Understanding the Dana 60 Front Axle Parts Diagram

In the realm of robust machinery, an intricate assembly of elements plays a crucial role in ensuring optimal performance. Each component is meticulously designed to withstand immense pressures while facilitating smooth operations. This discussion will explore the various essential elements that contribute to the functionality of these systems.

Visual representation serves as an invaluable tool for enthusiasts and professionals alike, allowing for a deeper understanding of how these pieces interact. By analyzing the arrangement and function of each segment, one can delve into the complexities that underlie heavy-duty constructions.

The ultimate goal is to equip individuals with knowledge about these vital components, enhancing both maintenance practices and overall efficiency. With this insight, one can appreciate the intricate dance of mechanics that keeps these powerful machines in motion.

Dana 60 Front Axle Overview

This section provides a comprehensive understanding of a vital component in heavy-duty vehicles, focusing on its design, functionality, and significance in performance. The assembly plays a crucial role in the overall dynamics of off-road and high-torque applications, ensuring stability and durability under extreme conditions.

| Component | Description |

|---|---|

| Housing | Strong outer shell providing protection and support. |

| Center Section | Core area housing the differential and gearing. |

| Bearings | Facilitate smooth rotation of shafts, reducing friction. |

| U-Joints | Connect shafts to allow for flexibility during movement. |

| Drive Shaft | Transmits torque from the transfer case to the assembly. |

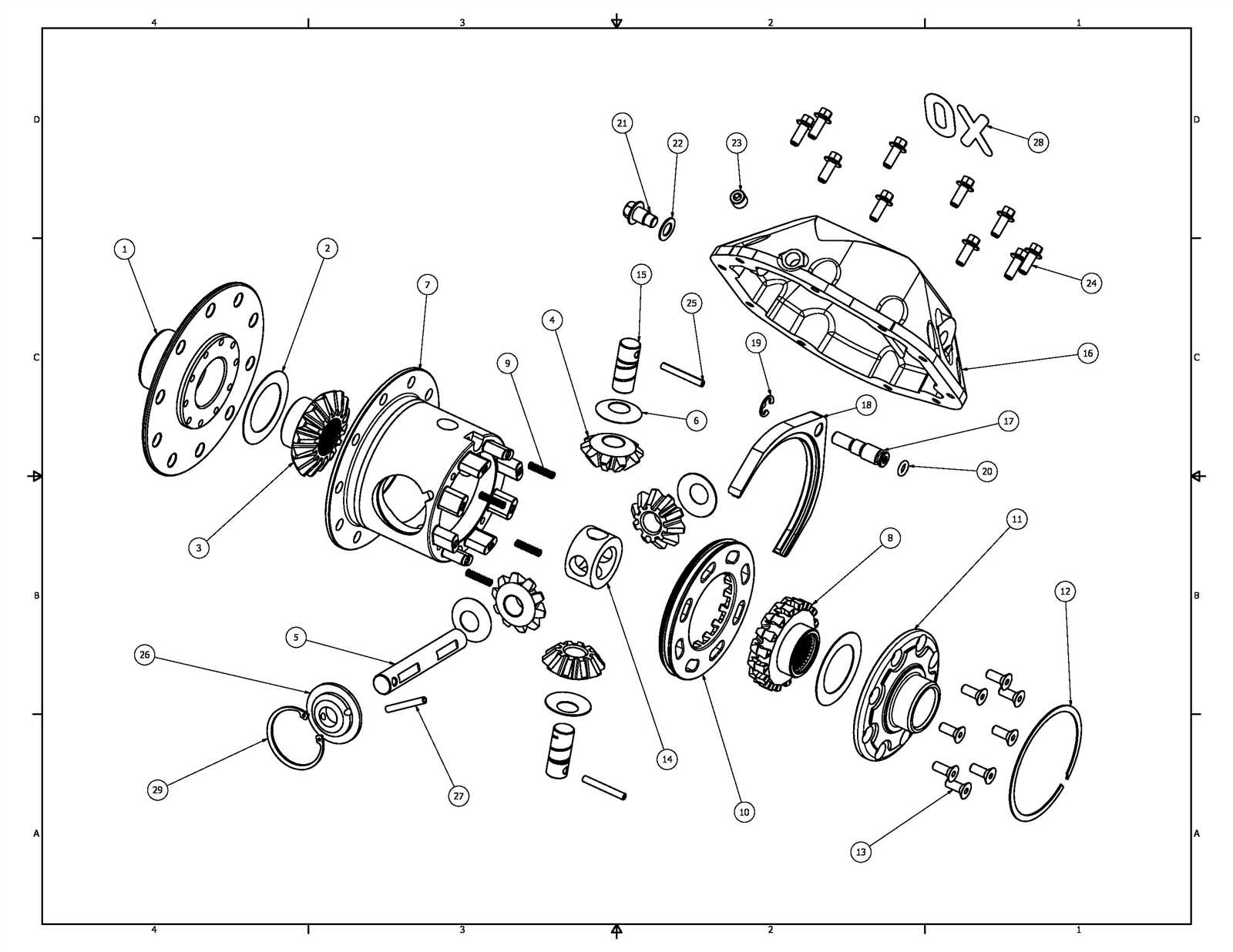

Key Components of Dana 60 Axle

The robust assembly in question is crucial for off-road performance and heavy-duty applications. Its design incorporates several essential elements that contribute to strength, durability, and efficiency. Understanding these components allows for better maintenance and upgrades, ensuring optimal functionality in various driving conditions.

At the core of this structure lies the differential, which facilitates power distribution between the wheels while allowing them to rotate at different speeds. This is vital for maintaining traction and handling during turns. Connected to the differential are the drive shafts, which transmit torque from the engine to the wheels, enabling effective movement.

Another significant element is the housing, which encases the internal components and provides structural integrity. It is typically made from high-strength materials to withstand harsh environments and heavy loads. Additionally, the knuckles play a pivotal role in steering, connecting the suspension system to the wheels and allowing for smooth directional changes.

Lastly, the bearings and seals ensure that the entire assembly operates smoothly and is protected from dirt and debris. Proper maintenance of these elements is essential for extending the lifespan of the entire system, ensuring reliable performance whether on rugged terrains or everyday roads.

Understanding the Axle Assembly

The assembly responsible for transferring power from the drivetrain to the wheels plays a crucial role in vehicle performance. It consists of various components that work together to ensure smooth movement, stability, and control. A solid grasp of this assembly is essential for anyone interested in automotive mechanics or enhancement.

