Comprehensive Guide to Ford 8N Parts Diagram

When it comes to maintaining agricultural machinery, having a clear view of its inner workings is essential for optimal performance. Understanding how each element interacts not only facilitates efficient repairs but also enhances the overall longevity of the equipment. This knowledge empowers operators to identify issues before they escalate, ensuring a smooth operation in the field.

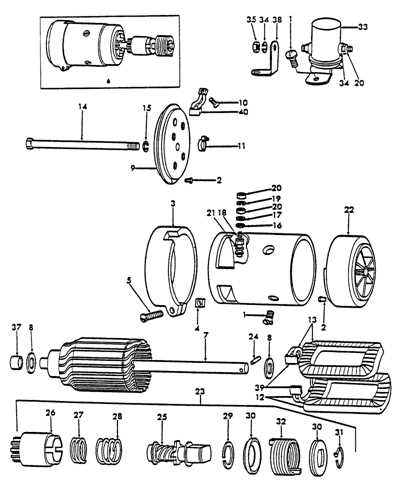

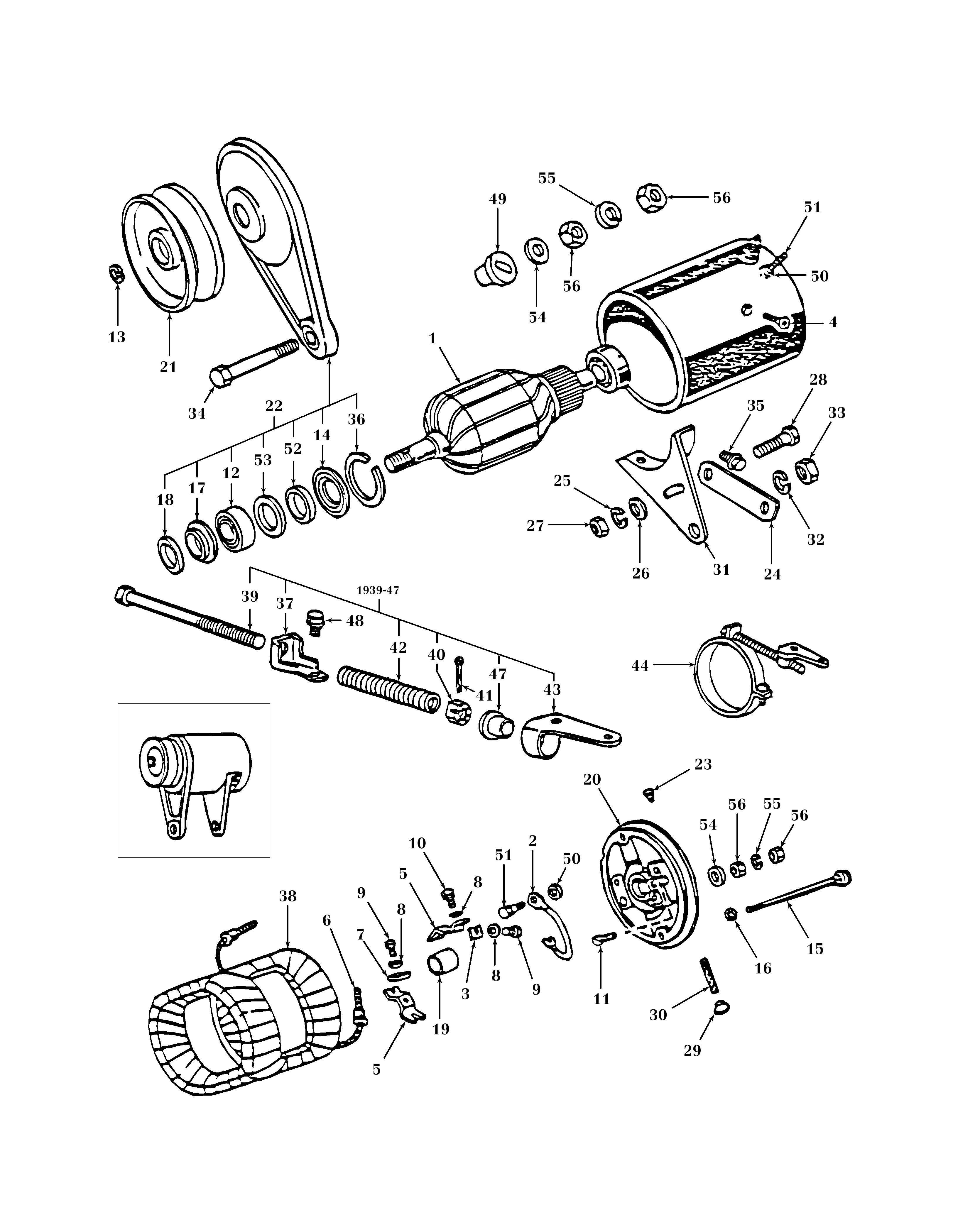

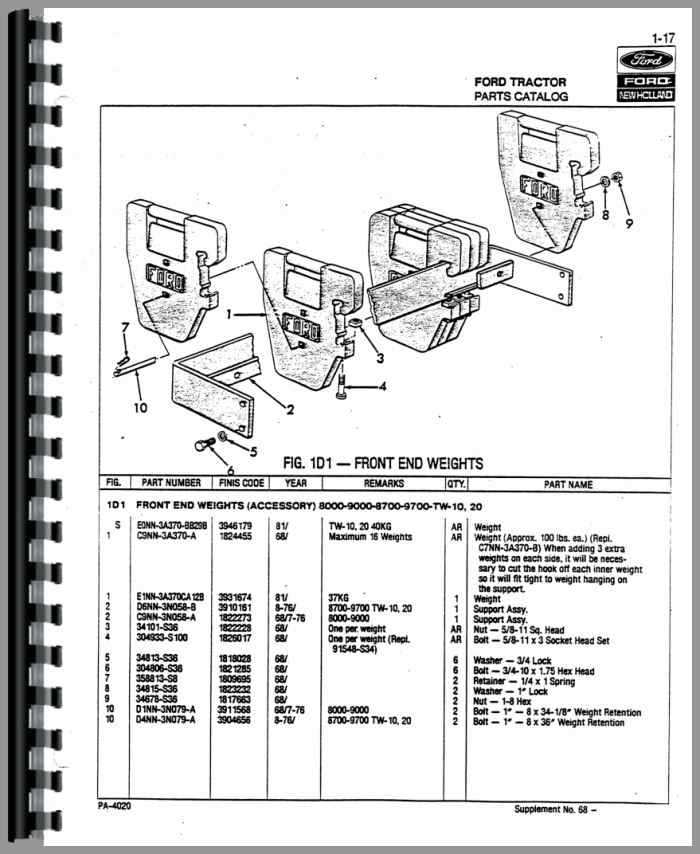

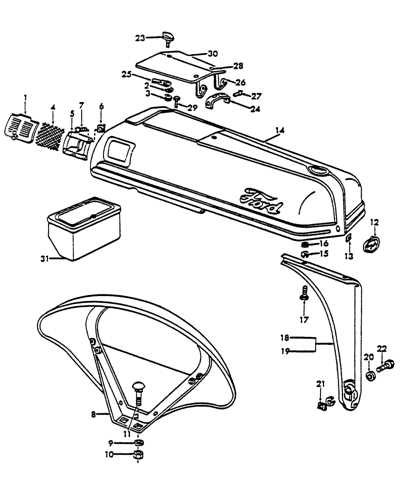

Visual representations of the various components play a crucial role in this process. They provide a structured layout that highlights the placement and function of each piece, making it easier for both seasoned mechanics and novice users to navigate the complexities of machinery. With a comprehensive visual guide, users can develop a deeper understanding of their equipment.

In this section, we will delve into the specifics of different elements within a popular tractor model, offering insights into their functions and importance. By exploring this detailed representation, you will gain the confidence needed to tackle maintenance tasks effectively, ensuring your machinery remains in top condition.

Understanding the Ford 8N Parts Diagram

Grasping the layout of essential components in a classic agricultural machine is crucial for maintenance and repair. Familiarity with the arrangement allows owners to identify issues quickly and perform necessary adjustments with confidence.

One key aspect to consider is the organization of elements within the schematic. This includes a visual representation that highlights relationships among various pieces. Understanding these connections can significantly enhance the efficiency of troubleshooting and restoration efforts.

