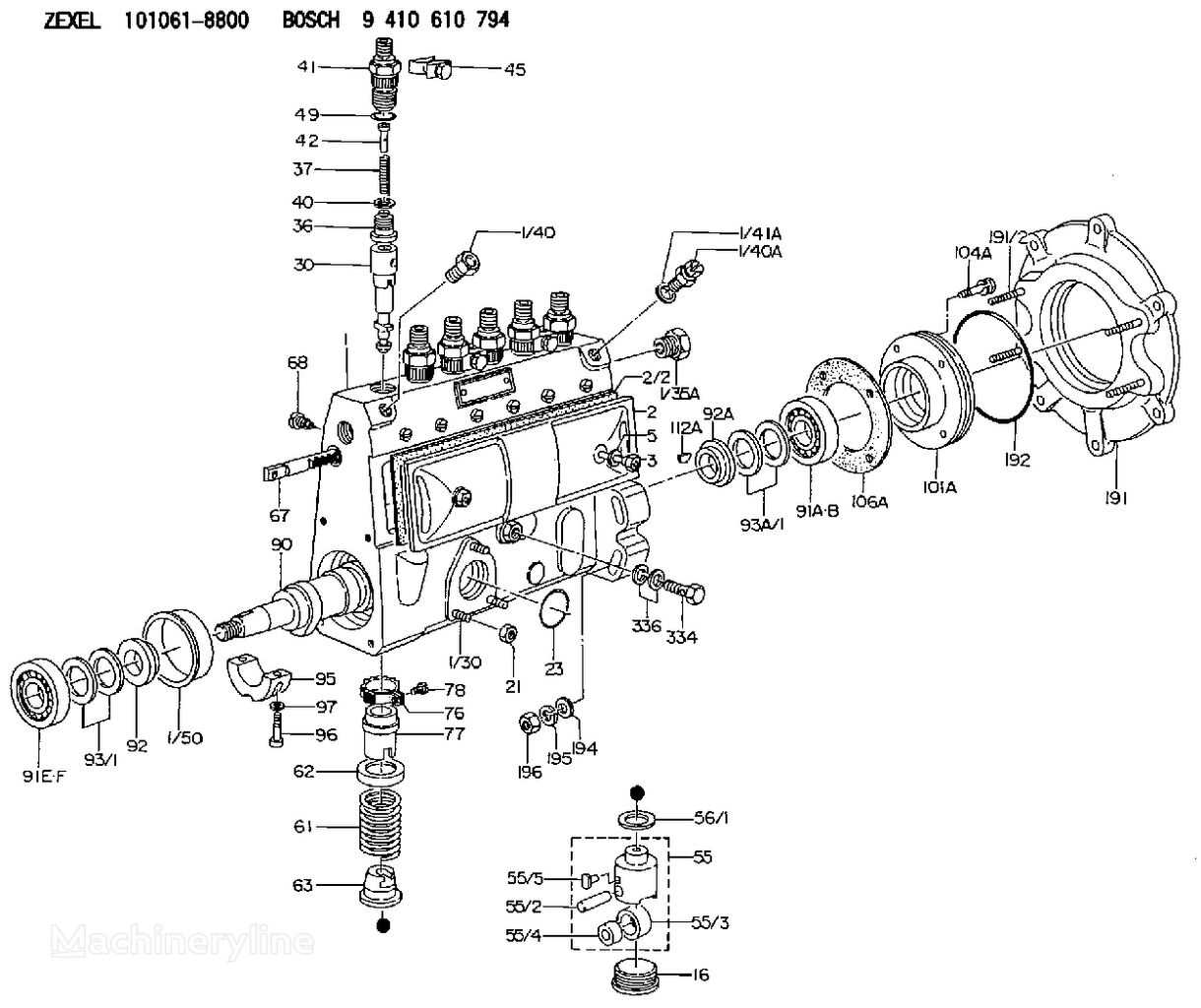

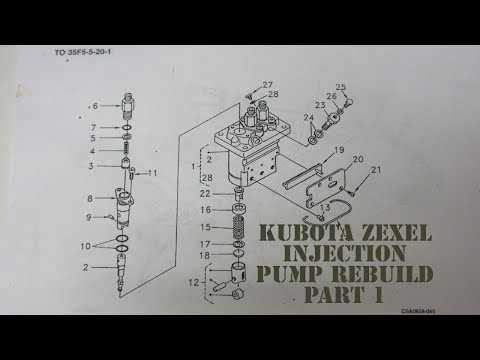

Zexel Fuel Injection Pump Parts Diagram Explained

The efficiency and performance of an engine heavily rely on the intricate assembly of various components that work in harmony. A detailed exploration of these elements reveals not only their individual functions but also how they interact to enhance overall functionality. This section aims to provide insights into the essential components that contribute to optimal engine operation.

