2011 Ford F250 Front End Components Overview

When maintaining or repairing a vehicle, understanding the complex structure of its mechanical systems is crucial. One of the most important areas involves the mechanisms that support and control the movement of the wheels. These interconnected elements ensure the safety, stability, and overall driving experience of the vehicle. Knowing how these pieces work together helps in identifying issues and keeping your ride smooth.

The suspension and steering systems consist of various elements that contribute to the vehicle’s handling and comfort. From components that absorb shocks to those that keep the wheels aligned, each part plays a significant role in ensuring optimal performance. Whether you’re diagnosing a problem or upgrading for better functionality, having a clear understanding of these systems is invaluable for both professionals and enthusiasts.

Overview of the 2011 Ford F250 Front End

The assembly at the front of the vehicle plays a crucial role in both its performance and safety. It includes a variety of components that work together to ensure smooth steering, proper suspension, and durability. Understanding how these elements interact is essential for maintaining the vehicle’s stability and efficiency on the road.

Key Components

There are several essential elements that contribute to the functionality of this area, each with a specific purpose. From supporting the vehicle’s weight to allowing for controlled movement, these components are critical for reliable operation.

| Component | Function |

|---|---|

| Suspension System | Maintains vehicle balance and absorbs shocks for a smooth ride. |

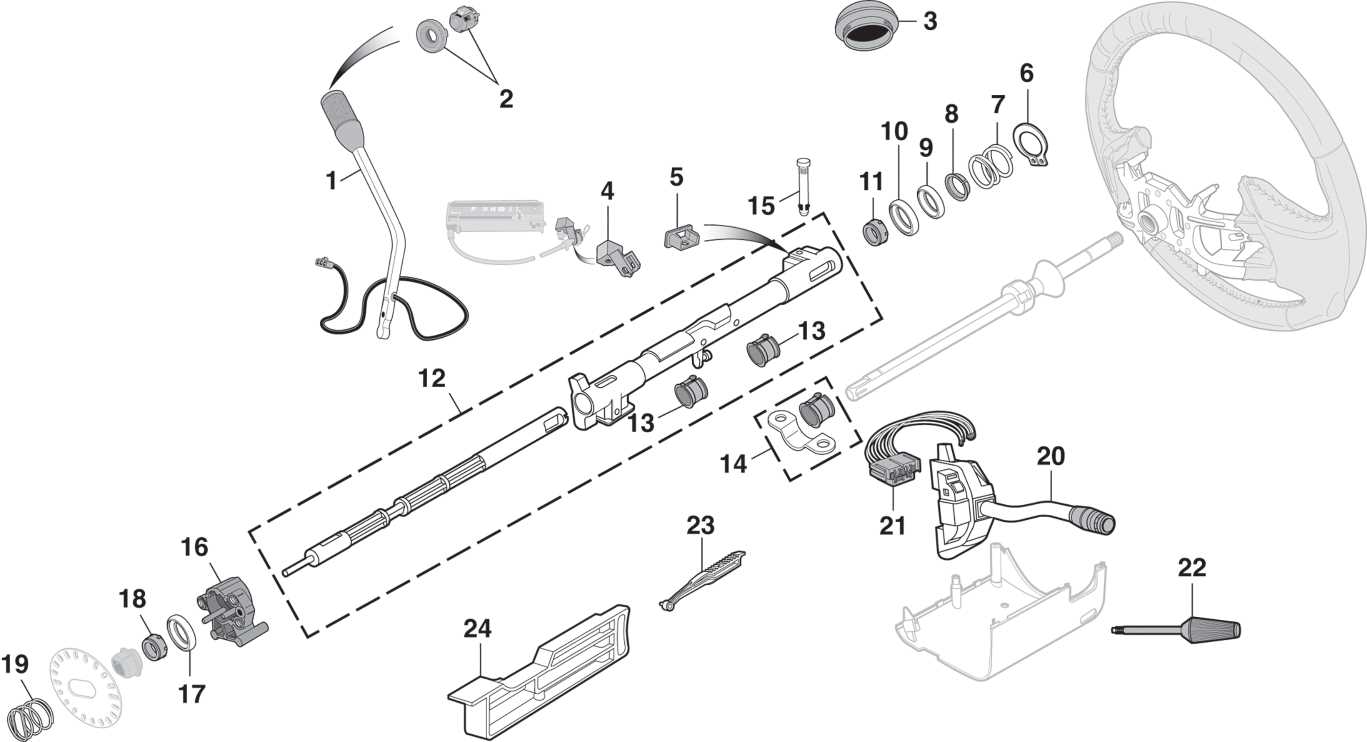

| Steering Linkage | Connects the steering wheel to the wheels, allowing for precise direction control. |

