Understanding the Frontier GM1072E Parts Diagram for Better Maintenance

When it comes to the maintenance and operation of agricultural equipment, having a clear overview of its various elements is essential. Each component plays a crucial role in ensuring the machinery functions smoothly and efficiently. By familiarizing oneself with the intricacies of these parts, operators can enhance their understanding of the overall system, leading to improved performance and longevity.

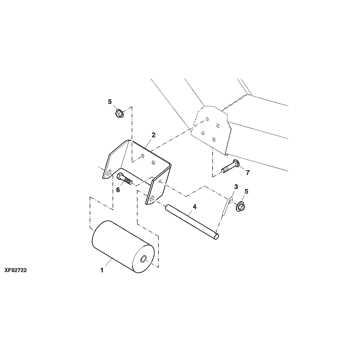

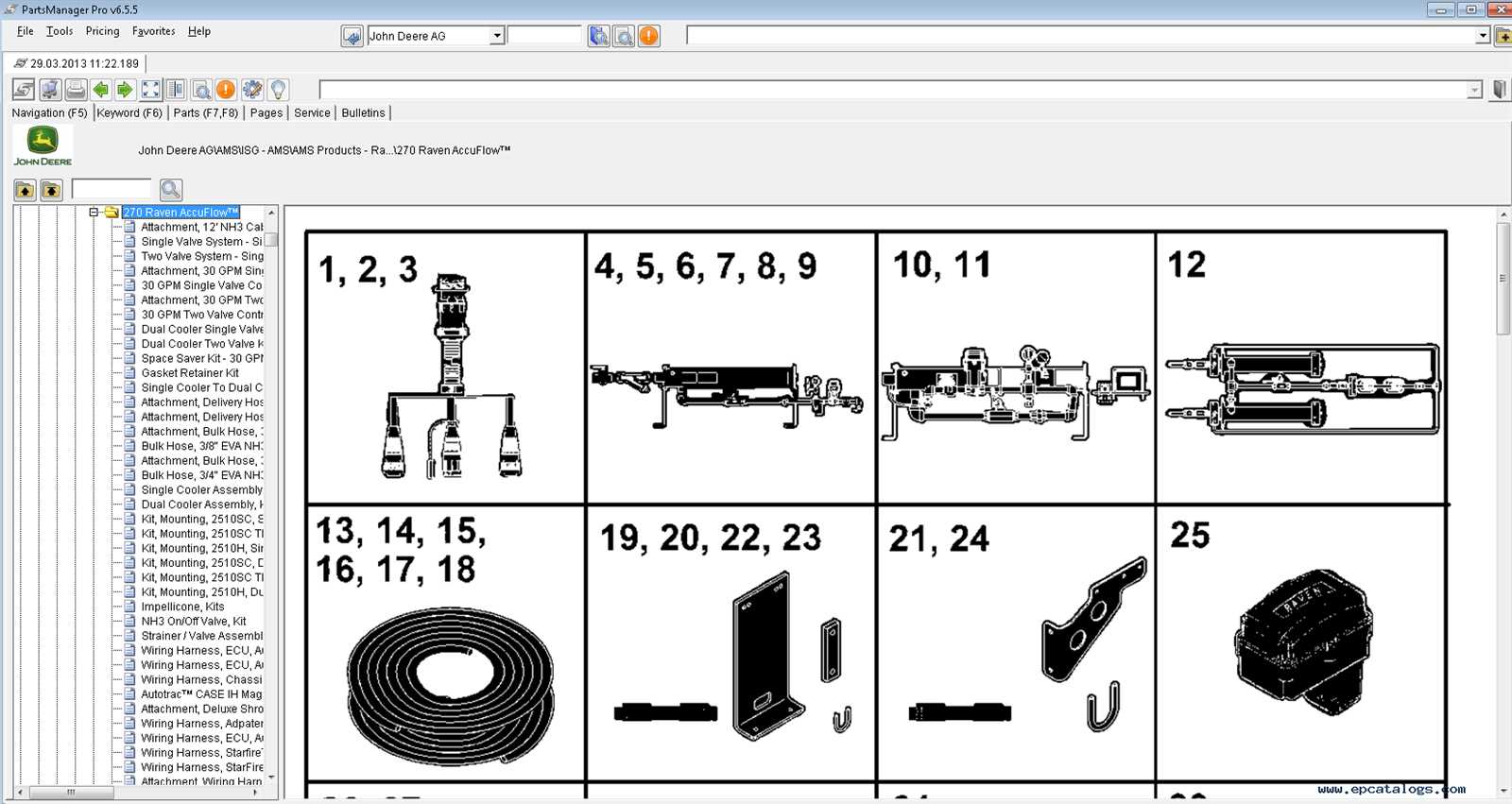

Visual aids that illustrate the arrangement and relationship between different components can be invaluable resources. They allow users to quickly identify individual parts, their functions, and how they interact with one another. This clarity not only simplifies repair and replacement processes but also aids in troubleshooting potential issues before they escalate.

