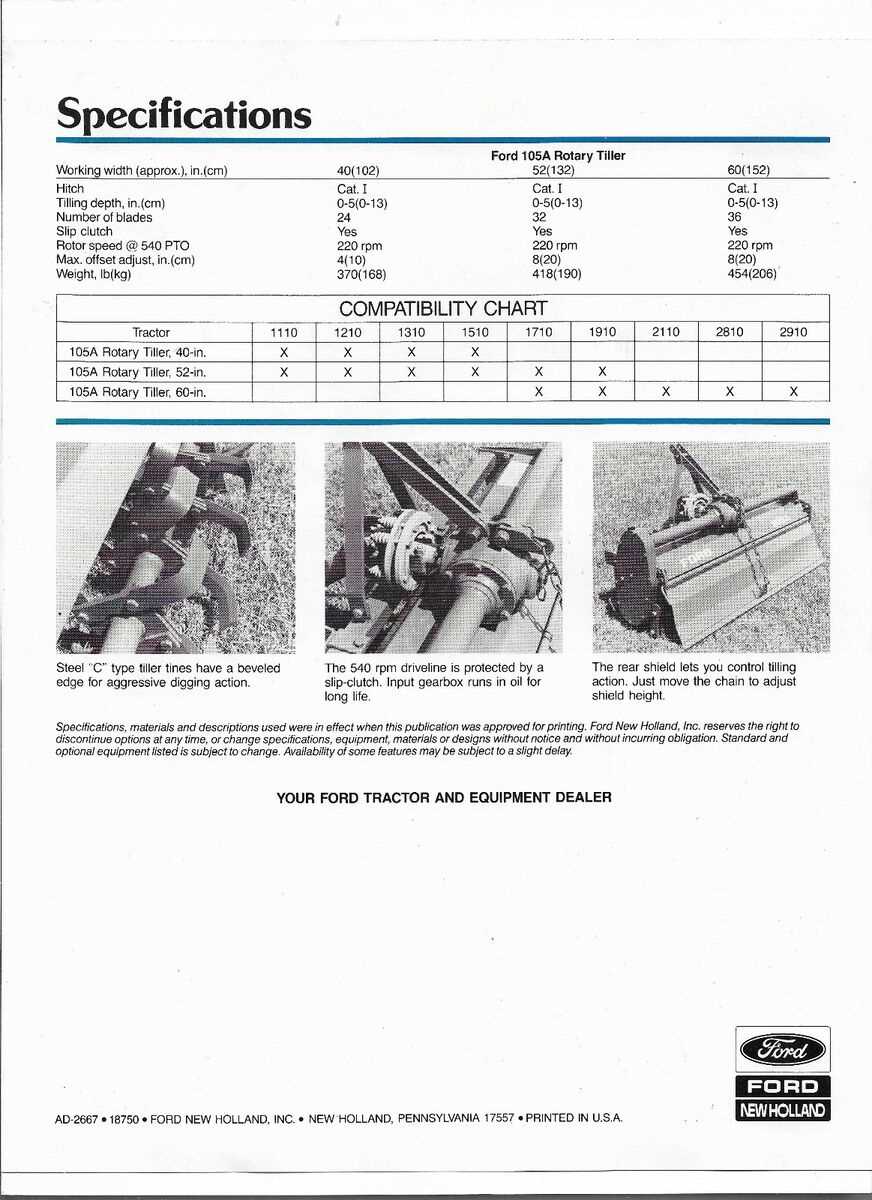

Understanding the Ford 105A Tiller Parts Diagram

In the realm of farming machinery, an intricate web of components plays a vital role in ensuring optimal functionality and efficiency. Each element, no matter how small, contributes to the overall performance of the equipment. A clear visual representation of these components can greatly assist operators and mechanics in understanding how each piece interacts within the larger system.

Identifying individual elements is essential for maintenance and repair, allowing users to pinpoint issues and streamline their workflow. Moreover, familiarity with these structures enhances the ability to make informed decisions about upgrades or replacements. This understanding fosters a more effective approach to agricultural practices, ensuring that tasks are completed smoothly and efficiently.

Whether you are a seasoned farmer or a newcomer to the field, having access to comprehensive resources that detail these essential components is invaluable. It empowers you to navigate the complexities of machinery with confidence, ultimately leading to improved productivity and better crop yields.

Understanding Ford 105A Tiller Components

The intricate machinery behind cultivation tools plays a crucial role in agricultural efficiency. Grasping the various elements that constitute these implements allows for better maintenance and improved performance. Each component works in harmony to enhance the functionality and effectiveness of the equipment.

