field, serving as a roadmap for understanding complex systems. These illustrations provide clarity, enabling individuals to grasp intricate relationships and functionalities within mechanical assemblies. Without accurate visuals, the risk of misinterpretation increases significantly, leading to errors in maintenance and assembly.

Moreover, detailed visuals enhance communication among professionals, allowing for a shared understanding of components and their interactions. This is particularly vital in environments where collaboration is key. A reliable schematic can reduce downtime and improve efficiency by streamlining troubleshooting processes.

In addition, precise representations can serve as valuable training tools. They allow new technicians to familiarize themselves with the layout and function of various elements, fostering a deeper comprehension that theoretical knowledge alone may not provide. Overall, the importance of accurate illustrations cannot be overstated, as they underpin effective operation, maintenance, and training in any technical discipline.

Common Issues with Engine Parts

In the realm of heavy machinery, various components can encounter problems that affect overall performance and reliability. Understanding these common challenges can aid in preventative maintenance and timely repairs, ensuring that the equipment operates smoothly and efficiently.

Frequent Malfunctions

One prevalent issue involves wear and tear from prolonged use, which can lead to diminished functionality. Components may suffer from excessive friction, resulting in overheating and potential failure. Regular inspections are crucial to identify these wear patterns early.

Leakage and Contamination

Another critical concern is the occurrence of leaks, often caused by damaged seals or gaskets. Such leaks can lead to fluid loss, compromising the system’s effectiveness. Additionally, contamination from dirt and debris can exacerbate wear, leading to further complications. Keeping systems clean and well-sealed is essential for optimal performance.

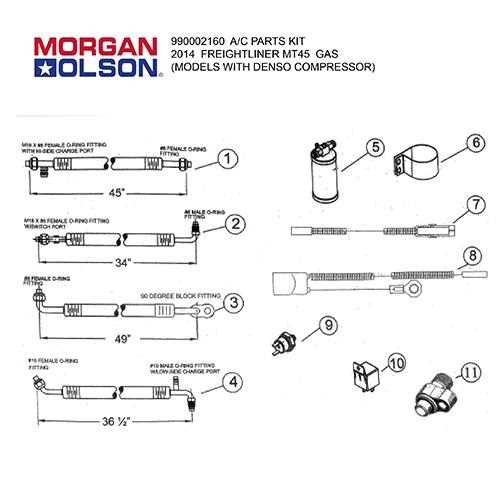

How to Read Engine Diagrams

Understanding complex illustrations can significantly enhance your knowledge and skills in maintenance and repair. These visual representations serve as guides, showcasing various components and their interconnections. Mastering the ability to interpret these visuals is essential for anyone involved in mechanical work.

Key Elements to Identify

When analyzing these visual aids, focus on the following elements:

- Symbols: Each icon represents a specific component. Familiarize yourself with standard symbols to quickly identify parts.

- Lines: Solid lines typically indicate physical connections, while dashed lines may signify electrical pathways or fluid systems.

- Labels: Read the annotations carefully; they provide vital information about functions and specifications.

- Legends: Many illustrations include a legend or key that explains symbols and color codes. Always refer to this for clarity.

Steps to Interpretation

- Start with the Overview: Get a sense of the entire layout before diving into details.

- Identify Major Sections: Look for divisions that categorize various functions or systems.

- Trace Connections: Follow the lines to see how components interact and work together.

- Cross-reference Information: Use manuals or additional resources to verify your understanding and fill in gaps.

By honing these skills, you will improve your efficiency and accuracy in diagnosing and solving mechanical issues.

Replacing Freightliner Engine Parts

Maintaining optimal performance in heavy-duty vehicles often requires replacing various components. Understanding the process can enhance efficiency and prolong the lifespan of your machine. This section outlines essential steps and considerations when undertaking such tasks.

Before initiating the replacement process, it’s crucial to prepare adequately. Follow these guidelines:

- Identify the specific component that needs to be replaced.

- Gather the necessary tools and safety equipment.

- Refer to the manual for specifications and guidelines.

Once prepared, the next steps involve careful execution:

- Ensure the vehicle is on a stable surface and secured.

- Disconnect any electrical connections and hoses linked to the component.

- Remove the old item, taking note of how it is installed for reference.

- Install the new component, ensuring it fits securely.

- Reconnect all electrical connections and hoses.

After installation, conduct a thorough check:

- Inspect for any leaks or irregularities.

- Test the system to ensure everything functions correctly.

- Document the replacement for future reference.

By following these steps, you can effectively replace essential components, ensuring your vehicle remains in peak condition.

Maintenance Tips for Engine Longevity

Ensuring the durability of your vehicle’s power source requires diligent care and regular upkeep. Implementing effective maintenance practices can significantly extend its operational life and enhance performance, ultimately saving you time and resources.

| Maintenance Practice | Description |

|---|---|

| Regular Oil Changes | Frequent replacement of lubrication fluid keeps components well-greased and minimizes wear. |

| Cooling System Checks | Consistently inspect the coolant levels and system integrity to prevent overheating. |

| Air Filter Replacement | Replacing the air filter ensures optimal airflow and enhances combustion efficiency. |

| Fuel Quality Monitoring | Using high-quality fuel reduces deposits and maintains smooth operation. |

| Regular Inspections | Routine checks of belts, hoses, and other components help identify issues before they escalate. |

By adopting these practices, you can foster a reliable and efficient performance, ensuring that your machinery operates at its best for years to come.

