Comprehensive Guide to Ford e-450 Parts Diagram

Understanding the arrangement of key elements in heavy-duty vehicles is crucial for both maintenance and repair. A clear visualization of how individual elements are connected helps ensure smoother workflows and reduces time spent troubleshooting.

Efficient organization of mechanical and electrical systems can enhance the vehicle’s performance. Technicians rely on these layouts to identify and address potential issues with accuracy. Comprehensive visual aids contribute to a better understanding of the structure, making repair work more streamlined.

Regular inspections and familiarization with component arrangements are vital to maintaining vehicle reliability. Having a thorough grasp of the system setup simplifies many complex repair tasks and allows for more efficient problem-solving when issues arise.

Understanding Ford e-450 Components

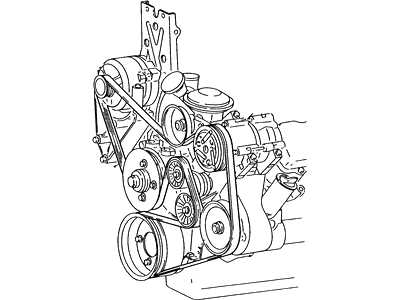

Exploring the key elements of this vehicle model’s structure can provide insight into its performance and maintenance needs. Various mechanical systems and assemblies work in unison to ensure reliability and functionality. Gaining a comprehensive understanding of how these components interact is essential for efficient upkeep and troubleshooting.

Key Elements and Their Functions

| Component | Function |

|---|---|

| Engine | Powers the vehicle by converting fuel into mechanical energy. |

| Transmission | Transfers power from the engine to the wheels, enabling movement. |