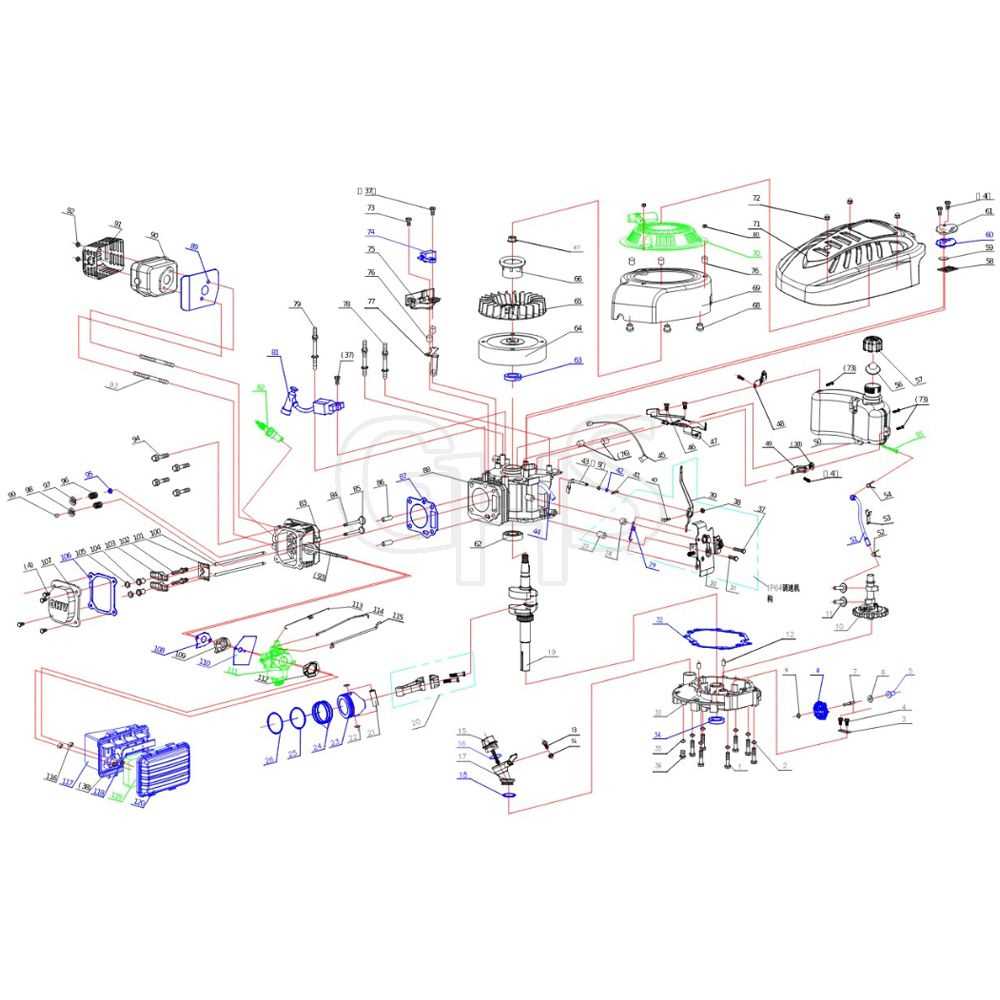

Engine: The heart of the device, providing the necessary power for operation. Its efficiency directly influences overall performance and durability.

Transmission: This system transmits power from the engine to the working parts. Understanding its mechanisms ensures optimal functionality and helps in troubleshooting issues.

Working Tools: These are the attachments that engage with the soil. Various designs cater to different types of terrain and crop conditions, making it essential to choose the right type for specific tasks.

Chassis: The structural frame supports all other components, providing stability and balance during operation. Regular checks for wear and tear are crucial for maintaining the integrity of the machine.

Controls: The interface through which the operator manages functions, allowing for adjustments in speed and depth. Familiarity with these controls is vital for effective use.

In summary, a thorough understanding of these elements not only aids in effective operation but also extends the lifespan of the machinery, ensuring it remains a valuable asset in agricultural endeavors.

Overview of Tiller Functionality

Understanding the mechanics behind soil preparation tools is essential for anyone looking to enhance their gardening or farming practices. These implements are designed to aerate, mix, and prepare the earth for planting, ensuring optimal growth conditions for crops and plants. By utilizing rotating blades, these machines effectively break up compacted soil, allowing for improved water retention and nutrient distribution.

Mechanics of Soil Preparation

The primary function of these devices is to penetrate the ground, disrupting hard layers that impede root growth. As the blades rotate, they churn the soil, which not only aerates but also incorporates organic matter. This process facilitates better drainage and enhances the soil structure, promoting a healthier environment for seedlings and established plants alike.

Benefits for Gardening and Agriculture

Employing such tools significantly reduces the physical effort required for land cultivation. They save time and increase efficiency, allowing gardeners and farmers to focus on other vital tasks. Moreover, consistent use leads to improved soil health over time, making it easier to maintain fertility and support diverse plant species.

