Comprehensive Guide to Onan 5500 Generator Parts Diagrams

The functionality of any machinery relies heavily on its intricate components and the synergy between them. A comprehensive understanding of these elements is essential for effective maintenance and troubleshooting. Knowledge of each segment not only enhances operational efficiency but also extends the lifespan of the entire system.

In this section, we will explore the intricacies of various elements that contribute to optimal performance. By examining the structural layout and connections, we can gain insights into how to address common issues and perform necessary repairs. This exploration serves as a guide for both enthusiasts and professionals alike, ensuring that you are equipped with the ultimate knowledge for success.

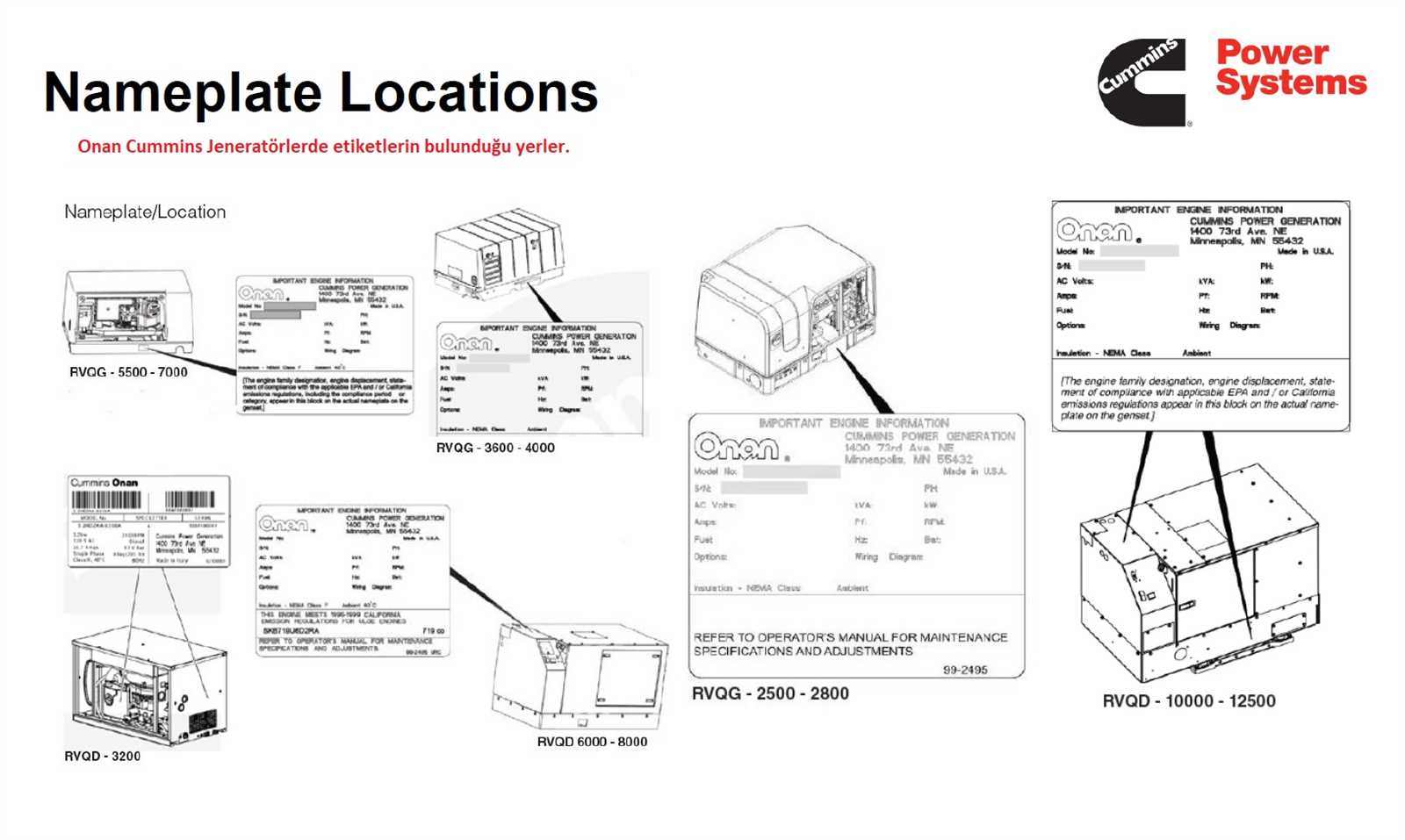

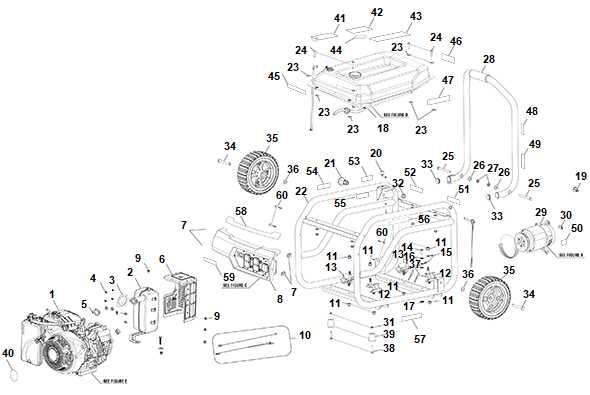

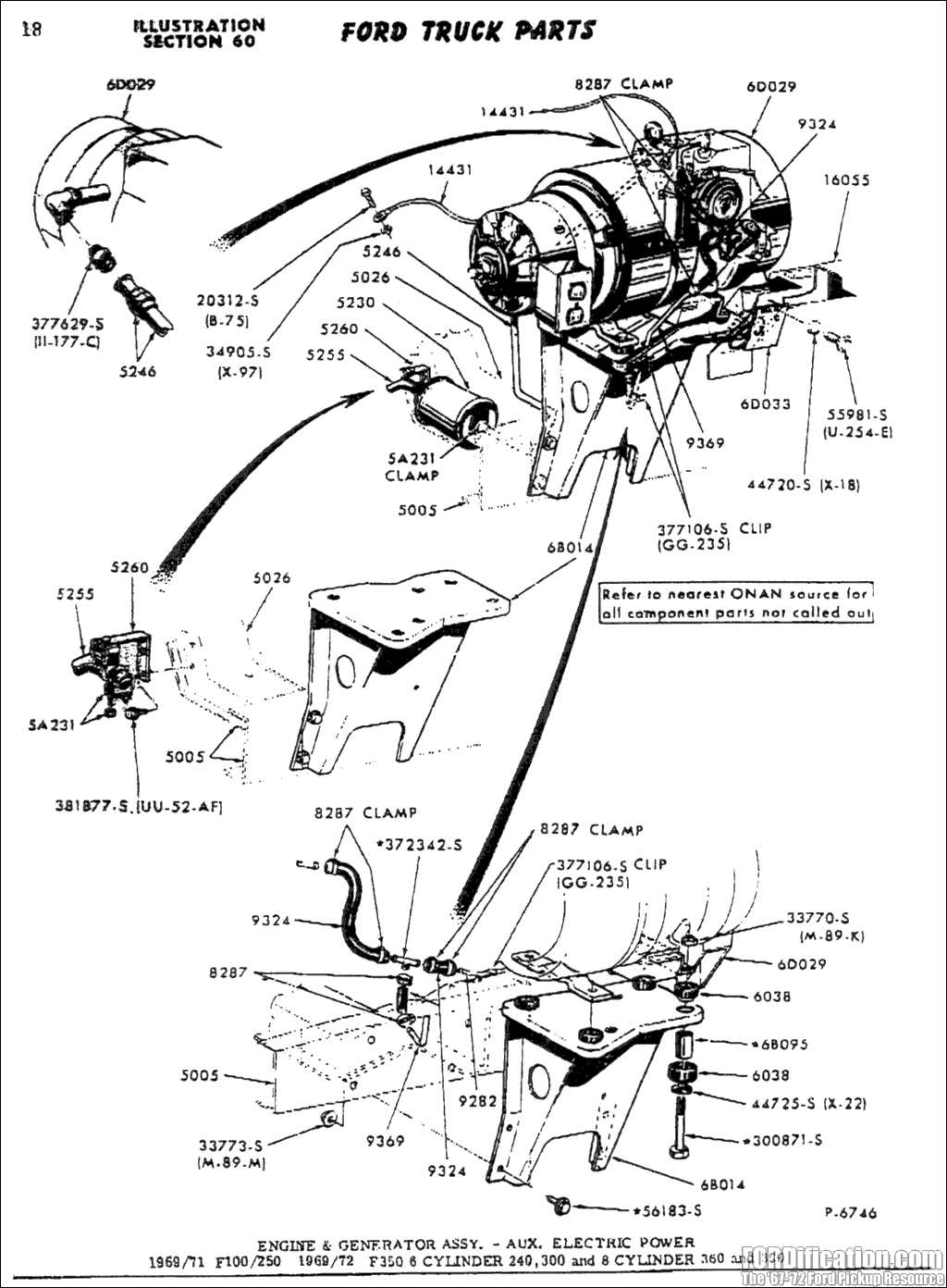

Detailed visual representations of these components will facilitate a deeper comprehension of their arrangement and function. With this understanding, users can confidently navigate the complexities of machinery, ensuring smooth operations and minimizing downtime. Embrace the opportunity to delve into this essential knowledge base and elevate your expertise.