By examining the structure and arrangement of these critical elements, we can better appreciate their roles in maintaining engine health. Each component serves a specific purpose, and understanding their relationship is vital for troubleshooting and maintenance. With this knowledge, users can ensure their machinery operates smoothly and efficiently.

Furthermore, a comprehensive breakdown of these elements aids in identifying potential issues and facilitates informed decision-making regarding repairs or upgrades. As we delve into the intricacies of this system, we will uncover valuable information that can assist both professionals and enthusiasts in their endeavors.

Zexel Fuel Injection Pump Overview

This section provides an overview of a vital component in internal combustion engines, highlighting its significance in ensuring optimal performance. It is designed to facilitate precise delivery of a vital resource to the combustion chamber, enhancing efficiency and power output.

Key Features

Among the notable characteristics of this component are its reliability, efficiency, and adaptability to various engine configurations. Understanding these features can aid in proper maintenance and troubleshooting.

Functional Mechanism

The mechanism operates by precisely regulating the flow of the essential resource, ensuring that the engine receives the correct amount for combustion. This controlled delivery is crucial for maintaining performance and minimizing emissions.

| Feature | Description |

|---|---|

| Reliability | Ensures consistent performance under various conditions. |

| Efficiency | Optimizes resource consumption, improving overall output. |

| Adaptability | Compatible with multiple engine designs for versatile use. |

Understanding Fuel Injection Pumps

Effective performance in modern engines relies on a critical component that precisely delivers a mixture of air and liquid to the combustion chamber. This mechanism plays a vital role in ensuring optimal efficiency, reducing emissions, and enhancing overall engine power. Grasping the fundamentals of this essential device can significantly impact maintenance practices and performance optimization.

The Mechanics Behind It

At its core, this device operates by utilizing a series of intricate mechanisms that control the volume and timing of the mixture. Various elements work together to ensure that the right amount reaches the engine at the right moment, enabling efficient combustion. Understanding these mechanics is crucial for anyone involved in engine maintenance or performance tuning.

Importance of Components

Each element within this assembly has a specific function, contributing to the overall efficacy of the system. For instance, precise timing and volume control are vital for achieving the desired performance levels. Recognizing how these components interact allows for better troubleshooting and enhancements, leading to improved engine operation.

Maintenance Considerations

Regular upkeep is essential to ensure long-lasting performance. Awareness of wear and tear on critical components can prevent potential issues before they escalate. By implementing routine checks and replacements, one can enhance reliability and maintain the efficiency of the entire system.

Conclusion

Understanding this vital mechanism equips individuals with the knowledge necessary to optimize engine performance and efficiency. A deeper insight into its workings fosters better maintenance practices and enhances overall vehicle operation.

