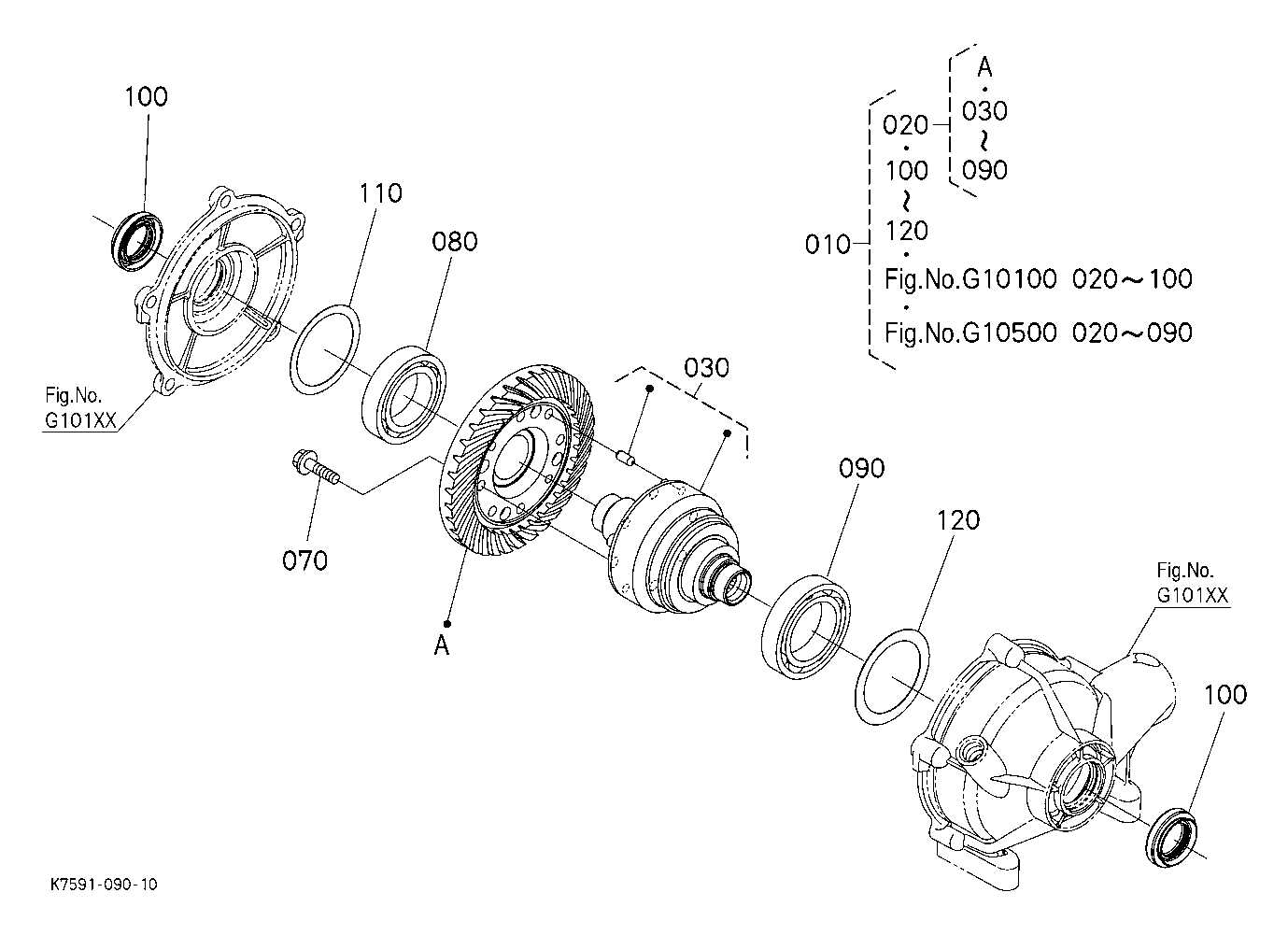

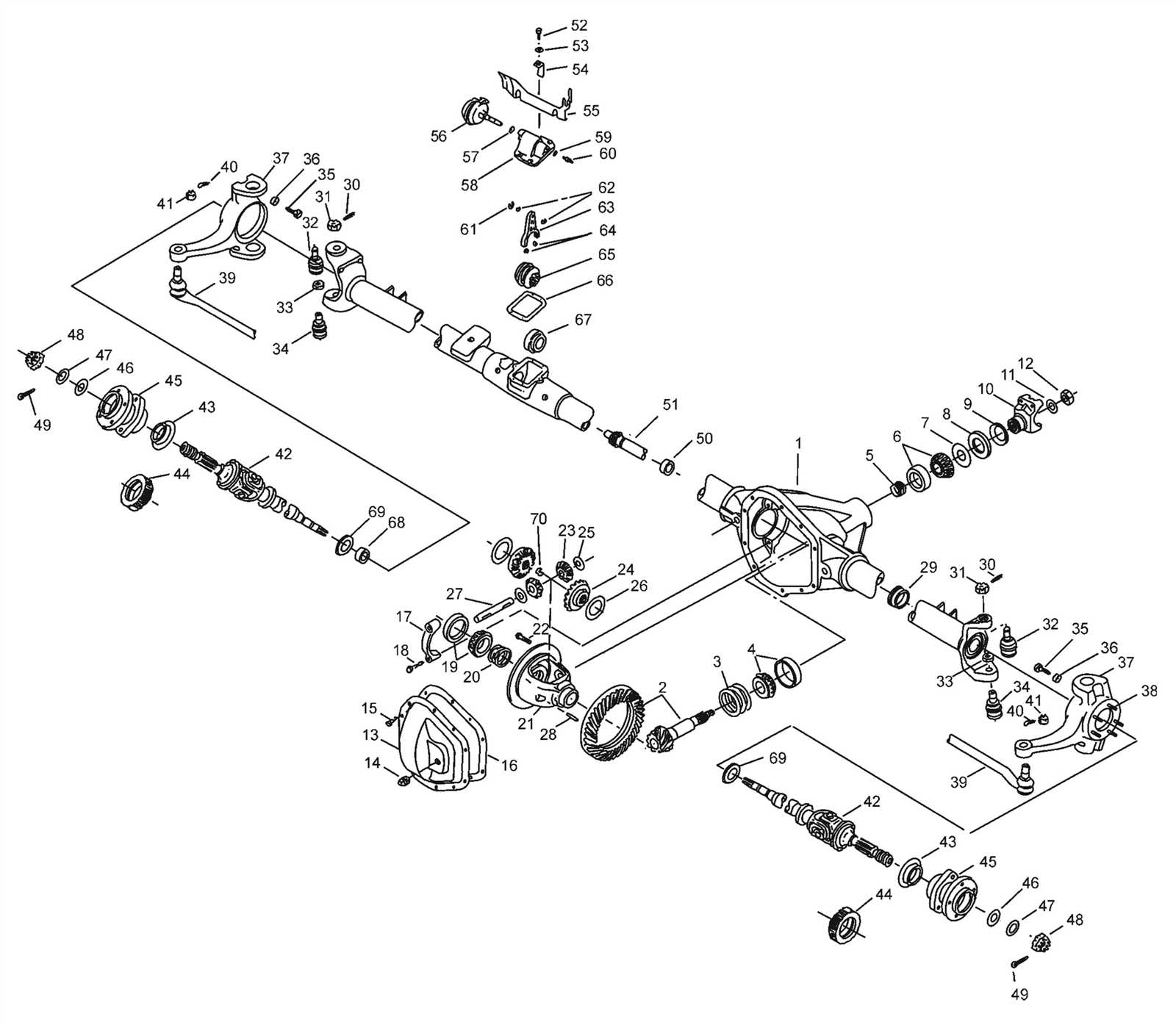

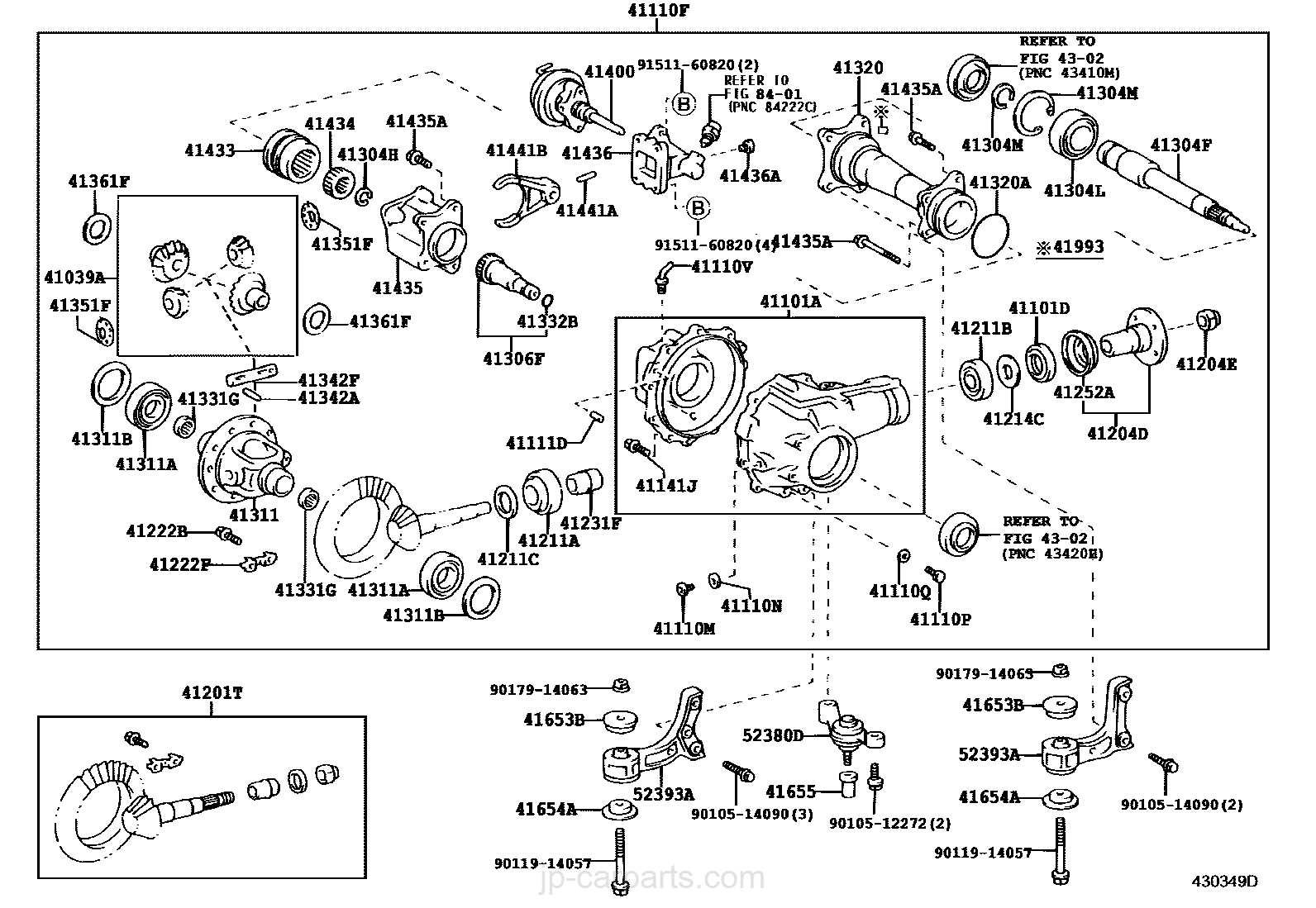

Front Differential Parts Diagram Overview

In modern vehicles, one of the key systems responsible for smooth operation involves a complex assembly of gears, shafts, and bearings. This system ensures that power is transferred efficiently to the wheels, allowing the vehicle to navigate various terrains with ease. Understanding the layout and functionality of these components is crucial for both maintenance and repair.

The system in question operates by distributing force between different sections of the vehicle’s powertrain, ensuring optimal control and performance. Each component plays a critical role in maintaining balance and smooth operation, especially when navigating turns or uneven surfaces. The proper alignment and condition of these elements are vital for the overall performance of the vehicle.

By examining the internal configuration of these interconnected parts, one can gain a deeper appreciation for the engineering involved. This knowledge not only helps in troubleshooting issues but also provides insights into improving the system’s longevity and efficiency. Whether you’re a mechanic or an enthusiast, a thorough understanding of this mechanism is essential.

Understanding the Function of a Front Differential

The central mechanism under the vehicle’s hood plays a vital role in ensuring that power is distributed effectively to the wheels. This process is essential for maintaining stability, especially when the vehicle encounters turns or uneven terrain. Without this system, drivers would face challenges related to control and smoothness during movement.

The Role in Power Distribution

The primary function of this component is to manage how energy from the engine is directed to each wheel. When a vehicle navigates bends, the inner and outer wheels rotate at different speeds. The device helps balance this, allowing for smoother handling and reducing stress on the tires.