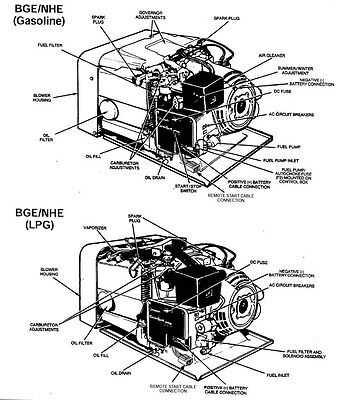

Understanding Onan 5500 Generators

This section explores the essential components and functionalities of a widely used power source, emphasizing its significance in various applications. A comprehensive grasp of these machines is vital for efficient operation and maintenance, ensuring reliability in diverse environments.

| Component | Description |

|---|---|

| Engine | Provides the primary source of power, converting fuel into mechanical energy. |

| Alternator | Transforms mechanical energy into electrical energy for various applications. |

| Control Panel | Offers interface for monitoring and managing the machine’s performance and settings. |

| Fuel System | Supplies fuel to the engine, ensuring consistent operation and efficiency. |

| Cooling System | Maintains optimal temperature during operation, preventing overheating. |

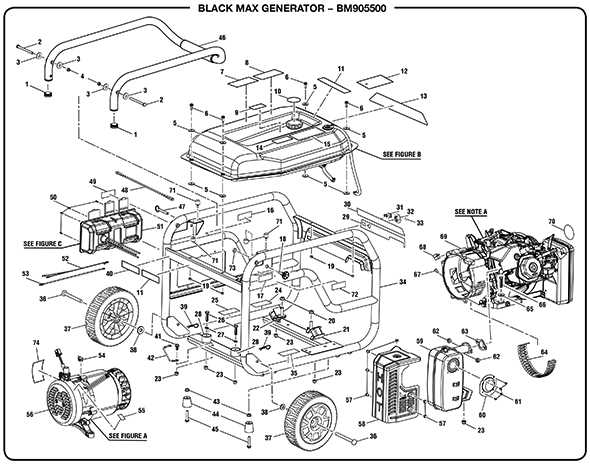

Key Components of the Generator

Understanding the essential elements of a power-producing unit is crucial for effective maintenance and operation. Each part plays a vital role in ensuring the efficiency and reliability of the entire system, contributing to its overall performance and longevity.

Main Elements

- Engine: The heart of the system, responsible for converting fuel into mechanical energy.

- Alternator: Converts mechanical energy into electrical energy, facilitating the generation of usable power.

- Fuel System: Supplies the necessary fuel to the engine, including the tank, lines, and pump.

- Cooling System: Maintains optimal operating temperatures, preventing overheating and damage.

- Control Panel: Provides users with essential information and controls for operation and monitoring.

Additional Components

- Exhaust System: Directs and expels gases produced during combustion.

- Battery: Stores electrical energy, facilitating starting and operation of the unit.

- Chassis: The framework that supports and houses all components, providing stability and protection.

- Wiring Harness: Connects various electrical components, ensuring proper functionality and safety.

- Vibration Dampers: Reduce noise and vibration, enhancing user comfort and equipment longevity.

