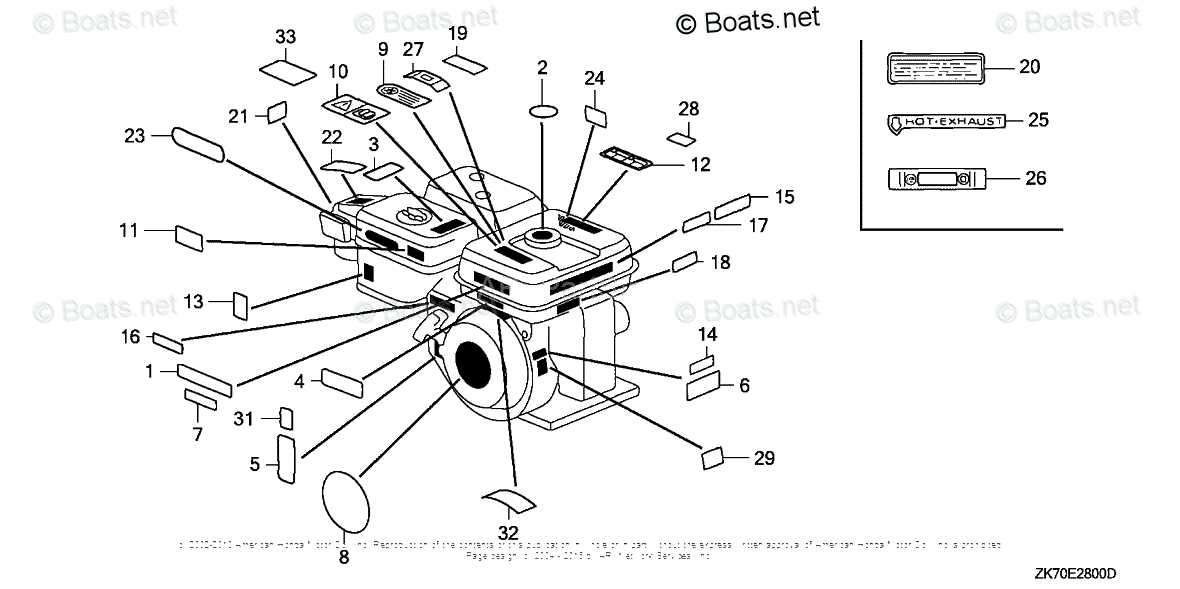

Understanding the Honda Small Engine Parts Diagram

In the realm of machinery, a thorough comprehension of the various elements that contribute to optimal functionality is essential. Each individual component plays a crucial role in ensuring that the system operates smoothly and efficiently. A clear representation of these elements can aid in diagnosing issues and enhancing performance.

Visual aids serve as invaluable resources for both novices and seasoned professionals alike. They provide a structured overview, allowing users to quickly identify specific sections and components, facilitating a deeper understanding of their relationships and functions. This organized approach simplifies maintenance and repairs, ensuring longevity and reliability.

Exploring the intricacies of these mechanical assemblies can unveil the secrets behind their operation. By familiarizing oneself with the layout and interaction of each component, one can cultivate a more profound appreciation for the technology at play. Whether for troubleshooting or routine upkeep, grasping this information is key to maximizing the efficiency of any compact power unit.

Understanding Honda Small Engines

Many individuals rely on compact power units for various applications, from gardening to recreational vehicles. These reliable machines are celebrated for their efficiency and durability, making them a staple in both residential and commercial settings. Grasping their fundamental components and functionality is essential for optimal performance and maintenance.

Typically, these power units consist of several key elements that work in harmony. Each component plays a vital role in ensuring smooth operation and longevity. Familiarity with these essential features can help users troubleshoot issues and enhance overall reliability.

Maintenance practices significantly contribute to the lifespan of these power sources. Regular checks and timely replacements of specific components can prevent malfunctions and ensure peak efficiency. Understanding the mechanics involved allows users to approach maintenance with confidence and competence.

In summary, a solid comprehension of these compact power units not only aids in effective use but also fosters a proactive approach to upkeep. This knowledge empowers users to maximize performance and prolong the life of their equipment.