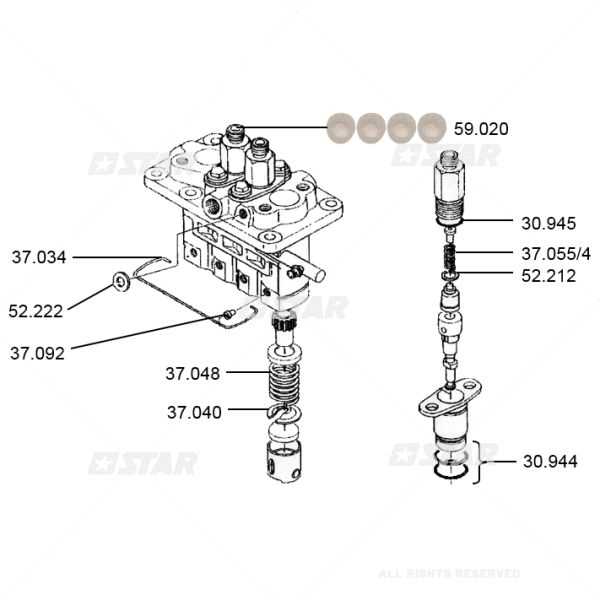

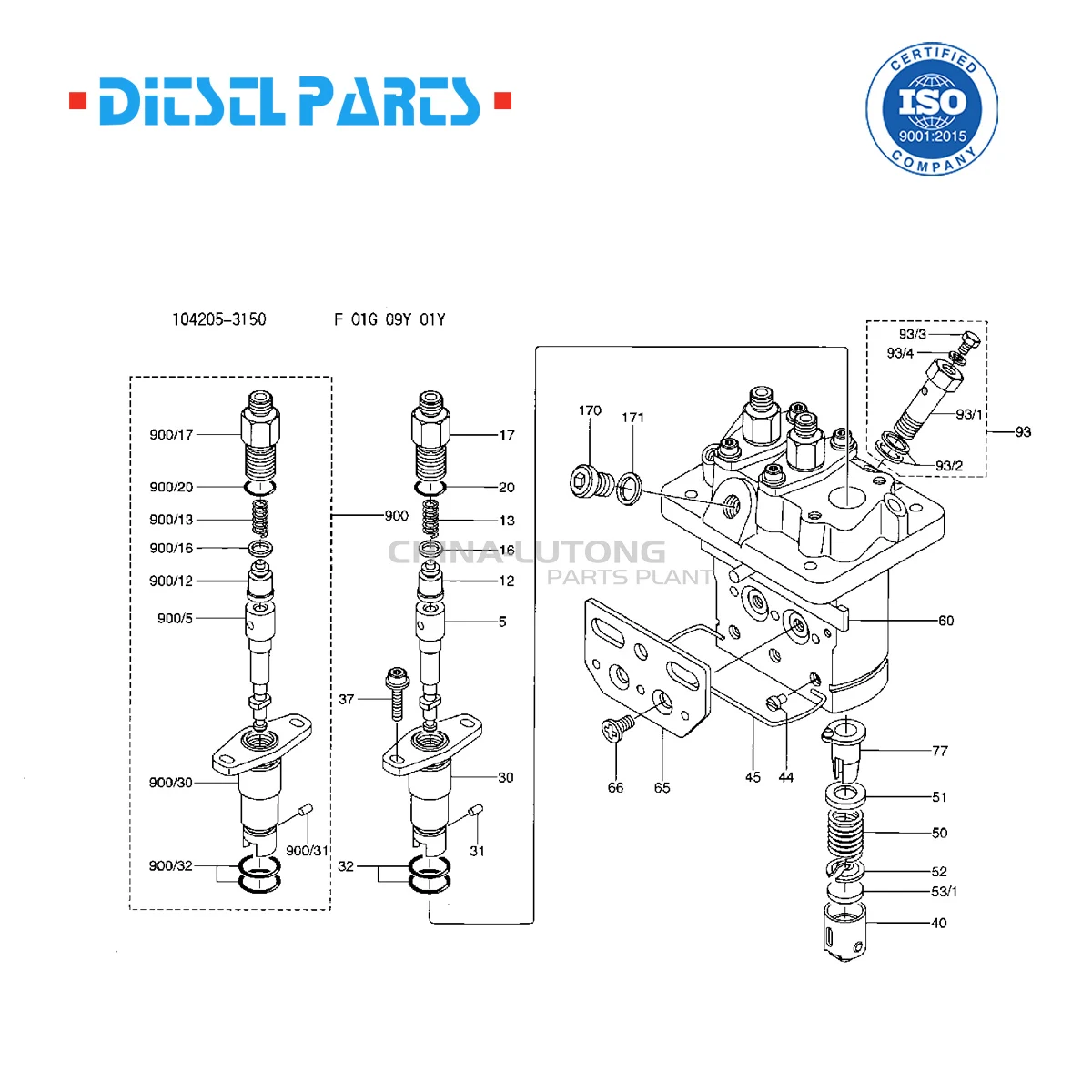

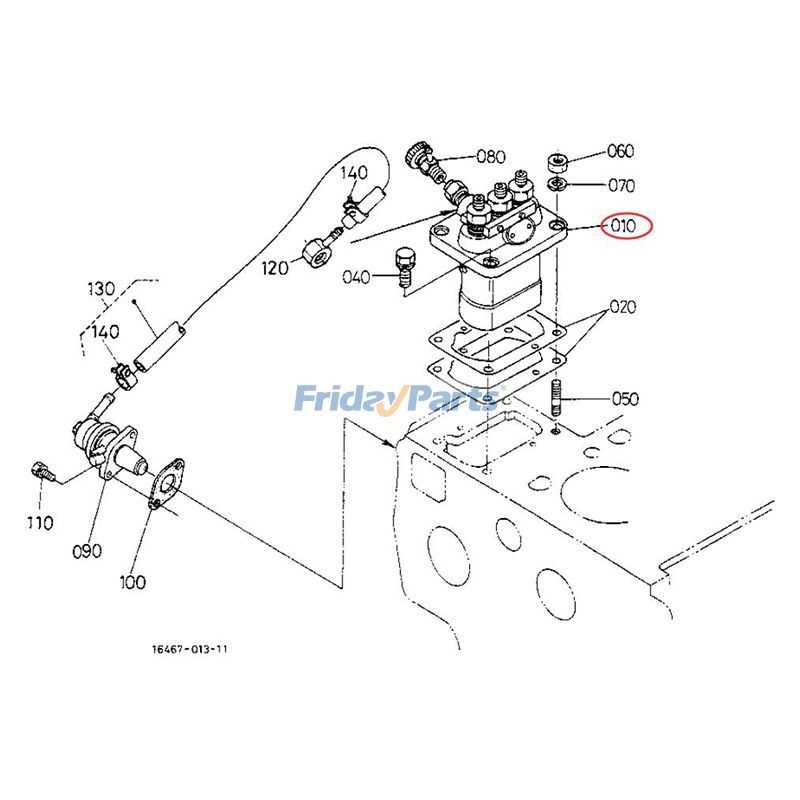

Key Components of Zexel Pumps

Understanding the essential elements of these mechanical systems is crucial for optimal performance and reliability. Each component plays a significant role in ensuring the unit operates efficiently, contributing to the overall functionality and durability.

Main Functional Elements

The principal components consist of various intricate parts that work together harmoniously. Key elements include the drive mechanism, control unit, and delivery system, all of which are vital for maintaining precise operation.

Component Overview

| Component | Function |

|---|---|

| Drive Mechanism | Transforms rotational motion into fluid movement. |

| Control Unit | Regulates the flow and timing of the fluid. |

| Delivery System | Distributes the fluid to the necessary locations. |

| Seals and Gaskets | Prevent leaks and maintain pressure. |

Importance of Accurate Diagrams

Precise illustrations serve as vital tools in the realm of mechanical systems, offering a visual representation that enhances understanding and facilitates maintenance. The clarity of these visual aids can significantly influence both efficiency and effectiveness in repairs and diagnostics.

Benefits of Detailed Visual Representations

- Enhanced Understanding: Clear visuals allow technicians to grasp complex structures quickly.

- Efficient Troubleshooting: Accurate representations help in pinpointing issues without unnecessary trial and error.

- Standardization: Consistent diagrams ensure all team members are on the same page, reducing miscommunication.

- Training Resource: New personnel can learn faster through visual aids that depict operational layouts and mechanisms.

