Comprehensive Honda GC160 Engine Parts Diagram Guide

The intricate world of small machinery relies heavily on a variety of components that work together seamlessly. Understanding how these elements fit into the larger system is essential for both maintenance and repair. A clear visualization of these components can greatly enhance one’s ability to troubleshoot and optimize performance.

Each segment plays a pivotal role, from the fuel delivery system to the ignition mechanism. By familiarizing oneself with the layout and functionality of each piece, operators can ensure their equipment runs smoothly and efficiently. Such knowledge not only aids in identifying potential issues but also empowers users to make informed decisions regarding upgrades or replacements.

For enthusiasts and professionals alike, having access to detailed representations of these elements simplifies the process of understanding how everything interconnects. This insight is invaluable, especially when addressing wear and tear over time. A well-organized overview can serve as a helpful reference, guiding users through the complexities of small engine maintenance.

Understanding the Honda GC160 Engine

This section aims to provide a comprehensive overview of a specific type of power unit commonly utilized in various outdoor applications. Recognized for its reliability and efficiency, this small motor has become a popular choice among users who seek dependable performance.

At its core, this machine features a four-stroke design, ensuring optimal fuel efficiency while delivering robust power output. The compact construction allows for versatility in usage, making it suitable for tasks ranging from gardening to light industrial applications.

Key Components: The functionality of this power source relies on several critical elements, including the combustion chamber, fuel delivery system, and the ignition mechanism. Each of these components plays a vital role in ensuring smooth operation and longevity.

Maintenance: Regular upkeep is essential to maximize the lifespan of the unit. Routine checks on oil levels, air filters, and spark plugs can significantly enhance performance and prevent unexpected breakdowns.

Understanding the intricacies of this motor not only aids in effective utilization but also empowers users to troubleshoot minor issues, ultimately leading to a more rewarding experience with the equipment.

Key Components of the GC160 Engine

This section explores the essential elements that contribute to the functionality and performance of a small four-stroke power unit. Understanding these vital components allows for better maintenance and optimization.

- Crankshaft: Central to the unit’s operation, converting linear motion into rotational force.

- Piston: Moves within the cylinder, playing a critical role in the combustion process.

- Connecting Rod: Connects the piston to the crankshaft, facilitating movement.

- Cylinder Head: Houses valves and contributes to air-fuel mixture intake and exhaust.

- Valves: Control the entry and exit of air and fuel, essential for efficient operation.

By focusing on these core components, users can ensure longevity and optimal performance of their power unit.