Whether you’re a seasoned operator or new to the field, gaining insights into the layout of essential machine elements empowers you to take proactive steps in maintenance. Knowledge of these configurations fosters a sense of confidence and competence, ultimately benefiting both the user and the equipment.

Understanding Frontier GM1072E Components

Familiarity with the various elements that comprise this specific equipment is crucial for optimal performance and maintenance. Each component plays a vital role, contributing to the overall functionality and efficiency of the machine. By exploring these elements, users can gain insights into how they work together, ensuring seamless operation and longevity.

Key Elements Overview

The primary components can be categorized into several groups based on their functions. These include mechanical, electrical, and operational parts. Understanding the purpose of each group allows for better troubleshooting and enhancement of machine capabilities.

| Component Type | Description |

|---|---|

| Mechanical | Includes parts like gears and frames that provide structural integrity and movement. |

| Electrical | Encompasses wiring, motors, and control panels essential for powering the system. |

| Operational | Features user interface elements and safety mechanisms ensuring efficient usage. |

Importance of Regular Inspection

Consistent monitoring and maintenance of these components is vital. Regular checks can prevent malfunctions and enhance the overall performance of the machinery. Users are encouraged to familiarize themselves with the layout and functionality of each part to address issues proactively.

Key Features of the GM1072E Model

The model is designed to enhance efficiency and performance across a variety of applications. With its innovative engineering and user-friendly features, it stands out in its category, providing reliability and ease of use for operators.

Advanced Performance

This equipment boasts a powerful engine that ensures optimal performance under various conditions. The cutting-edge technology implemented allows for swift operation, reducing downtime and maximizing productivity. Users can expect a seamless experience even in demanding environments.

User-Centric Design

Designed with the operator in mind, the controls are intuitive and accessible. The ergonomic layout minimizes fatigue during prolonged use, while the compact build allows for easy maneuverability in tight spaces. Safety features are also integrated, ensuring that the user can operate the machinery with confidence.

Overall, this model represents a blend of strength and sophistication, making it an ideal choice for professionals seeking reliable machinery.

Benefits of Using OEM Parts

When it comes to maintaining and repairing machinery, opting for original components offers numerous advantages. These manufactured elements are designed to meet the exact specifications of the original equipment, ensuring optimal performance and longevity.

Key benefits include:

- Quality Assurance: OEM components undergo rigorous testing and quality control, guaranteeing reliability and superior craftsmanship.

- Perfect Fit: These components are specifically engineered for compatibility, which minimizes installation issues and enhances overall efficiency.

- Enhanced Performance: Utilizing original parts ensures that the equipment operates as intended, preserving its performance and functionality over time.

- Warranty Protection: Many manufacturers offer warranties on their original components, providing peace of mind and financial security in case of defects.

- Increased Resale Value: Equipment maintained with original components tends to have a higher resale value, appealing to potential buyers who prioritize quality.

In summary, choosing original components not only safeguards the integrity of the machinery but also contributes to long-term savings and enhanced operational efficiency.

Common Issues with Frontier Equipment

In the realm of agricultural machinery, certain challenges frequently arise that can affect performance and efficiency. Understanding these common problems is essential for maintaining optimal operation and minimizing downtime. This section outlines prevalent issues that users may encounter, along with potential solutions to address them effectively.

Mechanical Failures

Mechanical breakdowns can occur due to wear and tear or inadequate maintenance. Users often report issues such as:

| Issue | Possible Causes | Suggested Solutions |

|---|---|---|

| Poor Cutting Performance | Dull blades, misalignment | Regular sharpening and adjustment |

| Overheating | Lack of lubrication, clogged filters | Frequent oil checks and filter cleaning |

Hydraulic System Challenges

Hydraulic issues can significantly impact functionality. Common signs include:

| Issue | Possible Causes | Suggested Solutions |

|---|---|---|

| Slow Response | Low fluid levels, air in the system | Check and refill fluid, bleed the system |

| Leaks | Worn seals, loose connections | Inspect and replace damaged components |

Addressing these frequent issues proactively can enhance the lifespan and reliability of your equipment, ensuring it operates efficiently throughout its service life.

How to Interpret Parts Diagrams

Understanding technical illustrations is essential for effective maintenance and repair tasks. These visual representations serve as crucial tools that convey the arrangement and relationship of various components within a machine. By decoding these graphics, users can identify individual elements, comprehend their functions, and determine how they interact with one another.

