Understanding the Fs130r Parts Diagram for Efficient Repairs

In the realm of outdoor power equipment, a comprehensive understanding of the various elements that make up a machine is essential for both maintenance and repair. Every unit consists of numerous components, each playing a crucial role in its overall functionality. Grasping the arrangement and interaction of these parts can significantly enhance the efficiency of the equipment.

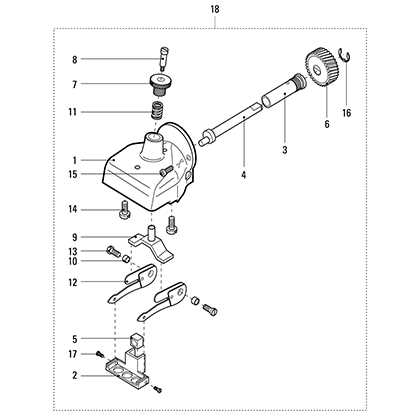

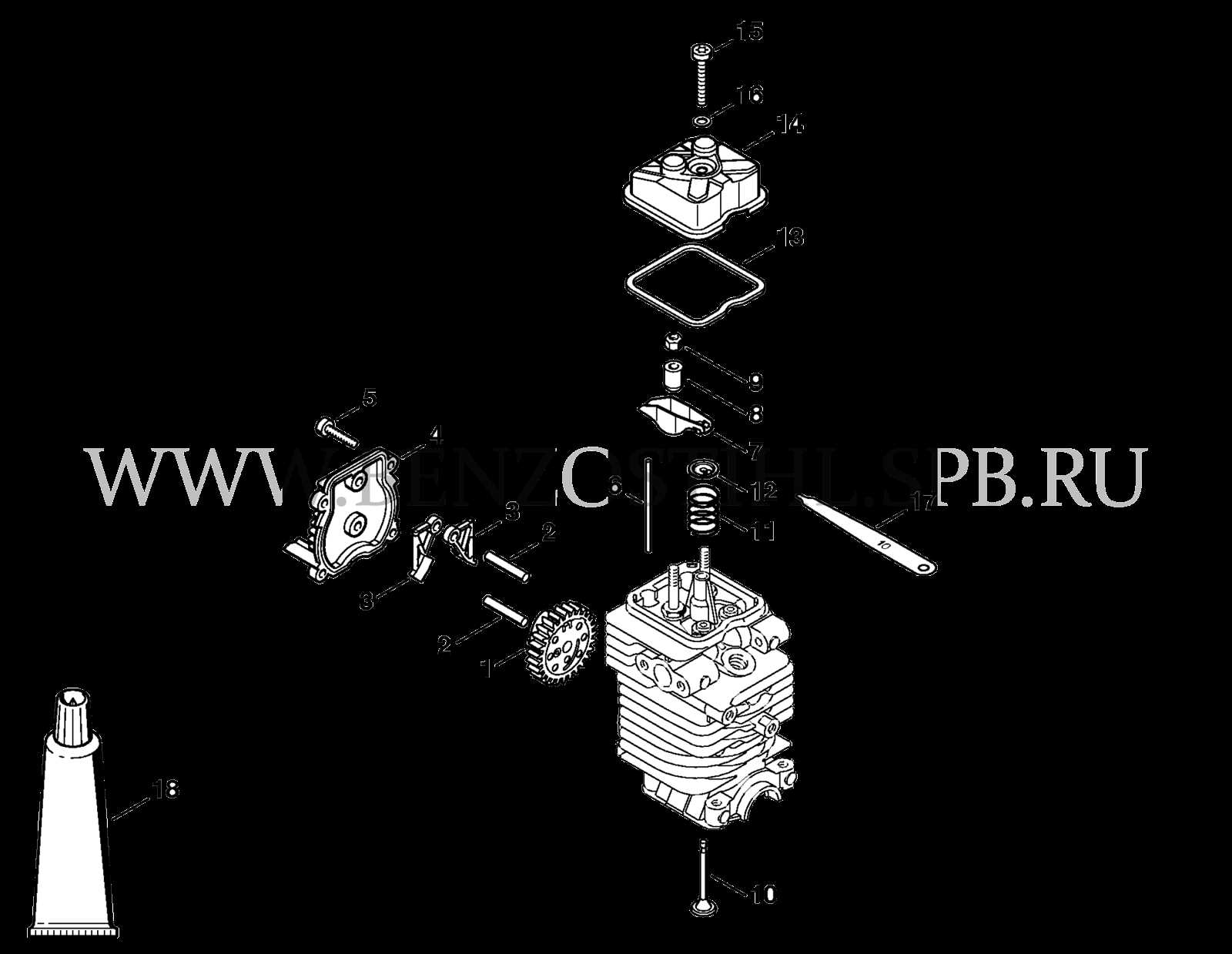

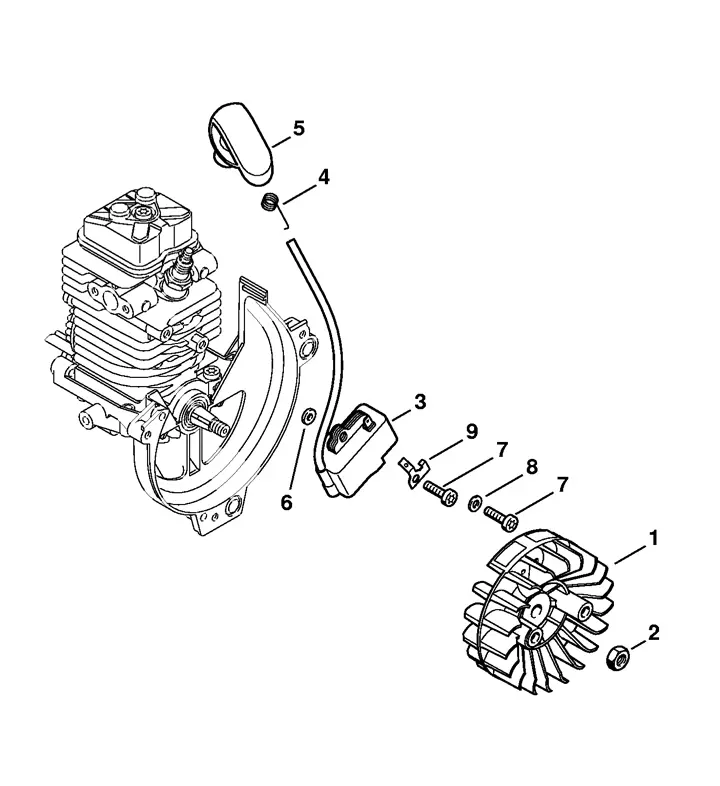

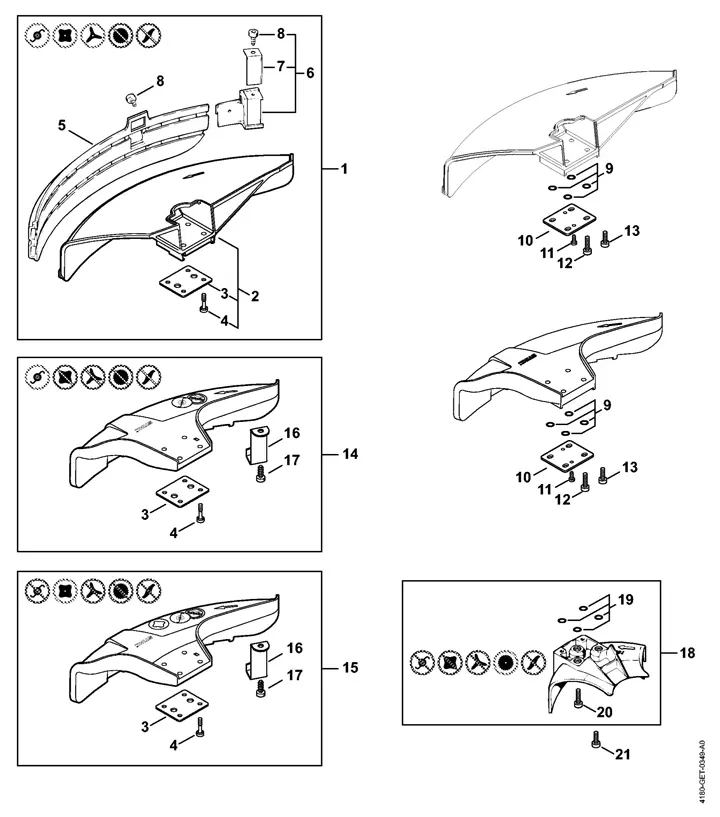

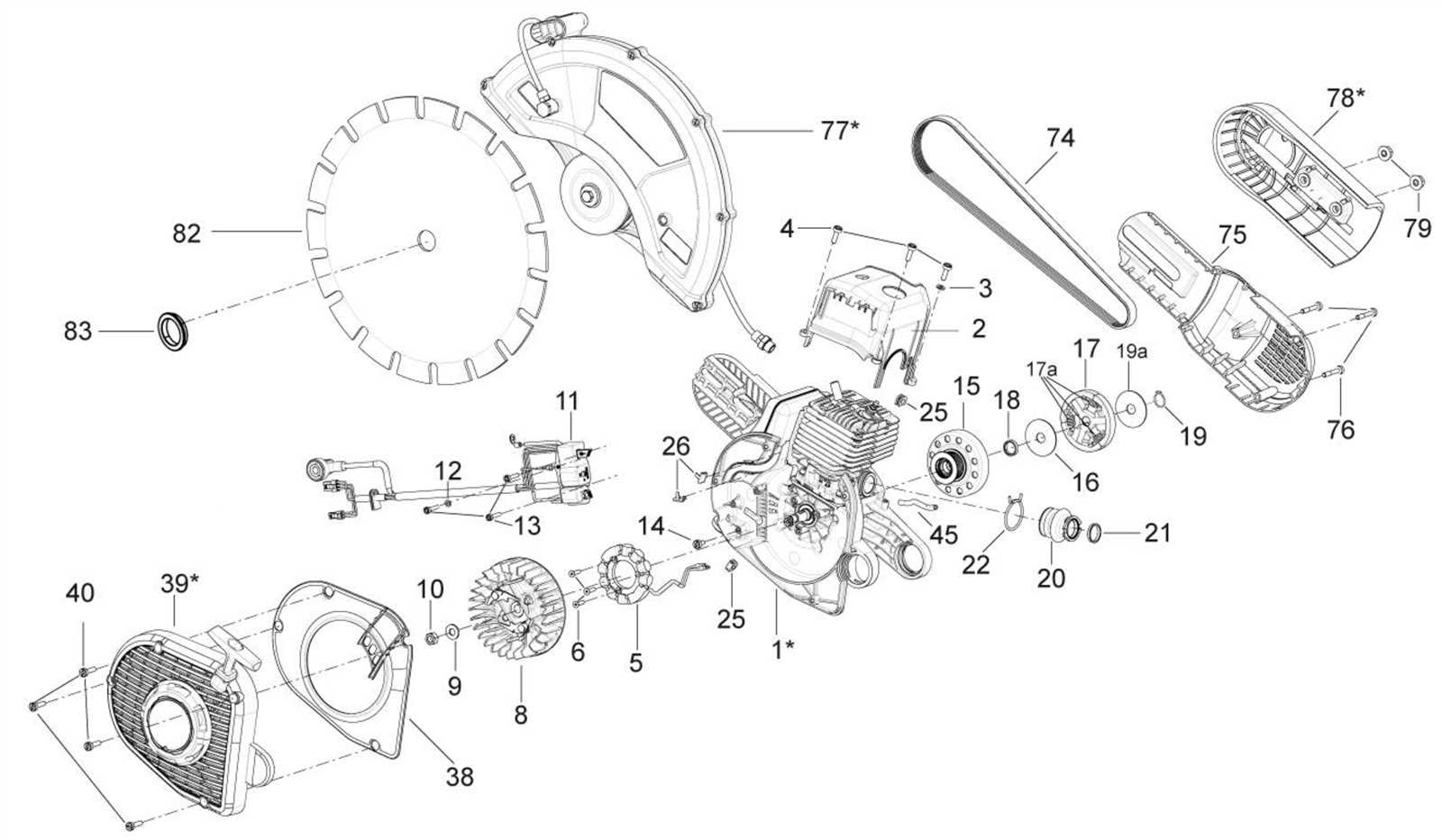

Visual aids often serve as invaluable tools for technicians and hobbyists alike, providing a clear representation of how each piece fits together. These illustrations not only facilitate easier identification of individual parts but also streamline the troubleshooting process. By breaking down the assembly into its basic elements, users can more effectively address any issues that arise.

Moreover, an intricate understanding of the structure can empower users to perform their own repairs or upgrades, fostering a greater sense of confidence and capability. With the right knowledge, one can navigate the complexities of their machinery with ease, ensuring it remains in optimal condition for years to come.