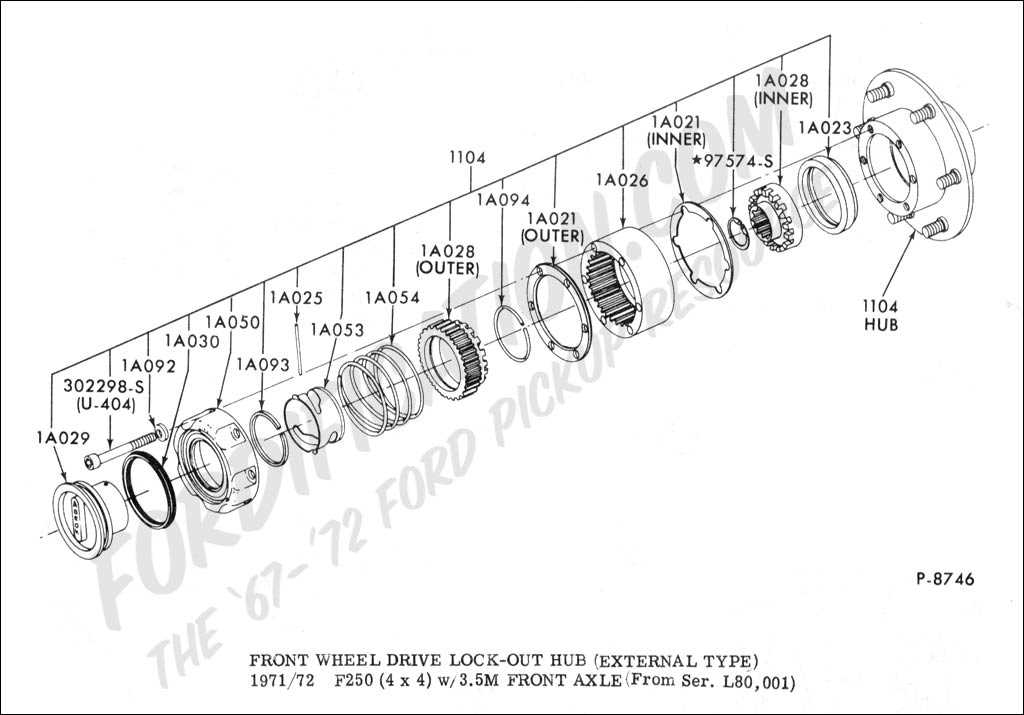

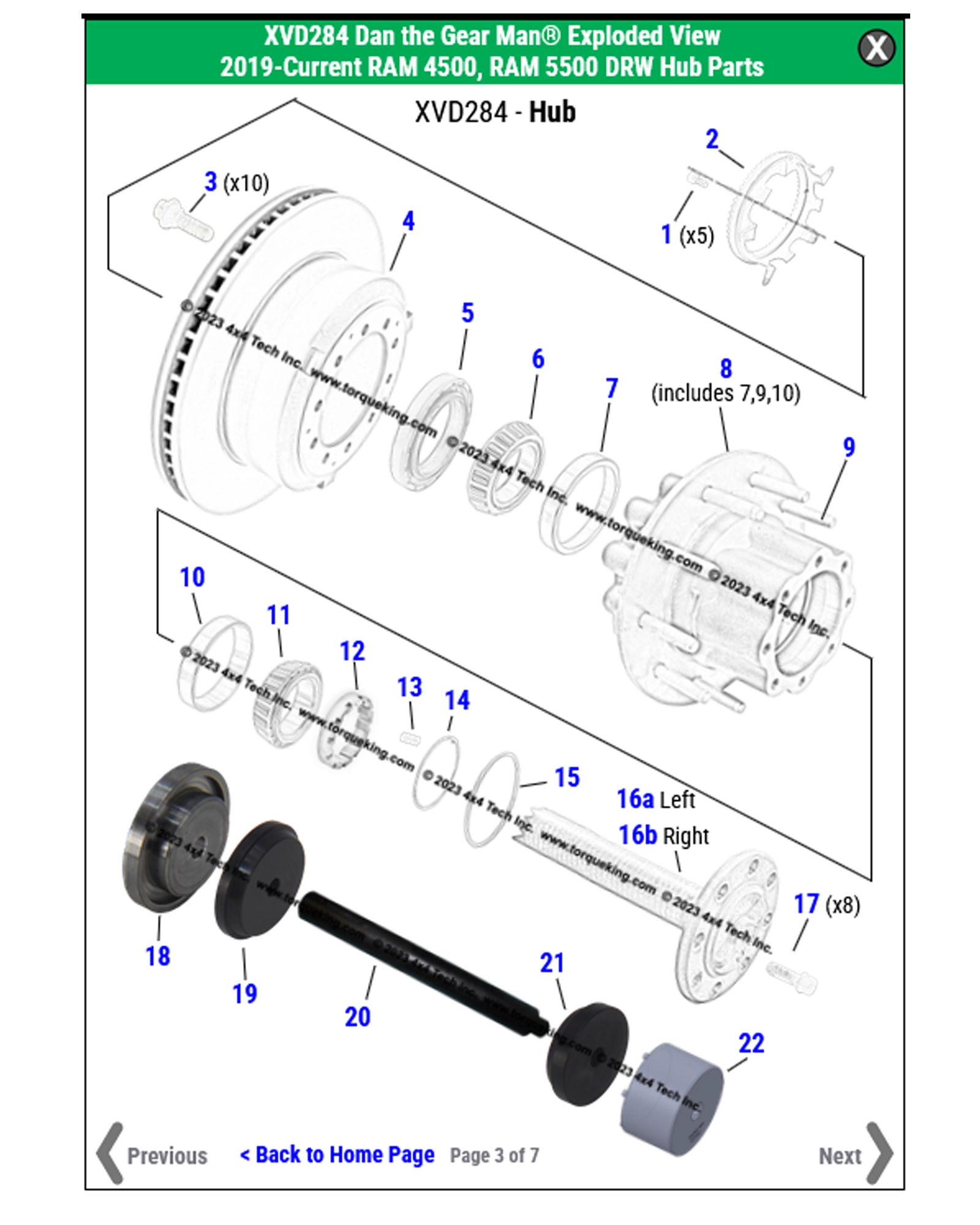

| Axle and Hub Assembly | Supports the weight of the vehicle and allows the wheels to rotate. |

| Braking Components | Ensures effective stopping power by converting kinetic energy into heat. |