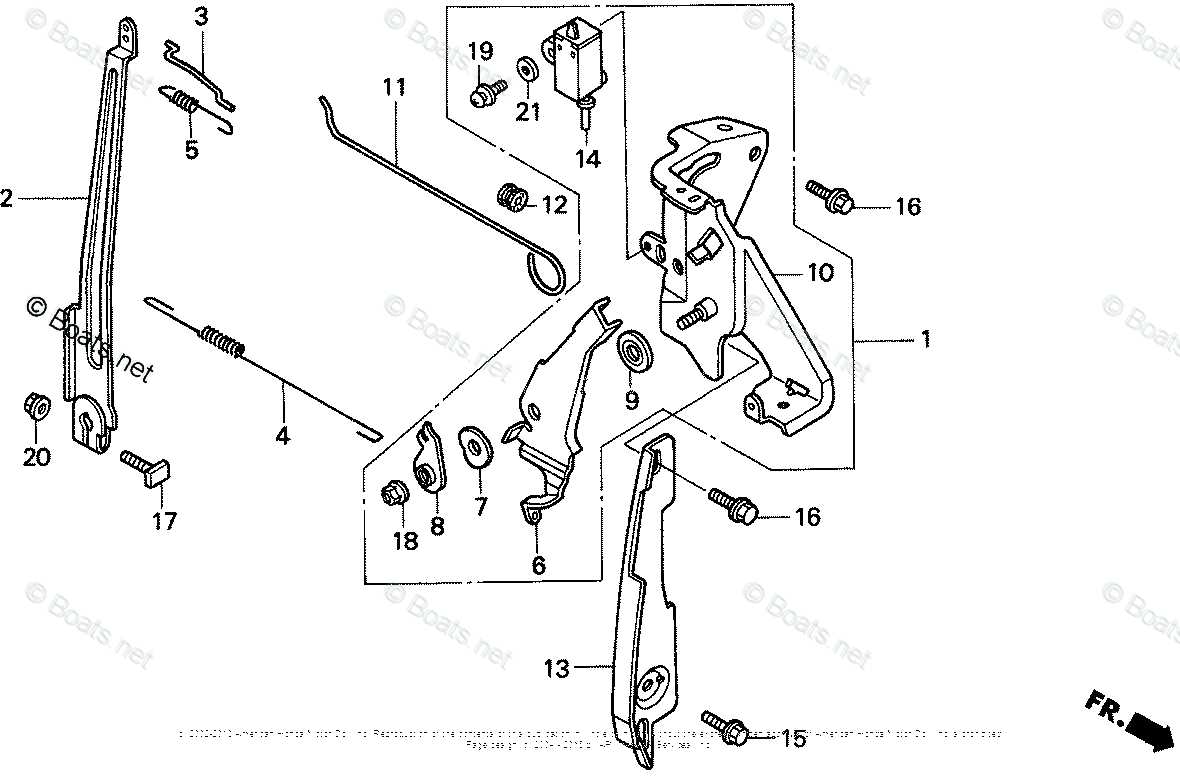

Importance of a Parts Diagram

A visual representation of components plays a crucial role in understanding mechanical assemblies. Such illustrations provide clarity and facilitate effective maintenance, repairs, and assembly processes.

Here are several reasons why these visuals are essential:

- Enhanced Understanding: A clear image helps users grasp the relationships between different components.

- Efficient Troubleshooting: Identifying issues becomes simpler when one can visually reference parts.

- Streamlined Assembly: Following a visual guide allows for a more organized and accurate assembly process.

- Accurate Ordering: Knowing exactly what is needed prevents errors when sourcing replacements.

- Improved Communication: Technicians and hobbyists can share information more effectively with a common visual reference.

In summary, having a comprehensive visual guide is invaluable for anyone working with mechanical systems, ensuring efficiency and accuracy in all related tasks.

Common Issues with GC160 Parts

Understanding frequent complications can greatly enhance maintenance and longevity. Many users encounter similar challenges, often stemming from wear and tear or improper handling.

- Difficulty starting due to fuel delivery issues.

- Overheating caused by cooling system failures.

- Loss of power linked to air filter blockages.

- Unusual noises from components signaling wear.

- Vibration problems due to misaligned or damaged elements.

Addressing these concerns promptly can ensure optimal performance and prevent more severe damage.

Maintenance Tips for Honda GC160

Regular upkeep is essential for ensuring optimal performance and longevity of your small machinery. Implementing a routine maintenance schedule can prevent unexpected breakdowns and enhance efficiency.

Routine Checks

Conduct periodic inspections of all critical components. Look for signs of wear and tear, ensuring that everything is securely fastened. Pay particular attention to oil levels, as proper lubrication is vital for smooth operation.

Cleaning and Care

Keep the exterior clean to prevent debris buildup. Use a soft brush or cloth to remove dirt and grime. Cleaning not only improves appearance but also helps in detecting potential issues early. Regular maintenance will ultimately lead to better performance and reliability.

How to Read Engine Diagrams

Understanding mechanical layouts is crucial for maintenance and repair tasks. Familiarizing yourself with these visuals helps in identifying components and their relationships, ensuring efficient troubleshooting and assembly processes.

Key Components of Diagrams

- Labels: Descriptions next to parts provide essential information.

- Symbols: Standard icons represent various elements, such as fasteners or connections.

- Lines: Different line styles indicate various relationships, such as electrical or mechanical connections.

Steps to Effectively Read Diagrams

- Start with the overall view to grasp the layout.

- Identify major components and their functions.

- Follow lines to understand how parts connect and interact.

- Refer to accompanying legends for clarification of symbols.

Where to Find Replacement Parts

Locating suitable components for your machinery is essential for maintaining optimal performance and longevity. Various sources offer a range of options to ensure you find what you need efficiently.

- Online Retailers: Numerous websites specialize in machinery components, providing extensive catalogs and user-friendly search functions.

- Local Dealers: Authorized distributors often carry specific components and can offer personalized assistance.

- Automotive Stores: Many local shops stock compatible items or can order them for you, making it convenient to acquire what you need.

