Understanding Generac Parts Diagram for Optimal Maintenance

When maintaining complex machinery, comprehending its components and their relationships is essential. A clear representation of these elements can significantly enhance troubleshooting and repair processes. This knowledge empowers users to efficiently manage their systems, ensuring optimal performance and longevity.

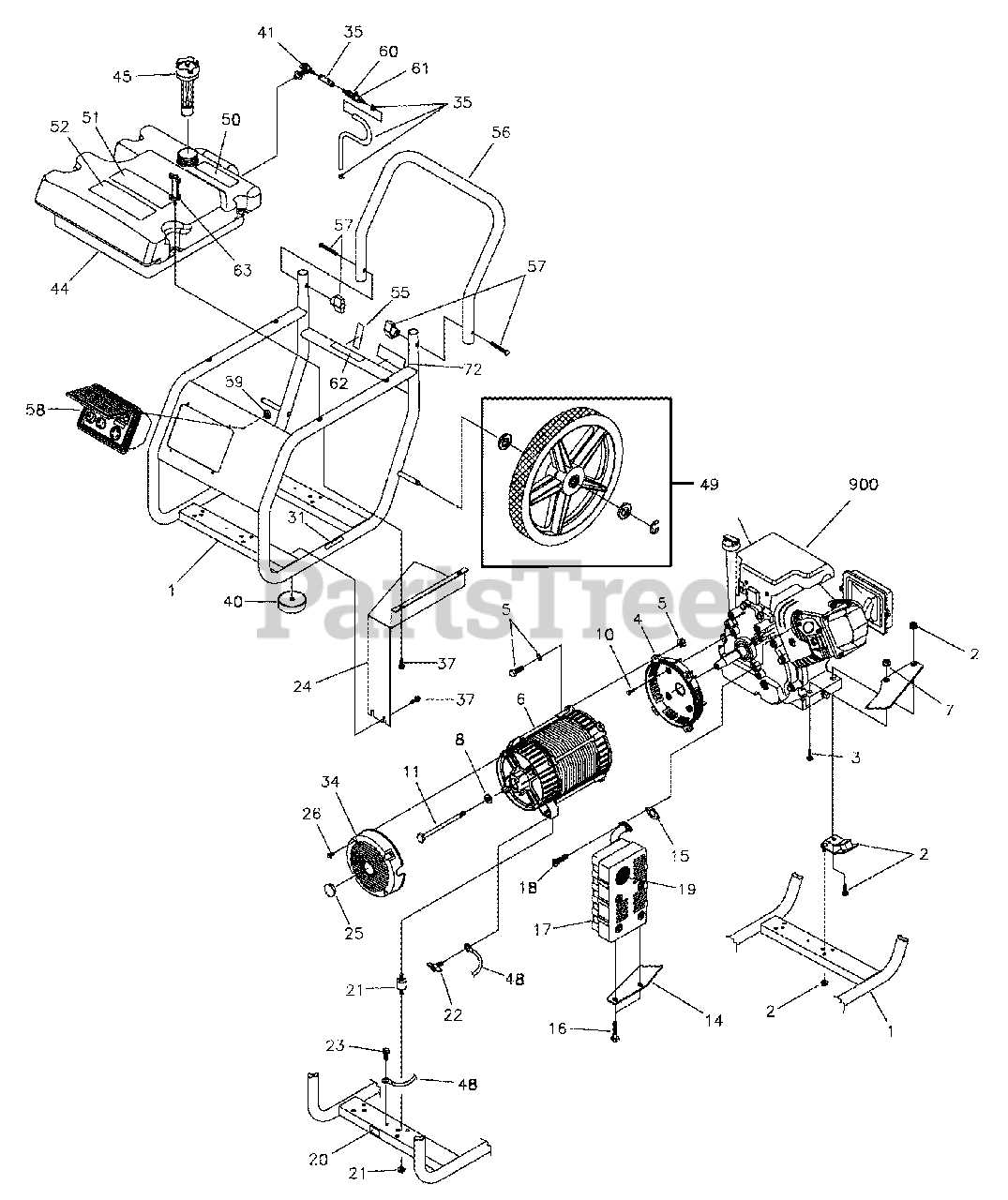

In the pursuit of mastery over your equipment, visual aids play a crucial role. These illustrations serve as guides, allowing you to identify each segment and its function seamlessly. By delving into these resources, you can uncover the ultimate insights needed for effective maintenance.

Whether you are a novice or a seasoned technician, having access to detailed visuals can transform your approach to repairs. Recognizing how each piece fits into the larger picture not only simplifies the task at hand but also fosters confidence in your abilities.

