Understanding the Generac XP8000E Parts Diagram for Better Maintenance

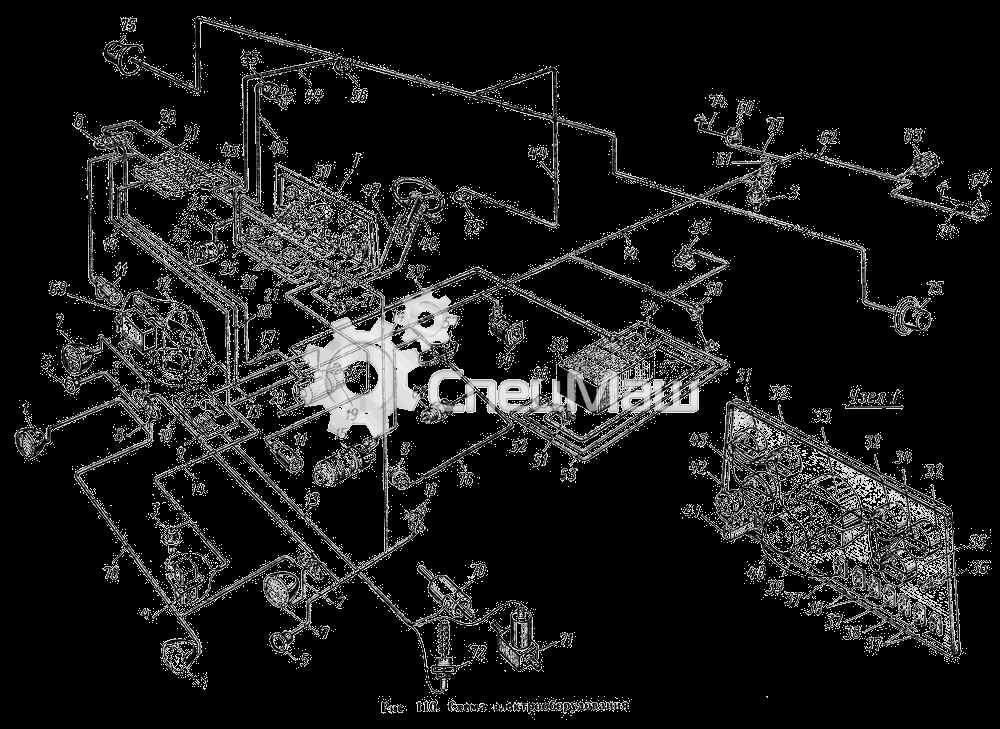

In the realm of portable power solutions, a thorough understanding of the individual elements that make up these machines is crucial for optimal performance and maintenance. Each generator consists of various integral components, each playing a specific role in ensuring efficient operation. Knowing how these parts interact can greatly enhance your experience and reliability.

When tackling issues related to power equipment, having a visual reference of the machine’s assembly can simplify repairs and part replacements. Such resources provide clarity, allowing users to quickly identify each component and its function within the overall system. This knowledge not only aids in troubleshooting but also empowers users to perform routine checks with confidence.

Whether you are a seasoned technician or a casual user, familiarizing yourself with the layout and specifications of these devices is essential. It fosters a deeper appreciation for the engineering behind them and equips you with the tools needed to maintain and enhance their longevity. Understanding these elements can transform your approach to power management, ensuring that you are prepared for any situation.

Understanding Generac XP8000E Overview

This section provides an overview of a robust power solution designed for various applications. The unit is known for its reliability and efficiency, making it an essential tool for both residential and commercial use. Its engineering ensures that users have access to a dependable source of energy when needed most, offering peace of mind in times of uncertainty.