At its core, the structure includes a central shaft that connects to the wheel hubs, supported by bearings and housing. Each element is designed to withstand significant stress while facilitating rotational motion. Understanding how these components interact can help diagnose issues and improve maintenance practices.

Moreover, various configurations exist to cater to different vehicle designs and purposes. Familiarity with these variations is beneficial for selecting the right components for upgrades or replacements. Key aspects to consider include load capacity, weight distribution, and compatibility with existing systems.

Common Issues with Dana 60 Parts

Understanding the typical challenges associated with heavy-duty drivetrain components can significantly enhance performance and longevity. Various mechanical failures can arise from wear and tear, improper installation, or substandard materials, impacting functionality and safety.

Wear and Tear: Over time, constant use leads to degradation of crucial components. Bearings and seals may exhibit signs of wear, resulting in leaks or noise that indicate potential failure.

Improper Installation: Misalignment during assembly can cause undue stress on different elements. This misalignment often leads to premature failure, requiring frequent repairs and replacements.

Material Quality: The use of inferior materials can compromise the durability of components. It’s essential to ensure that replacements meet or exceed original specifications to avoid issues down the line.

Heat Build-Up: Excessive heat generated from friction can warp or weaken metal components, leading to catastrophic failures. Regular maintenance and checks are vital to mitigate this risk.

Noise and Vibration: Unusual sounds or vibrations during operation often signal underlying problems. Identifying and addressing these symptoms early can prevent extensive damage and costly repairs.

Compatibility Issues: When mixing and matching components from different manufacturers, compatibility can become a concern. Always verify that parts are designed to work together to maintain optimal performance.

Maintenance Tips for Front Axles

Regular upkeep is essential for ensuring optimal performance and longevity of the vehicle’s steering and drive components. Neglecting this aspect can lead to costly repairs and compromised safety on the road.

Regular Inspections

Routine checks are vital. Look for signs of wear, such as unusual noises or vibrations, and inspect for leaks or damage. Early detection can prevent major issues down the line.

Proper Lubrication

Maintaining the right lubrication levels is crucial for smooth operation. Ensure that all moving parts are adequately greased to reduce friction and prevent premature wear.

Upgrades for Dana 60 Performance

Enhancing the capabilities of your heavy-duty assembly can significantly improve overall performance, ensuring it can handle rigorous conditions. Upgrading various components not only boosts strength and durability but also optimizes efficiency and responsiveness on challenging terrains.

Strengthening Components

Investing in high-quality gears and reinforced housings can prevent failures under extreme loads. Upgrading to aftermarket gears with lower ratios enhances torque delivery, making off-road experiences smoother and more controlled.