Where to Find Engine Diagrams

Locating detailed visual representations of mechanical assemblies is crucial for both professionals and enthusiasts. These illustrations aid in understanding the layout and interaction of various components, ensuring effective repairs and maintenance. Fortunately, there are several reliable sources where one can find comprehensive schematics.

Online Resources

The internet is a treasure trove of information. Websites dedicated to automotive maintenance often provide free access to high-quality visuals. Additionally, manufacturer websites can be excellent resources, featuring manuals and technical guides for their specific models.

Printed Manuals and Books

For those who prefer physical copies, printed manuals remain a valuable option. Service manuals and repair guides typically contain well-organized illustrations. Local libraries and bookstores may have a selection of relevant literature.

| Source Type | Examples | Accessibility |

|---|---|---|

| Online Resources | Manufacturer websites, automotive forums | Free, but may require registration |

| Printed Manuals | Service manuals, repair guides | Purchase or borrow from libraries |

Differences Between Engine Models

Understanding the variations among different power units is crucial for maintenance and performance optimization. Each model may offer unique features, configurations, and specifications that cater to specific applications and operational needs.

Key Variations

- Displacement: Different models may have varying displacement sizes, affecting power output and efficiency.

- Fuel Type: Options can include diesel, natural gas, or alternative fuels, influencing performance characteristics.

- Horsepower Ratings: Models can be designed to provide different horsepower levels, impacting overall performance.

- Torque Delivery: The way torque is delivered can vary significantly, influencing how the vehicle handles loads.

Component Differences

- Cooling Systems: Different designs and sizes can lead to variations in heat management.

- Turbochargers: Some units may include advanced turbocharging technology for improved power efficiency.

- Intake and Exhaust Configurations: These can significantly affect air flow and emissions.

- Control Systems: Variations in electronic controls can impact fuel management and overall efficiency.

Recognizing these differences is essential for selecting the appropriate unit for specific applications and ensuring optimal operation.

Aftermarket vs. OEM Parts

The choice between alternative components and those provided by the original manufacturer can significantly impact vehicle performance and longevity. Each option presents its own set of advantages and challenges, influencing both the cost and reliability of the overall system. Understanding the differences is essential for making informed decisions.

OEM components are designed and manufactured by the original company that produced the vehicle. These items often come with a guarantee of compatibility and quality, ensuring they meet the specific standards set by the manufacturer. This can provide peace of mind for owners who prioritize reliability and performance, particularly in critical applications.

On the other hand, aftermarket alternatives can offer a more cost-effective solution. These components are produced by various third-party companies and can sometimes surpass the original specifications in terms of performance or durability. However, they may vary in quality, and it’s crucial to research the reputation of the manufacturer before making a purchase.

Ultimately, the decision hinges on individual needs and priorities. While some may lean towards OEM for assurance and reliability, others might find aftermarket solutions appealing due to their affordability and potential for enhanced performance.

Tools Needed for Engine Repairs

Proper maintenance and restoration of mechanical systems require a specific set of instruments. Having the right tools ensures efficiency and precision during the repair process, which can significantly impact the longevity and performance of the machinery. Below are essential tools that should be included in any repair toolkit.

Basic Hand Tools

- Wrenches: Adjustable and fixed-size wrenches for various bolt sizes.

- Screwdrivers: A variety of flathead and Phillips screwdrivers for different fasteners.

- Sockets: A complete socket set with both metric and standard sizes.

- Pliers: Needle-nose and slip-joint pliers for gripping and twisting.

- Hammers: Rubber and steel hammers for driving and shaping components.

Specialized Equipment

- Torque Wrench: Ensures fasteners are tightened to the correct specifications.

- Oil Filter Wrench: Simplifies the removal of oil filters during maintenance.

- Diagnostic Tools: Scanners and multimeters for troubleshooting and analysis.

- Jack and Stands: Necessary for lifting the machinery safely during repairs.

- Work Light: Provides adequate illumination in tight or dark spaces.

Equipping yourself with these essential tools will streamline the repair process and contribute to effective maintenance, ultimately enhancing the reliability of the systems you work on.

Professional Help for Engine Work

When it comes to complex machinery, seeking expert assistance can be crucial for ensuring optimal performance and longevity. Engaging qualified technicians allows for accurate diagnostics and repairs, significantly reducing the risk of future complications. Professionals bring a wealth of experience and specialized knowledge that can save time and resources, making their support invaluable in any repair scenario.

Understanding the Benefits

Utilizing the skills of seasoned specialists not only enhances the efficiency of repairs but also guarantees the use of high-quality materials and tools. This ensures that all adjustments are made according to industry standards, ultimately leading to better reliability and performance. Moreover, regular maintenance performed by trained individuals can prevent minor issues from escalating into major problems.

Finding the Right Experts

When searching for the right professionals, consider their certifications and customer reviews. A reputable service provider will typically offer warranties on their work, demonstrating confidence in their abilities. In addition, establishing a long-term relationship with a reliable technician can provide peace of mind and ongoing support for your machinery needs.