The machine is equipped with advanced features that enhance its performance and user experience. Understanding its components is crucial for effective operation and maintenance. Below is a breakdown of the key elements that contribute to the overall functionality of this power generator.

| Component | Description |

|---|---|

| Engine | Delivers the necessary power output while ensuring fuel efficiency. |

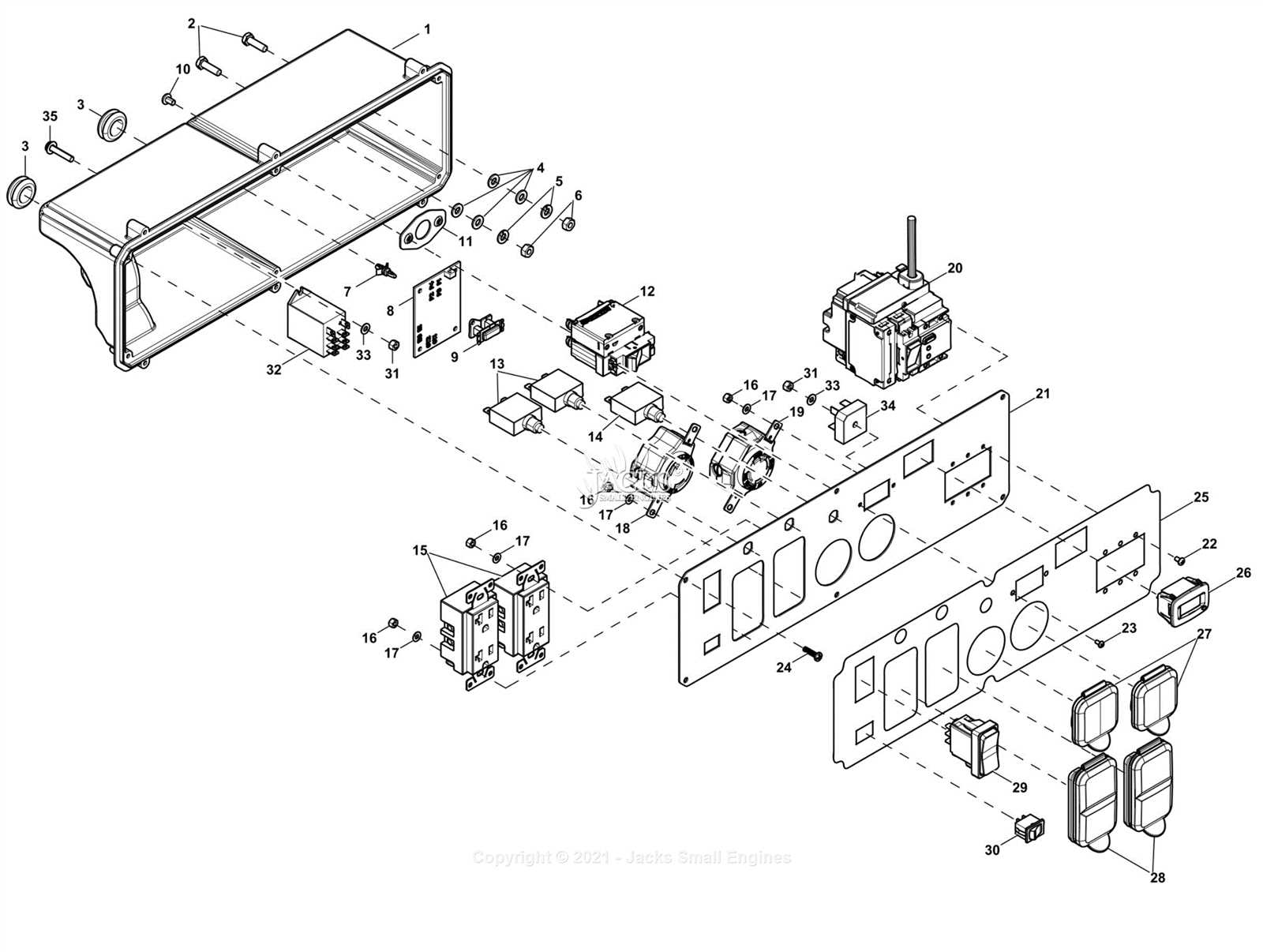

| Control Panel | Features gauges and controls for easy monitoring and management of power usage. |

| Fuel Tank | Stores fuel needed for operation, designed for optimal capacity and efficiency. |

| Wheels | Facilitate easy transportation, allowing for mobility in various settings. |

| Frame | Provides structural support and durability, ensuring long-lasting use. |

Familiarizing oneself with these components allows for better handling and maintenance of the unit, ensuring it remains a reliable source of power in critical situations.