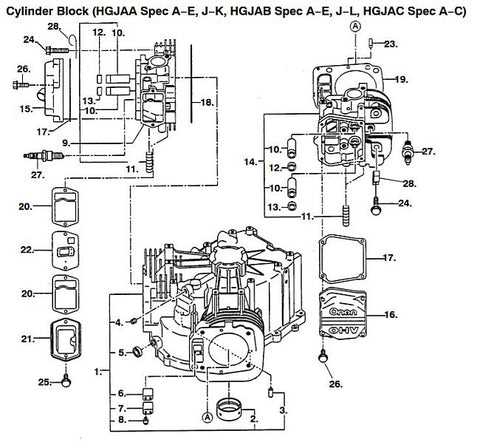

Importance of Parts Diagrams

Understanding the layout and components of any machinery is crucial for effective maintenance and repair. Visual representations of the various elements help users identify, organize, and access necessary items more efficiently. Such illustrations serve as a roadmap, guiding technicians through complex assemblies while simplifying troubleshooting processes.

Benefits of Visual Representations

- Enhanced Clarity: Diagrams provide a clear view of each component’s location, making it easier to locate parts during servicing.

- Efficient Maintenance: Technicians can quickly pinpoint issues and determine the required replacements, reducing downtime.

- Improved Communication: Visual aids facilitate better discussions among team members, ensuring everyone is on the same page regarding repairs and upgrades.

Utilization in Repair Processes

- Identification: Users can match symptoms with specific components, aiding in quicker diagnostics.

- Ordering Parts: Accurate references help ensure that the correct items are procured without unnecessary delays.

- Assembly Guidance: Step-by-step visuals assist in reassembling units correctly after maintenance, minimizing errors.

Overall, these graphical tools are indispensable for anyone working with complex machinery, as they not only streamline the repair process but also enhance understanding of the equipment as a whole.

Common Issues with Onan Generators

Operating a power supply unit can sometimes present challenges that may affect its performance and reliability. Understanding these frequent problems can help users troubleshoot and maintain their equipment effectively. This section explores typical concerns that owners might encounter, along with suggestions for resolution.