Consequences of Inaccurate Illustrations

- Increased Downtime: Errors in visual aids can lead to prolonged repair times and operational delays.

- Safety Risks: Misleading information may result in improper handling, leading to potential hazards.

- Higher Costs: Mistakes stemming from inaccurate visuals can incur additional expenses in labor and parts.

Overall, the importance of precision in visual documentation cannot be overstated, as it directly impacts the success of maintenance and repair operations.

Common Issues with Zexel Parts

Components in precision machinery can often encounter various challenges that affect performance and longevity. Understanding these issues is essential for maintaining optimal functionality and preventing costly repairs.

Wear and Tear: Over time, regular usage can lead to degradation of materials, resulting in reduced efficiency and potential failure. Identifying signs of wear early can help in proactive maintenance.

Contamination: External substances, such as dirt or moisture, can infiltrate systems and disrupt operations. Keeping components clean is crucial to avoid complications.

Improper Installation: Incorrect assembly or misalignment can lead to malfunctions and may even damage neighboring components. Adhering to proper guidelines during installation is vital.

Compatibility Issues: Using components that are not suited for specific applications can result in significant performance challenges. Always ensure parts are compatible with the intended system.

How to Interpret Diagrams

Understanding illustrations that represent mechanical components is essential for effective maintenance and troubleshooting. These visual aids provide crucial insights into the structure and function of various elements, helping users grasp complex relationships at a glance.

