Paccar Engine Parts Diagram Overview

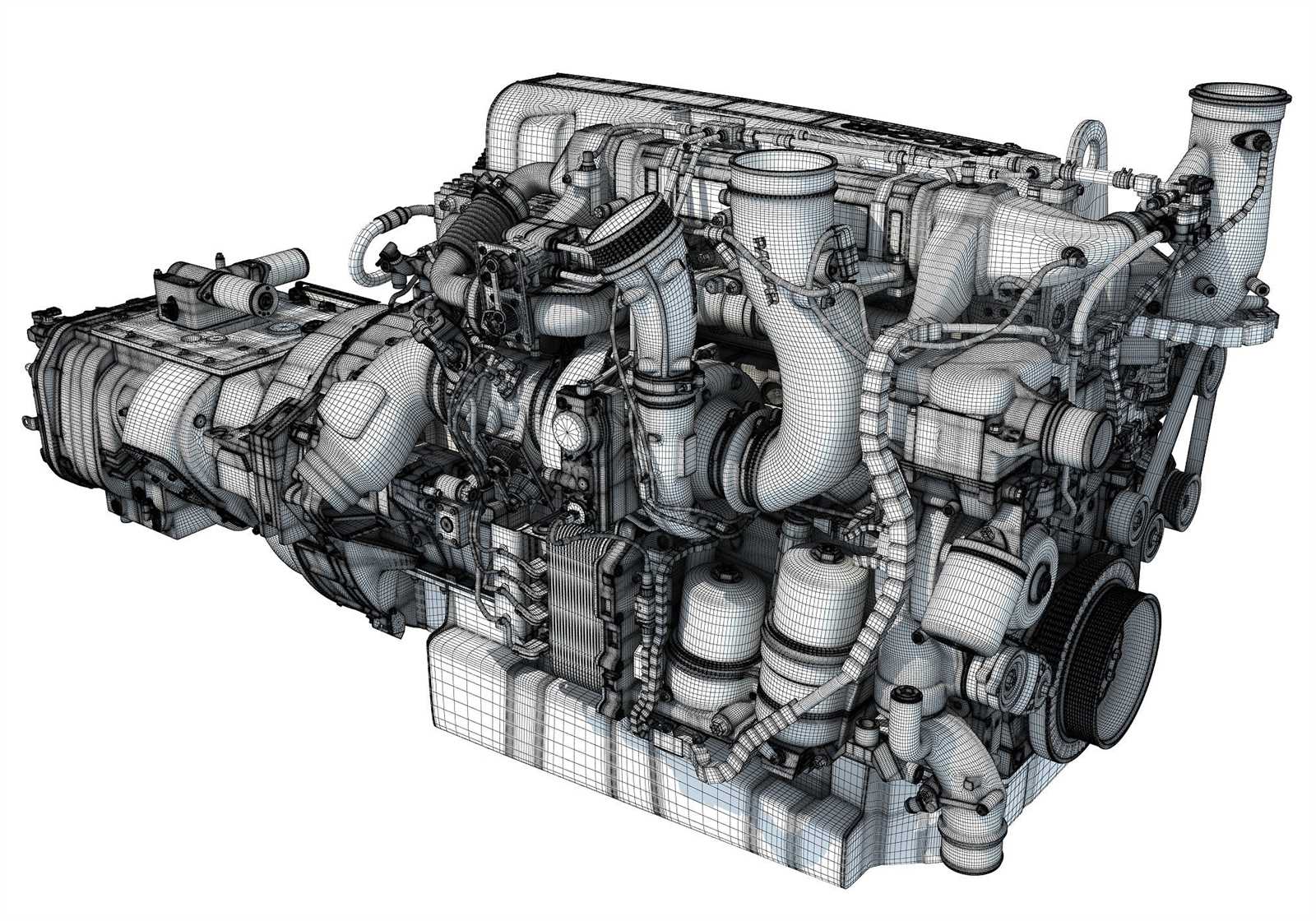

The intricate world of machinery often relies on a myriad of elements working in harmony. Each component plays a crucial role, contributing to the overall functionality and performance of the system. Grasping the layout and interaction of these vital elements is essential for both enthusiasts and professionals.

By exploring detailed visuals and organized schematics, one can gain valuable insights into how these mechanical features operate together. This knowledge not only enhances comprehension but also aids in maintenance and troubleshooting, ensuring longevity and efficiency.