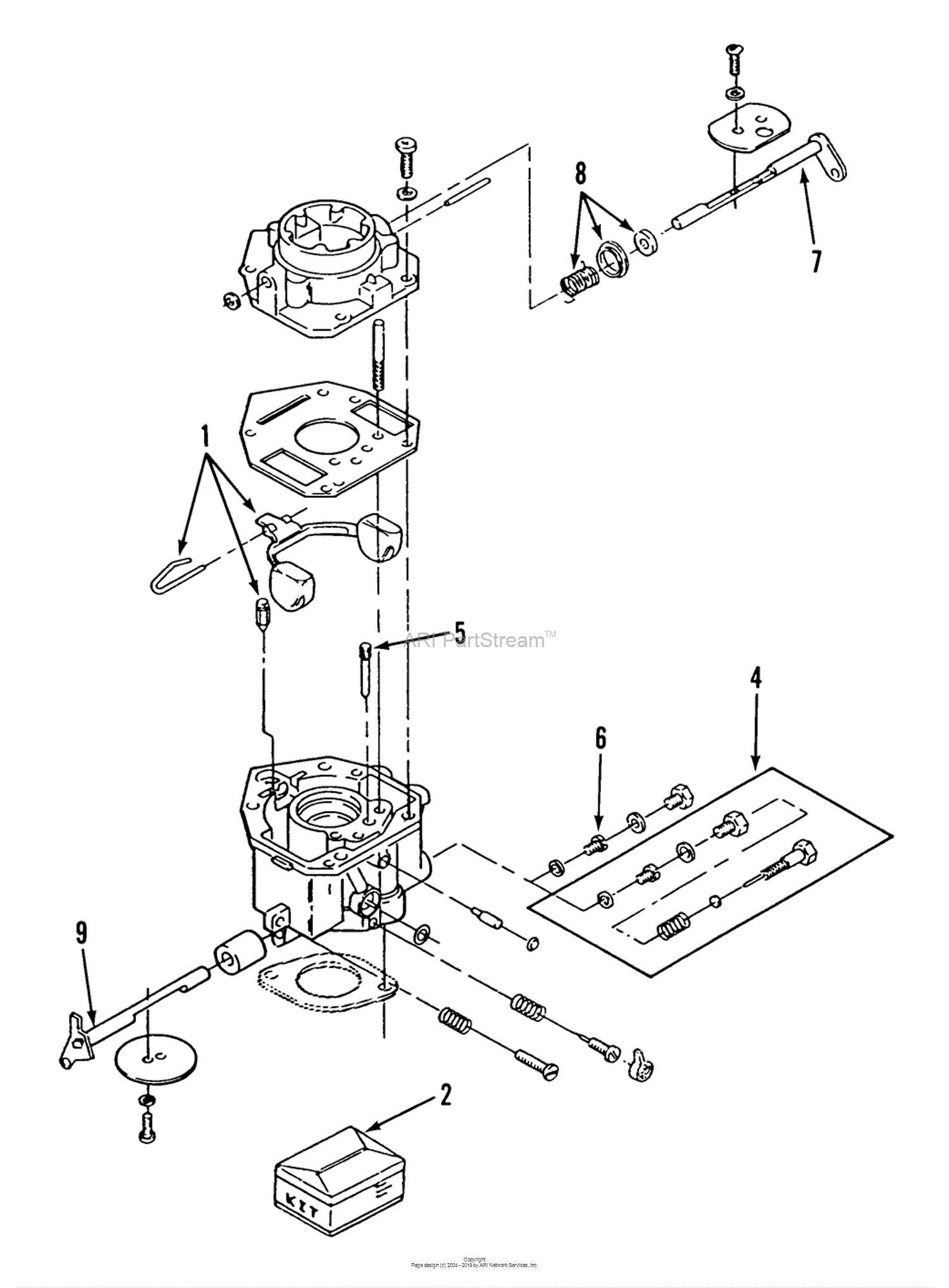

Fuel System Troubles

One of the primary areas where difficulties may arise is within the fuel system. Issues such as clogged filters, contaminated fuel, or faulty pumps can hinder proper operation. Regular inspection and maintenance of fuel lines and components are crucial to ensure smooth functionality. Replacing filters and using fresh fuel can often resolve these types of problems.

Electrical Malfunctions

Another common concern involves electrical components, which can experience failures due to wear or improper connections. Symptoms may include inconsistent power output or complete shutdowns. Conducting routine checks on wiring, connectors, and circuit boards is essential. Addressing any signs of corrosion or loose connections can significantly enhance performance and extend the lifespan of the unit.

How to Read Parts Diagrams

Understanding schematic illustrations is essential for anyone involved in maintenance or repairs. These visual representations simplify the identification of components, facilitating efficient troubleshooting and replacement processes. Grasping the symbols and layout can significantly enhance your ability to work effectively with machinery.

Key Components of Illustrations

Each illustration typically includes labels, numbers, and reference keys that correspond to a list of elements. Familiarity with these features is crucial for accurate interpretation.

| Element | Description |

|---|---|

| Label | Identifies each component for easy reference. |

| Number | Indicates the order of assembly or part sequence. |

| Reference Key | Links visual elements to detailed specifications or part lists. |

Tips for Effective Interpretation

To master the art of reading these visuals, take your time to study the layout and practice identifying components. Cross-referencing with manuals or guides will reinforce your understanding and boost confidence in your skills.

Replacing Faulty Components

Maintaining optimal performance of your equipment often involves identifying and substituting defective elements. This process is crucial for ensuring longevity and reliability. By understanding the various components involved, you can effectively tackle issues as they arise.

First, it’s essential to recognize the signs of wear or malfunction. Common indicators include unusual noises, decreased efficiency, or complete operational failure. Thoroughly inspecting each part will help you pinpoint the source of the problem.

Next, once a faulty element has been identified, sourcing a quality replacement is vital. Researching reputable suppliers can save you time and money in the long run. Ensure that the new component meets the required specifications to maintain functionality.

Finally, installation should be approached with care. Follow the recommended guidelines for replacing components, and double-check all connections to prevent further issues. A meticulous approach to maintenance can significantly enhance the performance and lifespan of your machinery.

Where to Find Diagrams Online

Locating technical illustrations online can greatly enhance your understanding and repair capabilities. Various resources are available that provide detailed visual aids to assist with assembly, disassembly, and troubleshooting.

Manufacturer Websites: Start by visiting the official websites of the equipment manufacturers. They often offer downloadable resources, including schematics and manuals, tailored for specific models.