Suspension and Steering Enhancements

Integrating advanced suspension systems can drastically improve handling and stability. Additionally, incorporating precision steering linkages provides better feedback and control, allowing for more confident maneuvering.

Tools Needed for Axle Repairs

Repairing the essential components of a vehicle’s drivetrain requires specific tools to ensure precision and efficiency. Having the right equipment not only facilitates the repair process but also enhances safety and longevity of the work performed. Below are the fundamental instruments that are typically required for these types of maintenance tasks.

Essential Tools

First and foremost, a sturdy set of wrenches is crucial for loosening and tightening various fasteners. A combination of metric and standard sizes will cover most needs. Additionally, a socket set with a ratchet will allow for quicker adjustments and access to tighter spaces.

Specialized Equipment

For more intricate repairs, specialized tools such as a bearing puller or a seal installer are invaluable. These instruments help remove and install components without causing damage. A torque wrench is also necessary to apply the correct pressure when securing parts, ensuring they function correctly under stress. Lastly, a workbench with a vice can provide the stability needed for precise work.

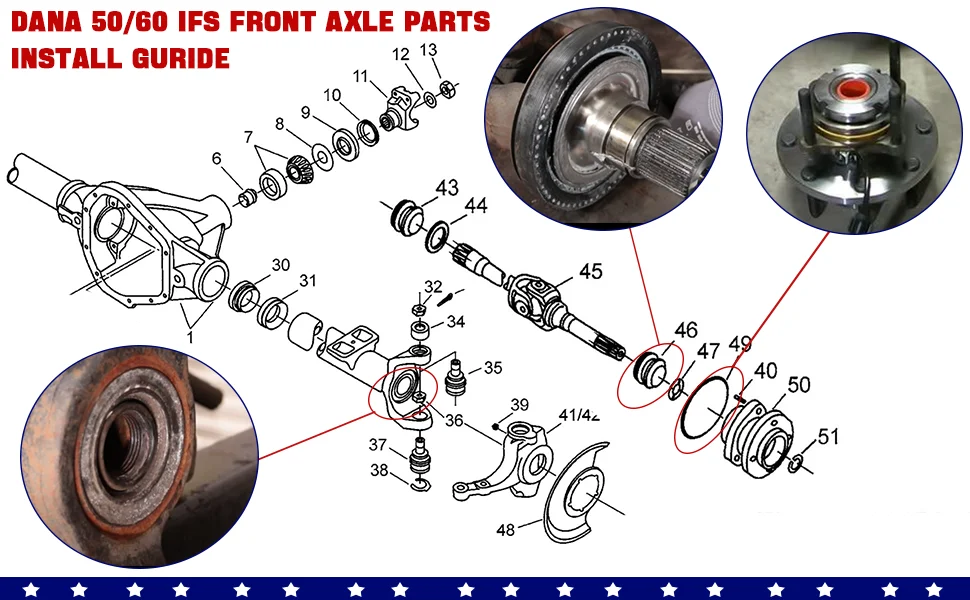

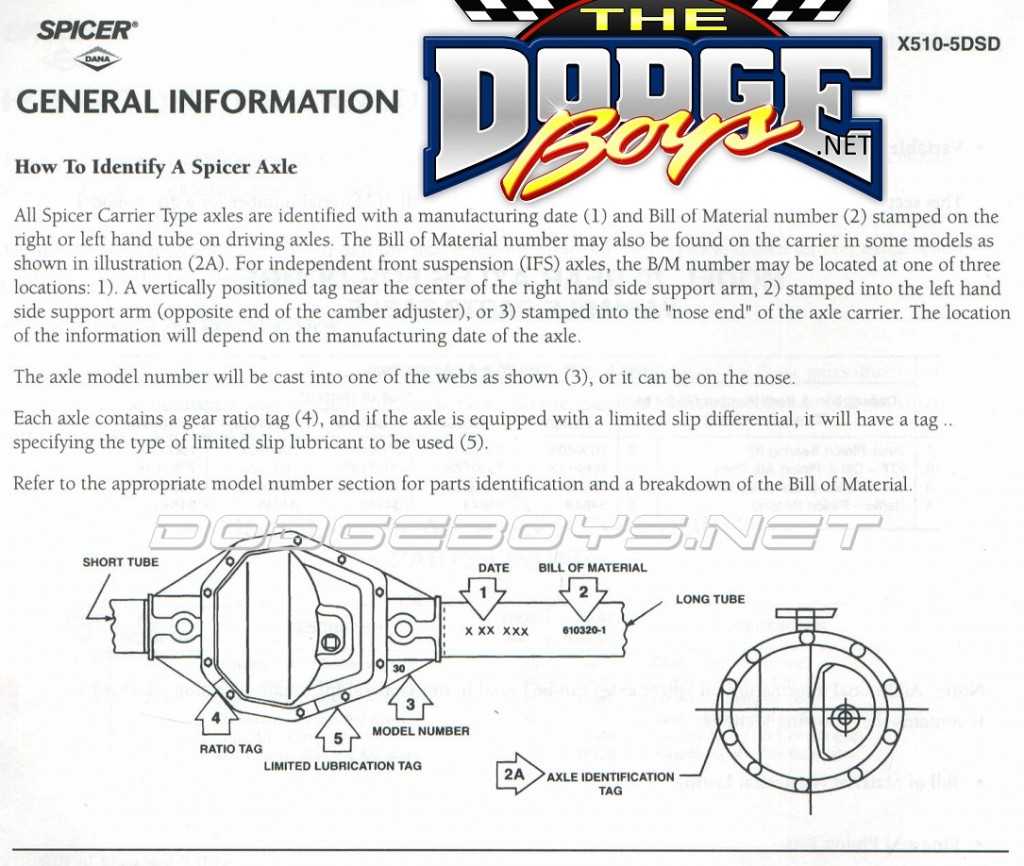

How to Read an Axle Diagram

Understanding the layout of mechanical components is essential for effective maintenance and repairs. Each visual representation conveys critical information about the assembly and its function, helping enthusiasts and professionals alike to navigate complex systems with ease.

Begin by identifying the key symbols used within the illustration. Each symbol typically corresponds to a specific element or feature, so familiarizing yourself with these representations will enhance your comprehension significantly.

Next, take note of the labels and annotations accompanying the visual. These often provide essential details such as measurements, material specifications, and assembly instructions that are crucial for accurate interpretation.

Finally, consider the overall layout. The arrangement of components can indicate the relationships and functions within the system, giving you insights into how each part interacts with others.

Comparing Dana 60 to Other Axles

When assessing the merits of different drive components, it’s essential to understand how various models stack up against one another. Each assembly offers unique advantages and drawbacks, influencing performance, durability, and suitability for specific applications. By exploring the characteristics and capabilities of one particular model in relation to others, enthusiasts and professionals alike can make informed decisions for their vehicles.