Understanding Generac Parts Diagrams

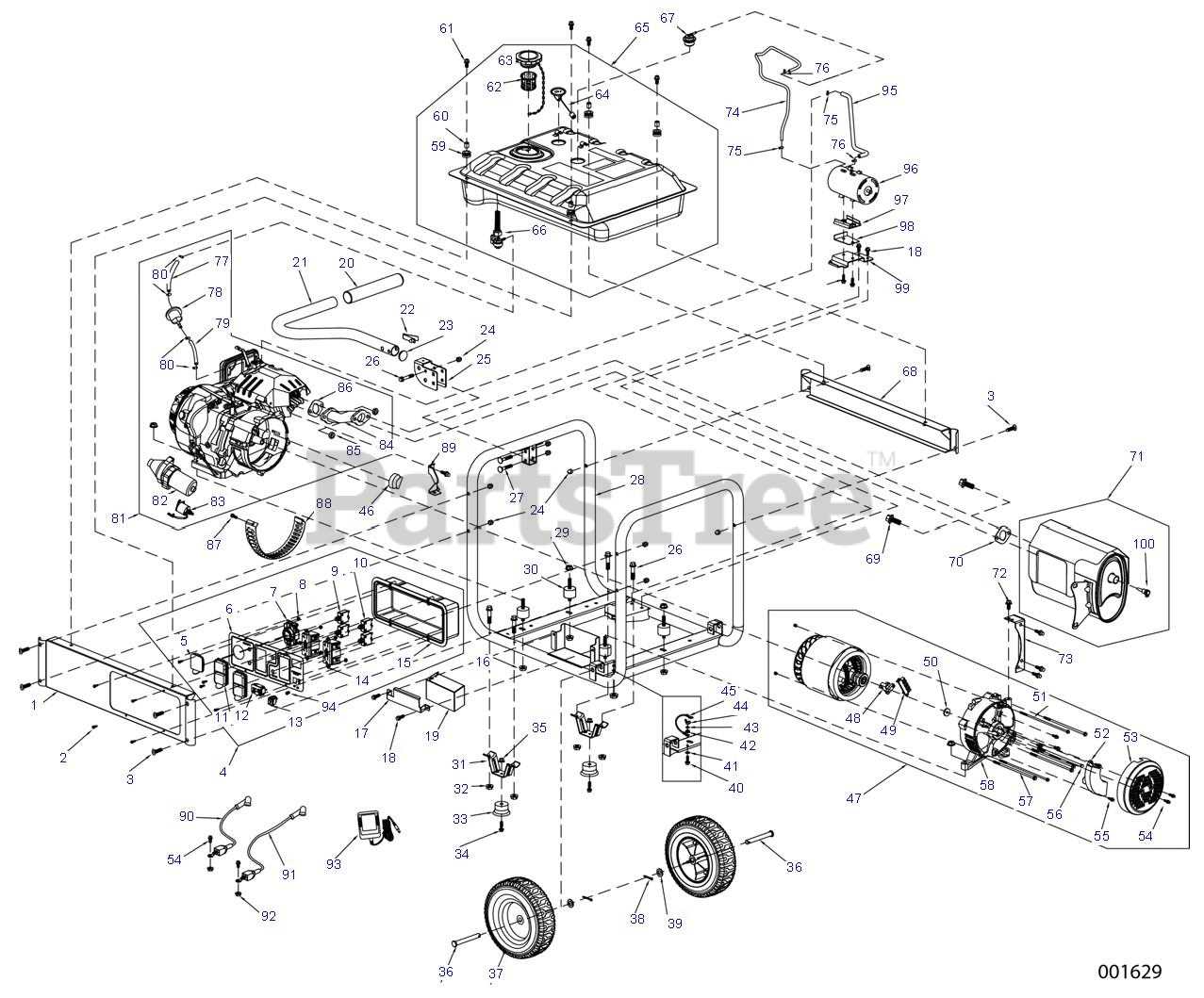

Interpreting technical illustrations is essential for maintaining and repairing machinery. These visual representations provide a clear overview of various components, their arrangement, and functionality. By grasping these schematics, users can enhance their understanding of the equipment, ensuring efficient operation and timely servicing.

Key Elements of Technical Illustrations

Familiarity with certain elements can significantly improve comprehension:

- Labels: Indicate specific components and their functions.

- Numbers: Often used to reference parts in accompanying manuals.

- Lines: Show connections and relationships between different sections.

- Symbols: Represent various functions or warnings relevant to operation.

Benefits of Using These Illustrations

Utilizing these schematics offers numerous advantages:

- Improved troubleshooting: Identifying issues becomes more straightforward.

- Efficient repairs: Understanding layout speeds up the repair process.