Importance of Maintenance

Regular inspection of these key

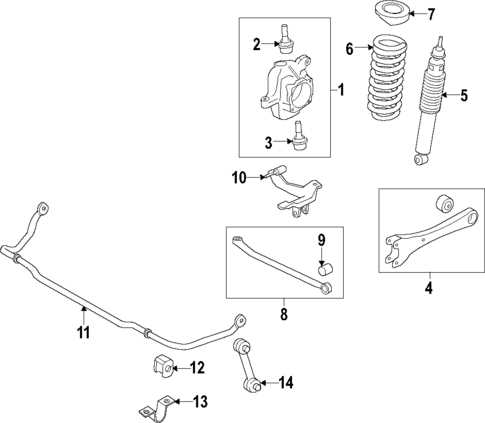

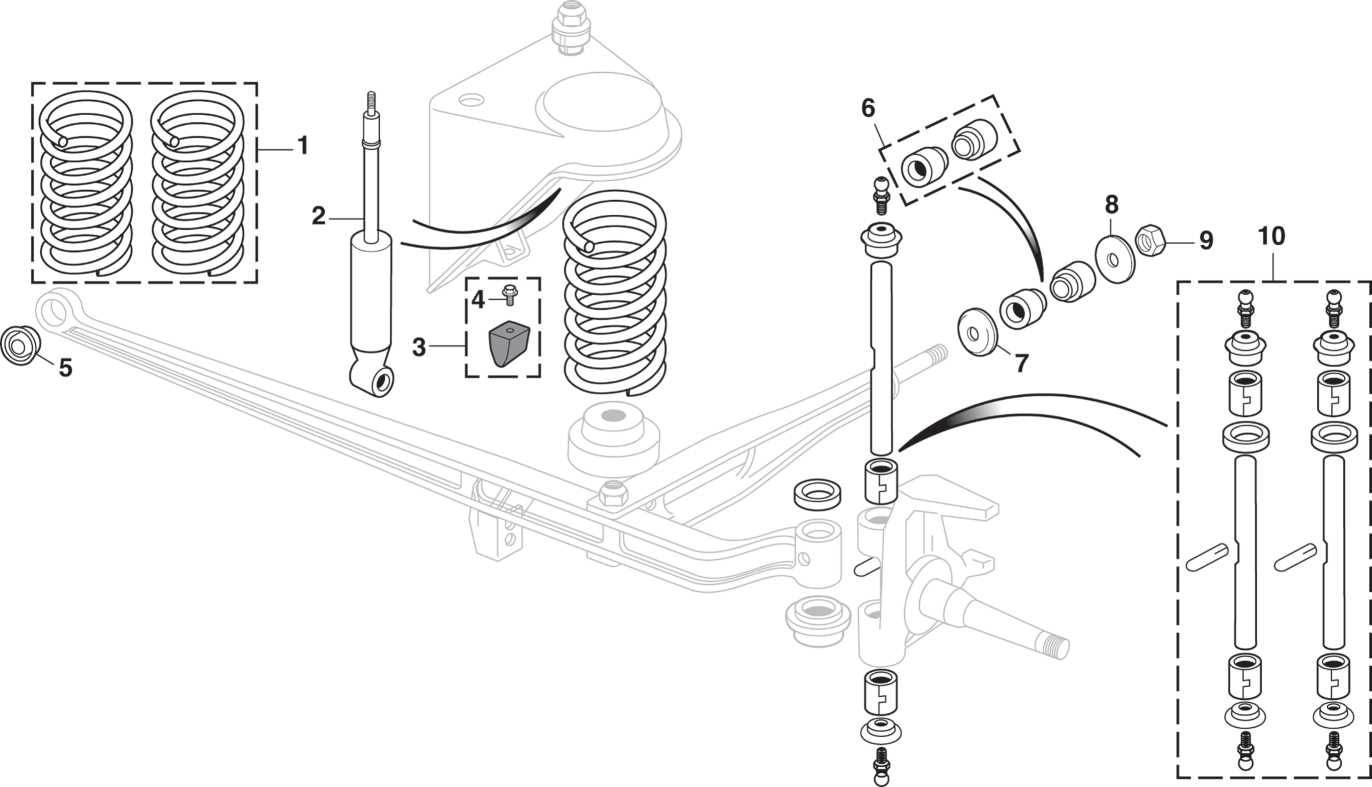

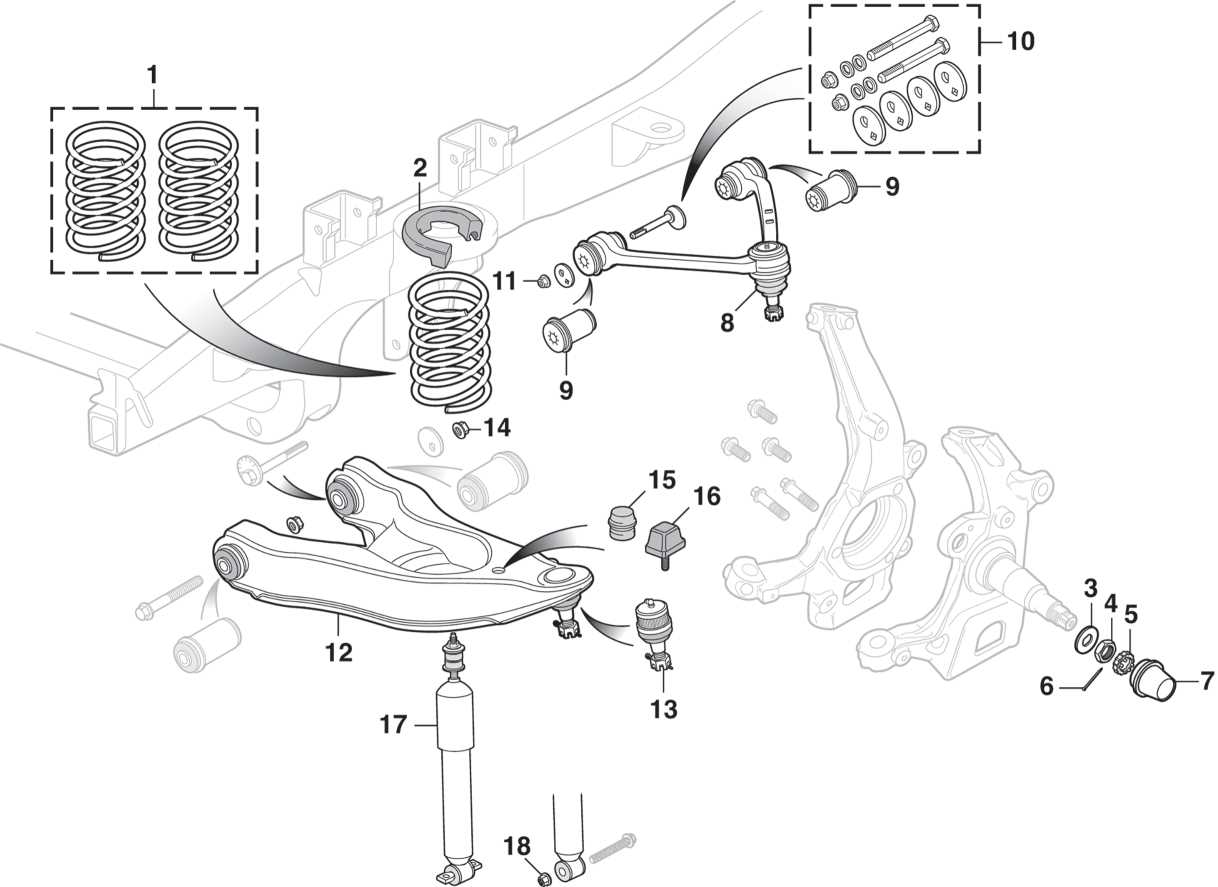

Main Components of the Front Suspension

The suspension system is crucial for ensuring vehicle stability, comfort, and control while driving. It connects the wheels to the main body, allowing for smooth movement over uneven surfaces, while maintaining the correct alignment and balance. Understanding the key elements that make up this system helps in maintaining and troubleshooting issues related to steering and handling.

| Component | Description | |

|---|---|---|

| Control Arms | These serve as the link between the frame and the wheels, allowing for vertical movement while keeping them properly aligned. | |

| Shock Absorbers | These are responsible for dampening the impact from road irregularities, ensuring a smooth ride. | |

| Ball Joints | Connecting the control arms to the steering knuckles, these allow for smooth pivoting as the vehicle steers and moves. | |

| Coil Springs | These absorb the energy from bumps and dips, providing a cushioned ride and maintaining vehicle height. | |

| Steering Knuckles | These connect the wheels to the suspension and allow for controlled steering while maintaining wheel alignment. |

| Component | Description | Material |

|---|---|---|

| Support Bracket | Provides structural integrity and supports the main assembly. | Steel |

| Bumper Cover | The outer shell that enhances visual appeal and protects against minor impacts. | Polyurethane |

| Energy Absorber | Absorbs energy during a collision to minimize damage to the vehicle. | EPP Foam |

| Grille | Allows airflow to the engine while providing a distinctive look. | Plastic |

Each of these elements is engineered to work in harmony, ensuring that the vehicle not only meets safety standards but also appeals to the driver’s personal style. By delving into the specifics of this protective assembly, one can appreciate the balance of form and function that goes into automotive design.

