Understanding Onan Generator Parts Diagrams for Better Maintenance

In the realm of machinery maintenance, having a clear visual representation of components is essential for effective troubleshooting and repair. These illustrations serve as invaluable tools for both professionals and enthusiasts alike, offering insights into the intricate relationships between various elements. By comprehending these visuals, one can navigate the complexities of mechanical systems with greater ease.

Moreover, detailed schematics can simplify the process of identifying specific elements within a unit. They provide a roadmap that can guide individuals in recognizing how different parts interact and function together. This understanding not only enhances the efficiency of repairs but also fosters a deeper appreciation for the engineering behind the machinery.

Furthermore, accessing accurate and comprehensive visuals is crucial for anyone engaged in maintenance or restoration tasks. With the right illustrations at hand, users can avoid common pitfalls and make informed decisions, ensuring that their equipment remains in optimal condition. Such resources empower users to tackle challenges confidently, ultimately leading to improved performance and longevity of their machines.

Understanding Onan Generator Components

Grasping the intricacies of a power supply unit’s elements is essential for effective maintenance and troubleshooting. Familiarity with each component’s function can enhance performance and longevity.

Key elements include:

- Engine: The heart of the system, responsible for converting fuel into mechanical energy.

- Alternator: Transforms mechanical energy into electrical energy, crucial for output stability.

- Control Panel: Provides user interface for monitoring and managing the unit’s operations.

- Fuel System: Ensures a steady supply of energy source, affecting overall efficiency.

- Cooling System: Maintains optimal operating temperature, preventing overheating.

By delving into each of these components, users can achieve a deeper understanding and ultimately ensure reliable functionality.

Importance of Accurate Diagrams

Precision in technical illustrations is crucial for effective maintenance and repair. Accurate representations serve as essential references, guiding users through complex procedures and ensuring that every component is properly identified and utilized. Without such clarity, the risk of errors increases, potentially leading to equipment malfunction or safety hazards.

Enhanced Understanding

Clear illustrations foster a deeper comprehension of the system’s layout and functionality. When users can easily identify elements and their relationships, they become more confident in executing tasks. This understanding not only improves efficiency but also enhances the overall experience of working with the machinery.

Time and Cost Efficiency

Having reliable references can significantly reduce downtime. When technicians can quickly locate the necessary components and follow accurate instructions, repairs and maintenance are completed more swiftly. This efficiency translates to lower operational costs and minimizes the impact on productivity.

In summary, precise illustrations are vital for effective operation and upkeep. They empower users to work confidently and accurately, ultimately contributing to the longevity and reliability of the equipment.