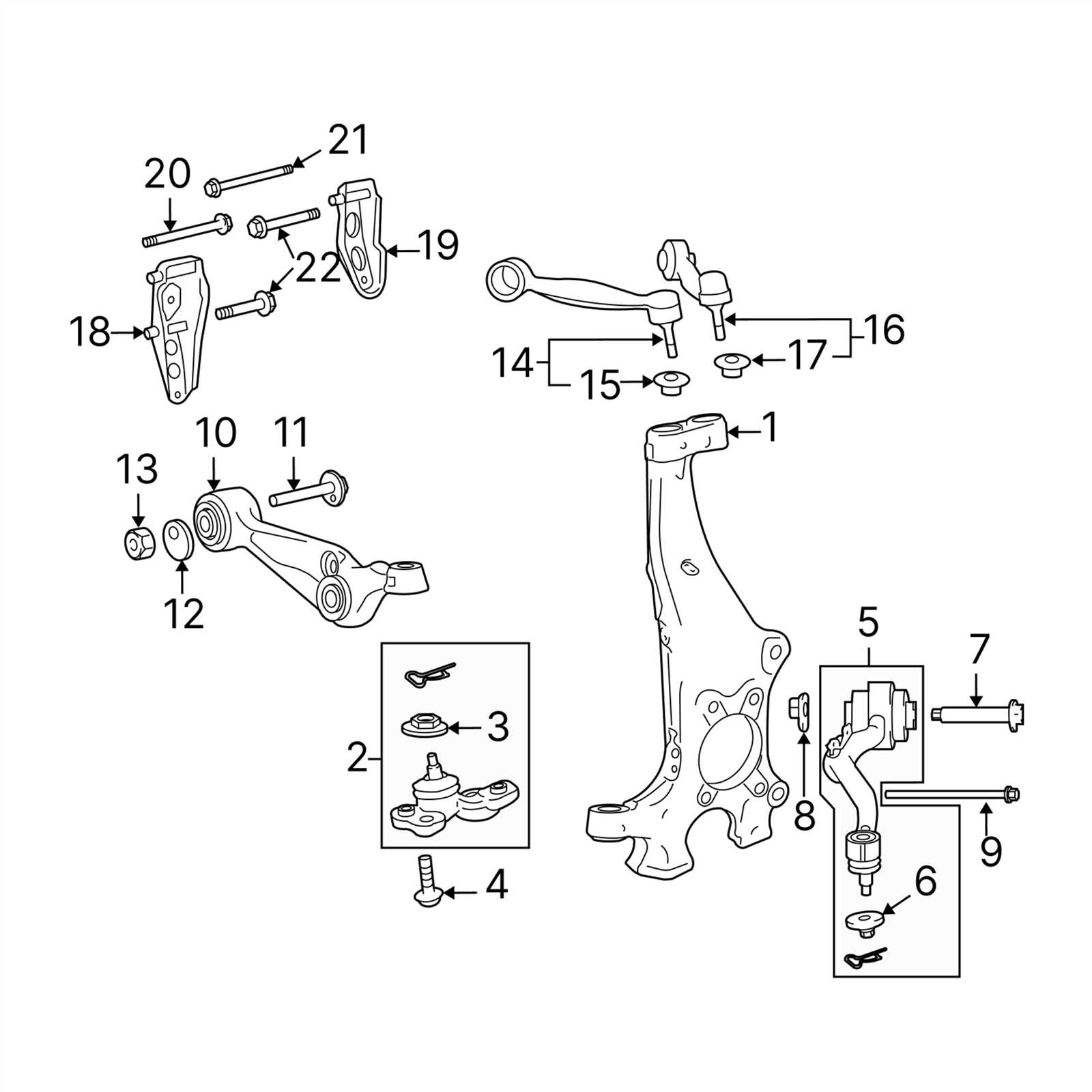

| Suspension | Provides stability and comfort by absorbing shocks from uneven roads. |

| Brakes | Ensures safe stopping by slowing or halting the vehicle. |

Overview of e-450 Parts Diagram

The detailed layout of this vehicle’s components offers a comprehensive look at the various mechanical and structural elements that make up its design. Understanding the arrangement and connection of these elements is essential for maintenance, repair, and overall functionality. The graphical representation highlights the relationships between key sections, providing insight into the inner workings of the system without diving into specific technical definitions. This section serves as a guide to help visualize the complexity of the vehicle’s build, ensuring clarity for users working on specific tasks.

Common Issues with e-450 Parts

Many vehicles encounter common mechanical and component-related challenges over time, especially with frequent use and exposure to various conditions. Understanding these typical issues can help in diagnosing and maintaining the system efficiently, ensuring longevity and safety.

Mechanical Wear and Tear

One of the most frequent problems involves the natural wear of key components. These can include issues like excessive friction, overheating, or component fatigue that gradually reduce efficiency and may lead to failure if not addressed promptly. Regular maintenance can mitigate many of these concerns.