To begin, familiarize yourself with the legend or key provided alongside the illustration. This guide will clarify symbols and notations, ensuring you accurately interpret the information presented. Pay close attention to the numbering system, as it typically correlates with a list of components, facilitating easy identification.

Next, analyze the layout of the image. Notice how the parts are organized; often, similar elements are grouped together, which can help you understand the overall structure and assembly process. Look for connecting lines or arrows, as these often indicate relationships, pathways, or movement directions between the elements.

Additionally, consider the context in which the visual representation is used. Understanding the purpose of the machine or system can provide insights into why certain components are designed as they are. This knowledge can enhance your ability to troubleshoot and make informed decisions during repairs.

Finally, practice makes perfect. The more you engage with these illustrations, the more proficient you will become at interpreting them. Over time, you will develop a keen eye for detail, enabling you to work more efficiently and effectively with any technical documentation you encounter.

Step-by-Step Maintenance Guide

Regular upkeep of your equipment is essential for optimal performance and longevity. This guide provides a systematic approach to maintaining your machinery, ensuring it operates efficiently and reduces the likelihood of unexpected breakdowns. Following these steps will help you keep everything in top shape, enhancing both productivity and safety.

Preparation

Before beginning the maintenance process, gather all necessary tools and materials. Make sure to disconnect any power sources and refer to your user manual for specific instructions. Proper preparation will help you avoid interruptions during the maintenance task.

Maintenance Steps

| Step | Action | Description |

|---|---|---|

| 1 | Inspect | Check for any visible wear or damage to components. |

| 2 | Clean | Remove dirt and debris from the machine to prevent buildup. |

| 3 | Lubricate | Apply appropriate lubricants to moving parts to ensure smooth operation. |

| 4 | Adjust | Make necessary adjustments to settings for optimal performance. |

| 5 | Test | Run the machine briefly to ensure everything functions correctly. |

By following this structured approach, you can maintain your equipment effectively, ensuring it remains reliable and efficient for years to come.

Essential Tools for Repairs

When tackling any maintenance task, having the right instruments at your disposal can make all the difference. A well-equipped toolkit not only enhances efficiency but also ensures that repairs are carried out effectively and safely. Whether you are a seasoned technician or a DIY enthusiast, understanding which tools are indispensable can streamline the repair process.

Wrenches and Sockets: A variety of wrenches, including adjustable and socket types, are crucial for loosening or tightening fasteners. These tools provide the leverage needed to tackle stubborn bolts and nuts with ease.

Screwdrivers: A set of screwdrivers, both flathead and Phillips, is essential for accessing various components. Their diverse sizes enable precise handling of different screw types found in many assemblies.

Pliers: Pliers serve multiple purposes, from gripping and twisting to cutting wires. Investing in needle-nose and slip-joint pliers can enhance your versatility during repairs.

Multimeter: This device is vital for diagnosing electrical issues. A multimeter allows for the measurement of voltage, current, and resistance, aiding in troubleshooting malfunctioning circuits.

Safety Gear: Never underestimate the importance of protective equipment. Safety glasses, gloves, and ear protection safeguard against potential hazards encountered during repair work.

Equipping yourself with these essential tools will not only prepare you for a variety of tasks but also increase your confidence in performing repairs effectively. A well-maintained toolkit can lead to more successful outcomes and prolong the life of the equipment you work on.

Where to Find Replacement Parts

Finding suitable components for your equipment can be a straightforward process if you know where to look. Numerous sources offer reliable options for obtaining necessary items, ensuring your machinery runs smoothly.

- Authorized Dealers: Always check with authorized dealers who specialize in your equipment’s brand. They often provide genuine components that guarantee compatibility and reliability.

- Online Retailers: Websites such as Amazon, eBay, and specialized machinery retailers frequently stock a wide range of items. Ensure you read reviews and verify the seller’s reputation before making a purchase.

- Local Hardware Stores: Some local stores may carry universal components or can order specific items for you. Establish a relationship with store personnel for personalized assistance.

- Manufacturer’s Website: Visit the official website of the equipment’s manufacturer. They often have a dedicated section for ordering replacement items directly.

- Second-Hand Market: Platforms like Craigslist or Facebook Marketplace can yield good finds. However, ensure that the quality and condition of used items meet your needs.

By exploring these avenues, you can efficiently locate the necessary components to keep your machinery in optimal condition.

Safety Precautions During Repairs

When undertaking maintenance tasks, it is essential to prioritize safety to prevent accidents and injuries. Understanding the potential hazards associated with the equipment and adhering to established guidelines can significantly reduce risks. Proper preparation and awareness are key components in ensuring a secure working environment.