- Better maintenance: Regular upkeep is facilitated by clear visual guides.

- Informed upgrades: Users can assess compatibility of new components easily.

Overall, mastering the intricacies of these visuals empowers users to engage with their equipment confidently and competently.

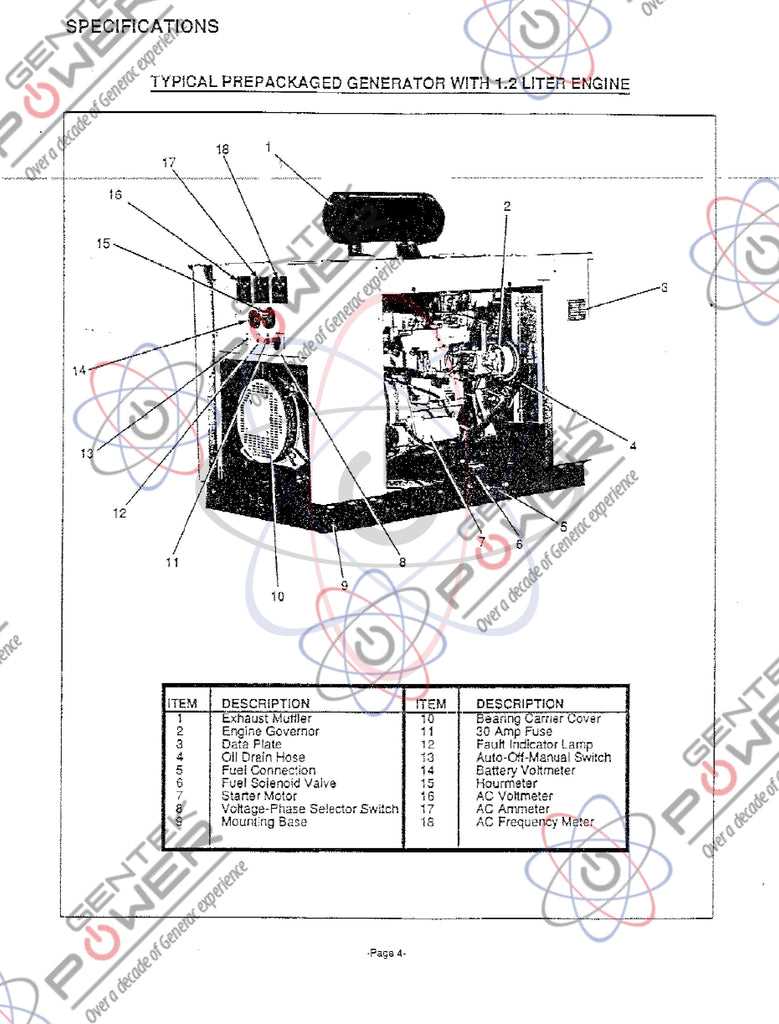

Components of Generac Generators

The functionality of a power generation unit relies on various essential elements, each playing a crucial role in ensuring reliable performance. Understanding these components helps users appreciate the intricacies involved in maintaining and operating such machines effectively.