Key Elements to Observe

Start by identifying the main features depicted. Look for labels that indicate specific components, as well as arrows or lines that illustrate connections or flow. This will guide your interpretation of how the system operates.

Utilizing a Legend

Many illustrations include a legend or key that explains symbols and terminology used. Familiarizing yourself with this information can enhance your understanding, allowing for a more comprehensive grasp of the entire assembly.

Maintenance Tips for Zexel Pumps

Ensuring longevity and optimal performance of your equipment requires a proactive approach to upkeep. Regular attention can prevent wear and tear, leading to fewer malfunctions and enhanced efficiency over time.

Regular Inspection

Conduct thorough checks at scheduled intervals. Look for signs of leakage, wear, or unusual noises. Early detection of issues can save time and costs associated with repairs.

Proper Lubrication

Maintain appropriate lubrication levels to reduce friction and overheating. Use the manufacturer-recommended lubricants, as they are formulated to provide the ultimate protection for moving components.

Emphasizing preventive care will ultimately enhance the reliability and lifespan of your equipment, ensuring smooth operation when you need it most.

Replacement Parts for Optimal Performance

Ensuring the efficiency of your engine system relies heavily on the quality and compatibility of its components. When it comes to maintaining peak functionality, selecting high-grade substitutes is essential. These alternatives not only enhance performance but also prolong the lifespan of the entire assembly, minimizing the need for frequent repairs.

Importance of Quality Components

Utilizing top-notch replacements significantly impacts overall efficiency. Poorly manufactured or incompatible elements can lead to malfunctions, reduced power output, and increased wear. Investing in reliable components ensures that each part operates harmoniously, providing a seamless experience and optimal results.

Choosing the Right Substitutes

When selecting replacements, consider factors such as durability, compatibility, and performance characteristics. Look for options that meet or exceed original specifications. Researching reputable suppliers and consulting with professionals can guide you toward the best choices for your specific requirements. Prioritizing quality in your selections will ultimately lead to improved operation and satisfaction.

Comparing Zexel with Other Brands

When assessing various manufacturers in the automotive component sector, understanding the strengths and weaknesses of each can significantly influence purchasing decisions. This evaluation highlights critical differences in performance, reliability, and cost-effectiveness.

Performance and Efficiency

Many brands offer unique engineering solutions that enhance overall performance. However, certain manufacturers excel in delivering consistent efficiency, resulting in improved vehicle operation under varying conditions. Brand A, for instance, is often recognized for its superior responsiveness, while Brand B tends to prioritize longevity in its designs.

Cost vs. Quality

Balancing affordability with quality is a challenge faced by consumers. Some brands may provide lower initial costs but compromise on durability, leading to higher long-term expenses. Conversely, premium options may come with a hefty price tag, justified by exceptional craftsmanship and support. Understanding these trade-offs is essential for making an informed choice.

