Comprehensive Guide to Homelite Generator Parts Diagram

The efficient functioning of outdoor machinery relies heavily on a thorough understanding of its internal elements and their configurations. By familiarizing oneself with the intricacies of these components, users can enhance performance, troubleshoot issues, and ensure longevity. Knowledge of how each piece fits together is invaluable for both novice and experienced operators.

In this section, we will explore the essential structure and organization of various elements within these mechanical systems. Visual aids can significantly enhance comprehension, offering clarity in recognizing each part’s purpose and interrelation. This understanding can aid in maintenance and repairs, preventing unnecessary downtime.

As we delve into the specifics, readers will gain insights into common features and their arrangements, making it easier to identify and address potential challenges. A well-informed operator is better equipped to maximize efficiency and safeguard the investment in their equipment.

Understanding Homelite Generators

This section provides insight into portable power solutions that are essential for various applications, from home backup to outdoor activities. A thorough comprehension of their components and functionality can enhance both performance and longevity.

Key Features

- Durability: Designed to withstand challenging conditions.

- Portability: Lightweight designs facilitate easy transport.

- Efficiency: Optimized fuel consumption for extended use.

Common Components

- Engine: The heart of the system, providing necessary power.

- Fuel tank: Stores the energy source, affecting runtime.

- Control panel: User interface for operation and monitoring.

- Wheels and handles: Aid in mobility and ease of use.

Understanding these features and components enables users to make informed decisions regarding maintenance and upgrades, ensuring optimal performance over time.

Key Components of Homelite Generators

Understanding the essential elements of these power-producing machines is crucial for effective maintenance and optimal performance. Each component plays a significant role in the overall functionality, ensuring reliability and efficiency during operation.

Main Elements

The primary sections of these machines include the engine, alternator, fuel system, and control panel. Each part is designed to work in harmony with the others, contributing to the seamless generation of electricity.

Table of Essential Parts

| Component | Function |

|---|---|

| Engine | Converts fuel into mechanical energy. |

| Alternator | Transforms mechanical energy into electrical energy. |

| Fuel System | Delivers fuel to the engine for combustion. |

| Control Panel | Allows users to monitor and control operations. |

| Chassis | Provides structure and support for all components. |

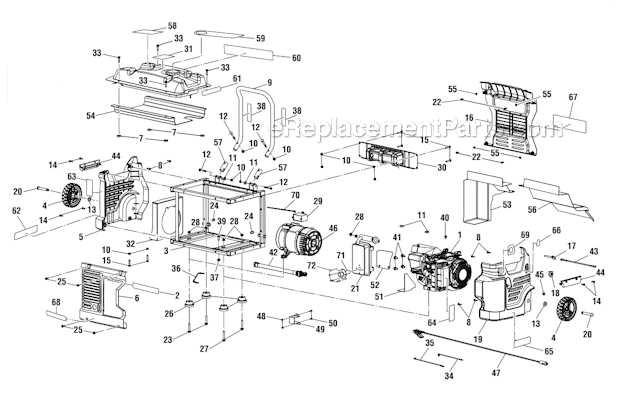

How to Read Parts Diagrams

Understanding technical illustrations is essential for anyone looking to maintain or repair equipment effectively. These visuals serve as a roadmap, guiding users through the various components and their interconnections. Familiarity with these illustrations can significantly enhance your ability to identify necessary elements and execute repairs with confidence.

To begin, it is crucial to recognize the symbols and notations used within these visuals. Each component is typically labeled with a specific identifier, which corresponds to a list or catalog of parts. This allows for easy cross-referencing and ensures that you can find the exact item you need. Pay close attention to the scaling of the illustration, as this can influence the size and placement of the parts within the actual assembly.

Next, observe the arrangement of the components. Many illustrations are organized in a way that reflects the assembly sequence, providing insight into how each piece fits together. By following this sequence, you can better understand the function of each part and how it interacts with others in the system.

Finally, consult any accompanying documentation that may explain specific details or offer troubleshooting tips. This additional information can enhance your comprehension of the illustration and provide context that is crucial for successful repairs. By mastering the art of reading these visuals, you empower yourself to tackle maintenance tasks with greater ease and proficiency.