Understanding the Fs130r Components

In any machinery, grasping the various elements that contribute to its functionality is essential. Each component plays a crucial role, working in harmony to ensure optimal performance. Familiarity with these parts enhances maintenance, troubleshooting, and overall efficiency, allowing users to maximize their equipment’s potential.

Key Elements of the Machinery

Examining the core components reveals their specific functions and interrelationships. Understanding these will enable users to identify issues more readily and make informed decisions about repairs and upgrades.

| Component | Description | Function |

|---|---|---|

| Engine | The power unit of the equipment. | Generates energy to drive the machine. |

| Transmission | System that transmits power from the engine. | Controls the speed and torque delivered to the wheels. |

| Chassis | The framework that supports all components. | Provides structural integrity and stability. |

| Fuel System | Includes all parts related to fuel storage and delivery. | Supplies fuel to the engine for combustion. |

| Cooling System | Regulates the engine’s temperature. | Prevents overheating and maintains efficiency. |

Importance of Component Familiarity

Recognizing each part’s significance enhances a user’s ability to perform regular checks and maintenance. This knowledge not only prolongs the lifespan of the machinery but also ensures safe and effective operation. An informed operator is better equipped to manage challenges that may arise during use.

Importance of Parts Diagrams

Understanding the intricacies of machinery requires more than just familiarity with the equipment; it necessitates a clear visual representation of its components. Such illustrations serve as crucial tools for technicians and engineers, enabling them to identify and locate specific elements within complex systems. This clarity not only aids in effective maintenance but also enhances the overall efficiency of repair processes.

Enhancing Maintenance Efficiency

Visual representations simplify the identification of components, allowing for quicker diagnostics and repairs. When a technician can easily locate a specific piece, the time spent on maintenance tasks is significantly reduced. This efficiency can lead to lower operational costs and minimize downtime for machinery, which is vital in any industrial setting.

Facilitating Communication and Training

Illustrated guides serve as valuable resources for training new personnel. They provide a common language for discussing machine elements, ensuring that everyone, from novices to seasoned professionals, can communicate effectively. Moreover, these visual aids can help in understanding complex systems, making it easier for team members to collaborate on maintenance and repair projects.

Key Features of Fs130r Model

This model is designed with a range of attributes that enhance its performance and usability. It combines innovative engineering with practical functionality, making it suitable for various applications. The thoughtful design incorporates user-friendly elements that contribute to efficiency and reliability.

Performance Specifications

The engine delivers impressive power while maintaining fuel efficiency, allowing users to accomplish tasks effectively. Its robust construction ensures durability, providing a long service life even under demanding conditions.

| Feature | Description |

|---|---|

| Engine Power | High-output engine for superior performance |

| Fuel Efficiency | Optimized for reduced fuel consumption |

| Durability | Built with materials that withstand wear and tear |

| User Comfort | Ergonomic design for ease of use |

Innovative Features

Advanced technology is integrated into the model, providing enhanced control and precision. Safety features are also a priority, ensuring that users can operate the equipment with confidence.