As we delve deeper into this subject, the ultimate goal is to empower readers with the understanding necessary to appreciate the complexities behind these technological marvels. Whether for educational purposes or practical application, a thorough exploration of these internal mechanisms is both enlightening and beneficial.

Paccar Engine Components Overview

This section provides an insightful look into the various essential elements that contribute to the overall functionality and performance of heavy machinery. Understanding these components is crucial for maintenance and optimal operation, as each plays a unique role in the system’s efficiency.

Key Functional Elements

Among the most significant elements are the block, crankshaft, and camshaft, which work harmoniously to facilitate movement and power generation. The block serves as the foundation, while the crankshaft transforms linear motion into rotational force. Meanwhile, the camshaft manages the timing of valve openings, ensuring a seamless flow of fuel and air.

Supportive Mechanisms

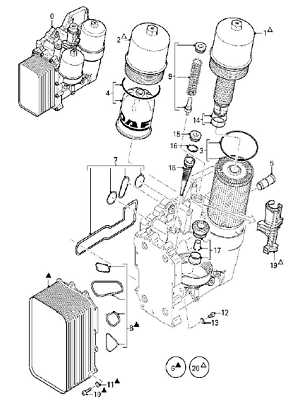

Additionally, components such as the fuel injection system and cooling apparatus are vital for maintaining optimal performance. The fuel injection system precisely delivers fuel, enhancing combustion efficiency, whereas the cooling apparatus regulates temperature, preventing overheating during operation.

Understanding Engine Diagrams Basics

Grasping the fundamentals of mechanical schematics is essential for anyone involved in automotive systems. These illustrations serve as vital tools for comprehension, providing clarity on how various components interact and function together. Mastering these visuals not only aids in troubleshooting but also enhances overall knowledge of the machinery.