Here are some vital components typically represented in such schematics:

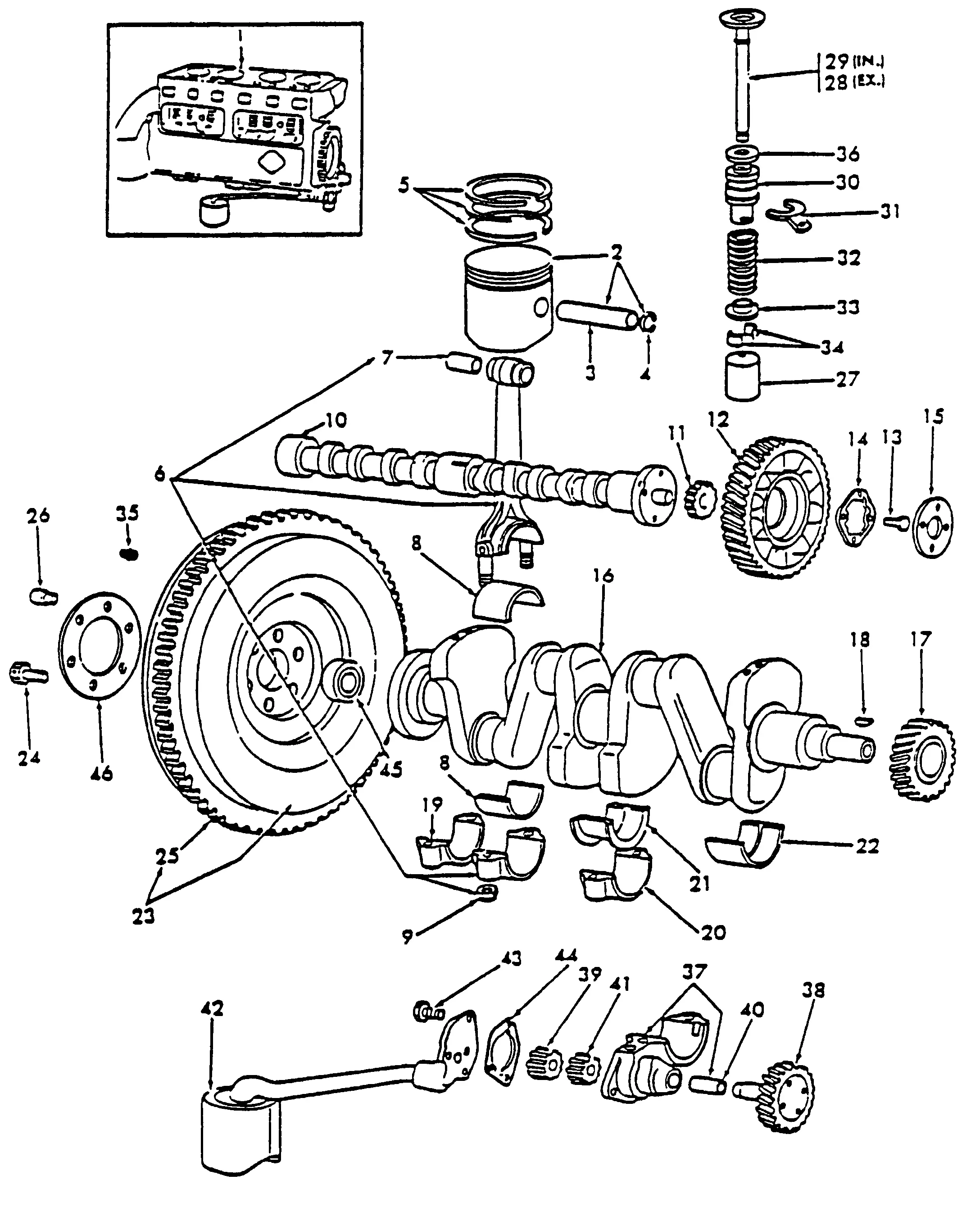

- Engine assembly

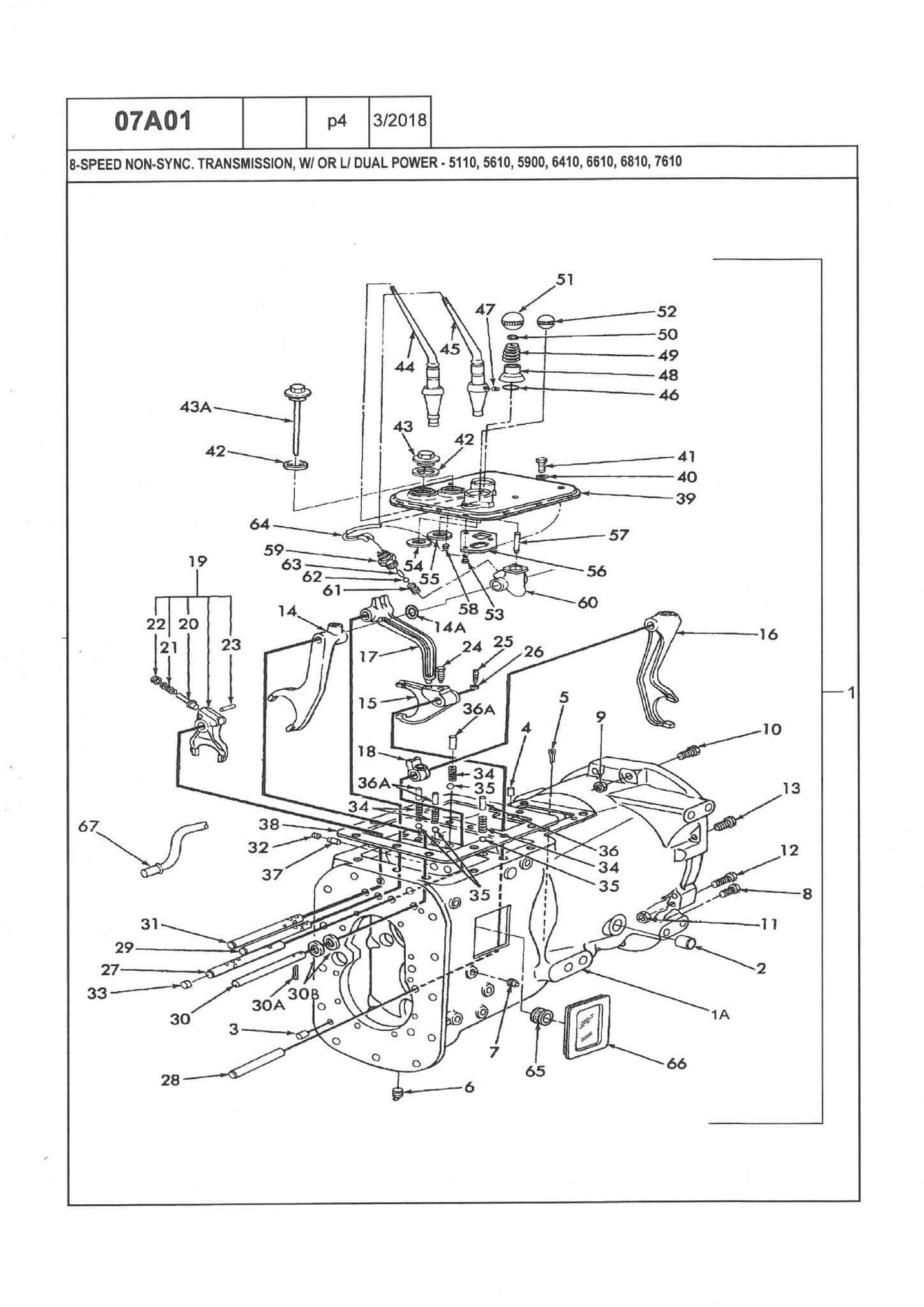

- Transmission system

- Hydraulic mechanisms

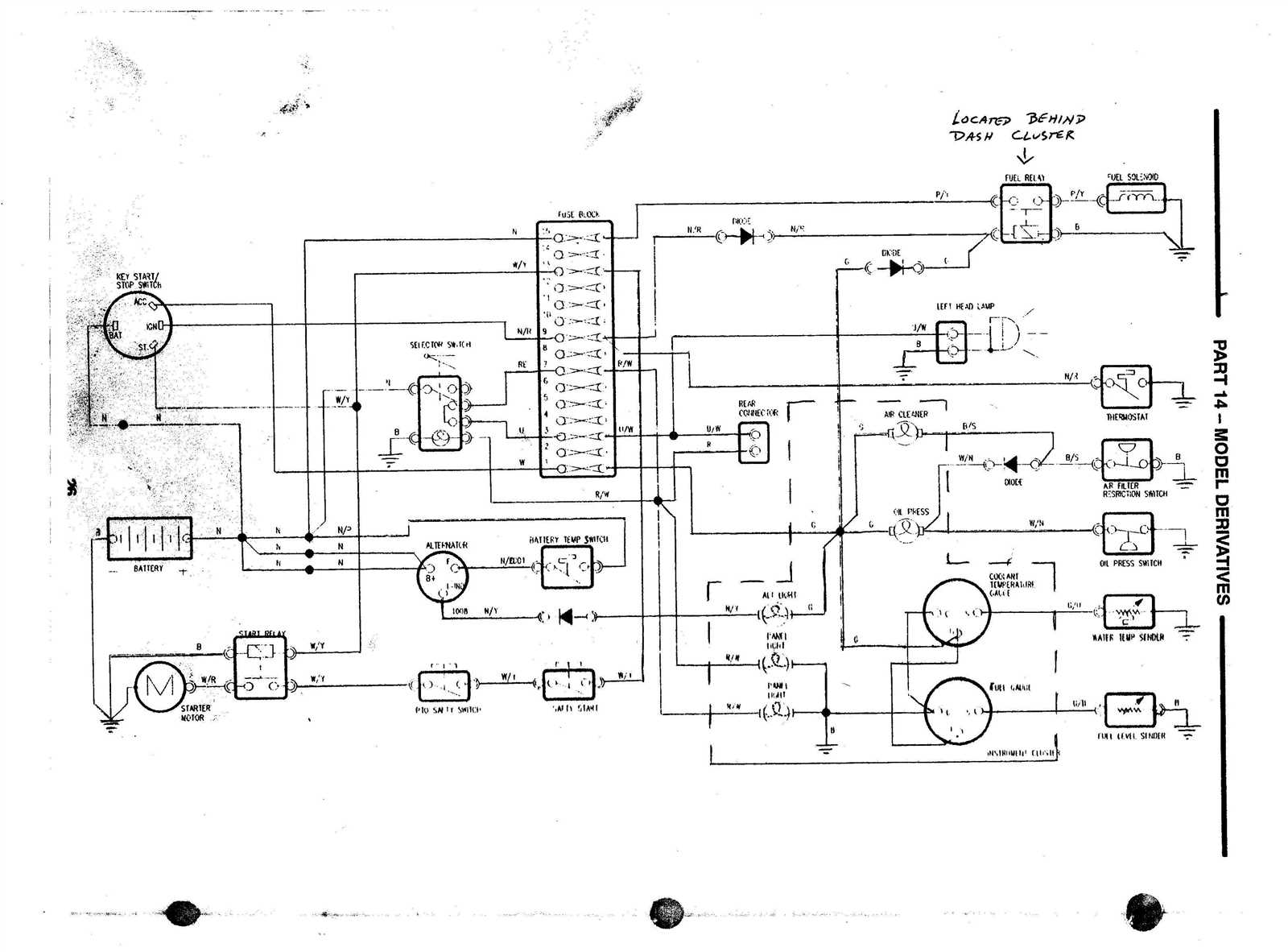

- Electrical wiring

- Steering and axle setup

Each category consists of numerous sub-elements that work together seamlessly. To navigate the layout effectively, consider the following tips:

- Familiarize yourself with the main categories and their functions.

- Use reference materials to understand the specific roles of individual components.

- Consult experienced mechanics or resources for guidance on common issues.

- Keep notes on repairs and adjustments for future reference.

By comprehending the arrangement of components, users can ensure longevity and optimal performance of their machinery, making informed decisions throughout the upkeep process.

Key Components of the Ford 8N