Common Issues and Repairs

When working with outdoor equipment, various challenges can arise that may hinder performance. Understanding these frequent problems and their corresponding solutions is essential for maintaining efficiency and prolonging the lifespan of the machinery. This section outlines some typical concerns and the necessary steps for effective repair.

Frequent Mechanical Failures

One common issue involves the machine not starting. This can be attributed to several factors, such as a drained battery, clogged fuel lines, or faulty ignition components. To address this, ensure the battery is fully charged, check for fuel obstructions, and inspect spark plugs for wear. Regular maintenance checks can help prevent these failures from occurring.

Performance Degradation

Another prevalent problem is a noticeable drop in performance, which might manifest as reduced power or uneven operation. This can stem from air filter blockages, dull cutting blades, or improper fuel mixture. To rectify these issues, clean or replace the air filter, sharpen or replace blades as needed, and ensure the correct fuel-to-oil ratio is maintained. Prompt attention to these details can enhance functionality and prevent further complications.

How to Read a Parts Diagram

Understanding a visual representation of components can greatly enhance your ability to maintain and repair machinery. This visual guide provides a clear breakdown of individual elements, helping you identify and locate each piece effectively. By familiarizing yourself with the structure, you can streamline your work process and ensure that you have all necessary elements for a successful project.

Identifying Key Components

Begin by examining the overall layout. Typically, the most important parts are highlighted or labeled for easy identification. Look for reference numbers next to each element, which correspond to a list that details their specifications. Familiarize yourself with these identifiers as they are crucial for locating the right items.

Understanding Relationships and Connections

Pay attention to how components are interconnected. Lines and arrows often indicate relationships between different parts, showcasing how they interact within the larger assembly. Recognizing these connections will aid you in understanding the function of each piece and how to replace or service them effectively.

Essential Maintenance Tips

Regular upkeep of your equipment is crucial for optimal performance and longevity. By adhering to a consistent maintenance schedule, you can prevent potential issues and ensure that your machinery operates smoothly. Below are some key practices to enhance the reliability of your tools.

Routine Inspection

Conducting frequent examinations of your device is vital. Check for any signs of wear and tear, such as frayed wires or loose components. Addressing minor concerns promptly can save you from more significant repairs down the line. Always refer to the manufacturer’s guidelines for specific inspection intervals.

Cleaning and Lubrication

Keeping your equipment clean is essential for its efficiency. Accumulated dirt and debris can hinder functionality. Use appropriate cleaning solutions and tools to maintain a tidy working area. Additionally, regular lubrication of moving parts is necessary to reduce friction and prevent overheating. Opt for high-quality lubricants that are suitable for your machine.

Finding Replacement Parts

When equipment requires repairs or upgrades, locating the right components becomes essential for optimal functionality. Understanding where to source these items can streamline maintenance and enhance performance.

Sources for Components

- Authorized Dealers: These sellers often provide genuine items, ensuring compatibility and reliability.

- Online Marketplaces: Websites like eBay or Amazon offer a wide variety of options, often at competitive prices.

- Local Retail Stores: Brick-and-mortar shops may have necessary components readily available, allowing for immediate purchases.

- Salvage Yards: For older models, these locations can be treasure troves of hard-to-find pieces.

Tips for Successful Search

- Gather specific information about the needed item, including model numbers and descriptions.

- Check reviews and ratings of sellers to ensure quality and reliability.

- Compare prices across different sources to find the best deal.

- Consider reaching out to online forums or communities for recommendations and advice.

Upgrading Your Fs130r Equipment

Enhancing your outdoor machinery can significantly improve performance and efficiency. By investing in quality upgrades, you can boost productivity and extend the lifespan of your equipment. Understanding the available options and selecting the right enhancements will ensure optimal results for your tasks.

Performance Enhancements: One of the most impactful ways to upgrade your machinery is by focusing on the engine and power delivery. Consider high-performance filters and spark plugs to increase horsepower and responsiveness. Upgrading to a more efficient carburetor can also enhance fuel consumption and overall functionality.