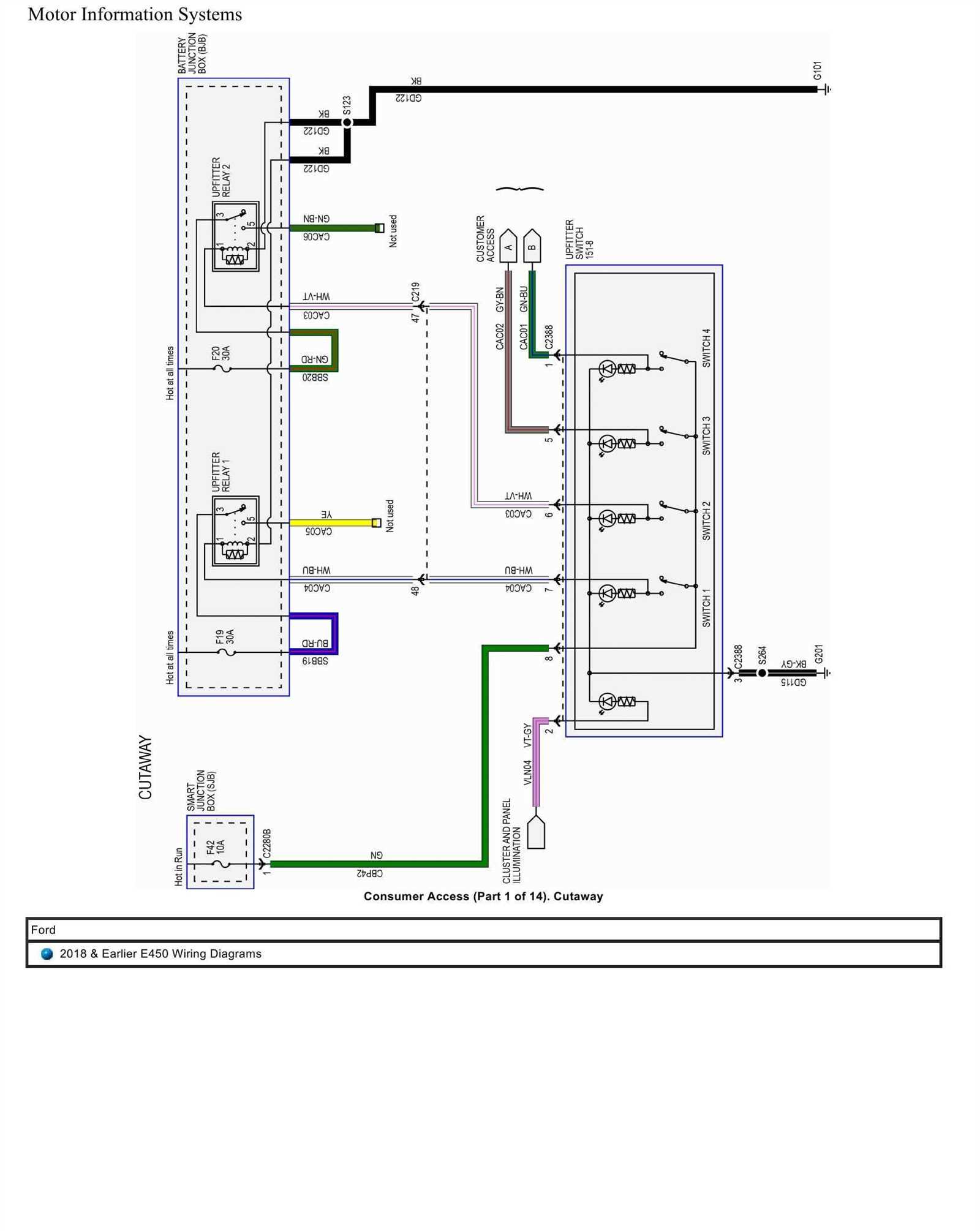

Electrical System Failures

Another prevalent concern is related to the electrical system, which is responsible for powering various functionalities. Faults in wiring, connectors, or sensors can cause malfunctions, leading to performance inconsistencies. Regular checks and timely replacement of failing parts can prevent these issues from escalating.

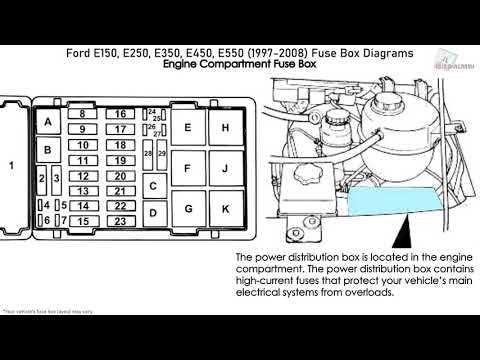

How to Read Parts Diagrams

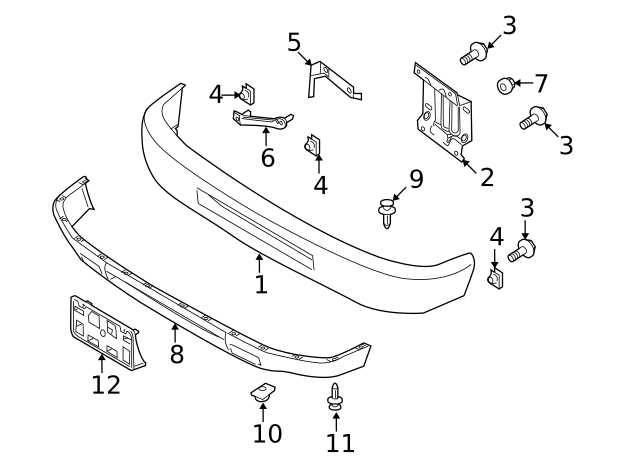

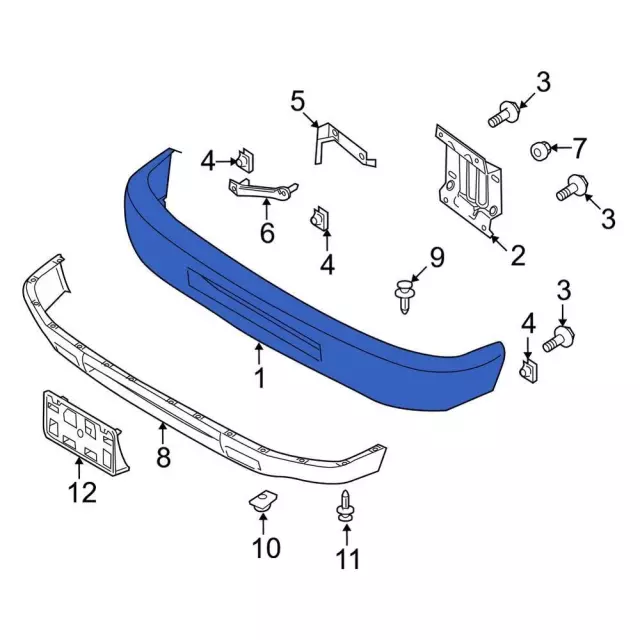

Understanding how to interpret technical illustrations is essential for anyone looking to repair or maintain equipment. These visual guides provide a simplified view of how individual components are arranged and interconnected, helping users identify each element and its place in the overall structure.