Power Generation Mechanism

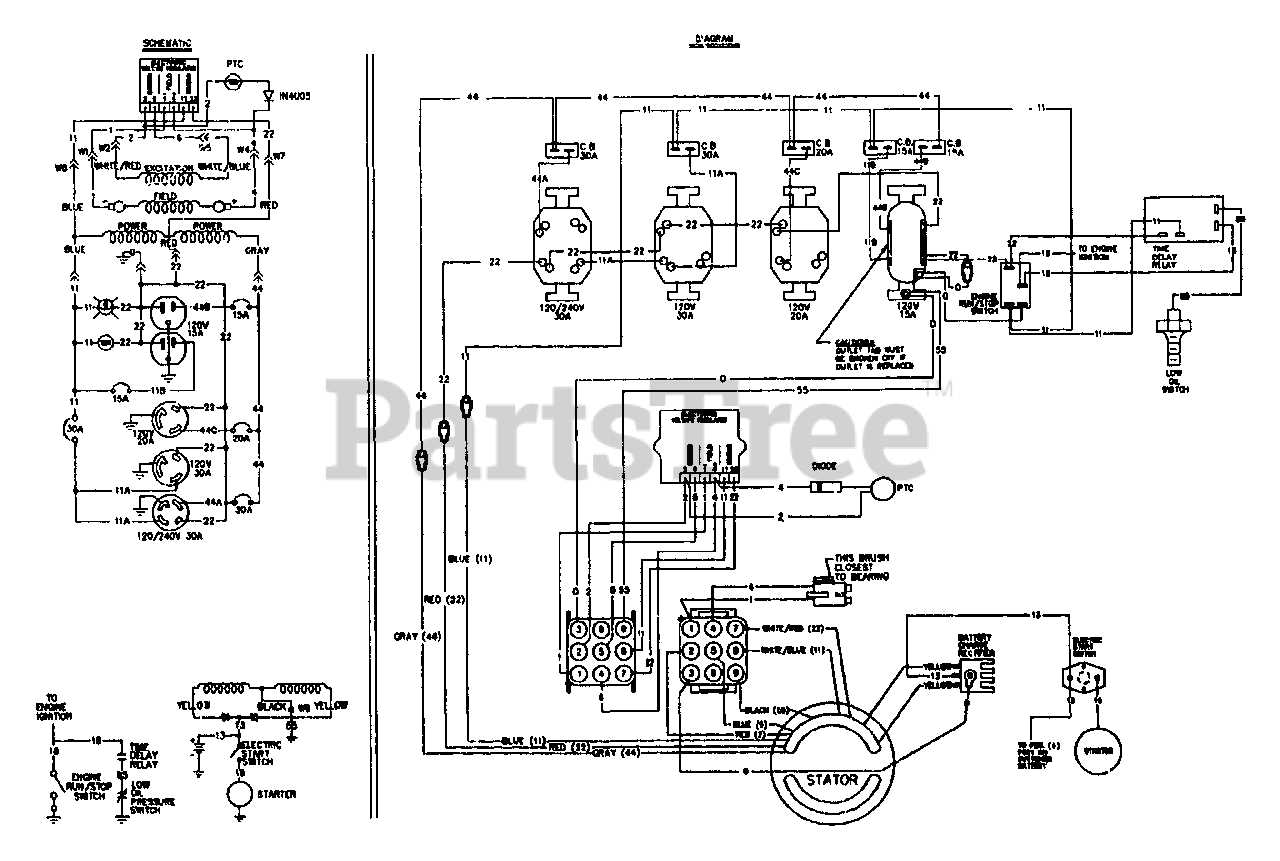

At the heart of every generator lies the engine, responsible for converting fuel into mechanical energy. This mechanical energy is then transformed into electrical energy through a series of interconnected systems. The alternator, an integral part of this process, facilitates the conversion of rotational energy into electrical output, ensuring a stable power supply.

Control Systems and Safety Features

Advanced control panels serve as the command center for operation, allowing users to monitor performance metrics and make adjustments as necessary. Additionally, safety mechanisms are critical in preventing malfunctions and ensuring user safety, including overload protection and automatic shutoff features that activate during irregular conditions.