- Prevents wheel slippage by managing torque distribution

- Helps in navigating turns efficiently

- Reduces wear on tires by controlling wheel speed differences

Performance and Longevity

This system not only enhances the driving experience but also contributes to the longevity of the vehicle’s suspension and tire life. Proper functioning of the mechanism ensures that wear and tear on various components is minimized, leading to fewer maintenance requirements.

- Ensures balanced load on the wheels

- Improves traction on uneven or slippery surfaces

- Contributes to overall vehicle efficiency and stability

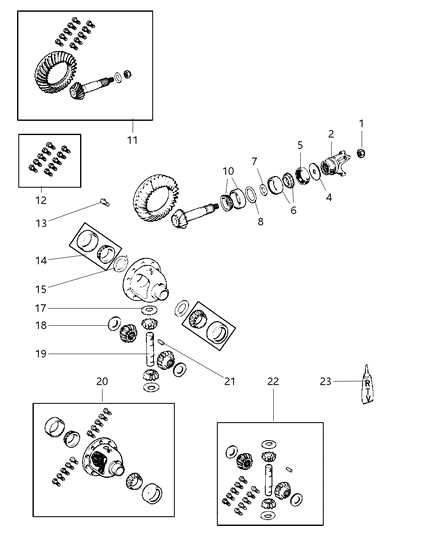

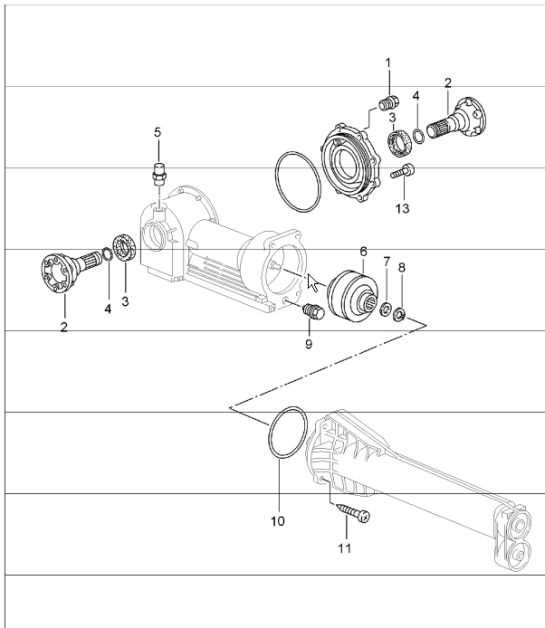

Key Components of Front Differential Systems

Modern vehicles rely on complex systems that distribute power and manage the movement of wheels, ensuring efficient and stable operation. These systems consist of various essential elements working in harmony to maintain balance, handle varying speeds, and support smooth navigation through turns and rough terrain.

| Component | Function |

|---|---|

| Pinion Gear | Transfers rotational energy from the main drive shaft to other parts of the system. |

| Ring Gear | Works in conjunction with the pinion gear to transmit power, controlling motion within the assembly. |

| Axle Shafts | Convey torque to the wheels, allowing for movement and adjustment of wheel speed. |

| Carrier Assembly | Houses internal components, providing a framework for the system to operate effectively. |

| Bearings | Support rotational components by reducing friction, ensuring smooth and efficient operation. |

How a Front Differential Affects Vehicle Handling

Understanding how certain components in a vehicle’s drivetrain influence its behavior on the road is crucial for grasping overall control and stability. These mechanisms play a vital role in distributing power to the wheels, ensuring the car reacts predictably during various driving conditions. Without this system, smooth turns and balanced traction would be difficult to achieve, affecting the driving experience significantly.

| Key Factor | Impact on Handling |

|---|---|

| Power Distribution | Improves balance by directing force appropriately to both sides of the vehicle, helping to navigate turns more efficiently. |

| Traction Control | Enhances grip on varying surfaces, allowing for better stability on slippery or uneven roads. |

| Cornering Performance | Optimizes the vehicle’s ability to take sharp turns without losing control, making the driving experience smoother. |

The Role of Gears in Front Differentials

Gears play a crucial role in ensuring the smooth and efficient operation of the mechanical systems within vehicles. Their function revolves around managing the power generated by the engine and distributing it in a way that allows for controlled movement. By regulating speed and torque, these components are essential for stable and reliable performance, especially when navigating through turns or uneven surfaces.

Power Distribution and Gear Interaction

In any vehicle, gears work together to adjust how force is applied to the wheels. The interaction between them ensures that each wheel receives the appropriate amount of power, preventing slips and ensuring stability. This balanced force is vital for traction and maneuverability, especially in changing road conditions.