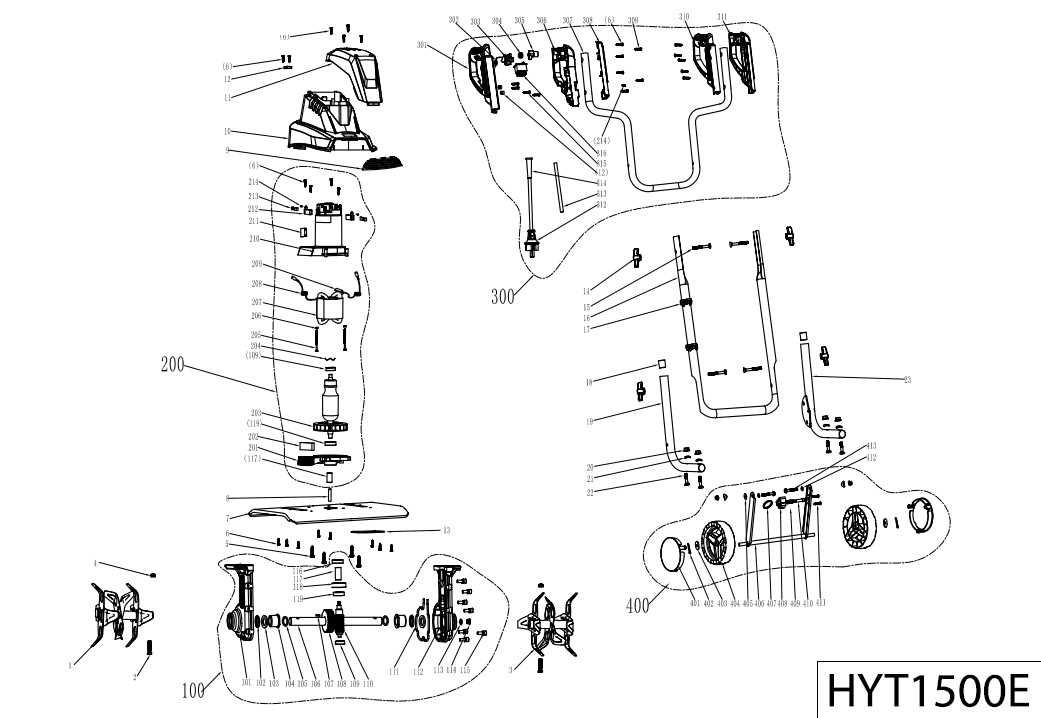

Essential Parts of the Ford 105A

Understanding the key components of this agricultural equipment is crucial for efficient operation and maintenance. Each element plays a vital role in ensuring optimal performance and durability. Here, we explore the fundamental parts that contribute to its functionality.

Core Components

- Engine: The powerhouse of the machine, providing the necessary energy for operation.

- Transmission: This system transfers power from the engine to the wheels, enabling movement.

- Chassis: The framework that supports all other components, ensuring stability and strength.

- Blade Assembly: Essential for soil cultivation, this part cuts and turns the earth effectively.

Additional Essential Elements

- Fuel System: Supplies the engine with the energy needed for operation.

- Cooling System: Maintains optimal engine temperature, preventing overheating.

- Control Mechanisms: Allows the operator to manage various functions and settings with precision.

- Wheels: Provide mobility and support, designed for various terrains.

Each of these components works together to enhance the overall efficiency and effectiveness of the equipment, making regular inspection and maintenance essential for longevity and performance.