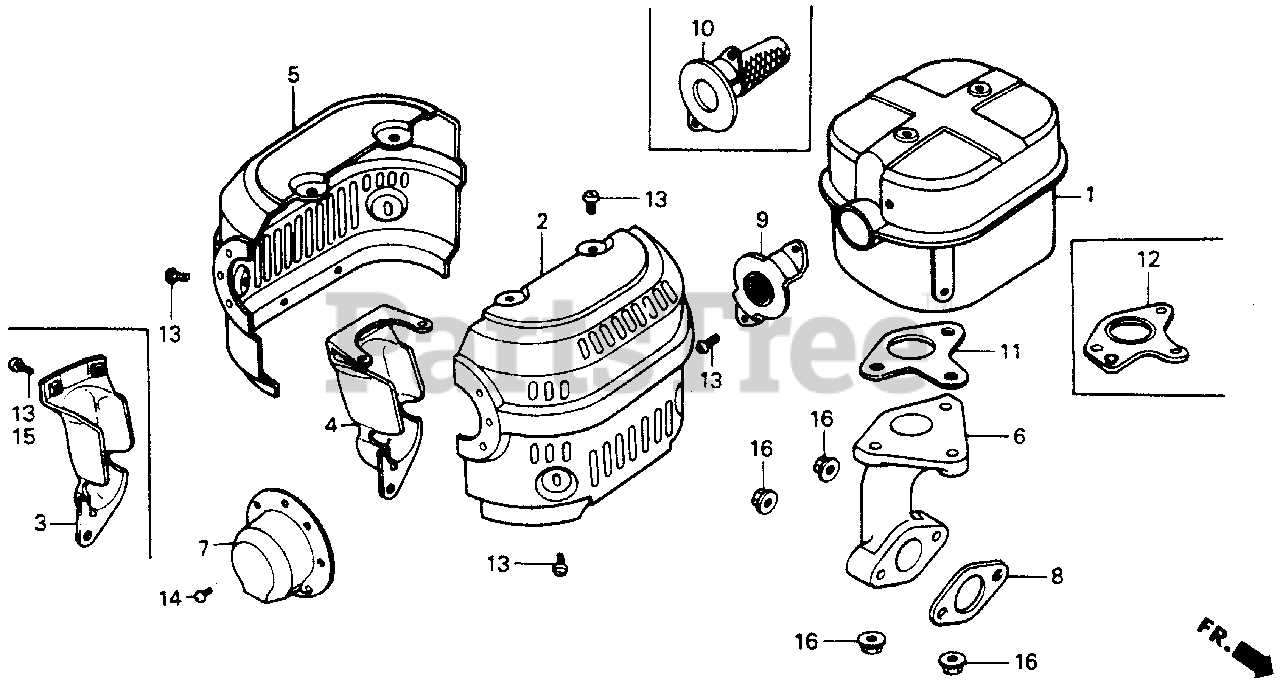

Key Components of Small Engines

Understanding the essential elements of compact power units is crucial for effective maintenance and repair. These fundamental components work together to ensure optimal performance and efficiency, playing a vital role in various applications such as gardening, construction, and recreational activities.

The primary elements include:

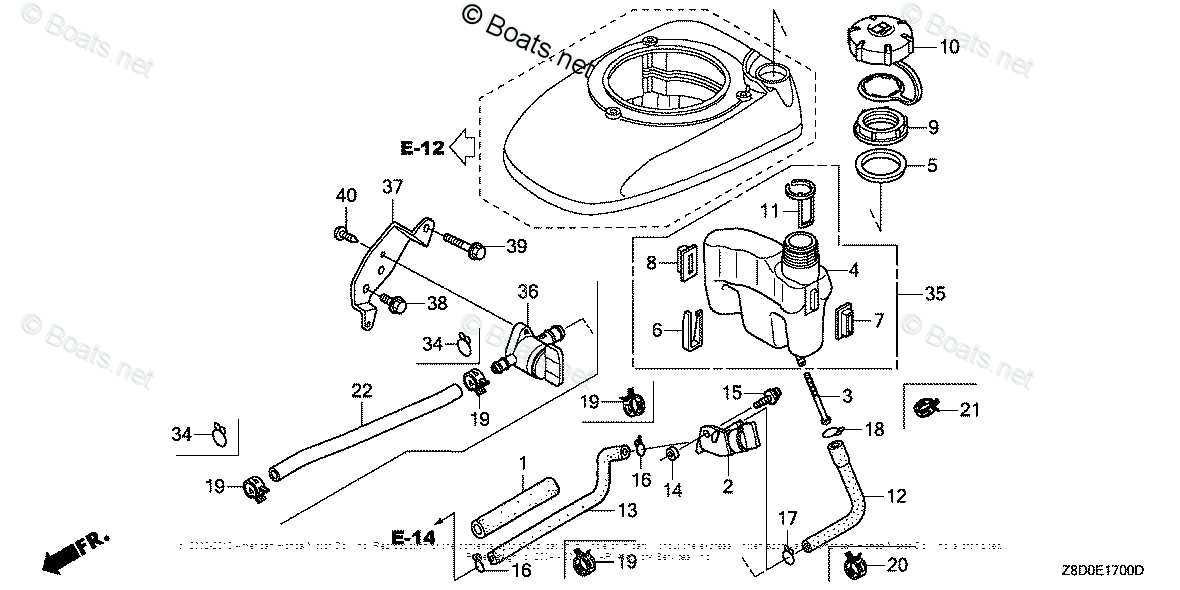

- Fuel System: Responsible for delivering the necessary energy source.

- Ignition System: Ensures the combustion process initiates correctly.

- Cooling Mechanism: Maintains optimal operating temperatures to prevent overheating.

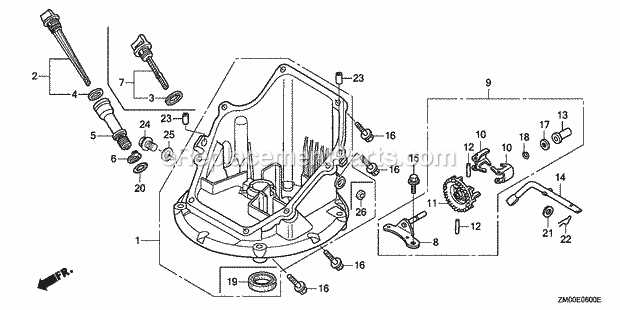

- Lubrication System: Reduces friction and wear between moving parts.

- Exhaust System: Directs harmful gases away from the unit and the operator.

Each of these components plays a unique role, contributing to the overall functionality and reliability of the machinery. Proper understanding and regular inspection can significantly enhance longevity and performance.

In addition, several auxiliary components enhance usability and control:

- Air Filter: Ensures clean air intake, essential for efficient combustion.

- Starter System: Facilitates the initial activation of the unit.

- Chassis: Provides structural integrity and support for all components.

- Control Mechanisms: Allow operators to manage speed and functionality effectively.

Familiarity with these critical elements will empower users to make informed decisions regarding maintenance and repair, ultimately leading to improved performance and satisfaction.

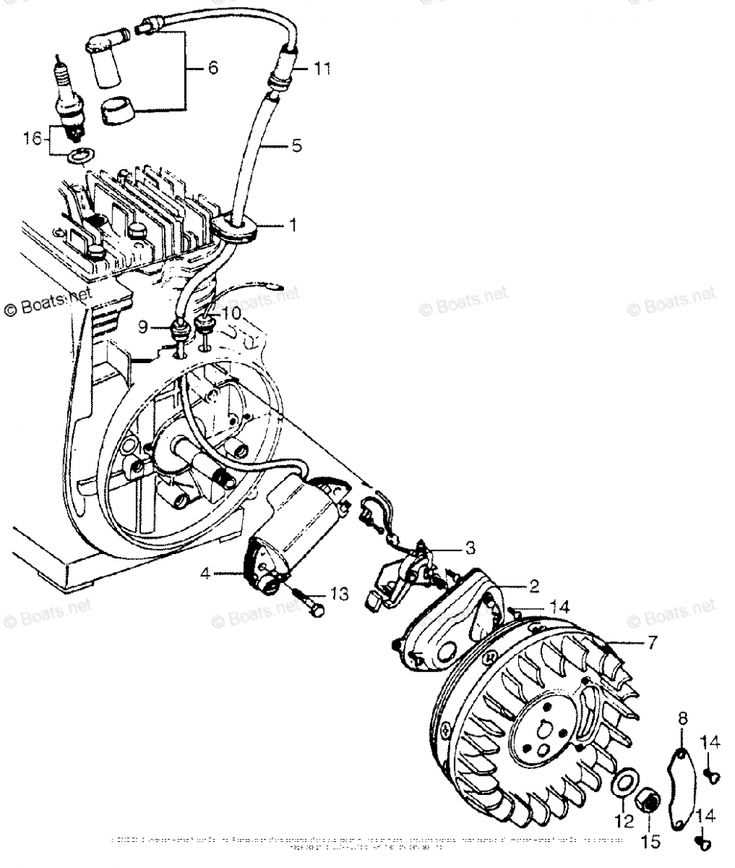

Importance of Accurate Diagrams

Precise illustrations play a crucial role in the maintenance and repair of machinery. They provide a visual representation that enhances understanding and aids in the identification of components, ensuring that tasks are performed correctly and efficiently.