Online Forums: Join dedicated online communities and forums where enthusiasts share knowledge and resources. These platforms can be invaluable for finding user-shared diagrams and advice.

Instructional Videos: Platforms like YouTube often feature video tutorials that include visual breakdowns, making complex processes easier to comprehend.

Specialized Retailers: Many retailers that sell equipment may also provide access to manuals and diagrams on their websites, so it’s worth checking their resources as well.

Document Sharing Sites: Websites that focus on document sharing can be a treasure trove for technical illustrations, where users upload manuals and schematics for various machines.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your equipment requires regular attention and care. Implementing a consistent maintenance routine can significantly extend its lifespan and enhance reliability. Here are essential practices that can help you achieve long-lasting efficiency.

Regular Inspections

Conduct frequent assessments to identify any signs of wear or potential issues. Check for leaks, loose connections, and overall cleanliness. Early detection of minor problems can prevent major repairs and ensure smooth operation.

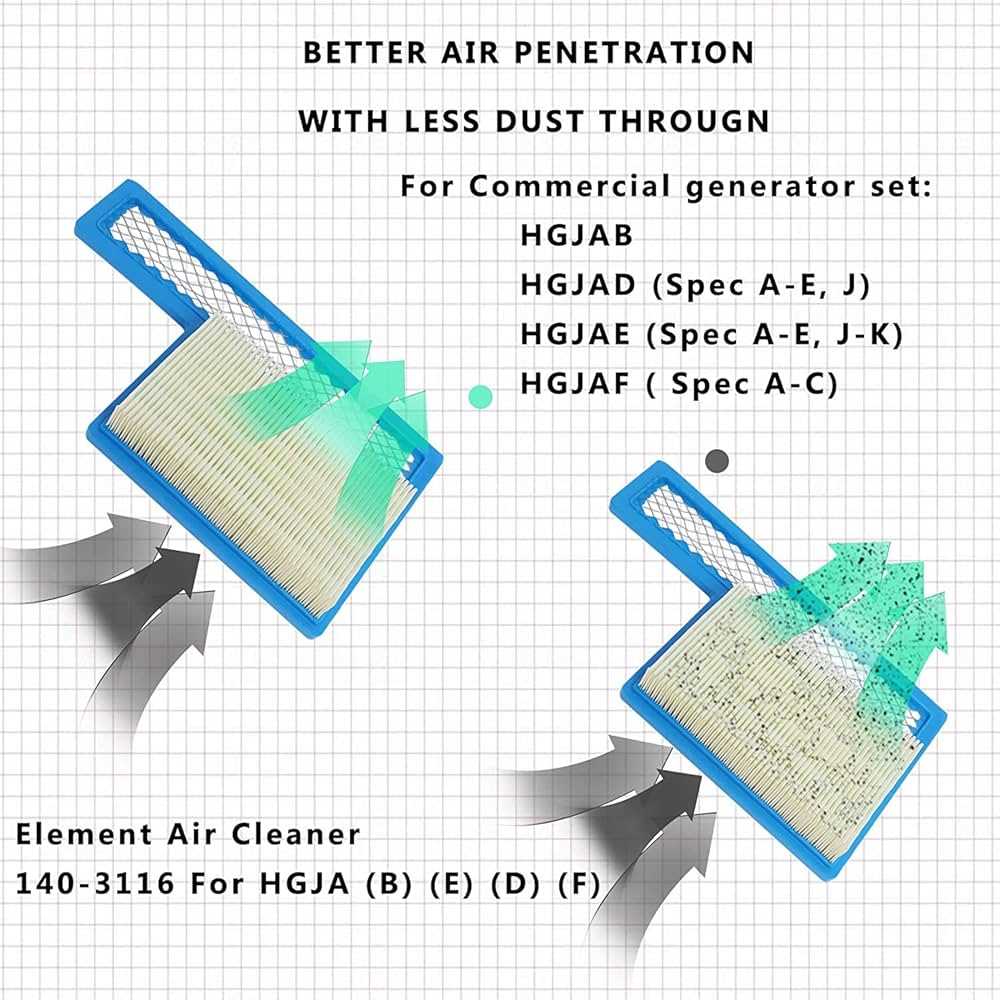

Fluid Changes and Filter Replacements

Changing fluids and replacing filters at recommended intervals is crucial. Clean fluids promote efficient functioning, while fresh filters prevent contaminants from causing damage. Adhering to this schedule is vital for maintaining peak performance.