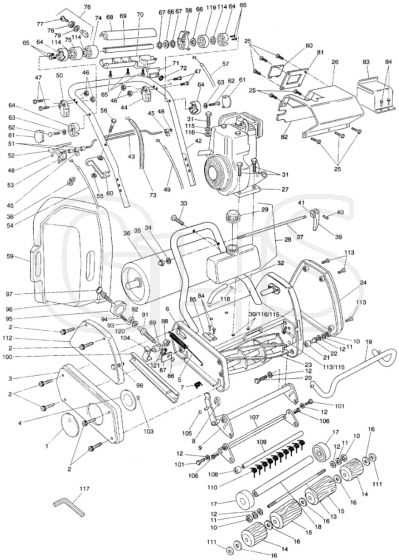

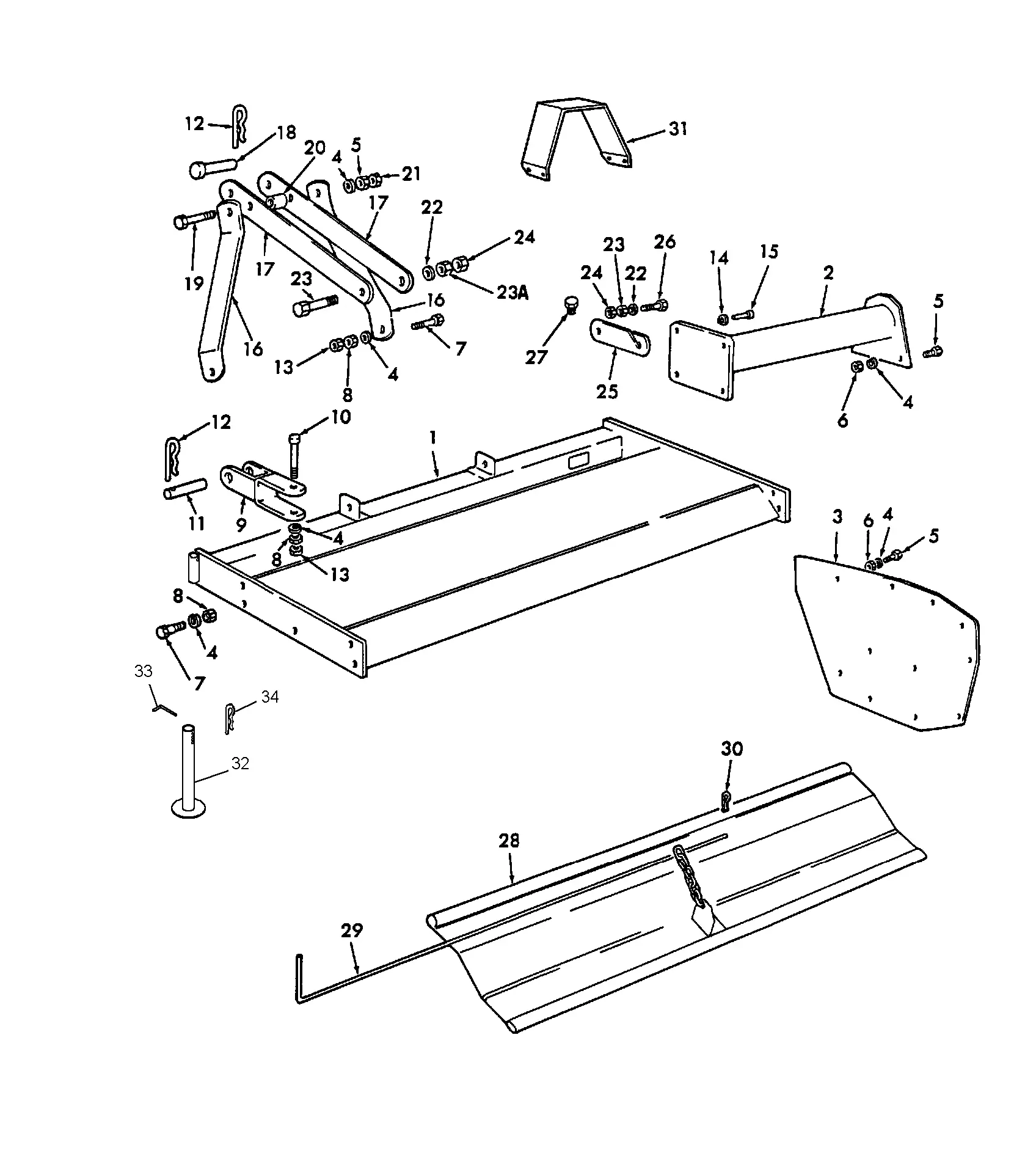

How to Read Parts Diagrams

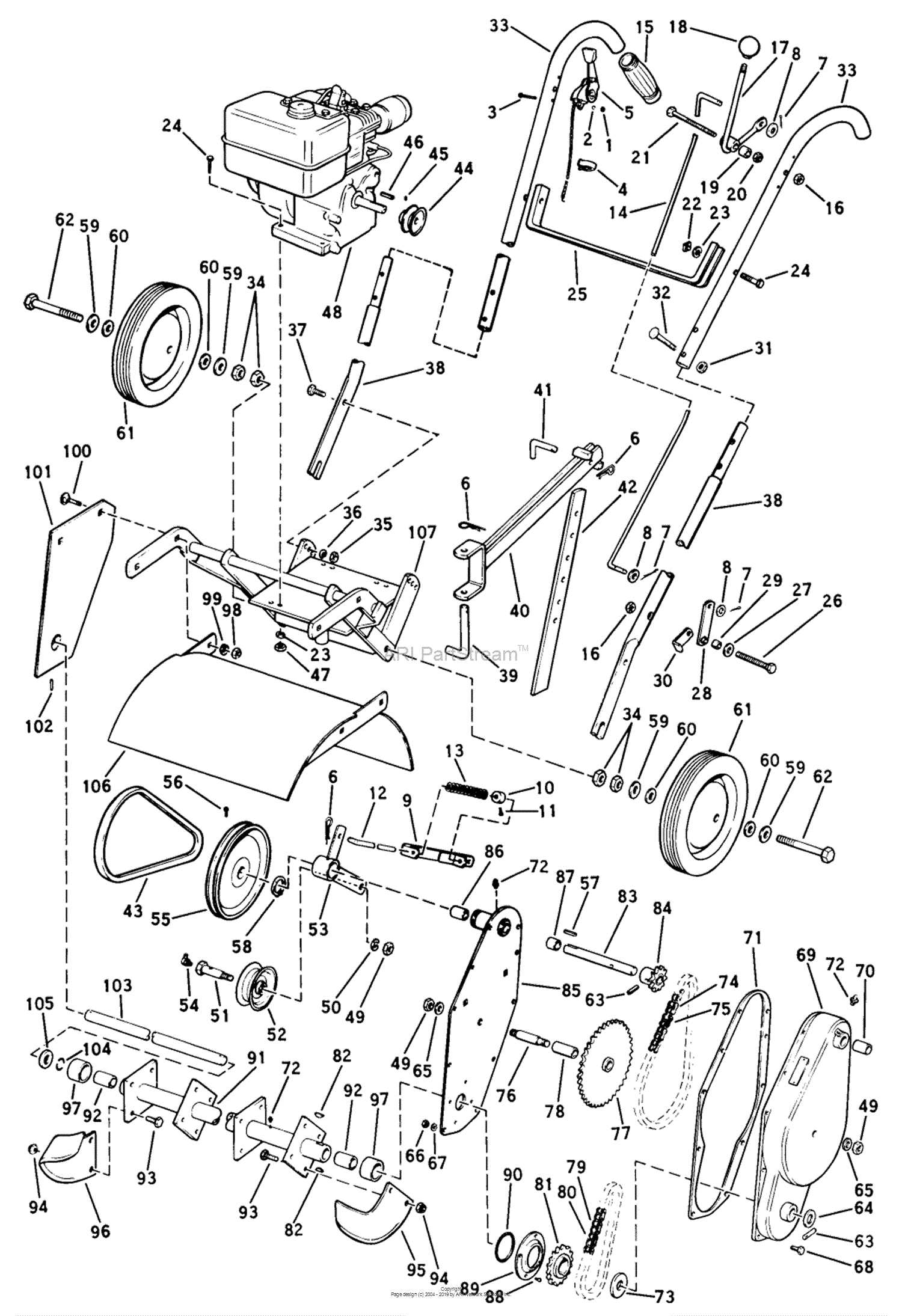

Understanding visual schematics can greatly enhance your ability to maintain and repair machinery. These illustrations serve as a roadmap, showing how individual components fit together and function as a whole. Here are some tips to effectively interpret these graphics.