Benefits of Accurate Illustrations

- Improved Clarity: Clear visuals help users grasp complex layouts and structures, reducing the likelihood of errors.

- Time Efficiency: Detailed schematics allow for quicker diagnosis and repairs, minimizing downtime.

- Enhanced Safety: Knowing the exact locations and functions of various elements contributes to safer handling and operations.

Consequences of Inaccurate Representations

- Misidentification of components, leading to incorrect replacements.

- Increased risk of mechanical failure due to improper assembly.

- Wasted time and resources, causing frustration for technicians and users alike.

In summary, having accurate visual guides is essential for successful operation and upkeep. They not only facilitate effective problem-solving but also promote a safer and more efficient working environment.

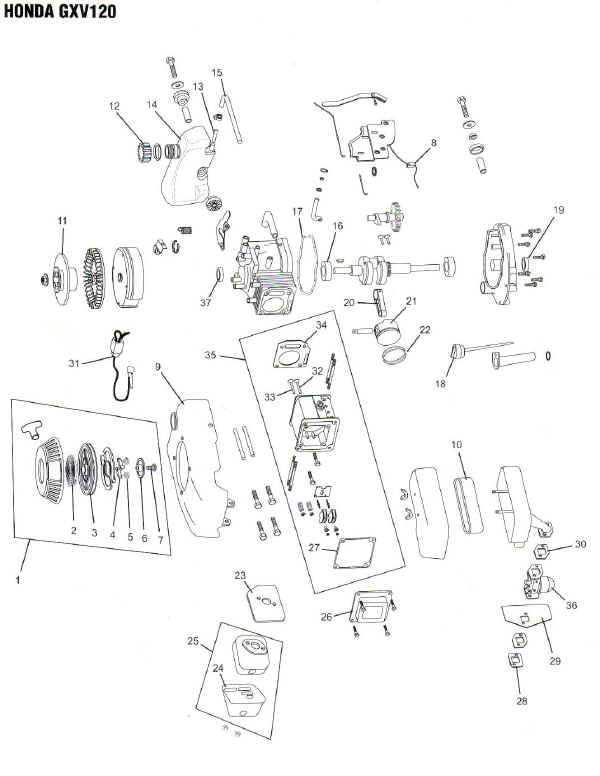

Common Honda Engine Models

Understanding the variety of popular power units is essential for anyone working with outdoor equipment or machinery. Each model is designed to serve specific applications, providing efficiency and reliability. Below are some well-known types that are frequently utilized in various settings.

GX Series units are renowned for their durability and performance. These models are often found in commercial applications due to their robust design and capability to handle heavy workloads. Their reputation for reliability makes them a top choice for professionals.

GC Series focuses on residential use, providing an ideal balance between power and efficiency. These compact units are perfect for home lawn care and light landscaping tasks, offering easy operation and maintenance for everyday users.

GXV Series introduces advanced features suited for recreational vehicles and larger machinery. These models are designed with enhanced technology to deliver superior performance, ensuring that they meet the demands of various industries.

F Series units are known for their lightweight design and versatility. Ideal for portable applications, they are commonly used in smaller equipment and tools, making them essential for hobbyists and DIY enthusiasts.

By familiarizing oneself with these popular models, users can make informed decisions about which power units best meet their needs, ensuring optimal performance and satisfaction in their endeavors.

How to Read Engine Diagrams

Understanding technical illustrations related to machinery can significantly enhance your ability to maintain and repair equipment. These visual representations provide a detailed overview of components and their interconnections, making it easier to identify parts and their functions. Familiarity with common symbols and notations is essential for effective interpretation.

1. Familiarize Yourself with Symbols: Most technical illustrations use standardized symbols to represent various components. Taking the time to learn these can save you confusion when trying to identify parts. Look for a legend or key that explains what each symbol means.