Speed Regulation and Torque Control

The gears are not just about power distribution; they also manage speed. When making turns, the wheels rotate at different speeds. This difference is handled by the gear setup, allowing one side to move faster than the other while maintaining control. Properly functioning gears ensure that this process happens seamlessly, providing a smooth driving experience

Lubrication Requirements for Front Differentials

Proper lubrication is essential for ensuring smooth operation and preventing wear in complex mechanical systems that are responsible for transmitting torque. By following specific guidelines, one can extend the life of these components and avoid costly repairs due to friction and heat buildup.

The type of lubricant used, as well as the maintenance schedule, significantly affects the overall performance. Using the right fluid ensures that gears and other moving parts are protected under different conditions, including high load and varying temperatures.

| Lubricant Type | Recommended Usage | Temperature Range | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Synthetic Oil | Heavy-duty applications, high-stress environments | -30°C to 150°C | |||||||||||||||

| Mineral Oil | Standard usage, moderate conditions | -10°C to 100°C | |||||||||||||||

| Blended Oil | Versatile applications, mixed conditions | -20°C to 120°C |

| Issue | Description | Symptoms |

|---|---|---|

| Fluid Leakage | Seals may degrade, allowing lubricant to escape. | Low fluid levels, noise, and overheating. |

| Worn Gears | Gears can wear down over time, affecting operation. | Grinding noises and reduced responsiveness. |

| Incorrect Gear Ratio | Mismatch in gear ratios can lead to improper functioning. | Vibrations and unusual handling characteristics. |

| Bearing Failure | Bearing wear can cause misalignment and noise. | Humming sounds and increased play in the mechanism. |

Maintenance Tips for Optimal Differential Performance

Regular upkeep is essential for ensuring the smooth operation of your vehicle’s drivetrain system. Proper maintenance not only enhances performance but also extends the lifespan of crucial components. Implementing a few proactive measures can significantly improve overall functionality and reduce the likelihood of issues arising over time.

Start by frequently checking the lubricant levels within the assembly. Ensuring that the fluid is at the recommended level and in good condition is vital for reducing friction and heat buildup. If you notice any discoloration or contamination, it’s advisable to replace the fluid to maintain optimal performance.

Additionally, inspect the seals and gaskets for any signs of wear or leakage. Addressing minor issues before they escalate can prevent costly repairs in the future. It’s also beneficial to schedule periodic inspections by a professional who can identify potential problems that may not be apparent during routine checks.

Furthermore, when driving, pay attention to any unusual noises or handling characteristics. Strange sounds can indicate underlying issues that require immediate attention. Early detection of problems will contribute to a safer and more efficient driving experience.

Lastly, always adhere to the manufacturer’s recommendations for maintenance intervals and procedures. Following these guidelines will help ensure that your vehicle remains reliable and performs at its best, providing peace of mind during your travels.

Impact of Front Differentials on Off-Road Driving

In off-road exploration, the components responsible for distributing power to the wheels play a crucial role in enhancing traction and stability. Their functionality is vital for navigating challenging terrains, allowing vehicles to tackle obstacles that would otherwise hinder performance. A well-designed system can significantly improve maneuverability and control, ensuring a smoother experience on rugged paths.

The efficiency of these mechanisms directly influences a vehicle’s ability to traverse uneven landscapes, climb steep inclines, and maneuver through soft surfaces like sand or mud. When engaging in off-road activities, the interplay of various elements becomes apparent, as power distribution affects each wheel’s grip on the terrain. This capability not only boosts confidence among drivers but also enhances safety by minimizing the likelihood of getting stuck or losing control.

Moreover, the integration of advanced technologies in these systems has revolutionized off-road driving, allowing for adaptive responses to changing conditions. Features such as locking mechanisms can provide additional support when facing particularly difficult obstacles, ensuring that all wheels receive adequate power for optimal traction. Overall, these components are essential for maximizing a vehicle’s potential in adventurous driving scenarios.

Signs of a Failing Front Differential

Recognizing the early indications of a malfunctioning assembly is crucial for maintaining optimal vehicle performance. When this component starts to experience issues, it can lead to a range of problems that affect handling and safety. Awareness of the signs can help in timely intervention, preventing further damage and costly repairs.

- Unusual Noises: A grinding or whining sound while driving can indicate internal wear or damage.

- Vibration: Excessive shaking or vibrations during acceleration may point to misalignment or other problems.

- Fluid Leaks: Spots of fluid under the vehicle can suggest leaks from seals or gaskets.