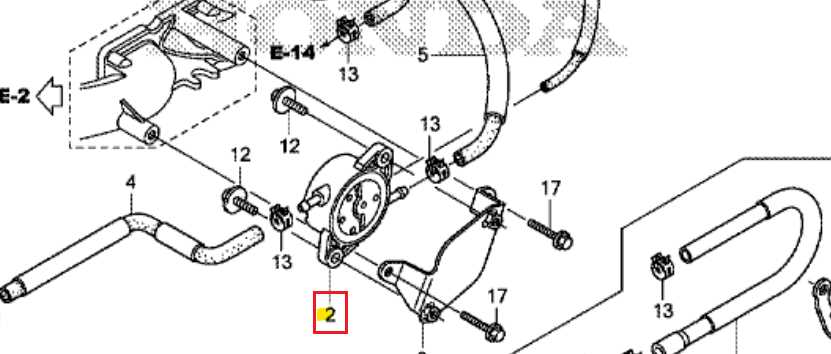

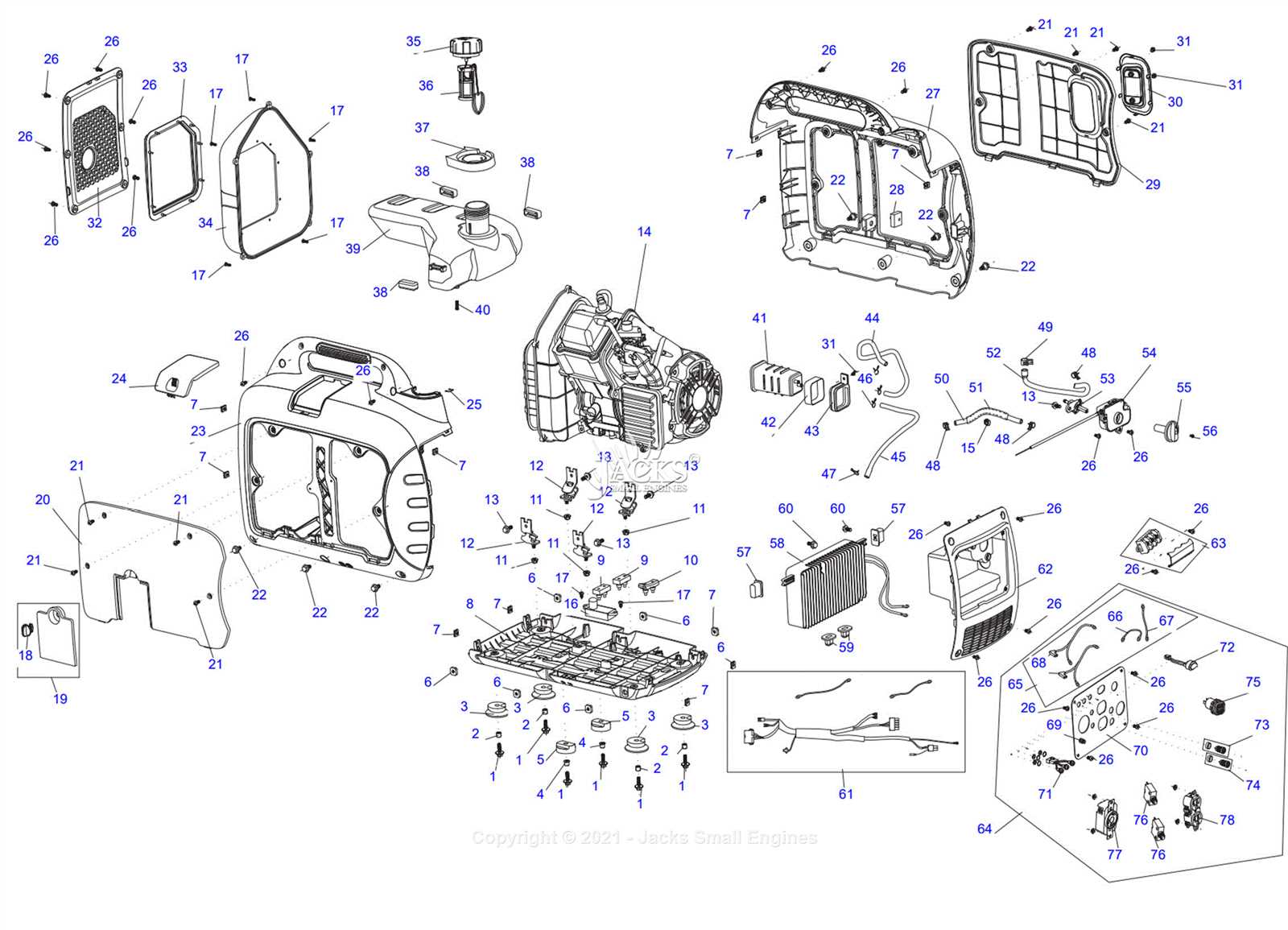

How to Read Parts Diagrams

Understanding visual representations of components can greatly enhance your ability to identify and replace items effectively. These illustrations serve as a guide to help you navigate through various elements, ensuring you grasp their arrangement and function within a system.

Familiarize Yourself with Symbols

Each visual guide typically includes unique symbols and notations. Knowing these can simplify the process:

- Study the legend for explanations of each symbol.

- Note any color coding that indicates different types of materials.

- Recognize common shapes that denote specific components.

Identify Key Sections

Most illustrations are organized into sections that group related items. Pay attention to:

- Sections labeled with numbers or letters for easy reference.

- Connections that illustrate how elements interact.

- Notes or arrows that indicate assembly order or orientation.

Common Issues with Generator Parts

Generators, while essential for providing backup power, can encounter various complications related to their components. Understanding these common issues can help users maintain their equipment effectively and avoid unexpected failures. Regular inspections and knowledge of potential problems are key to ensuring optimal performance.

Frequent Complications

Several common complications can arise from the various components of a generator. These issues often lead to decreased efficiency or even complete operational failure. Here are some of the most frequently encountered problems:

| Component | Common Issue | Symptoms |

|---|---|---|

| Battery | Corrosion or Weakness | Difficulty starting, dim lights |

| Fuel System | Clogs or Contamination | Engine sputtering, loss of power |

| Cooling System | Overheating | Unusual noises, smoke |

| Electrical Connections | Loose or Damaged Wires | Intermittent operation, flickering power |

Preventive Measures

To minimize the likelihood of encountering these complications, regular maintenance and monitoring are essential. Cleaning, timely replacements, and proper storage practices can significantly extend the lifespan of a generator’s components. Additionally, keeping detailed records of any repairs or changes can help track the health of the equipment over time.

Finding Replacement Parts Easily

Locating suitable components for maintenance or repair can often feel overwhelming. However, with the right strategies, the process can become straightforward and efficient, ensuring your equipment remains in optimal condition.