Identifying Components

The first step in reading these illustrations is to locate the labels that correspond to each item. These labels often include numbers or letters that match a list of elements shown alongside the drawing, allowing for easy identification. Recognizing how each element fits into the system can simplify troubleshooting and repairs.

Following the Layout

Once components are identified, it’s crucial to observe how they connect with each other. The layout is designed to show both spatial relationships and functional connections, giving a clear understanding of how the system works as a whole. Pay attention to the arrangement, as it often mirrors the actual setup of the equipment, helping you plan repairs or replacements effectively.

Importance of OEM vs Aftermarket Parts

When it comes to replacing components in vehicles, choosing between original equipment manufacturer (OEM) products and aftermarket alternatives is a crucial decision. Both options offer unique advantages, but understanding their differences can greatly impact the performance and longevity of your vehicle.

Advantages of OEM Components

OEM components are designed and produced by the original manufacturer, ensuring exact compatibility with your vehicle. They are often more reliable and come with warranties, providing peace of mind regarding their quality. This option is ideal for those who prioritize a perfect fit and long-term durability.

Benefits of Aftermarket Alternatives

Aftermarket options are made by third-party manufacturers and offer a wider range of choices. These parts can be more affordable, with some even outperforming their OEM counterparts in specific areas. For those seeking customization or budget-friendly solutions, aftermarket components provide flexibility and variety.

Step-by-Step Maintenance Guide

Proper upkeep is crucial for ensuring the long-lasting performance of any vehicle. This guide provides clear instructions to help you perform routine maintenance tasks efficiently. By following these steps, you can keep your vehicle running smoothly and avoid potential issues.

Inspect Fluids Regularly

To maintain the smooth operation of the engine, it’s important to frequently check and top off essential fluids like oil, coolant, and brake fluid. Regular monitoring helps prevent overheating and engine wear.

Check Tire Condition

Inspecting the tires for even wear and proper inflation is vital for both safety and fuel efficiency. Adjust the air pressure according to the manufacturer’s recommendations and replace worn-out tires promptly.

Clean and Replace Filters

Air filters and cabin filters should be cleaned or replaced periodically to ensure proper air flow and a comfortable driving experience. A clogged filter can reduce engine performance and cause discomfort inside the vehicle.

Monitor Brake Performance

Pay attention to any unusual sounds or vibrations when applying the brakes. Regular inspection and replacement of brake pads will help maintain optimal stopping power and enhance driving safety.

Tools Needed for e-450 Repairs

When working on large vehicles, having the right set of tools is essential for completing repairs efficiently and safely. Whether you’re handling routine maintenance or more complex tasks, proper equipment ensures smooth work and avoids unnecessary complications.

Basic Equipment for General Maintenance

- Socket set: A comprehensive set of sockets helps with loosening and tightening bolts of various sizes.

- Wrenches: Both adjustable and fixed-size wrenches are useful for different fasteners.

- Screwdrivers: A variety of flathead and Phillips screwdrivers are necessary for smaller components.

- Pliers: Needle-nose and slip-joint pliers provide grip for electrical and mechanical tasks.

Specialized Tools for Specific Repairs

- Torque wrench: Ensures precise tightening of bolts to avoid over-tightening or under-tightening.

- Jack and stands: Essential for safely lifting the vehicle for underbody inspections or repairs.

- Diagnostic scanner: Helps to identify electronic issues and read error codes quickly.

- Brake tool kit: Specialized for handling brake calipers and

Identifying Wear and Tear Signs

Over time, mechanical components inevitably experience degradation due to regular use. Recognizing early symptoms of wear is essential to ensure optimal functioning and prevent potential malfunctions. Proper identification can prolong the lifespan of various mechanisms and avoid more severe complications.

Visual Indicators

External signs often serve as the first clue of deterioration. Look for cracks, rust, or any deformities on surfaces. These can indicate material fatigue, especially in areas exposed to friction or high stress. Regular inspections can help detect these early warning signs before they escalate.