Tools Needed for Repairs

Successful maintenance and troubleshooting require a set of essential instruments. Having the right equipment ensures that tasks are performed efficiently and safely, allowing for effective resolution of issues.

Essential Tools

Below is a list of key instruments that are crucial for carrying out repairs:

| Tool | Purpose |

|---|---|

| Wrench Set | For loosening and tightening fasteners. |

| Screwdriver Set | For adjusting and removing screws. |

| Pliers | For gripping and twisting materials. |

| Socket Set | For accessing tight spaces with nuts and bolts. |

| Multimeter | For measuring voltage, current, and resistance. |

Additional Accessories

In addition to the basic tools, a few accessories can enhance repair efficiency:

| Accessory | Function |

|---|---|

| Flashlight | To illuminate dark areas during repairs. |

| Work Gloves | To protect hands while working. |

| Safety Goggles | To shield eyes from debris. |

Understanding Electrical Systems

Grasping the intricacies of electrical frameworks is essential for both maintenance and troubleshooting. These systems operate through a series of interconnected components that work together to produce and manage power efficiently. Familiarity with these elements can enhance comprehension of their roles and functions.

Key Components of Electrical Frameworks

Every electrical system comprises several critical components, each contributing to its overall functionality. Understanding these parts is crucial for effective management and repair.

| Component | Function |

|---|---|

| Battery | Stores electrical energy for startup and operation. |

| Alternator | Converts mechanical energy into electrical energy. |

| Control Panel | Allows for monitoring and control of the electrical system. |

Importance of Understanding

A solid grasp of electrical systems empowers users to diagnose issues effectively, perform routine maintenance, and optimize performance. This knowledge ultimately enhances reliability and longevity, ensuring the system operates at its best.

Safety Precautions During Repairs

Ensuring safety while performing maintenance and repairs is crucial to preventing accidents and injuries. Proper precautions not only protect the individual carrying out the work but also preserve the integrity of the equipment being serviced. Familiarizing oneself with essential safety guidelines is the first step toward a secure working environment.

Personal Protective Equipment

Wearing the appropriate personal protective equipment (PPE) is fundamental. This includes gloves, safety goggles, and ear protection if necessary. Such gear minimizes exposure to hazardous materials and reduces the risk of injury from sharp objects or loud noises.

Work Environment Considerations

Before starting any task, ensure the workspace is clean and organized. Remove any unnecessary tools and debris that could lead to tripping hazards. Additionally, ensure adequate ventilation, especially when working with substances that emit fumes. Proper lighting is also essential to see all components clearly and avoid mistakes during repairs.

Upgrading Generator Parts

Enhancing the components of your power unit can significantly improve its efficiency and longevity. By selecting high-quality replacements, users can achieve better performance and reliability in various applications.

Consider the following benefits of upgrading your unit’s components:

- Increased efficiency

- Improved fuel economy

- Enhanced durability

- Better operational stability

When selecting new elements, keep these tips in mind:

- Research compatibility with existing systems.

- Choose reputable manufacturers.

- Evaluate customer reviews and ratings.

- Consider the ultimate performance goals you wish to achieve.

Investing in quality upgrades not only enhances functionality but also contributes to the overall safety and effectiveness of your machinery.

Manufacturer Support and Resources

Access to comprehensive support and resources is essential for ensuring the optimal performance and longevity of any mechanical equipment. Reliable assistance from the manufacturer can greatly enhance user experience and provide necessary guidance for troubleshooting and maintenance.

Available Support Channels

- Customer Service: Reach out via phone or email for direct assistance from knowledgeable representatives.

- Online Resources: Explore the manufacturer’s website for detailed manuals, troubleshooting guides, and FAQs.

- Community Forums: Engage with other users to share experiences, tips, and solutions to common issues.

Documentation and Technical Information

- User Manuals: Access detailed instructions for setup, operation, and maintenance.

- Technical Bulletins: Stay informed about updates, recalls, and enhancements to your equipment.

- Service Literature: Find schematics and service instructions for repairs and replacement of components.

Utilizing these resources effectively can ensure that users remain informed and equipped to handle any challenges they may encounter, thereby maximizing efficiency and satisfaction with their equipment.