Utilizing Online Resources

Today, numerous online platforms offer comprehensive listings and search tools for specific components. Utilizing these digital resources allows users to quickly identify the items they need, often accompanied by helpful visuals and specifications.

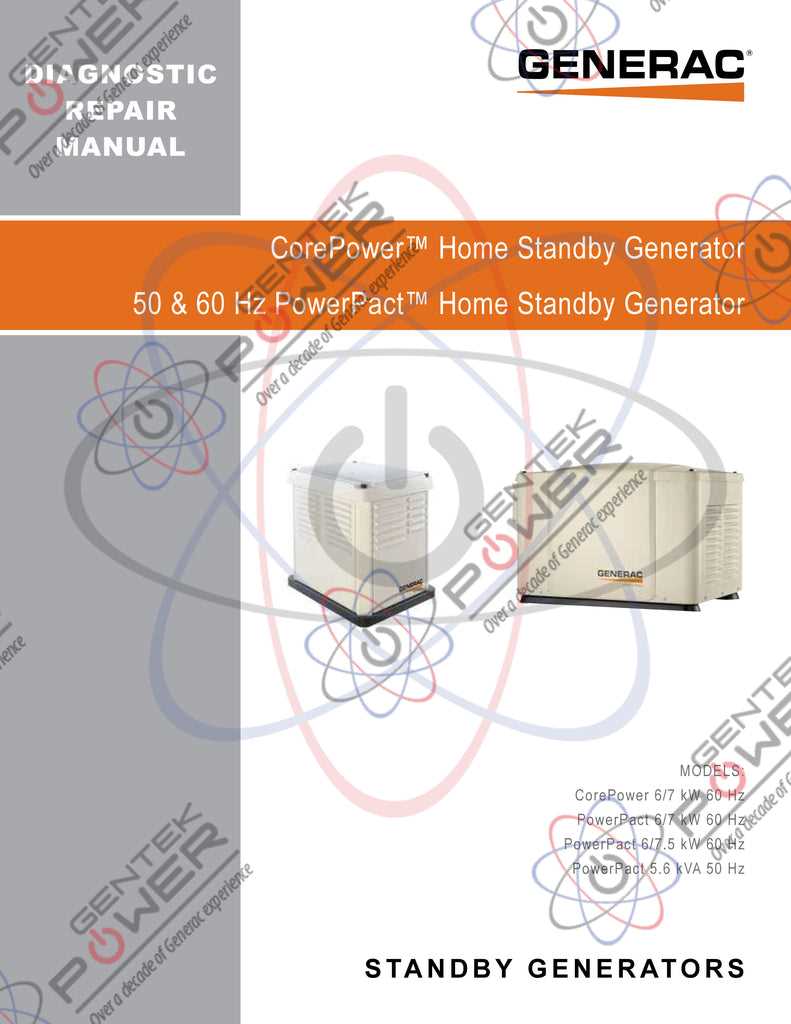

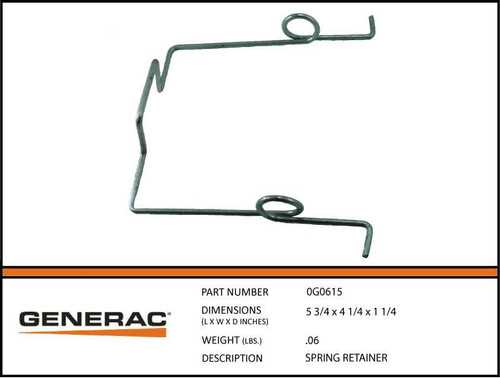

Consulting Manuals and Guides

Referencing manuals or guides can greatly enhance your understanding of the required components. These documents often contain valuable information, including part numbers and installation instructions, making the search for replacements more manageable.

In conclusion, by leveraging available online tools and referencing essential documentation, you can navigate the replacement process with ease and confidence. Empower yourself with knowledge and simplify your search for the right components.

Benefits of Using Original Parts

Utilizing authentic components for machinery ensures optimal performance and longevity. These elements are crafted to meet stringent quality standards, ultimately enhancing the overall efficiency of the equipment.

Quality Assurance

Original components undergo rigorous testing, guaranteeing their reliability and durability. Benefits include:

- Consistent performance

- Enhanced safety features

- Lower risk of failure

Warranty Protection

Choosing genuine components often preserves the manufacturer’s warranty. Key advantages are:

- Protection against voiding warranties

- Access to professional support

- Increased resale value

Maintenance Tips for Generac Units

Regular upkeep of your power equipment is essential to ensure optimal performance and longevity. Implementing a consistent maintenance routine can help prevent unexpected breakdowns and enhance the efficiency of your unit. Here are some key practices to follow for effective care.