Performance Changes

Changes in operation, such as unusual noises, vibrations, or loss of responsiveness, can also signal wear. These symptoms typically point to internal components struggling to maintain their efficiency due to aging or damage. Monitoring performance can help identify these issues and take corrective action in time.

Symptom Possible Cause Action Squeaking sound Friction between moving parts Apply lubrication or inspect for wear Increased vibrations Worn bearings Replace affected parts Loss of responsiveness Worn Where to Source Quality Parts

Finding reliable components for your vehicle is essential to ensure longevity and optimal performance. The quality of these materials directly impacts the efficiency and safety of the system. Whether you’re maintaining or upgrading, it’s important to choose reputable sources for your purchases.

- Authorized Retailers: These outlets are a trustworthy option for acquiring genuine components, as they work closely with manufacturers to ensure authenticity.

- Specialized Stores: Local shops with a focus on specific vehicle systems often provide expert knowledge and a wide selection of options to meet your needs.

- Online Marketplaces: Digital platforms offer a convenient way to browse a variety of products, but it’s important to verify the credibility of the seller and the quality of the items.

By selecting reputable sources, you can ensure that your vehicle remains in top condition, minimizing the risk of future issues.

Cost Comparison of Parts Options

When maintaining a vehicle, evaluating the financial aspects of different component alternatives is crucial. This analysis not only helps in understanding the initial investment but also in forecasting potential long-term expenses associated with each choice. Below, we will explore various options available, highlighting their cost implications and benefits.

Types of Components

- Original Equipment Manufacturer (OEM) Components

- Aftermarket Alternatives

- Reconditioned or Remanufactured Options

Cost Factors to Consider

- Initial Price: The upfront cost may vary significantly between OEM and aftermarket selections.

- Quality and Longevity: Assessing how long each option lasts can influence overall spending.

- Warranty and Support: Understanding the warranty terms can provide insights into potential future expenses.

Upgrades for Enhanced Performance

Enhancing the functionality of your vehicle can lead to improved efficiency and responsiveness. By incorporating various modifications, you can elevate the driving experience while also extending the lifespan of key components. This section explores several popular enhancements that contribute to better overall performance.

- Engine Tuning: Adjusting the engine’s control unit can optimize power output and fuel efficiency.

- Suspension Upgrades: Investing in upgraded suspension systems can enhance stability and handling, especially under heavy loads.

- Exhaust System Improvements: A performance exhaust system can improve airflow, resulting in increased horsepower and a more aggressive sound.

- Brake Enhancements: Upgrading to high-performance brake pads and rotors can significantly improve stopping power and reduce brake fade.

- Tire Selection: Choosing tires designed for specific driving conditions can enhance grip and handling characteristics.

Implementing these upgrades can transform the driving dynamics, making the vehicle more responsive and enjoyable to operate. Careful consideration of each modification will ensure that the enhancements align with your performance goals.

Safety Features in e-450 Design

The design of this vehicle prioritizes the well-being of occupants and ensures a secure driving experience. Various safety measures have been incorporated to enhance protection during transit and mitigate potential risks associated with road travel.

Robust Structural Integrity

The framework of this model is engineered with advanced materials that provide exceptional strength and resilience. This robust construction minimizes the impact of collisions, safeguarding passengers and critical components effectively.

Advanced Driver Assistance Systems

Equipped with a range of cutting-edge technologies, this vehicle features numerous driver assistance systems. These innovations support enhanced visibility, improved maneuverability, and reduced blind spots, contributing significantly to overall safety on the road.

Tips for Efficient Repair Process

Streamlining the maintenance workflow can significantly enhance the overall effectiveness of the repair process. By implementing strategic approaches and best practices, technicians can minimize downtime and improve service quality. This section provides insights into optimizing repair operations for better results.

Preparation and Planning

Thorough preparation is essential for a successful repair endeavor. Begin by gathering all necessary tools and materials beforehand. Creating a detailed plan that outlines each step of the procedure will help avoid confusion during the actual work. Consider checking the available resources and making an inventory to ensure that nothing is overlooked.

Utilizing Resources

Leverage online resources and community forums to gather information and advice. Engaging with experienced individuals can provide valuable insights and tips that enhance your understanding of the task. Furthermore, utilizing instructional videos or guides can serve as a useful reference throughout the process, ensuring that you stay on track and execute repairs efficiently.