- Familiarize Yourself with Symbols: Each drawing often uses standardized symbols. Learn what these symbols represent to make sense of the layout.

- Identify Key Sections: Diagrams are usually divided into sections. Locate the main groups of components to understand their relationships.

- Follow the Numbering System: Many visuals include numbers or letters to identify specific pieces. Use this coding to find the exact items you need.

- Refer to a Legend: Look for a legend or key that explains symbols and codes. This can clarify any confusion you may encounter.

- Cross-Reference with Manuals: Use the schematic alongside service manuals or guides for detailed explanations on assembly and functionality.

By mastering these skills, you can enhance your understanding and execution of repairs, ensuring efficient maintenance of your equipment.

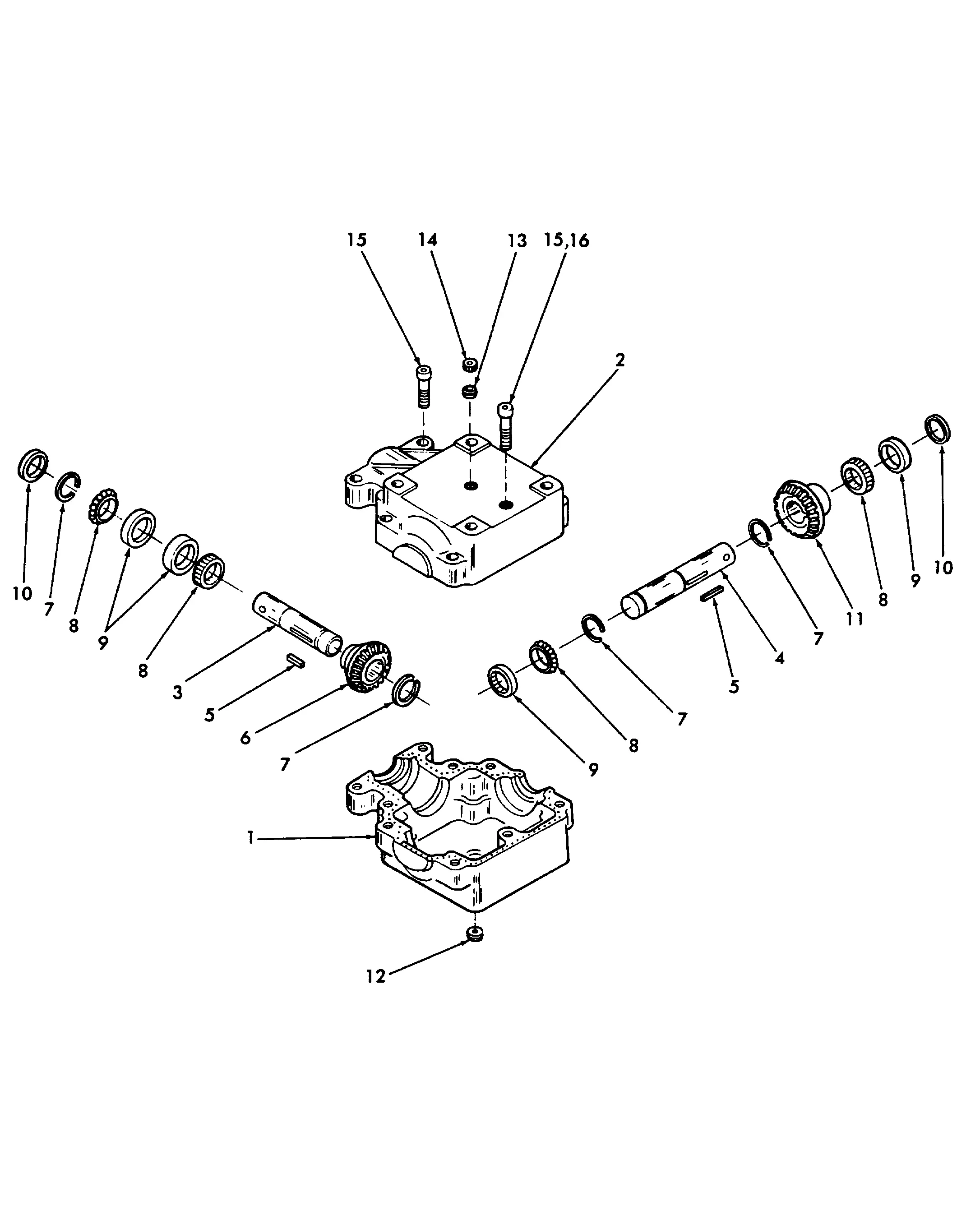

Identifying Key Components in Diagrams

Understanding the intricate layout of machinery requires a keen eye for detail. Recognizing essential elements within visual representations is crucial for effective maintenance and repair. By familiarizing oneself with the various symbols and annotations, users can navigate complex schematics with greater ease.

Each symbol serves a specific function, conveying vital information about the operation and assembly of the equipment. Components are often categorized into different groups, such as mechanical parts, electrical elements, and connection points. Understanding these classifications can significantly enhance one’s ability to troubleshoot and resolve issues.