- Difficulty Turning: Struggling to make turns or a sensation of binding can be a sign of issues.

- Warning Lights: Activation of dashboard indicators related to the drivetrain should not be ignored.

Addressing these symptoms promptly can help ensure the longevity of the entire assembly, as well as enhance the overall safety of the vehicle.

Importance of Bearings in Differential Function

Bearings play a crucial role in the operation of complex mechanical systems, ensuring smooth movement and effective load distribution. Their design and functionality directly impact performance, reliability, and longevity. Understanding their significance helps in appreciating their role in enhancing overall efficiency.

These essential components serve various purposes, including:

- Facilitating smooth rotation of interconnected elements.

- Minimizing friction, which leads to increased efficiency and reduced wear.

- Providing structural support, allowing for optimal alignment of moving parts.

Incorporating high-quality bearings is vital for maintaining performance. When selecting bearings, consider the following factors:

- Load capacity: Ensure the chosen bearings can handle the expected loads.

- Material: Opt for materials that offer durability and resistance to environmental factors.

- Maintenance: Regular inspection and upkeep are necessary to prolong the lifespan of bearings.

In summary, the role of these components cannot be understated. Their quality and maintenance are essential for optimal function and longevity of the entire system.

Exploring the Variations in Differential Types

The mechanics of power distribution among wheels is a fundamental aspect of automotive design, influencing traction and handling. Various designs cater to specific performance needs, resulting in diverse configurations that enhance vehicle dynamics. Understanding these variations allows enthusiasts and engineers alike to make informed choices for their specific applications.

Common Types of Mechanisms

-

Open Gearset:

A standard configuration that provides basic torque distribution. While simple and effective for everyday driving, it may struggle in low-traction conditions.

-

Limited-Slip Gearset:

This variation incorporates additional components to transfer torque to the wheel with the most grip, improving stability during acceleration and cornering.

-

Locking Gearset:

Designed for off-road or performance applications, this type can engage both wheels for maximum traction when needed.

-

Electronic Control Units:

Modern vehicles often use electronic systems to dynamically adjust torque distribution, enhancing performance and safety.

Factors Influencing Selection

When choosing among these mechanisms, several factors should be considered:

- Driving Conditions: Assess the typical environments in which the vehicle will operate, such as urban, off-road, or racetrack.

- Performance Requirements: Determine the desired balance between handling and comfort to select the most suitable design.

- Vehicle Type: Different types of vehicles, from sports cars to SUVs, may require unique solutions to optimize their capabilities.

Cost Considerations for Front Differential Repairs

Repairing a vehicle’s essential components can involve significant financial implications. Understanding the various factors that influence expenses is crucial for budgeting effectively. This includes not only the price of replacement elements but also labor costs, which can vary based on the complexity of the repair and the expertise required.

One of the primary factors affecting overall expenses is the quality of replacement components. Opting for original equipment manufacturer (OEM) pieces may provide assurance of compatibility and longevity but often comes with a higher price tag. Alternatively, aftermarket options can be more economical, though they may vary in quality. It’s essential to weigh the potential long-term savings against initial costs.

Labor expenses are another critical consideration. Repair shops may charge differing rates based on their location and reputation. A detailed inspection may be required to identify underlying issues, potentially increasing labor hours and, consequently, total costs. It’s advisable to obtain quotes from multiple service providers to ensure a fair price.

Additionally, some repairs may necessitate specialized tools or equipment, which can add to the overall expenditure. It’s beneficial to ask the technician about any potential extra charges beforehand. Understanding these factors can help vehicle owners make informed decisions and manage their repair budgets more effectively.

Aftermarket Upgrades for Front Differential Systems

Enhancing the performance of your vehicle’s traction and handling can be achieved through a variety of modifications designed for specific components. Upgrading these systems not only improves efficiency but also enhances overall driving experience, making it crucial for enthusiasts and everyday drivers alike to consider various aftermarket options.

Benefits of Upgrading

One of the primary advantages of these enhancements is improved stability and control in various driving conditions. Upgraded systems often feature better materials and designs, leading to increased durability and performance. These modifications can significantly reduce wear and tear, providing longer service life and better reliability.

Popular Modifications

Among the most sought-after upgrades are gear ratios that optimize power delivery and response. Additionally, reinforced components can withstand greater stress, catering to more demanding driving styles. Furthermore, installing adjustable units allows for fine-tuning based on personal preferences, making each journey tailored to the driver’s needs.