Importance of Parts Diagrams

Understanding the assembly of machinery and equipment is crucial for effective maintenance and repairs. Visual representations of components not only provide clarity but also enhance the efficiency of troubleshooting and servicing. These illustrations serve as valuable references for both novice and experienced technicians, allowing them to identify and locate specific elements quickly.

Enhanced Clarity and Understanding

Visual schematics break down complex systems into manageable sections, making it easier to comprehend how each element interacts. By seeing the layout and connections, users can gain insights into functionality that may not be evident from written instructions alone. This clarity helps prevent errors during reassembly, ensuring that every part is correctly placed and secured.

Facilitating Efficient Repairs

Having a visual guide significantly streamlines the repair process. Technicians can quickly pinpoint the required components, reducing downtime and increasing productivity. Moreover, these illustrations can assist in ordering the correct replacements, minimizing the risk of purchasing incompatible items. Overall, a clear visual reference fosters a more effective approach to maintenance and enhances the longevity of the equipment.

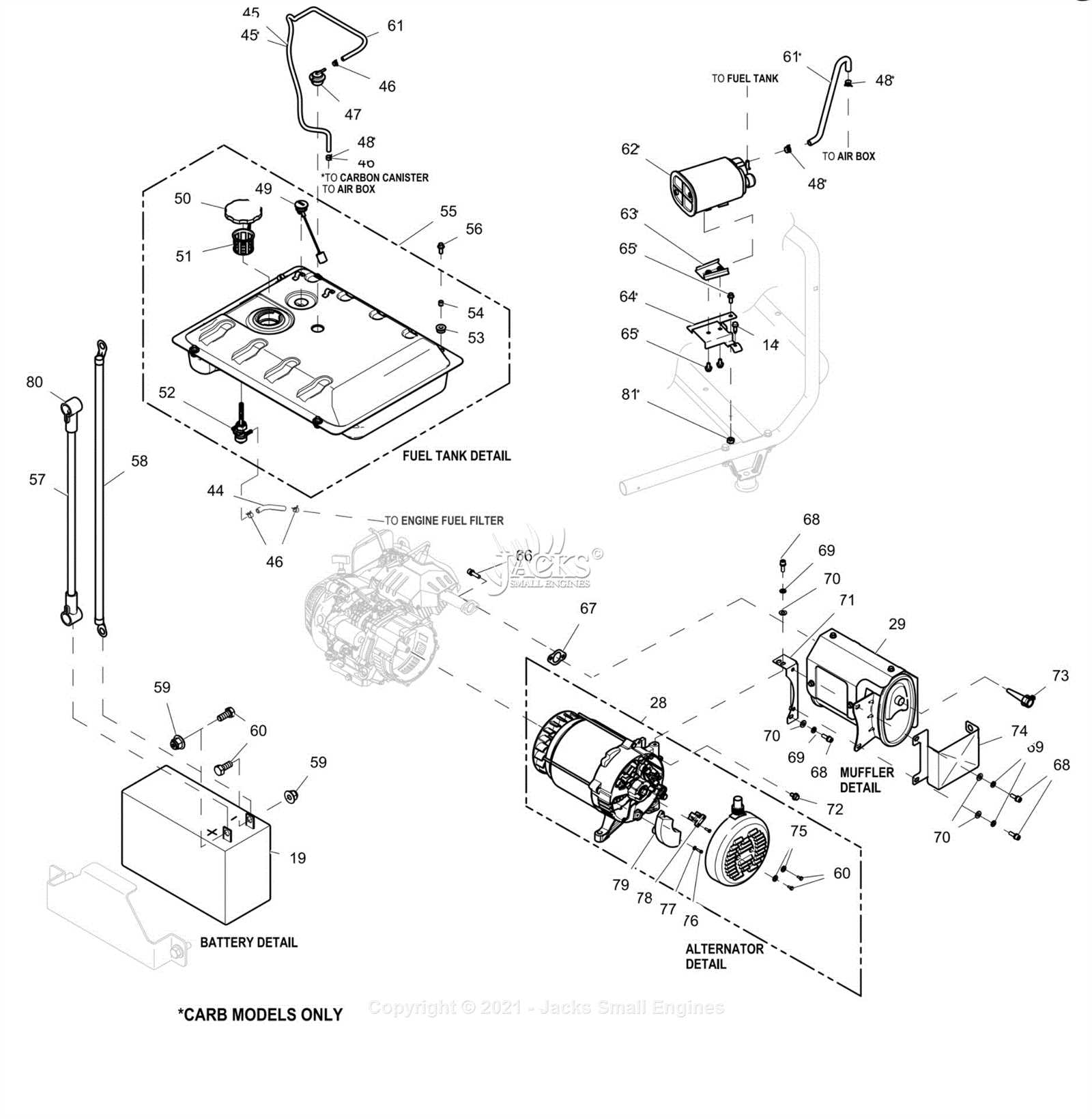

Key Components of XP8000E Generator

Understanding the essential elements of a power generator is crucial for effective operation and maintenance. Each part plays a significant role in ensuring reliable performance and efficiency. This section highlights the primary components that contribute to the functionality of the unit.

Major Parts

- Engine: The heart of the generator, responsible for converting fuel into mechanical energy.

- Alternator: Converts mechanical energy into electrical energy, providing power to connected devices.

- Fuel System: Includes the tank and lines that store and transport fuel to the engine.

- Control Panel: The interface for users to monitor and manage the generator’s operations.

- Chassis: The framework that houses and supports all components, ensuring stability and protection.

Additional Features

- Cooling System: Maintains optimal operating temperatures, preventing overheating.

- Exhaust System: Safely directs harmful gases away from the generator and users.

- Starting System: Facilitates the ignition process, enabling the generator to power up efficiently.

- Safety Features: Includes circuit breakers and alarms to protect against overloads and malfunctions.