Components and Their Relationships

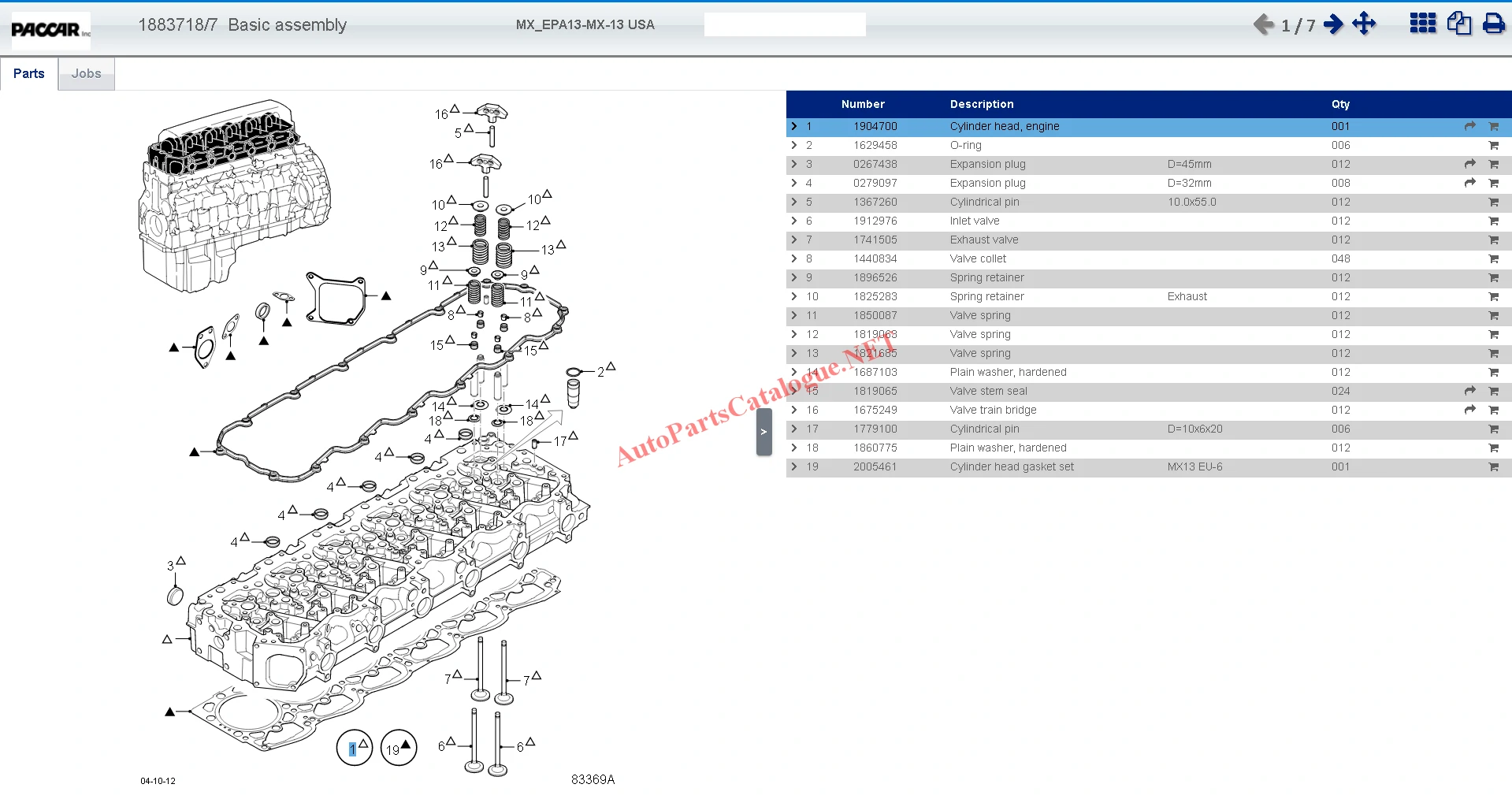

Each schematic typically includes various elements that represent different mechanical sections. Recognizing how these sections connect and operate collectively is crucial for effective maintenance and repair. Understanding these relationships can significantly improve efficiency in diagnosing issues.

Interpreting Visual Information

Learning to interpret these visuals requires familiarity with common symbols and notations. Developing this skill allows for a quicker assessment of systems, leading to more informed decisions. A well-interpreted schematic can serve as the ultimate roadmap for any technician.

Key Parts of Paccar Engines

Understanding the essential components of a power unit is crucial for maintaining optimal performance and longevity. Each element plays a significant role in ensuring smooth operation, efficiency, and reliability, contributing to the overall functionality of the system.

Core Components

At the heart of the system lies the block, which houses vital mechanisms. Complementing this are the pistons, responsible for converting fuel into motion. The crankshaft and camshaft work in tandem, controlling the timing and power delivery.

Supporting Elements

In addition, the cooling and lubrication systems are pivotal. The radiator keeps temperatures in check, while the oil pump ensures that all moving parts remain well-lubricated, preventing wear and tear over time.

Importance of Accurate Diagrams

Clear and precise visual representations play a crucial role in technical fields, providing essential guidance for assembly, maintenance, and troubleshooting. These illustrations serve as invaluable tools that help individuals understand complex systems, ensuring that each component is correctly identified and utilized.

Accurate visuals enhance efficiency by minimizing the risk of errors during installation or repair. When users can easily refer to detailed schematics, they are more likely to follow proper procedures, leading to better outcomes and prolonged lifespan of the machinery involved.

Moreover, high-quality illustrations foster effective communication among technicians and engineers. When all parties have access to consistent and well-detailed representations, it reduces misunderstandings and streamlines collaboration, ultimately improving overall productivity.

In addition, reliable visuals support training and onboarding processes for new personnel. By equipping them with comprehensive and accurate information, organizations can ensure that their teams are well-prepared to handle tasks efficiently and with confidence.

Common Issues with Engine Parts

Mechanical systems are often prone to a variety of challenges that can impact their performance and reliability. Understanding the frequent problems that can arise with these components is essential for maintaining optimal functionality and ensuring longevity. Recognizing these issues can aid in prompt diagnosis and effective solutions, ultimately enhancing operational efficiency.

Wear and Tear

One of the most prevalent challenges faced involves gradual degradation due to regular use. Over time, friction and heat can lead to the deterioration of materials, resulting in decreased efficiency and potential failures. Regular inspections can help identify early signs of wear, allowing for timely interventions.

Sealing Failures

Another common concern is the failure of seals, which can lead to leaks and contamination. Proper installation and routine maintenance are crucial to preventing such issues. If left unaddressed, leaks can cause significant damage and necessitate costly repairs.

How to Read Engine Diagrams

Understanding technical illustrations is essential for grasping complex machinery. These visual representations provide crucial information about components, their relationships, and functionality. By learning to interpret these visuals, one can enhance their mechanical knowledge and troubleshooting skills.