2. Follow the Flow: Many illustrations depict a flow of energy or motion. Tracing the pathways can help you understand how the different elements interact. Pay attention to arrows and lines, as they indicate the direction of movement or the relationship between components.

3. Break It Down: Instead of attempting to understand the entire illustration at once, break it into smaller sections. Focus on one area, identify the components, and comprehend their roles before moving on to the next part.

4. Reference the Manual: Often, the accompanying manual will provide additional context or explanations. Cross-referencing this information can enhance your understanding and clarify any doubts about the representation.

5. Practice Regularly: Like any skill, becoming proficient at reading technical illustrations requires practice. Regularly engage with different types of visuals to improve your speed and comprehension.

Essential Parts for Maintenance

Proper upkeep of machinery is crucial for ensuring longevity and optimal performance. Understanding the fundamental components involved can significantly enhance the efficiency and reliability of your equipment. Regular inspection and timely replacement of these elements will help avoid unexpected breakdowns and extend operational life.

Key Components

Filters play a vital role in maintaining cleanliness within the system. Regular replacement of air and fuel filters ensures that only clean substances circulate, preventing wear and tear on internal mechanisms. Additionally, spark plugs are essential for ignition, and their condition directly influences the efficiency of combustion. Replacing worn spark plugs can lead to improved fuel efficiency and smoother operation.

Lubrication and Seals

Proper lubrication is fundamental for reducing friction and heat in moving parts, thereby minimizing wear. Utilizing high-quality oils and regularly checking levels can safeguard against potential failures. Furthermore, gaskets and seals are critical for maintaining integrity and preventing leaks. Over time, these components may degrade, so monitoring their condition and replacing them as needed is essential for optimal functioning.

Replacing Worn Engine Components

Maintaining the efficiency and performance of any machinery requires regular inspection and timely replacement of worn components. As mechanical elements endure stress over time, their functionality may decline, leading to decreased performance and potential failure. Identifying which components need attention is crucial for ensuring longevity and reliability.

When assessing the condition of various elements, look for signs of wear such as cracking, discoloration, or unusual noises during operation. Components like gaskets, seals, and bearings are often subjected to high levels of friction and heat, making them prime candidates for replacement. Addressing these issues proactively not only enhances performance but also prevents further damage to other connected parts.

Once worn items are identified, sourcing high-quality replacements is essential. Using compatible replacements ensures that the machinery continues to operate efficiently. Careful installation is equally important, as improper fitting can lead to more significant problems down the line. Always consult technical resources or experienced professionals if unsure about the replacement process.

In conclusion, regular monitoring and timely replacement of worn components are vital for maintaining optimal functionality. By taking these steps, you can extend the life of your machinery and keep it running smoothly.

Tools Needed for Engine Repairs

When it comes to restoring and maintaining mechanical systems, having the right equipment is essential for success. Various tasks require specific instruments to ensure precision and efficiency. Understanding which tools to have on hand can make a significant difference in both the quality of the repair and the time it takes to complete it.

Essential Instruments

Some of the most crucial tools include wrenches, screwdrivers, and pliers. These basic implements are indispensable for disassembling components and making adjustments. A reliable set of sockets and ratchets can enhance accessibility to hard-to-reach areas, ensuring that every bolt and screw can be managed effectively.

Specialized Equipment

In addition to standard tools, specialized devices may be necessary for specific tasks. For instance, torque wrenches help achieve the proper tension on fasteners, while compression testers can assess the overall health of the system. Having a quality multimeter allows for the diagnosis of electrical issues, ensuring all parts function harmoniously.

Preparation and organization are key to a smooth repair process. Keeping tools neatly arranged and readily accessible can streamline your workflow, reducing downtime and frustration. Investing in a sturdy toolbox or storage system will further enhance your efficiency and effectiveness in any mechanical undertaking.