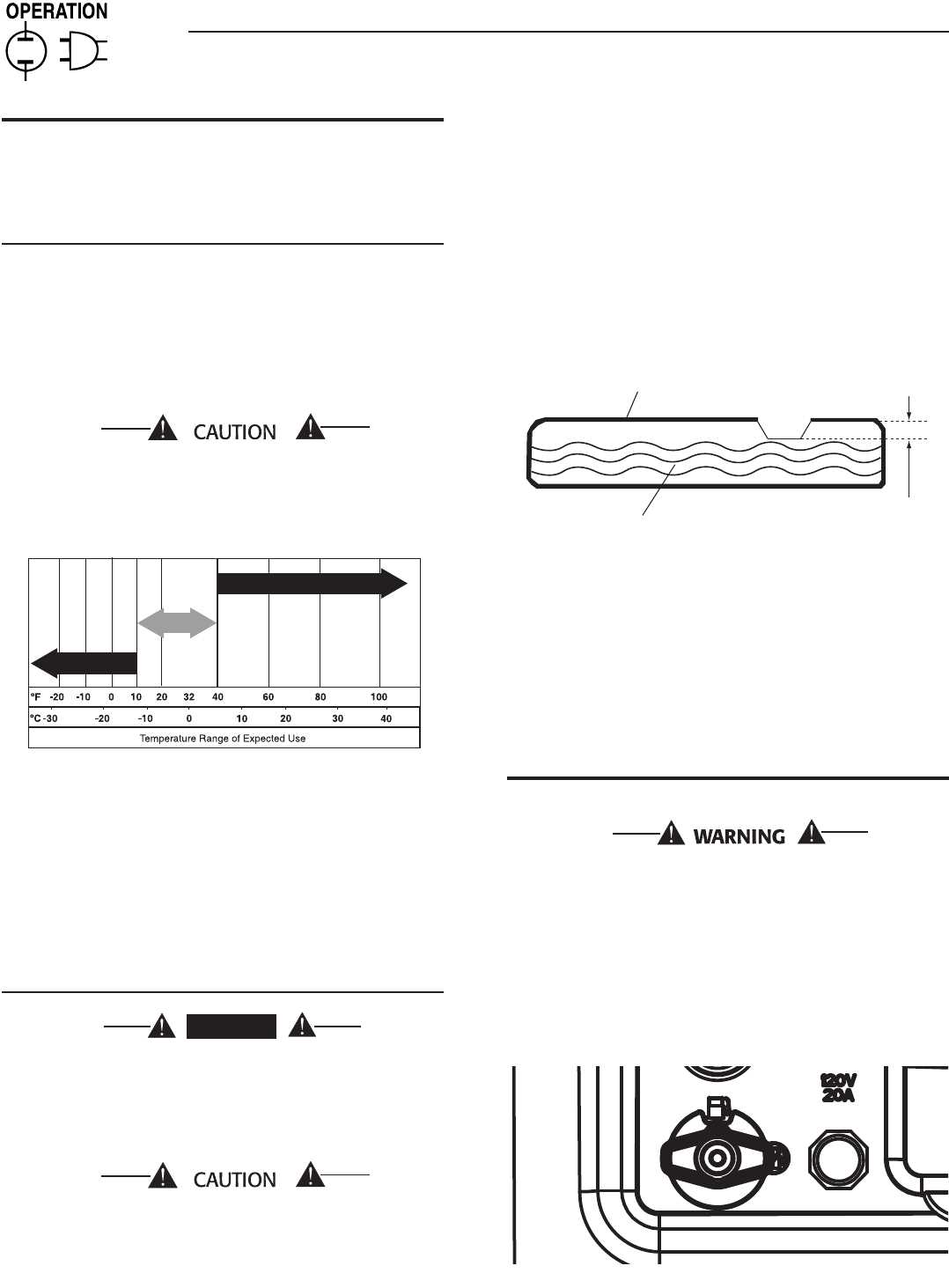

How to Read Parts Diagrams

Understanding technical illustrations is essential for effective maintenance and repair tasks. These visual representations break down complex machinery into manageable components, allowing users to identify individual elements quickly. By familiarizing yourself with the layout and symbols used, you can streamline your repair process and ensure accuracy in replacements.

Start by examining the overall structure of the illustration. Typically, components are organized logically, often grouped by function or location within the system. Look for a key or legend that explains any symbols or color coding used, as these will provide crucial insights into the parts’ roles.

Pay attention to the numbering system often employed in these visuals. Each element usually has a specific identifier that corresponds to a list, helping you easily locate and order the necessary pieces. Additionally, observe any directional arrows or lines that indicate connections or flow between components, as these details are vital for understanding how everything fits together.

Finally, take note of any notes or additional information that may accompany the visual. This supplementary text can offer important specifications or maintenance tips, enhancing your comprehension of the system as a whole. By mastering these illustrations, you will be better equipped to tackle repairs and ensure your equipment operates efficiently.

Common Issues with Generac Generators

Portable power sources can encounter various challenges that may hinder their performance. Understanding these common problems can help users troubleshoot and maintain their equipment effectively.

- Starting Problems:

- Insufficient fuel supply

- Faulty spark plug

- Battery issues

- Overheating:

- Blocked air vents

- Low oil levels

- Excessive load on the generator

- Electrical Issues:

- Voltage fluctuations

- Tripped circuit breakers

- Faulty connections

- Fuel System Problems:

- Clogged fuel filter

- Old or contaminated fuel

- Fuel line leaks

- Noise Levels:

- Loose components

- Worn-out muffler

- Improper placement on uneven ground

Regular maintenance and prompt attention to these issues can enhance the reliability and lifespan of your equipment.

Maintenance Tips for XP8000E

Regular upkeep is essential for ensuring optimal performance and longevity of your power generator. Following a systematic maintenance routine not only enhances efficiency but also minimizes the risk of unexpected failures. Here are some key practices to consider for keeping your unit in top shape.