This section explores the essential elements that make up the classic agricultural machine, focusing on their functions and importance in the overall operation. Understanding these components provides valuable insights for maintenance and restoration, ensuring optimal performance and longevity.

Engine and Transmission

The heart of any machine is its engine, which provides the necessary power for various tasks. Coupled with the transmission, it enables smooth operation and control over speed and torque. Regular maintenance of these components is crucial for efficiency and reliability.

Hydraulic System

The hydraulic system is vital for lifting and controlling implements, making it an indispensable feature. This system operates through a network of cylinders and hoses, allowing for precision in handling heavy loads. Ensuring the hydraulic components are in good condition enhances overall functionality.

| Component | Description | Function |

|---|---|---|

| Engine | Four-cylinder, gasoline-powered | Provides power for operation |

| Transmission | Four-speed manual | Controls speed and torque |

| Hydraulic Pump | Provides hydraulic fluid flow | Operates lifting mechanisms |

| Steering System | Manual or power-assisted | Enables maneuverability |

| Cooling System | Radiator and fan assembly | Prevents engine overheating |

Benefits of Using a Parts Diagram

Utilizing a visual representation of components can significantly enhance the maintenance and repair processes for machinery. This approach allows users to quickly identify each element, ensuring a more efficient workflow and reducing the likelihood of errors.

Here are several advantages of employing such visuals:

- Enhanced Understanding: Visual aids provide clarity, making it easier to comprehend the relationships between different components.

- Streamlined Repairs: Quickly locating the necessary elements speeds up the repair process, minimizing downtime.

- Improved Accuracy: Clear images help prevent mistakes, ensuring the right components are identified and used.