Additionally, familiarizing oneself with the legend or key accompanying the illustration is paramount. This reference provides insights into what each symbol represents, allowing for a clearer interpretation of the overall design. By mastering these aspects, users can approach repairs with confidence and precision.

Common Issues with Tiller Parts

In the realm of agricultural equipment, various components can face challenges that impact their performance and reliability. Understanding these frequent problems is crucial for maintaining functionality and prolonging the lifespan of your machinery.

Wear and Tear

One of the most prevalent issues arises from the natural wear and tear of components over time. Continuous use can lead to diminished efficiency, particularly in high-friction areas. Regular inspections are essential to identify parts that may need replacement or repair.

Improper Maintenance

Neglecting regular maintenance can result in numerous complications. Lack of lubrication, unaddressed dirt buildup, and failure to tighten connections can all lead to malfunction. Establishing a routine check-up schedule can help mitigate these risks and ensure smooth operation.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your gardening equipment requires regular attention and care. By implementing a few essential practices, you can significantly extend the lifespan of your machinery and maintain optimal performance. Proper maintenance not only prevents costly repairs but also enhances the overall functionality of your tools.

Regular Cleaning: After each use, thoroughly clean your equipment to remove dirt, debris, and residue. This simple task helps prevent rust and corrosion, preserving the integrity of the materials.

Lubrication: Apply appropriate lubricants to moving parts to reduce friction and wear. Regular lubrication minimizes the chances of mechanical failures and ensures smoother operation.

Check for Wear: Periodically inspect components for signs of wear or damage. Early detection of issues allows for timely repairs, preventing further deterioration and ensuring safe usage.

Proper Storage: Store your equipment in a dry, sheltered location when not in use. Protecting it from harsh weather conditions can prevent rust and extend its lifespan.

Follow Manufacturer Guidelines: Adhere to the maintenance schedule and recommendations provided by the manufacturer. These guidelines are designed to optimize performance and reliability.

By following these maintenance tips, you can enjoy years of efficient service from your gardening tools while maximizing their potential in your outdoor projects.

Finding Genuine Replacement Parts

When it comes to maintaining your equipment, sourcing authentic components is crucial for optimal performance and longevity. High-quality replacements not only ensure seamless operation but also protect your investment by minimizing the risk of future issues. Whether you are repairing or upgrading, understanding how to identify genuine elements is essential.

Importance of Authentic Components

Utilizing original items guarantees compatibility and reliability. Imitation parts may seem cost-effective, but they often lead to more significant problems down the line, resulting in increased repair costs. By choosing authentic components, you secure the integrity of your machine and enhance its overall efficiency.

Where to Find Reliable Sources

To locate trustworthy suppliers, consider authorized dealers and well-known retailers. Online marketplaces can also provide a variety of options, but always check for reviews and ratings to ensure credibility. Engaging with local service centers or forums dedicated to your machinery can offer valuable insights and recommendations on where to find the right components.

Comparison of Aftermarket vs. OEM Parts

The choice between alternative components and original manufacturer offerings can significantly influence the performance and longevity of equipment. Each option presents its own set of advantages and potential drawbacks, making it essential to evaluate them based on specific needs and preferences.

When considering alternatives, it’s important to weigh the following factors:

- Cost: Generally, alternative components tend to be more budget-friendly, appealing to those seeking to minimize expenses.

- Availability: Alternative options may be more readily accessible through various retailers, potentially reducing downtime during repairs.

- Quality: The quality of alternative components can vary widely; some may perform well, while others may not meet expectations.

On the other hand, original manufacturer offerings have distinct characteristics:

- Reliability: These components are designed specifically for certain equipment, ensuring compatibility and dependable performance.

- Warranty: Often accompanied by a warranty, providing assurance against defects and potential issues.

- Resale Value: Equipment maintained with original components may retain a higher resale value due to perceived quality.

Ultimately, the decision between alternative and original options depends on individual priorities, such as budget constraints, maintenance goals, and personal preferences regarding quality and reliability.

Tools Needed for Tiller Repairs

Maintaining and fixing garden machinery requires a well-equipped toolkit. Having the right implements at hand not only facilitates efficient repairs but also ensures safety and longevity of the equipment. A thoughtful selection of tools can make the difference between a successful repair and a frustrating experience.

Essential Tools

To tackle most mechanical issues, you will need a variety of implements. A reliable set of wrenches and sockets is crucial for loosening and tightening fasteners. Screwdrivers of various sizes are indispensable for adjusting components and securing covers. Additionally, pliers can be beneficial for gripping and twisting wires or small parts.

Specialized Equipment

In certain situations, specialized tools may be required to address specific problems. A torque wrench is essential for ensuring that bolts are tightened to the manufacturer’s specifications, preventing damage from overtightening. Furthermore, a multimeter can help diagnose electrical issues by measuring voltage and continuity, ensuring that all systems function correctly.

Ultimately, equipping yourself with the right tools not only streamlines the repair process but also enhances your ability to maintain and extend the life of your gardening machinery.