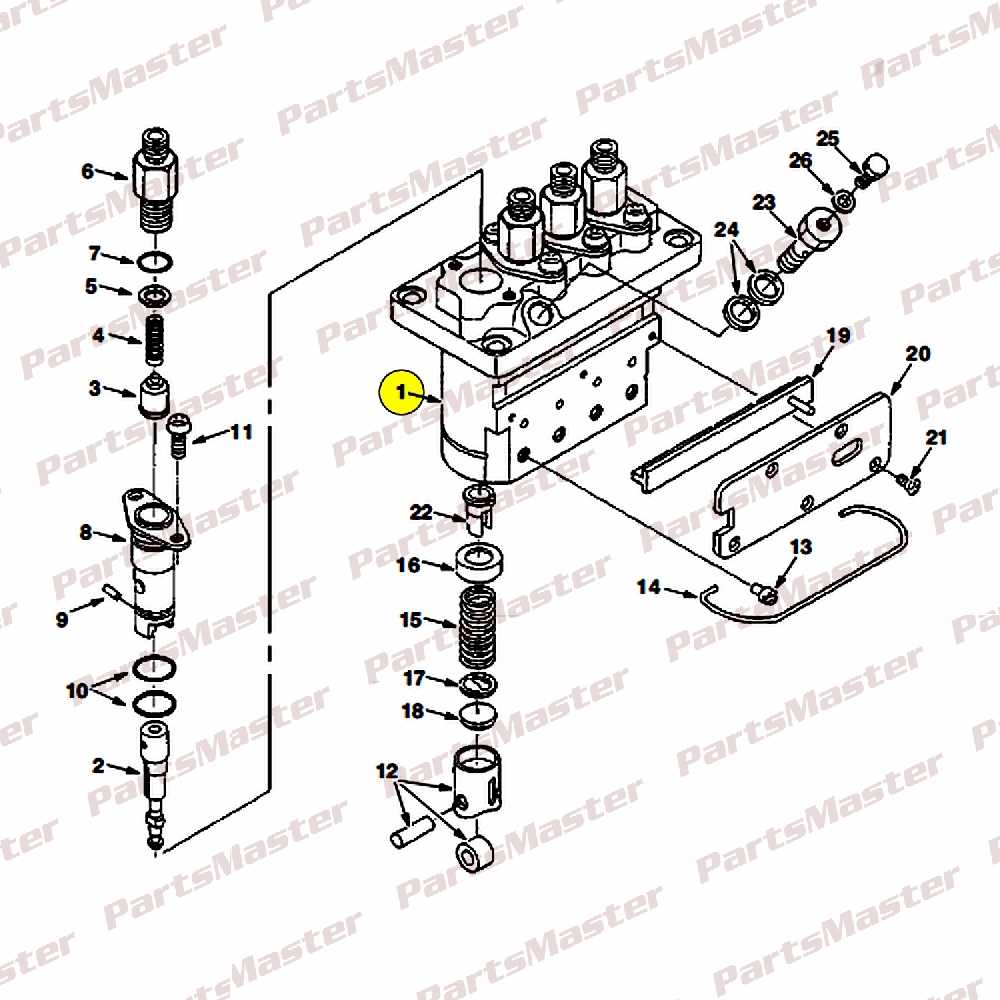

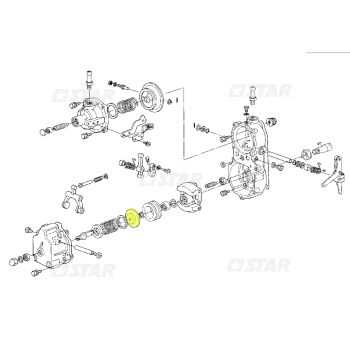

Assembly Process of Fuel Injection Pumps

The assembly of precision delivery mechanisms involves a meticulous sequence of steps to ensure optimal performance and reliability. Each component must be carefully integrated to function harmoniously within the system. This process not only requires technical expertise but also a thorough understanding of the various elements and their interactions.

The initial stage includes the preparation of all necessary components, ensuring that each piece meets stringent quality standards. Cleaning and inspecting parts for any defects are crucial to prevent future malfunctions. Following this, the assembly begins with the foundation elements, establishing a sturdy base for subsequent components.

Assembling the internal mechanisms is a critical phase. This involves aligning and fitting intricate elements that control the flow and pressure of the delivered substance. Precision is paramount, as even minor misalignments can lead to significant performance issues.

Once the internal structure is in place, external casings are added to protect the internal components and provide structural integrity. Sealing elements are applied to prevent leakage, ensuring that the assembly operates efficiently under varying conditions.

The final steps include rigorous testing and calibration. Each assembled unit undergoes thorough evaluation to verify functionality and adherence to specifications. This ensures that the mechanism will perform reliably in real-world applications.

Finding Reliable Zexel Parts Suppliers

When searching for dependable suppliers of components, it is essential to consider several key factors that ensure quality and reliability. The right vendor not only provides authentic items but also supports your needs with expertise and service. A thorough understanding of the marketplace and diligent research can lead to successful partnerships.

Start by researching online reviews and testimonials. Feedback from other customers can provide valuable insights into the reliability of a supplier. Look for platforms that aggregate ratings and experiences, as these can help you gauge the reputation of potential vendors.

Additionally, seek recommendations from industry peers or professionals. Networking within your field can unveil hidden gems that may not be easily found through standard searches. Personal endorsements often lead to trustworthy connections.

Verify the authenticity of the components offered. Reputable suppliers typically provide documentation or certifications that attest to the quality and compliance of their items. Ensure that the vendor follows industry standards and regulations to avoid counterfeit products.

Consider the availability of customer support. A reliable supplier should be accessible and willing to assist with inquiries or issues. Excellent customer service reflects a commitment to building long-term relationships with clients.

Ultimately, taking the time to investigate potential sources will pay off in the form of superior products and reliable service. Establishing a strong relationship with a trustworthy supplier can significantly enhance your operational efficiency.