- Easier Communication: Sharing visuals with team members enhances collaboration, as everyone can refer to the same source of information.

- Training Resource: New users can learn about the assembly and functions of components more effectively with visual references.

In summary, leveraging a visual guide can lead to improved efficiency, reduced errors, and enhanced collaboration in any maintenance or repair task.

How to Read the Diagram Effectively

Understanding a technical illustration is crucial for anyone looking to maintain or repair machinery. It serves as a visual guide, enabling users to identify components and their relationships. Mastering the skill of interpreting these illustrations can significantly enhance your ability to troubleshoot and execute repairs efficiently.

Key Elements to Focus On

When approaching the illustration, pay attention to the following elements:

| Element | Description |

|---|---|

| Labels | These indicate the names and specifications of various components. |

| Symbols | Commonly used symbols represent different parts and functions. |

| Lines | Connecting lines show relationships and connections between parts. |

| Views | Different angles provide a comprehensive understanding of how components fit together. |

Steps for Effective Interpretation

To effectively interpret the illustration, follow these steps:

- Familiarize yourself with common symbols and terminology.

- Identify the main components and their respective labels.

- Trace connections and understand how parts interact.

- Refer to any accompanying notes or legends for additional context.

Commonly Replaced Parts for Ford 8N

Maintaining agricultural machinery often involves replacing certain components to ensure optimal performance and longevity. This section highlights the most frequently swapped elements that are essential for smooth operation and reliability. Understanding these common replacements can help owners keep their equipment running efficiently.

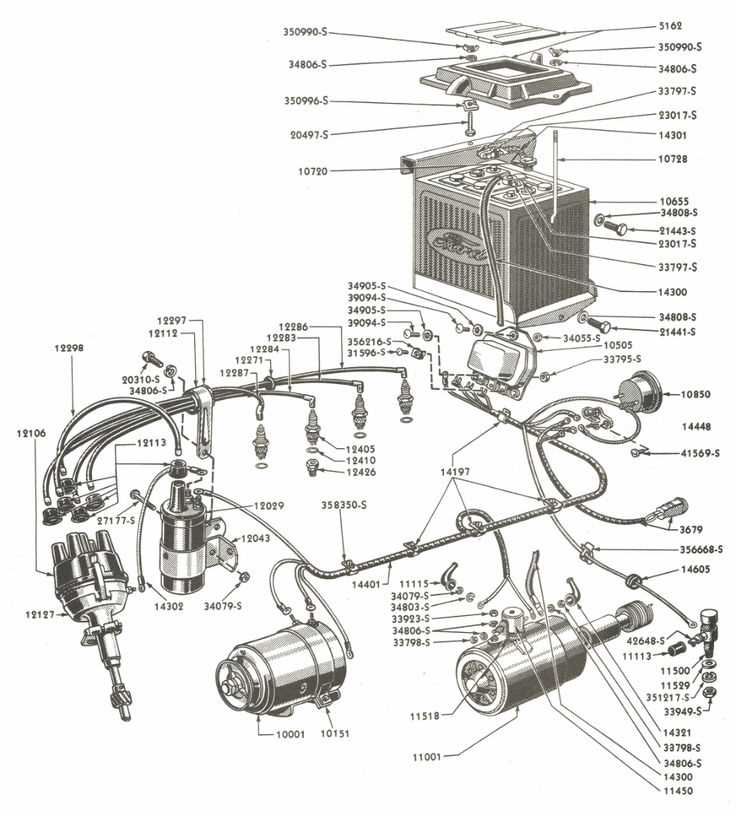

Ignition System Components: One of the first areas to consider is the ignition system. Items like spark plugs and ignition coils wear out over time, affecting starting and engine efficiency.

Cooling System Elements: The cooling system is vital for preventing overheating. Components such as the radiator and thermostat often require replacement due to corrosion or wear, ensuring the engine maintains a safe operating temperature.

Fuel Delivery Parts: Efficient fuel delivery is crucial for performance. Common replacements include fuel pumps and filters, which may become clogged or fail, impacting power and efficiency.