Always wear appropriate personal protective equipment. This includes gloves, goggles, and sturdy footwear to safeguard against sharp edges and potential debris. Additionally, ensure your workspace is well-ventilated to avoid inhaling harmful fumes or dust particles.

Before starting any repair, disconnect power sources to eliminate the risk of electrical shock. Familiarize yourself with the equipment’s manual to identify safe procedures and recommended tools. Keeping your workspace organized will also help prevent accidents caused by clutter.

Finally, never hesitate to seek assistance if you are unsure about any aspect of the repair process. Collaborating with a knowledgeable colleague can provide valuable insights and enhance overall safety. Adhering to these guidelines will contribute to a successful and secure repair experience.

Frequently Asked Questions about GM1072E

This section addresses common inquiries regarding the machinery in question. Understanding the functionality, maintenance, and troubleshooting can greatly enhance your experience and ensure optimal performance.

- What are the key features of this equipment?

The model boasts various capabilities, including advanced technology, user-friendly controls, and efficient performance metrics.

- How can I maintain my machine effectively?

Regular maintenance is crucial. Follow these steps:

- Perform routine inspections to identify wear and tear.

- Keep all components clean and free from debris.

- Ensure that lubrication is applied as recommended.

- Replace worn parts promptly to avoid further damage.

- What should I do if I encounter a malfunction?

In case of an issue, consider the following troubleshooting tips:

- Refer to the user manual for guidance on common problems.

- Check for loose connections or blocked components.

- Restart the unit to see if the issue resolves itself.

- If problems persist, consult a professional technician.

- Where can I find replacement components?

Replacement parts are available through authorized distributors and online platforms specializing in machinery supplies. Always ensure compatibility with your specific model.

- Is there a warranty on the product?

Yes, warranty details can vary. It is advisable to review the warranty information provided at the time of purchase for specific coverage terms.

Tips for Troubleshooting Equipment Problems

Identifying and resolving issues with machinery can often be a daunting task. However, a systematic approach can make the process more manageable. By following specific steps and utilizing effective strategies, operators can efficiently diagnose problems, ensuring minimal downtime and optimal performance.

Step-by-Step Diagnosis

Start by observing the equipment’s behavior. Take note of any unusual sounds, vibrations, or performance discrepancies. Next, consult the user manual to familiarize yourself with common issues and their solutions. If necessary, isolate the equipment to eliminate external factors that might be influencing its operation. Performing regular maintenance checks can also help in preemptively identifying potential failures.

Utilizing Resources and Tools

Leverage available resources such as online forums, manufacturer websites, and troubleshooting guides. Having the right tools on hand, such as multimeters or diagnostic software, can greatly assist in pinpointing the source of a problem. Additionally, maintaining a log of previous issues and resolutions can provide valuable insights for future troubleshooting efforts.

Comparing GM1072E with Similar Models

This section explores the characteristics and functionalities of a specific model in relation to its peers within the same category. By examining these similarities and differences, we can gain insights into performance, efficiency, and usability.

When evaluating comparable models, several factors come into play:

- Design and Build Quality: Assessing the materials used and the overall durability.

- Performance Specifications: Comparing engine power, cutting width, and operational speed.

- Ease of Use: Looking at user-friendliness, including controls and maintenance requirements.

- Cost Efficiency: Analyzing initial purchase price versus long-term operational costs.

- Technology Integration: Reviewing the inclusion of advanced features like GPS or automated systems.

In summary, evaluating models against each other allows potential users to make informed decisions based on their specific needs and preferences. Understanding these differences can significantly impact the choice of equipment suitable for various tasks.

Understanding Warranty and Support Options

When investing in equipment, it is crucial to be aware of the various assurance and assistance programs available. These offerings not only provide peace of mind but also help ensure that your investment remains operational over time. Familiarizing yourself with these options can significantly enhance your experience and support your operational needs.

Warranty agreements typically cover repairs and replacements for a specified period, protecting users from unexpected costs. Support services often include technical assistance, troubleshooting, and maintenance guidance, ensuring optimal performance. Below is a table outlining common types of warranty and support options available:

| Type | Description | Duration |

|---|---|---|

| Standard Warranty | Covers defects in materials and workmanship. | 1-2 years |

| Extended Warranty | Additional coverage beyond the standard period. | 3-5 years |

| Technical Support | Access to help with installation, usage, and troubleshooting. | Varies; often included for the warranty period |

| Maintenance Services | Regular check-ups and preventative care. | Annual or bi-annual |

Choosing the right combination of warranty and support services can greatly affect the longevity and reliability of your equipment. Always review the terms and conditions to fully understand what is included and how to access these valuable resources.