Common Issues with Generator Parts

When operating a portable power source, various components may encounter difficulties that can affect overall performance. Recognizing these common challenges can help in troubleshooting and maintaining efficiency. This section highlights frequent concerns and offers insights into their resolutions.

| Issue | Symptoms | Potential Solutions |

|---|---|---|

| Fuel Blockage | Engine won’t start, sputtering | Inspect and clean fuel lines; check the fuel filter |

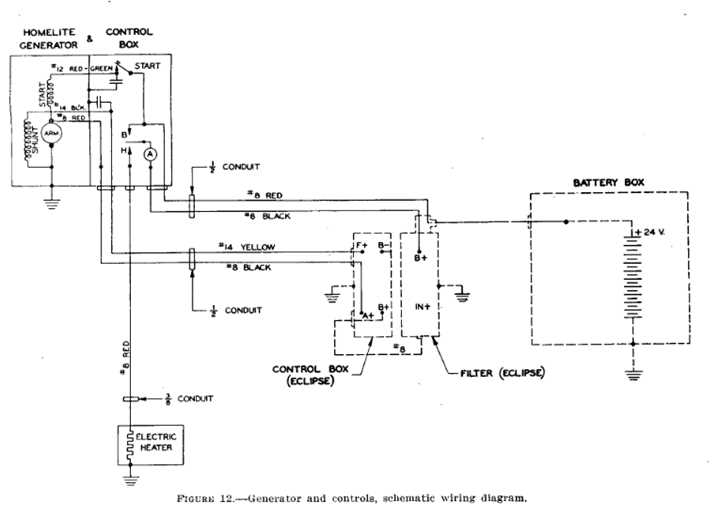

| Electrical Malfunction | Inconsistent power output, flickering lights | Examine wiring connections; replace damaged components |

| Overheating | Excessive heat, automatic shutdown | Ensure proper ventilation; check oil levels |

| Worn Brushes | Reduced efficiency, unusual noises | Inspect and replace brushes as necessary |

| Battery Failure | Difficulty starting, dim lights | Test battery condition; recharge or replace |

Importance of Regular Maintenance

Regular maintenance offers several key benefits:

- Increased Lifespan: Routine checks and replacements can significantly extend the usable life of the equipment.

- Optimal Performance: Keeping all parts in good condition ensures that the device operates at peak efficiency.

- Cost Savings: Addressing minor issues early can prevent costly repairs or replacements in the future.

- Safety: Regular inspections can identify hazards before they become serious problems, protecting users and bystanders.

To achieve these advantages, consider implementing the following practices:

- Establish a routine schedule for inspections and servicing.

- Keep a record of all maintenance activities to track performance and needs.

- Use quality replacement components to ensure compatibility and reliability.

- Consult the manufacturer’s guidelines for specific maintenance recommendations.

In conclusion, maintaining mechanical equipment is not just a good practice; it is vital for ensuring efficient operation and safety. By prioritizing maintenance, users can enjoy a more reliable and durable experience over time.

Finding Replacement Parts Online

In today’s digital age, sourcing components for various machinery has become increasingly convenient. The internet provides a vast array of options, allowing users to locate the necessary items with just a few clicks. This guide aims to assist you in navigating the online landscape to find the ideal replacements efficiently.

Identifying the Right Components

Before diving into the online marketplace, it’s crucial to understand what you need. Ensure you have the model number and specifications on hand, as these details will help you filter through options and find the exact items required for your equipment.

Where to Search

Several platforms offer a variety of components. Here’s a table summarizing the best places to look:

| Platform | Description |

|---|---|

| Manufacturer’s Website | Direct access to original components, often with diagrams for easy identification. |

| Online Retailers | Major e-commerce sites typically offer competitive pricing and user reviews. |

| Specialty Stores | Stores focused on specific machinery often provide knowledgeable customer support. |

| Forums and Community Groups | Online communities can offer recommendations and sometimes sell used items. |

By utilizing these resources, you can streamline the process of finding the necessary components and ensure your machinery remains in top condition.

Tools Needed for Repairs

When undertaking maintenance or troubleshooting tasks, having the right instruments at your disposal is essential for efficient and effective repairs. The appropriate tools not only facilitate the process but also ensure that the job is completed safely and correctly.

Basic hand tools are typically required for most repair tasks. This includes items such as wrenches, screwdrivers, and pliers, which allow you to manipulate various components with precision. Additionally, a set of sockets can prove invaluable for loosening or tightening bolts and nuts.

For more intricate repairs, specialized equipment may be necessary. Tools like multimeters help in diagnosing electrical issues, while compression gauges can assist in evaluating the performance of internal mechanisms. Furthermore, having a repair manual or guide specific to your device can provide valuable insights and instructions.

Don’t overlook the importance of safety gear as well. Wearing gloves, goggles, and other protective equipment can prevent injuries during the repair process. Ensuring that you are well-prepared with the right tools and safety measures will lead to a smoother and more successful repair experience.

Identifying Model-Specific Parts

Understanding the unique components of your equipment is essential for effective maintenance and repair. Each model comes with its own set of specifications, making it crucial to recognize the exact elements that correspond to your particular version. This knowledge not only aids in proper servicing but also ensures that replacements fit seamlessly and function optimally.

To begin, locate the identification number or model designation typically found on the unit itself. This information serves as the foundation for identifying compatible components. Once you have the model details, consult the manufacturer’s resources or trusted online databases to access accurate descriptions and illustrations of the necessary elements.