Comfort and Usability: Ergonomics play a vital role in long-term usage. Adding cushioned grips or adjustable handles can minimize fatigue during prolonged operation. A well-placed throttle control or improved harness system will increase your comfort and make handling the equipment more intuitive.

Durability Improvements: Strengthening the structure of your machinery can lead to better performance in challenging conditions. Investing in reinforced components and weather-resistant materials ensures your equipment can withstand wear and tear over time, reducing maintenance needs and downtime.

Technological Additions: Integrating advanced technology, such as GPS tracking or smart monitoring systems, can greatly enhance efficiency. These features allow for precise operation and better management of your tasks, ultimately saving time and resources.

By carefully considering these upgrades, you can transform your machinery into a more effective tool, tailored to meet your specific needs and challenges.

Comparing Similar Models

When evaluating various machines within a specific category, it’s essential to understand their similarities and differences. This analysis helps potential users make informed decisions based on their unique needs, preferences, and the specific tasks they intend to accomplish. By focusing on comparable units, one can gain insights into performance, durability, and usability that are crucial for optimal selection.

Performance Characteristics

Different models often exhibit varying levels of efficiency and power output. It’s vital to compare metrics such as engine capacity, cutting width, and operational speed. These factors not only affect the overall performance but also influence the ease of use and maintenance requirements. For instance, while one variant may excel in speed, another might offer superior torque, making it more suitable for specific applications.

Build Quality and Features

The construction materials and additional features of each unit can greatly impact longevity and user experience. Assessing elements like frame design, vibration dampening systems, and ergonomic controls can reveal which options provide enhanced comfort and stability during operation. Additionally, integrated safety features and maintenance accessibility are essential considerations that can vary significantly between similar machines.

Tools Needed for Repairs

When it comes to performing maintenance or fixing machinery, having the right tools is essential for achieving optimal results. A well-equipped toolkit not only simplifies the process but also enhances efficiency, ensuring that repairs are completed smoothly and effectively. Understanding the necessary instruments and their functions can make a significant difference in your repair experience.

Essential Hand Tools

Basic hand tools are the backbone of any repair task. Items such as screwdrivers, wrenches, and pliers should be readily available. Each tool serves a specific purpose, making it easier to tackle various components and assemblies. For instance, a torque wrench is crucial for applying the right amount of force when tightening fasteners, while a set of hex keys is indispensable for accessing those hard-to-reach screws.

Power Tools and Equipment

In addition to hand tools, certain power tools can greatly expedite repair tasks. A reliable drill can save time when making holes or driving screws, while a saw is essential for cutting through materials with precision. Investing in a quality impact driver can also be beneficial, as it provides the necessary torque for loosening stubborn bolts or screws.

Frequently Asked Questions

This section addresses common inquiries related to the components and maintenance of specific equipment. Here, we provide insights that can help users better understand their machinery and troubleshoot issues effectively.

General Queries

- What are the most frequently replaced items in this type of equipment?

- How can I identify a malfunctioning component?

- Where can I find replacement parts?

Maintenance Tips

- Regularly inspect all moving parts for wear and tear.

- Clean components thoroughly to ensure optimal performance.

- Consult the user manual for recommended service intervals.

Resources for Further Learning

Exploring additional materials can significantly enhance your understanding of machinery and their components. A variety of educational tools, online courses, and reference guides are available to deepen your knowledge and improve your skills in maintenance and repair. Engaging with these resources will provide valuable insights and practical knowledge.

Online Platforms

Numerous websites offer comprehensive tutorials and courses focused on mechanical systems. Platforms such as Coursera and Udemy provide structured learning paths, covering everything from basic principles to advanced techniques. These courses often include video content, quizzes, and interactive forums for discussion.

Reference Materials

Books and manuals are excellent resources for detailed information. Look for specialized literature that focuses on machinery maintenance and troubleshooting. Technical handbooks and manufacturer manuals can serve as invaluable references, offering step-by-step instructions and diagrams that clarify complex concepts.