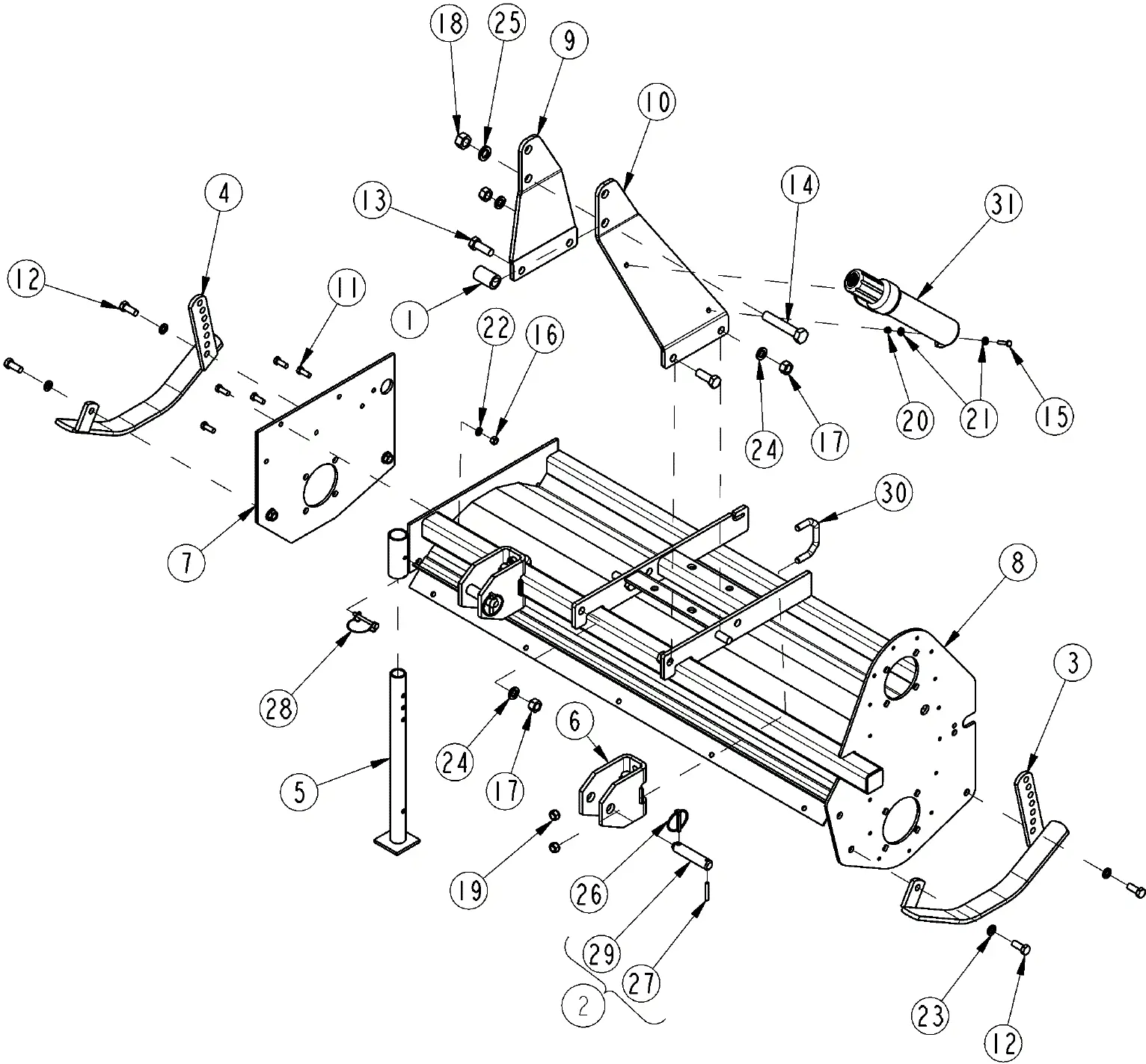

Step-by-Step Repair Guide

This section provides a comprehensive approach to restoring your equipment, ensuring optimal performance and longevity. By following a structured method, you can address common issues effectively, minimizing downtime and enhancing functionality.

1. Gather Necessary Tools and Materials

Before starting the repair process, assemble all required tools such as wrenches, screwdrivers, and replacement components. Having everything on hand will streamline your efforts and prevent interruptions.

2. Review the Manual

Consult the user manual for specific instructions related to your model. Familiarizing yourself with the layout and functions of various parts will provide valuable insights and facilitate easier repairs.

3. Disconnect Power Sources

Safety is paramount. Ensure that all power sources are disconnected before proceeding with any disassembly. This will protect you from accidental starts and electrical hazards.

4. Disassemble Carefully

Begin disassembling the unit by removing outer covers and components. Take care to keep track of screws and small parts. Using labeled containers can help maintain organization.

5. Inspect and Replace Damaged Components

Thoroughly examine each part for signs of wear or damage. If any components are found to be faulty, replace them with high-quality alternatives to ensure reliability and performance.

6. Reassemble and Test

Once repairs are completed, reassemble the unit carefully, ensuring all parts fit securely. After reassembly, reconnect the power source and perform a test run to verify that everything functions correctly.

7. Maintain Regularly

To extend the life of your equipment, schedule regular maintenance checks. This proactive approach will help identify potential issues early and keep your machinery operating smoothly.

Upgrading Your Tiller Components

Enhancing the efficiency and performance of your gardening machinery can significantly improve your productivity. By focusing on specific components, you can ensure that your equipment operates at its best, providing a smoother experience while tackling your gardening tasks. This section will explore various ways to elevate the functionality of your device.

Key Areas for Improvement

- Blades: Upgrading to sharper or more durable blades can enhance cutting efficiency and reduce the effort needed.

- Engine: Consider a more powerful engine for improved performance, particularly for larger projects.

- Transmission: A smoother transmission can provide better speed control and increase overall maneuverability.