Shock Absorbers and Their Importance

Shock absorbers play a crucial role in maintaining vehicle stability and comfort during operation. They are essential components that help control the movement of the suspension system, ensuring a smooth ride over various surfaces.

These devices are designed to dampen the impact of road irregularities, preventing excessive bouncing and swaying. This functionality not only enhances comfort for passengers but also contributes to the overall safety of the vehicle.

Key benefits of shock absorbers include:

- Improved Handling: By stabilizing the vehicle’s movement, they enhance steering response and control.

- Increased Tire Life: Proper damping reduces tire wear by maintaining better contact with the road surface.

- Enhanced Safety: They help maintain traction during abrupt maneuvers, reducing the risk of loss of control.

- Comfortable Ride: By absorbing shocks, they provide a smoother experience for passengers.

Regular maintenance and timely replacement of shock absorbers are vital for optimal vehicle performance. Worn or damaged shocks can lead to a host of issues, including decreased handling capabilities and increased wear on other suspension components.

Function of the Control Arms

The control arms play a crucial role in the suspension system of a vehicle, connecting the chassis to the wheel assemblies. They enable smooth movement while maintaining alignment, contributing significantly to overall stability and ride quality.

These components are designed to pivot and allow the wheels to move up and down over bumps and uneven surfaces. By doing so, they help absorb shocks and impacts, enhancing comfort for passengers. Additionally, control arms aid in maintaining the proper alignment of the wheels, ensuring optimal tire contact with the road.

Moreover, they serve as a critical link in the steering mechanism, allowing for accurate handling and maneuverability. Their structure typically includes bushings that facilitate movement and minimize vibrations, further improving driving experience. Proper maintenance and timely replacement of these elements are essential for maintaining vehicle performance and safety.

Front Sway Bar and Stability

The sway bar is a crucial component in the suspension system, playing a significant role in maintaining vehicle stability during turns and uneven terrain. Its primary function is to minimize body roll, enhancing the overall driving experience by providing better handling and control.

When discussing the functionality of the sway bar, several key aspects come into play:

- Body Roll Reduction: By connecting opposing wheels, the sway bar helps distribute weight evenly, reducing the amount of tilt experienced during cornering.

- Improved Handling: A well-functioning sway bar allows for more responsive steering and improved traction, especially in challenging driving conditions.

- Stability on Uneven Terrain: The sway bar aids in maintaining balance when navigating bumpy or uneven surfaces, enhancing driver confidence and safety.

Proper maintenance of the sway bar and its associated components is essential. Signs of wear or damage can lead to compromised stability and handling characteristics. Regular inspections and timely replacements can ensure optimal performance and safety.

In conclusion, understanding the role of the sway bar in a vehicle’s suspension system is vital for any driver seeking a smooth and stable ride. This knowledge enables better decision-making regarding maintenance and upgrades, ultimately contributing to a safer driving experience.

Signs of Wear in Front End Parts

Recognizing the signs of deterioration in crucial components of a vehicle’s suspension and steering systems is essential for maintaining safety and performance. As these elements endure continuous stress during operation, they may exhibit various symptoms that indicate the need for inspection or replacement. Being attentive to these warning signs can prevent more significant issues down the line and ensure a smoother driving experience.

Common Indicators of Deterioration

One of the primary indicators of wear is unusual noises, such as clunking or grinding sounds while turning or driving over bumps. These sounds often suggest that certain components have lost their structural integrity. Additionally, irregular tire wear can point to misalignment or damaged elements, affecting traction and handling. Drivers may also notice vibrations in the steering wheel, which can signal imbalances or looseness in the assembly.

Visual and Performance Cues

Regular visual inspections can reveal signs of damage, including cracks, leaks, or rust on components. Such imperfections may compromise functionality and safety. Moreover, changes in steering responsiveness or difficulty in maneuvering can be early signs of component degradation. Prompt attention to these cues can significantly extend the lifespan of the vehicle’s suspension and steering systems, enhancing overall driving confidence.