Familiarize with Symbols

Each illustration utilizes specific icons and notations to represent various elements. Studying these symbols helps decode the overall layout and flow. Pay attention to legends and keys, which often clarify meanings and provide context.

Identify Connections and Flow

Observing how components interact is vital. Look for lines that indicate movement or flow between parts. Recognizing these connections can reveal how different sections operate together, facilitating a deeper understanding of the overall system.

Maintenance Tips for Paccar Engines

Regular upkeep is essential for ensuring optimal performance and longevity of heavy machinery. Following best practices not only enhances efficiency but also minimizes the risk of unexpected failures. This section outlines key strategies to maintain these robust systems effectively.

Routine Inspections

Frequent checks are vital. Inspect fluid levels, filters, and belts regularly. Look for signs of wear and tear, as early detection can prevent more significant issues. Always adhere to the manufacturer’s guidelines regarding inspection intervals.

Fluid Changes

Maintaining clean fluids is crucial for the smooth operation of the machinery. Schedule oil and coolant changes at recommended intervals. Using high-quality lubricants helps reduce friction and extend the lifespan of components. Always dispose of used fluids properly to protect the environment.

Incorporating these practices into a maintenance routine will significantly enhance reliability and performance.

Replacement Parts: What You Need

Ensuring optimal performance of your machinery often requires the timely replacement of various components. Understanding which elements to focus on can significantly enhance reliability and longevity, ultimately reducing downtime.

| Component Type | Description | Common Signs of Wear |

|---|---|---|

| Filters | Essential for maintaining fluid cleanliness. | Reduced efficiency, abnormal noises. |

| Belt Systems | Crucial for transferring power within the system. | Cracking, fraying, or slipping. |

| Gaskets | Prevent leaks and ensure proper sealing. | Oil spots, fluid leaks. |

| Valves | Control the flow of various fluids. | Sticking, irregular operation. |

Benefits of Using Genuine Components

Utilizing authentic components offers a multitude of advantages that enhance overall performance and longevity. These original items are designed specifically for compatibility and optimal functioning, ensuring a seamless integration with the system they support.

Quality Assurance

One of the primary benefits of genuine components is their quality assurance. Manufacturers meticulously test these items to meet stringent standards, providing reliability and peace of mind. Counterfeit or aftermarket alternatives often lack such rigorous testing, leading to potential failures and inefficiencies.

Enhanced Performance

Authentic components contribute significantly to enhanced performance. Their precise engineering allows for improved functionality, resulting in better efficiency and reduced wear over time. Choosing original items ultimately leads to lower maintenance costs and extends the lifespan of the machinery.

Identifying Engine Component Functions

Understanding the roles of various mechanical elements is crucial for optimal performance and maintenance. Each component plays a specific part in the overall operation, contributing to the efficiency and reliability of the system. Recognizing how these elements interact can enhance troubleshooting and repair processes.

Starting with the primary elements, the combustion chamber is where the fuel-air mixture ignites, driving the pistons. Adjacent to this, the crankshaft converts linear motion into rotational energy, essential for propelling the vehicle. Additionally, the cooling system, composed of the radiator and thermostat, regulates temperature, preventing overheating and ensuring smooth operation.

The fuel delivery system, which includes the injectors and fuel pump, ensures the proper amount of fuel reaches the combustion area, influencing power output and efficiency. Moreover, the exhaust system channels harmful gases away, reducing emissions and maintaining performance standards. Understanding these functionalities allows for better diagnostics and maintenance strategies.

In summary, a thorough grasp of each element’s purpose enhances the ability to maintain and improve the overall functionality, ensuring the longevity and reliability of the entire mechanism.

Resources for Further Research

Exploring intricate machinery requires access to reliable information and tools. This section provides a curated selection of resources to enhance your understanding and facilitate deeper investigation into various components and their functionalities.

- Technical Manuals: Detailed guides that offer insights into assembly and maintenance.

- Online Forums: Communities where enthusiasts and professionals share knowledge and experiences.

- Manufacturer Websites: Official platforms often contain valuable documentation and product specifications.

Additionally, consider these resources:

- Research Papers: Academic articles exploring advancements and technologies.

- YouTube Channels: Video tutorials demonstrating practical applications and troubleshooting tips.

- Trade Shows: Events showcasing the latest innovations and networking opportunities.