First, always check the oil levels and quality. Changing the oil at recommended intervals keeps the engine lubricated and functioning smoothly. Additionally, inspect the air filter regularly; a clean filter allows for better airflow and improves combustion, ultimately enhancing performance.

Fuel maintenance is also crucial. Use fresh fuel and consider adding a stabilizer if the equipment will not be used for an extended period. This helps prevent fuel degradation and engine issues. Moreover, ensure that the fuel lines and connections are free from leaks and damage.

Another important aspect is the battery. Keep it charged and check for corrosion on terminals. Cleaning the connections can prevent starting issues. Lastly, inspect the unit for any loose bolts or components, and tighten them as needed to maintain stability and functionality.

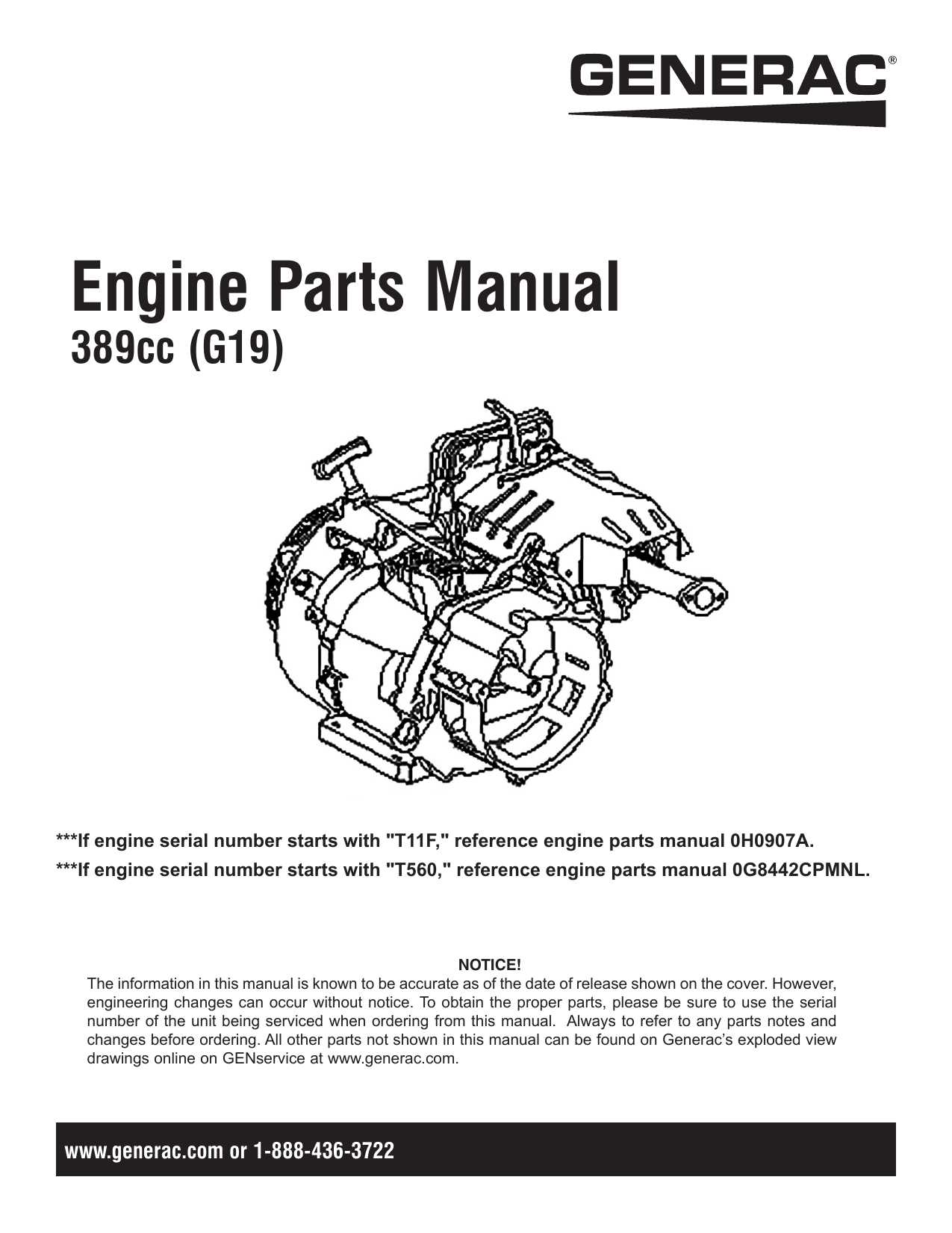

Identifying Parts by Model Number

Understanding how to pinpoint components based on model identifiers is essential for efficient maintenance and repair. This process ensures that users can quickly locate the necessary items for their specific machines, enhancing performance and longevity.