Additionally, engaging with community forums can provide insights from fellow users who have faced similar challenges. They often share valuable tips and specific details about their experiences, helping you to navigate the selection of the right items for your equipment.

Step-by-Step Repair Guide

This guide provides a systematic approach to troubleshooting and restoring equipment functionality. Following these steps will help you identify issues and implement effective solutions, ensuring reliable operation.

-

Assess the Problem: Begin by observing the malfunction. Note any unusual sounds, performance issues, or visible damage.

-

Gather Necessary Tools: Prepare a toolkit that includes screwdrivers, wrenches, pliers, and replacement components.

-

Refer to the Manual: Consult the instructional manual for specific troubleshooting techniques and component locations.

-

Disconnect Power Supply: Always ensure the device is powered off and disconnected before attempting any repairs to avoid electrical hazards.

-

Examine Components: Open the casing carefully and inspect internal parts for wear, corrosion, or damage.

- Check connections for tightness.

- Look for signs of leaks or burnt components.

-

Replace Faulty Parts: If any components are damaged, remove them and install replacements as indicated in the manual.

-

Reassemble the Unit: Carefully put the casing back together, ensuring all screws and bolts are securely fastened.

-

Test Functionality: Reconnect the power source and conduct a test run to verify that the issue has been resolved.

By following these steps diligently, you can enhance the performance and longevity of your equipment, ensuring it remains in optimal working condition.

Safety Precautions During Repairs

When engaging in maintenance and troubleshooting tasks, prioritizing safety is essential to prevent accidents and injuries. Adhering to specific guidelines can significantly reduce risks and ensure a secure working environment.

- Always disconnect the power source before beginning any repairs.

- Use appropriate personal protective equipment, such as gloves and safety goggles.

- Ensure the workspace is well-ventilated to avoid inhaling harmful fumes.

Before starting any work, take a moment to assess your surroundings and the tools you will be using. This can help you anticipate potential hazards and plan accordingly.

- Keep tools organized and within reach to avoid unnecessary movements.

- Double-check that all components are intact and functioning before reassembly.

- Follow manufacturer instructions carefully to avoid mishaps.

By following these safety measures, you can protect yourself and ensure a more efficient repair process.

Upgrading Your Generator Components

Enhancing the efficiency and longevity of your power source is essential for optimal performance. By selecting and replacing specific elements, you can significantly improve functionality and reliability. Upgrading not only boosts output but also helps in addressing common issues, ensuring that your unit operates smoothly over time.

Several key components can be considered for enhancement. Here’s a brief overview of the most impactful upgrades:

| Component | Benefits |

|---|---|

| Air Filter | Improves airflow and increases efficiency, prolonging engine life. |

| Fuel System | Enhances fuel delivery, ensuring consistent performance and better fuel economy. |

| Battery | Upgrading to a higher capacity unit improves starting reliability and runtime. |

| Exhaust System | Reduces noise and emissions, leading to a cleaner and quieter operation. |

| Voltage Regulator | Ensures stable voltage output, protecting connected devices from damage. |

By focusing on these upgrades, you can create a more robust and dependable power solution tailored to your needs. Regularly assessing and updating these components will ensure peak performance for years to come.

Where to Purchase Quality Parts

When seeking to acquire components for your machinery, the quality of the items is paramount. Opting for reliable sources ensures longevity and optimal performance. Various avenues exist for sourcing these essential elements, each with distinct advantages and considerations.

Authorized Dealers

Visiting authorized retailers often guarantees authenticity and quality assurance. These establishments typically offer a comprehensive selection, along with expert advice.

Online Marketplaces

The digital landscape provides an extensive range of options, making it easy to compare prices and reviews. Be cautious, however, to verify the credibility of the sellers to avoid counterfeit products.

| Source Type | Advantages | Considerations |

|---|---|---|

| Authorized Dealers | Quality assurance, expert guidance | Potentially higher prices |

| Online Marketplaces | Wide selection, price comparison | Risk of counterfeit items |

| Local Repair Shops | Personalized service, immediate availability | Limited stock |

Understanding Warranty and Returns

When purchasing equipment, it is essential to be aware of the terms related to warranty and returns. These aspects not only provide peace of mind but also ensure that you are protected against defects and dissatisfaction with your purchase. Familiarizing yourself with these policies can significantly enhance your overall buying experience.

A warranty typically covers repairs or replacements for a specified period, safeguarding consumers from manufacturing flaws. It is important to read the details of the warranty, including what is covered, any exclusions, and the process for filing a claim. Understanding these elements can help avoid unexpected challenges if issues arise.

Returns policies vary by seller, so it is crucial to understand the conditions under which items can be returned. Look for information on timeframes, condition requirements, and potential restocking fees. This knowledge will empower you to make informed decisions and ensure you can return an item if it does not meet your expectations.

Overall, comprehending the nuances of warranty and return policies is vital for any buyer. It not only protects your investment but also builds confidence in your purchasing decisions.