- Handlebars: Ergonomic designs can reduce strain, making long hours of use more comfortable.

Benefits of Component Upgrades

- Increased efficiency, allowing for faster completion of tasks.

- Improved durability, leading to a longer lifespan for your machinery.

- Enhanced user comfort, reducing physical strain during operation.

- Better adaptability to different soil types and gardening conditions.

Investing in these upgrades not only enhances performance but also contributes to a more enjoyable gardening experience. Evaluate your equipment and identify the areas that would benefit most from enhancement to achieve optimal results.

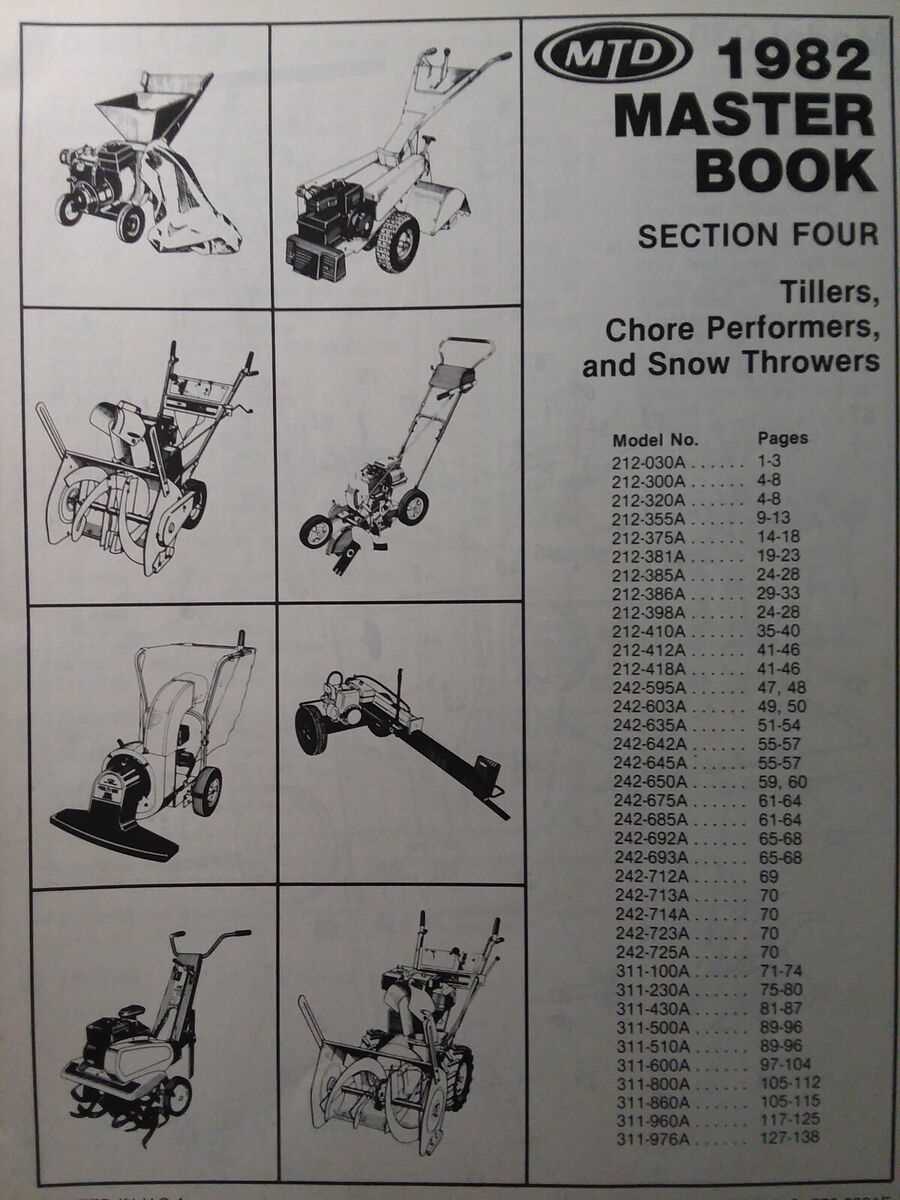

Community Resources for Ford Tiller Owners

For enthusiasts of tilling equipment, engaging with a community can significantly enhance the ownership experience. Accessing shared knowledge, resources, and support from fellow users creates a rich environment for learning and problem-solving. Various platforms offer valuable information ranging from maintenance tips to troubleshooting advice, fostering a sense of camaraderie among users.

Online Forums and Discussion Groups

Participating in online forums can provide immediate assistance and insights from experienced users. Many communities host dedicated spaces for discussion, where members can share their experiences and solutions. These platforms often feature threads focused on common issues, allowing for collaborative problem-solving.

Local Clubs and Meetups

Joining local clubs or attending meetups can be a rewarding way to connect with others who share similar interests. These gatherings often include demonstrations, workshops, and informal discussions that enrich members’ understanding of their equipment. Networking with local enthusiasts can also lead to resource sharing and access to unique tools and techniques.

| Resource Type | Description | Example |

|---|---|---|

| Online Forums | Platforms for discussion and troubleshooting | GardenTillerForum.com |

| Social Media Groups | Community pages for sharing tips and experiences | Facebook Groups |

| Local Clubs | In-person gatherings for sharing knowledge | Community Garden Club |

| Workshops | Hands-on sessions for skill improvement | Local Agriculture Extension Office |