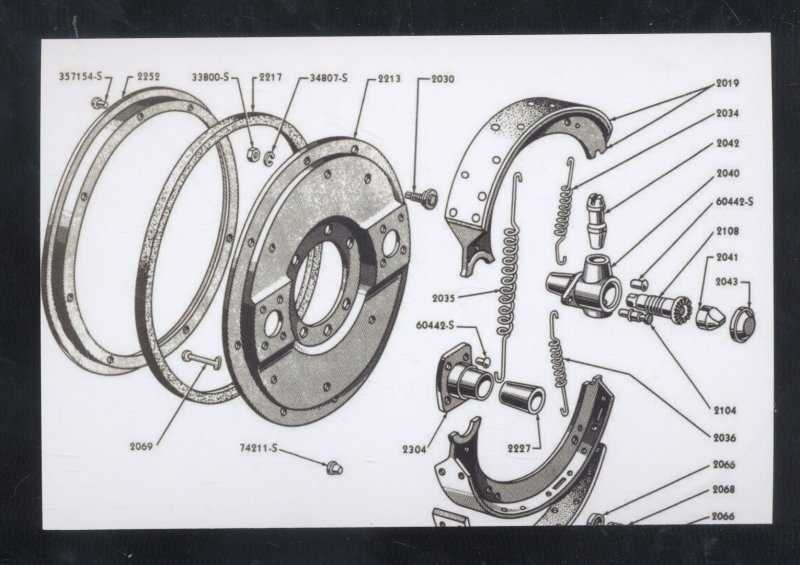

Hydraulic System Components: For those utilizing hydraulic features, elements like hydraulic hoses and cylinders may need to be changed regularly to prevent leaks and maintain functionality.

Transmission Elements: The transmission system is another critical area. Components such as gaskets and seals can deteriorate over time, leading to fluid leaks and operational issues.

By being aware of these commonly replaced items, operators can better prepare for maintenance and ensure their machinery remains in peak condition for years to come.

Where to Find Quality Replacement Parts

When it comes to maintaining machinery, sourcing high-quality components is crucial for ensuring optimal performance and longevity. Numerous avenues exist for acquiring reliable replacements, each offering distinct benefits. Understanding these options can help streamline your search and enhance your repair efforts.

Online Marketplaces

Digital platforms have revolutionized the way enthusiasts and professionals procure essential components. Websites dedicated to machinery often feature extensive inventories, user reviews, and detailed specifications. Exploring these resources allows for informed decisions, ensuring that you select products that meet rigorous standards.

Local Suppliers and Salvage Yards

Visiting local suppliers or salvage yards can yield valuable finds. These establishments often carry a variety of options, including new and refurbished items. Building a relationship with local vendors may also lead to personalized service and insider knowledge, helping you uncover the best solutions for your needs.

Maintenance Tips for Ford 8N Owners

Regular upkeep is essential for ensuring the longevity and reliability of classic machinery. Proper care not only enhances performance but also prevents costly repairs down the line. This section will provide valuable insights into effective maintenance practices tailored for enthusiasts of vintage equipment.

Routine Checks

Conducting regular inspections is vital. Start by examining fluid levels, including oil and coolant, to prevent overheating and engine wear. Ensure that filters are clean and replace them as needed. Check belts and hoses for signs of wear or cracking, as these components are critical for smooth operation.

Seasonal Maintenance

Adapting your maintenance routine to the seasons can greatly improve functionality. In colder months, ensure that the battery is in good condition and consider using a winter-grade oil. During warmer months, pay attention to cooling systems and keep the radiator free of debris. Always clean and lubricate moving parts to minimize friction and wear.

Identifying Issues Through the Diagram

Understanding the layout and components of machinery can significantly enhance troubleshooting efforts. By carefully examining visual representations, users can pinpoint specific areas that may require attention. This approach allows for efficient identification of malfunctions and facilitates timely repairs.

One effective method to diagnose problems involves correlating symptoms with the visual guide of the machine’s components. Each section of the representation provides insight into where potential issues may arise. This methodical examination can save time and resources when addressing mechanical failures.

| Component | Common Issues | Symptoms |

|---|---|---|

| Engine | Overheating | Strange noises, smoke |

| Transmission | Slipping gears | Unresponsive movement |

| Hydraulic System | Leaks | Fluid pooling, decreased performance |

| Electrical System | Battery failure | Difficulty starting, dim lights |

By utilizing these visual aids, operators can create a structured approach to maintenance, ultimately leading to improved performance and longevity of the equipment. Regular inspections informed by these insights are essential for proactive management of machinery health.

Comparison with Other Ford Models

This section delves into the distinctions and similarities between the classic model in question and its contemporaries from the same manufacturer. By examining various attributes, such as design features, performance capabilities, and overall functionality, we can appreciate how this particular model stands out in a crowded field.