- Manufacturer Websites: Directly visiting the official website can lead you to a dedicated section for finding genuine replacements.

- Forums and Community Groups: Engaging with fellow enthusiasts can yield recommendations for trusted sources and even second-hand options.

By exploring these avenues, you can ensure that your equipment runs smoothly and efficiently for years to come.

Assembly Instructions for GC160 Engine

When piecing together a mechanical unit, it’s essential to follow a structured approach to ensure optimal performance. This guide provides clear steps to facilitate the assembly process, highlighting critical components and their interactions.

1. Preparation: Before starting, gather all necessary tools and components. Ensure you have a clean workspace to prevent any contaminants from interfering with the assembly.

2. Base Assembly: Begin by securing the main framework. This acts as the foundation for other components. Align all parts carefully to guarantee stability.

3. Component Installation: Next, introduce essential elements such as the crankshaft and piston. Ensure they fit snugly into their designated positions, checking for proper orientation.

4. Connection of Auxiliary Parts: After the main components are in place, attach the auxiliary parts. This includes fittings and connectors, which must be tightened to prevent any leaks.

5. Final Checks: Once everything is assembled, conduct a thorough inspection. Ensure all connections are secure and that no parts are left loose. Testing the unit for functionality is recommended before putting it into regular use.

Following these steps will lead to a well-assembled unit, primed for reliable operation and longevity.

Comparing GC160 with Similar Models

When evaluating small power units, it’s essential to consider how different models stack up against each other in performance and reliability. By examining the features and specifications of various alternatives, users can make informed decisions that best suit their needs.

Performance is a critical factor; some models may offer higher torque, while others excel in fuel efficiency. Durability also plays a significant role, as certain designs are built to withstand harsher conditions, extending their lifespan significantly.

Additionally, maintenance requirements vary among units, with some necessitating more frequent servicing than others. This aspect can greatly influence the overall cost of ownership and convenience for users.

Finally, accessibility of replacement components can impact long-term usability. Models with readily available parts are often favored by users who seek to minimize downtime and ensure consistent operation.

Upgrades for Enhanced Performance

Boosting the efficiency and output of small machinery can significantly enhance overall functionality. Various modifications can lead to improved power, fuel efficiency, and longevity, making them essential for enthusiasts and professionals alike. Exploring a range of enhancements can unlock the full potential of your equipment, ensuring it meets specific demands and performs reliably in diverse conditions.

Improved Airflow and Filtration

One of the most effective ways to increase performance is by optimizing airflow. Upgrading to a high-performance air intake system allows for greater air volume and reduced restrictions. Additionally, utilizing a quality filter can trap more impurities while ensuring a consistent flow of clean air. This combination leads to better combustion, ultimately resulting in enhanced output and efficiency.

Enhanced Fuel System Components

Another crucial aspect of performance upgrades is the fuel delivery mechanism. Consider replacing standard components with advanced versions designed for higher efficiency. A performance carburetor can optimize the air-fuel mixture, leading to more power and smoother operation. Coupling this with a premium fuel pump ensures that your system maintains adequate pressure, preventing any potential loss of power during demanding tasks.

Investing in these enhancements not only improves immediate performance but can also contribute to the durability and reliability of your machinery. With careful consideration of upgrades, users can achieve remarkable results tailored to their specific needs.

Frequently Asked Questions About GC160

This section addresses common inquiries related to a popular small power unit, focusing on its functionality, maintenance, and components. Users often seek clarity on various aspects to ensure optimal performance and longevity.

What are the typical applications for this type of power unit?

These units are commonly used in various tools and equipment, including lawn mowers, generators, and pressure washers. Their versatility makes them suitable for both residential and commercial use.

How often should I perform maintenance?

Regular upkeep is essential for efficiency. It’s recommended to check and change the oil every 20-50 hours of operation, along with air filter inspection and spark plug replacement as needed.

What should I do if the unit won’t start?

If starting issues arise, first ensure there’s fuel and that the on/off switch is set correctly. Check the spark plug for wear and inspect the fuel system for clogs or leaks.

Where can I find replacement components?

Replacement components can typically be found at local hardware stores, specialty shops, or online retailers. It’s advisable to reference the specific model number for accurate matching.

Are there any common issues to be aware of?

Common problems include fuel leaks, starting difficulties, and reduced power output. Regular maintenance can help mitigate these issues and enhance overall reliability.