Troubleshooting Engine Issues

Identifying and resolving complications in mechanical systems can be a daunting task. However, with a systematic approach, one can efficiently diagnose problems and restore functionality. This section will outline common symptoms, potential causes, and recommended solutions to help guide you through the troubleshooting process.

| Symptom | Possible Causes | Suggested Solutions |

|---|---|---|

| Difficulty starting | Faulty ignition system, clogged fuel line, weak battery | Check spark plugs, inspect fuel delivery, recharge or replace battery |

| Unusual noises | Loose components, worn bearings, inadequate lubrication | Tighten fittings, replace damaged parts, ensure proper oil levels |

| Overheating | Coolant leaks, blocked airflow, malfunctioning thermostat | Inspect hoses, clear debris from vents, test thermostat function |

| Reduced power | Clogged filters, fuel quality issues, exhaust restrictions | Replace air and fuel filters, use high-quality fuel, check exhaust system |

| Excessive smoke | Oil contamination, improper fuel mixture, worn piston rings | Change oil, adjust fuel mixture, inspect and replace rings if necessary |

By understanding these common issues and their remedies, you can take the necessary steps to ensure optimal performance and longevity of your mechanical systems. Always refer to reliable manuals or seek professional assistance when needed.

Benefits of Using Genuine Parts

Opting for authentic components in machinery maintenance ensures optimal performance and longevity. These specialized items are crafted to meet exact specifications, which enhances reliability and efficiency. When it comes to repairs or replacements, genuine options stand out for their superior quality and compatibility.

Enhanced Performance

Using original components significantly improves the functionality of your equipment. Genuine parts are designed to work seamlessly with the overall system, minimizing the risk of malfunctions. This precise fit results in smoother operation, which translates to better productivity and reduced downtime.

Long-Term Cost Efficiency

While aftermarket alternatives may seem tempting due to lower initial costs, they often lead to frequent replacements and repairs. Investing in authentic components ultimately proves to be more economical over time. The durability and reliability of these items reduce the likelihood of unexpected failures, saving you both time and money in the long run.

Aftermarket vs. Original Components

The choice between replacement components produced by the original manufacturer and those made by third-party suppliers often sparks debate among enthusiasts and professionals alike. Each option presents its own advantages and disadvantages, influencing both performance and budget considerations.

Quality and Performance

Original components typically offer superior quality and reliability, as they are designed specifically for compatibility with the original design. These parts undergo rigorous testing and adhere to strict manufacturing standards. In contrast, aftermarket alternatives may vary widely in quality, with some providing exceptional performance while others fall short, potentially leading to issues down the line.

Cost and Availability

While original components tend to come with a higher price tag, they are often more readily available through authorized dealers. Aftermarket options, however, can provide significant savings and may be more accessible, particularly for older models where original parts might be scarce. This makes aftermarket solutions an attractive choice for those looking to balance cost with performance.

Best Practices for Engine Care

Caring for your machinery is essential for maintaining optimal performance and longevity. By following a few key practices, you can ensure that your equipment operates smoothly and efficiently over time. Regular maintenance not only enhances performance but also reduces the risk of unexpected breakdowns.

Regular Maintenance Schedule

Establishing a consistent maintenance routine is crucial. Here are some important tasks to include:

- Check and change lubricants regularly to prevent wear and tear.

- Inspect air filters and clean or replace them as necessary.

- Monitor fuel levels and quality to avoid contamination.

- Examine belts and hoses for signs of wear and replace them promptly.

Proper Storage Techniques

When not in use, ensuring proper storage can greatly extend the life of your machinery. Consider the following:

- Keep the equipment in a dry, sheltered location to avoid moisture damage.

- Cover machinery to protect it from dust and debris.

- Store fuel in a safe container, away from heat sources.

- Run the machinery periodically to keep components lubricated and functional.

By adhering to these best practices, you can enhance the performance and reliability of your equipment for years to come.

Resources for Honda Engine Parts

When it comes to maintaining machinery, having access to the right components and their information is essential. There are various resources available that provide detailed insights and supplies to ensure optimal performance. Whether you’re a seasoned mechanic or a casual user, knowing where to find reliable information can make all the difference.

Here are some valuable resources to consider:

- Online Retailers:

- Numerous websites specialize in offering a wide array of components.

- Many provide user reviews and ratings to help with informed choices.

- Manufacturer Websites:

- Official sites often have catalogs and manuals available for download.

- They may also offer customer support for inquiries regarding specific items.

- Forums and Community Groups:

- Online communities can be a wealth of knowledge for troubleshooting and advice.

- Members frequently share experiences and sources for sourcing components.

- Local Dealers:

- Authorized retailers can provide original equipment, ensuring compatibility.

- They may also offer maintenance services and advice on usage.

Utilizing these resources can significantly enhance the reliability and efficiency of your machinery, ensuring it remains in peak condition for years to come.