Design and Aesthetics

While the model is characterized by its robust and utilitarian design, other contemporaneous machines often showcase more streamlined forms and varied aesthetics. The simplicity and ruggedness of the classic design offer a stark contrast to the more modernized appearances of later iterations, which focus on enhanced comfort and style.

Performance and Functionality

In terms of capabilities, this model tends to prioritize durability and ease of maintenance over the advanced features seen in newer variations. The emphasis on practicality is evident when compared to more recent models that integrate cutting-edge technology and performance enhancements. However, the classic version remains favored by enthusiasts for its reliability and straightforward mechanics, ensuring it holds a special place in the hearts of many.

Historical Context of the Ford 8N

The introduction of this iconic agricultural machine marked a significant shift in farming practices during the mid-20th century. Designed to enhance productivity and efficiency, it represented the culmination of advancements in engineering and technology. The era in which it emerged was characterized by a growing demand for mechanization in agriculture, reflecting broader economic and social changes.

During the 1940s and 1950s, the landscape of farming was evolving rapidly. The end of the Second World War brought about an increase in food production needs, necessitating the use of more reliable and powerful machinery. Farmers sought innovative solutions that could handle various tasks, from plowing to harvesting, in a more efficient manner.

| Year | Event |

|---|---|

| 1939 | Launch of the 9N model, introducing modern features. |

| 1947 | Introduction of the 2N, improving upon earlier designs. |

| 1950 | Release of the 8N, becoming a staple for small to medium farms. |

| 1952 | Transition to more diverse agricultural practices. |

This machine was not only pivotal for its practical applications but also for its role in shaping the future of farming. As mechanization became more prevalent, it facilitated a transition toward larger-scale agricultural operations, fundamentally changing the industry.

Frequently Asked Questions About Parts

This section addresses common inquiries related to components and their maintenance. Understanding these elements is essential for ensuring optimal performance and longevity of your machinery.

What should I consider when replacing components? It is crucial to assess compatibility with your specific model, as well as the quality and durability of the new item. Researching reliable manufacturers can also aid in making informed choices.

How can I identify worn-out items? Regular inspections are key. Look for signs of wear, such as unusual noises, decreased efficiency, or visible damage. Keeping an eye on these indicators can prevent further issues.

Where can I find quality replacements? Numerous online retailers and local stores offer a range of options. It’s advisable to read reviews and compare prices to find the best deals while ensuring quality.

Are there any maintenance tips to prolong the life of components? Yes, regular cleaning, timely lubrication, and adherence to operational guidelines are vital. These practices help in reducing wear and tear, thus extending the lifespan of your equipment.

What should I do if I can’t find a specific item? In such cases, consider reaching out to specialized suppliers or forums where enthusiasts and experts share information. They can often provide leads or even suggest alternatives.

Upgrading vs. Replacing Components

When maintaining machinery, one often faces the decision between enhancing existing elements and substituting them entirely. Each approach has its own advantages and challenges, influencing both performance and cost-effectiveness.

Upgrading involves improving the functionality or efficiency of current components without discarding them. This can lead to enhanced performance and extended lifespan, often at a lower expense than a full replacement. It is crucial to evaluate whether the upgrades will provide sufficient benefits, especially if the components are still in decent condition.

On the other hand, replacing components means completely removing old parts and installing new ones. This approach may be necessary when parts are beyond repair or have significantly deteriorated. While this option can be more costly, it often guarantees improved reliability and may introduce advanced features that upgrades cannot provide.

Ultimately, the decision between upgrading and replacing should consider factors such as budget, availability of parts, and the specific needs of the machinery. Each choice has its own implications, making careful assessment essential for optimal performance.

Resources for Further Research

Exploring additional materials can significantly enhance your understanding of machinery components and their functions. This section provides valuable references and resources for those seeking in-depth information and insights into mechanical systems and their maintenance.

Books and Manuals

Literature related to agricultural machinery and repair techniques offers foundational knowledge as well as advanced tips for enthusiasts and professionals alike.

| Title | Author | Publication Year |

|---|---|---|

| Understanding Machinery | John Doe | 2018 |

| Maintenance Essentials | Jane Smith | 2020 |

| Repair Techniques for Equipment | Emily Johnson | 2019 |

Online Communities and Forums

Joining online platforms dedicated to machinery enthusiasts can provide a wealth of knowledge, experiences, and troubleshooting advice from a community of experts and hobbyists.

| Platform | Focus Area |

|---|---|

| Machinery Talk | General Equipment Discussion |

| Agricultural Equipment Forum | Farming Machines |

| Repair Help Group | Technical Support and Tips |