Why Model Numbers Matter

Model identifiers serve as a unique reference, allowing for accurate identification of specific elements. Knowing the significance of these numbers can streamline the selection process.

- Ensures compatibility with existing equipment

- Facilitates easy sourcing of replacements

- Reduces the risk of errors during repairs

How to Locate the Model Number

Finding the model identifier is often straightforward. Here are some common locations to check:

- On the machine’s frame or chassis

- Inside the user manual

- On the original packaging or receipt

By mastering the art of identifying components through model numbers, users can delve deeper into effective maintenance strategies, ultimately ensuring optimal performance of their equipment.

Where to Purchase Generac Parts

Finding components for your power equipment is essential for maintaining optimal performance. There are various avenues available to acquire these items, ensuring that your machinery remains functional and reliable.

Online Retailers: Numerous websites specialize in selling equipment accessories, offering convenience and often competitive pricing. Be sure to compare different sources for the best deals.

Authorized Dealers: Visiting official distributors can provide peace of mind regarding the authenticity of the items. These dealers often have knowledgeable staff who can assist with specific inquiries.

Local Hardware Stores: Many community hardware shops carry a selection of necessary components, making it easy to find what you need without lengthy shipping times.

Second-hand Markets: Exploring online marketplaces or local classified ads can yield affordable options, though it’s wise to verify the condition and compatibility of the items.

In summary, whether opting for online shopping, authorized outlets, or local stores, there are numerous strategies to ensure you obtain the components necessary for your equipment’s longevity.

Using Online Resources for Diagrams

Accessing digital tools for visual representations can greatly enhance your understanding and maintenance of equipment. These platforms offer a wealth of information, allowing users to explore components and their arrangements effectively.

Key benefits of utilizing online tools include:

- Immediate availability of detailed visuals

- Comprehensive information on various models

- Ease of navigation through user-friendly interfaces

To maximize your experience, consider the following strategies:

- Search for reputable websites that specialize in technical resources.

- Utilize forums or community groups for shared knowledge and tips.

- Bookmark useful sites for quick future reference.

Engaging with these resources not only simplifies the process but also empowers users to tackle issues with confidence and precision.

Importance of Regular Inspections

Regular evaluations of equipment are crucial for ensuring optimal performance and longevity. By conducting thorough checks, potential issues can be identified early, preventing costly repairs and downtime.

Routine assessments not only enhance reliability but also contribute to safety. They help in recognizing wear and tear, which can lead to hazardous situations if left unaddressed. Implementing a schedule for these inspections fosters a proactive approach, reducing the likelihood of unexpected failures.

In conclusion, prioritizing consistent evaluations is an ultimate strategy for maintaining efficiency and safeguarding investment in machinery. This practice ultimately leads to improved operational performance and peace of mind for users.

DIY Repairs and Parts Replacement

Engaging in home maintenance can empower you to address issues promptly and efficiently. Understanding how to identify and swap out essential components can save time and money while enhancing the longevity of your equipment.

Benefits of DIY Maintenance

- Cost Savings: Reduce repair costs by handling minor fixes yourself.

- Enhanced Knowledge: Gain insights into the workings of your machinery.

- Convenience: Perform repairs at your convenience without waiting for a technician.

Essential Tools for Repairs

- Wrenches: For loosening and tightening various fittings.

- Screwdrivers: Crucial for removing covers and securing screws.

- Multimeter: Useful for diagnosing electrical issues.

- Replacement Kits: Ensure you have the right components on hand.

Taking the initiative to repair and replace parts on your own can be a rewarding experience, ultimately leading to better functioning equipment and increased self-reliance.

Understanding Warranty Policies for Parts

Warranty policies are essential for consumers, offering assurance regarding the quality and durability of purchased items. These agreements define the terms under which replacements or repairs are provided, ensuring buyers feel secure in their investments. Understanding these policies helps in making informed decisions and knowing what to expect in case of product failure.

Key Aspects of Warranty Agreements

Warranty agreements typically outline coverage duration, conditions for claims, and specific exclusions. It’s crucial to pay attention to details such as labor costs, which may not be included, and to understand what qualifies as a valid claim. Additionally, certain actions, like unauthorized repairs, might void the warranty.

Maximizing Your Warranty Benefits

To fully benefit from warranty coverage, keep all receipts and documentation related to the purchase. Regular maintenance and proper usage can also prevent issues that may lead to claims being denied. Familiarizing oneself with the warranty terms can ultimately lead to a smoother process should any problems arise.