Routine Inspections

Conduct frequent inspections to identify any wear or damage. Check for loose connections, frayed wires, and signs of corrosion. Ensuring that all components are secure will prevent operational issues and extend the lifespan of the equipment.

Fluid Management

Maintaining proper fluid levels is crucial for the effective functioning of the machine. Regularly check and change the oil as recommended in the manual, and keep an eye on the fuel and coolant levels. Clean or replace the air filter to ensure efficient airflow, which directly impacts performance.

Regular maintenance not only enhances the reliability of your generator but also promotes safety during operation. Taking proactive steps can help you avoid costly repairs and ensure your equipment is always ready when you need it.

Finding Genuine Replacement Parts

When it comes to maintaining the longevity and efficiency of your equipment, sourcing authentic components is crucial. High-quality replacements ensure optimal performance and safety, preventing potential damage that counterfeit or substandard items might cause.

Here are some tips for locating trustworthy alternatives:

- Check Official Retailers: Start by visiting authorized dealers who specialize in original products.

- Utilize Manufacturer Resources: Explore the manufacturer’s website for recommendations on where to purchase authentic components.

- Read Customer Reviews: Look for feedback from other users to gauge the reliability of the seller.

Additionally, consider the following when shopping:

- Verify Compatibility: Ensure that the item matches the specifications of your equipment.

- Request Documentation: Ask for proof of authenticity or warranty details from the supplier.

- Compare Prices: While genuine components might be more expensive, extremely low prices could indicate counterfeit products.

By following these guidelines, you can confidently find the right authentic replacements to keep your machinery in top condition.

Tools Needed for Repairs

When undertaking maintenance or fixing machinery, having the right equipment is essential for ensuring efficiency and safety. Each task may require specific instruments to address various components effectively. Below are some essential tools that can facilitate smooth repair processes.

Essential Hand Tools

- Screwdrivers: A set of flathead and Phillips screwdrivers for loosening and tightening screws.

- Wrenches: Both adjustable and fixed wrenches are crucial for gripping and turning nuts and bolts.

- Pliers: Needle-nose and standard pliers help in gripping small parts and wires.

- Socket Set: A comprehensive socket set enables efficient removal and installation of fasteners.

Power Tools

- Drill: Useful for making holes or driving screws into various materials.

- Impact Wrench: Ideal for loosening stubborn bolts and fasteners with ease.

- Angle Grinder: Effective for cutting, grinding, or polishing metal components.

Equipping yourself with these tools not only enhances the repair experience but also promotes a more effective approach to handling machinery. Always ensure that tools are well-maintained to guarantee optimal performance during repairs.

FAQs About XP8000E Parts

This section aims to address common inquiries related to components and accessories for a specific generator model. Understanding these elements can significantly enhance the user experience and ensure efficient operation.

What Should I Consider When Replacing Components?

When it comes to substitutions, it’s crucial to consider compatibility and quality. Always opt for high-grade materials to maintain performance and longevity. Checking the manufacturer’s recommendations can also provide guidance on suitable replacements.

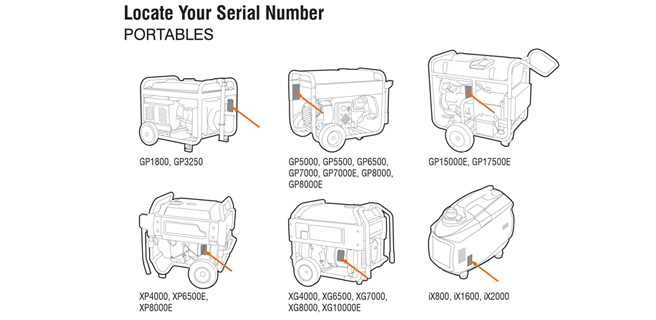

How Do I Identify the Right Accessories for My Unit?

To pinpoint the appropriate accessories, refer to the unit’s manual for specifications. Additionally, examining existing components can help you find the correct match. If uncertain, consulting with a professional can prevent errors and ensure optimal functionality.