One of the most notable distinctions lies in load-bearing capacity. Some alternatives are designed to handle lighter loads, making them suitable for everyday driving, while others excel in off-road conditions or heavy-duty use. The robustness of the unit in question often makes it a favored choice among those who prioritize durability and strength.

Another factor worth considering is the ease of modification and availability of aftermarket upgrades. Certain assemblies have a well-established presence in the market, resulting in a plethora of options for enhancements. This can significantly affect performance and customization potential, allowing users to tailor their systems to specific needs.

In terms of weight, the comparative heaviness or lightness of these components can influence fuel efficiency and overall handling characteristics. A lighter assembly may contribute to better maneuverability, whereas a sturdier variant could provide increased stability under challenging conditions.

Lastly, the overall design and engineering innovations present in various units can lead to significant differences in maintenance requirements and longevity. Understanding these aspects allows users to choose a component that not only meets their immediate needs but also aligns with their long-term goals for performance and reliability.

Installing New Parts on Dana 60

Upgrading components can significantly enhance performance and durability. Proper installation is crucial to ensure everything functions seamlessly and reliably.

Here’s a step-by-step guide to facilitate the process:

- Gather necessary tools and components.

- Carefully disassemble the existing assembly.

- Inspect each element for wear and tear.

- Begin installing the new elements, starting with the larger components.

- Ensure all fasteners are tightened to manufacturer specifications.

- Double-check alignment and functionality.

- Conduct a test run to verify the installation.

Following these steps will help achieve optimal results and longevity in your upgrades.

Resources for Dana 60 Enthusiasts

For those passionate about off-road performance and rugged vehicle enhancements, a wealth of information and tools is available. Whether you’re a seasoned builder or a newcomer eager to learn, the following resources provide invaluable insights and support for your projects.

Online forums and communities are excellent places to connect with fellow enthusiasts, sharing experiences, troubleshooting tips, and modification ideas. Websites dedicated to off-roading often feature comprehensive guides, reviews, and tutorials that can help you navigate upgrades and maintenance.

Specialty shops offer not only high-quality components but also expert advice on optimizing your setup. Additionally, instructional videos on platforms like YouTube provide visual guidance, making complex processes easier to understand.

Books and manuals specific to vehicle modifications can serve as essential references, while social media groups keep you updated on the latest trends and innovations. Engaging with these resources can ultimately enhance your knowledge and skills, leading to a more fulfilling hobby.