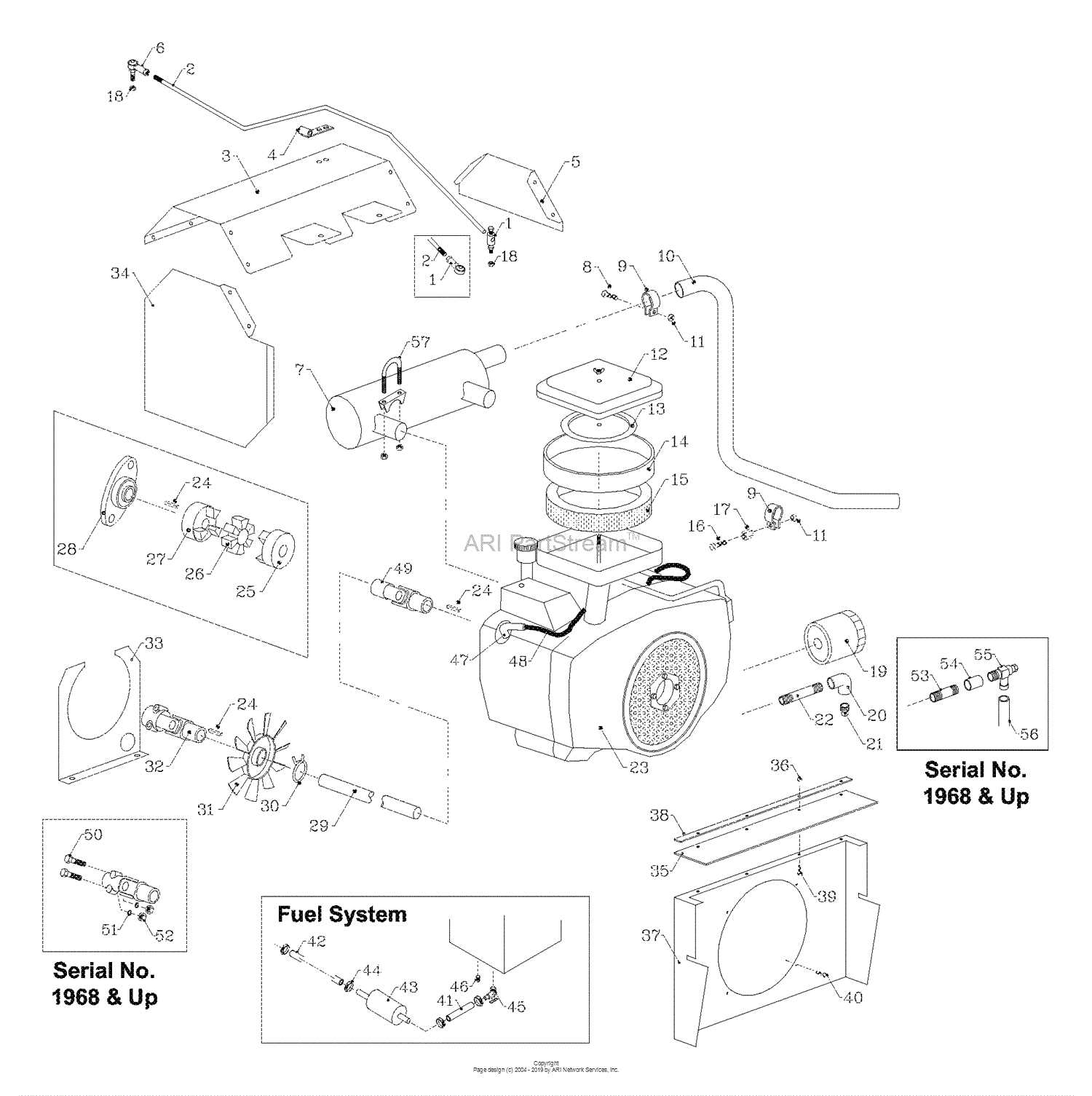

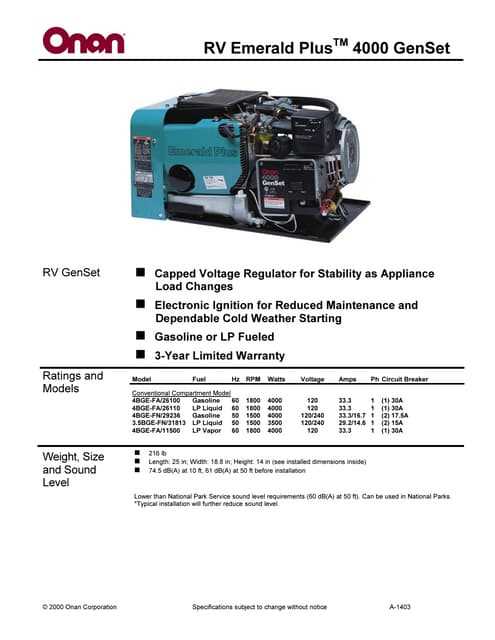

Common Onan Generator Models Overview

This section provides an overview of various popular power-producing units, highlighting their features, applications, and unique specifications. Understanding these models can assist users in making informed decisions regarding maintenance and operational needs.

One of the most widely recognized types is the compact unit, often favored for its reliability and ease of use. Designed for portability, these models are ideal for recreational activities and small-scale applications. Their lightweight construction and efficient fuel consumption make them a preferred choice for outdoor enthusiasts.

Another notable type includes larger, stationary systems that cater to industrial requirements. These units typically feature robust build quality and enhanced power output, making them suitable for commercial applications. With advanced control systems, they offer excellent performance in demanding environments.

Additionally, there are specialized variants designed for specific uses, such as residential backup solutions. These models provide a seamless transition during power outages, ensuring continuity of essential services. Equipped with user-friendly interfaces, they allow homeowners to operate them with minimal effort.

In summary, familiarity with these diverse power-producing models enhances users’ ability to select the right unit for their needs, ensuring optimal performance and longevity.

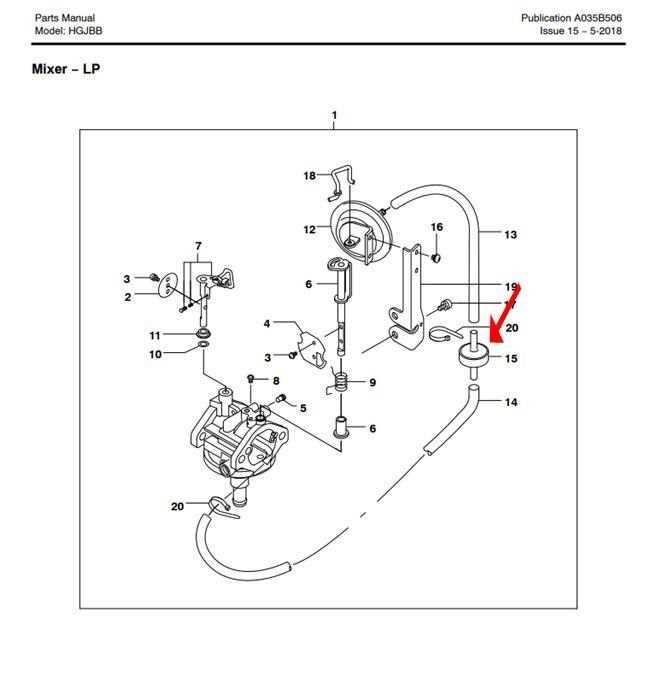

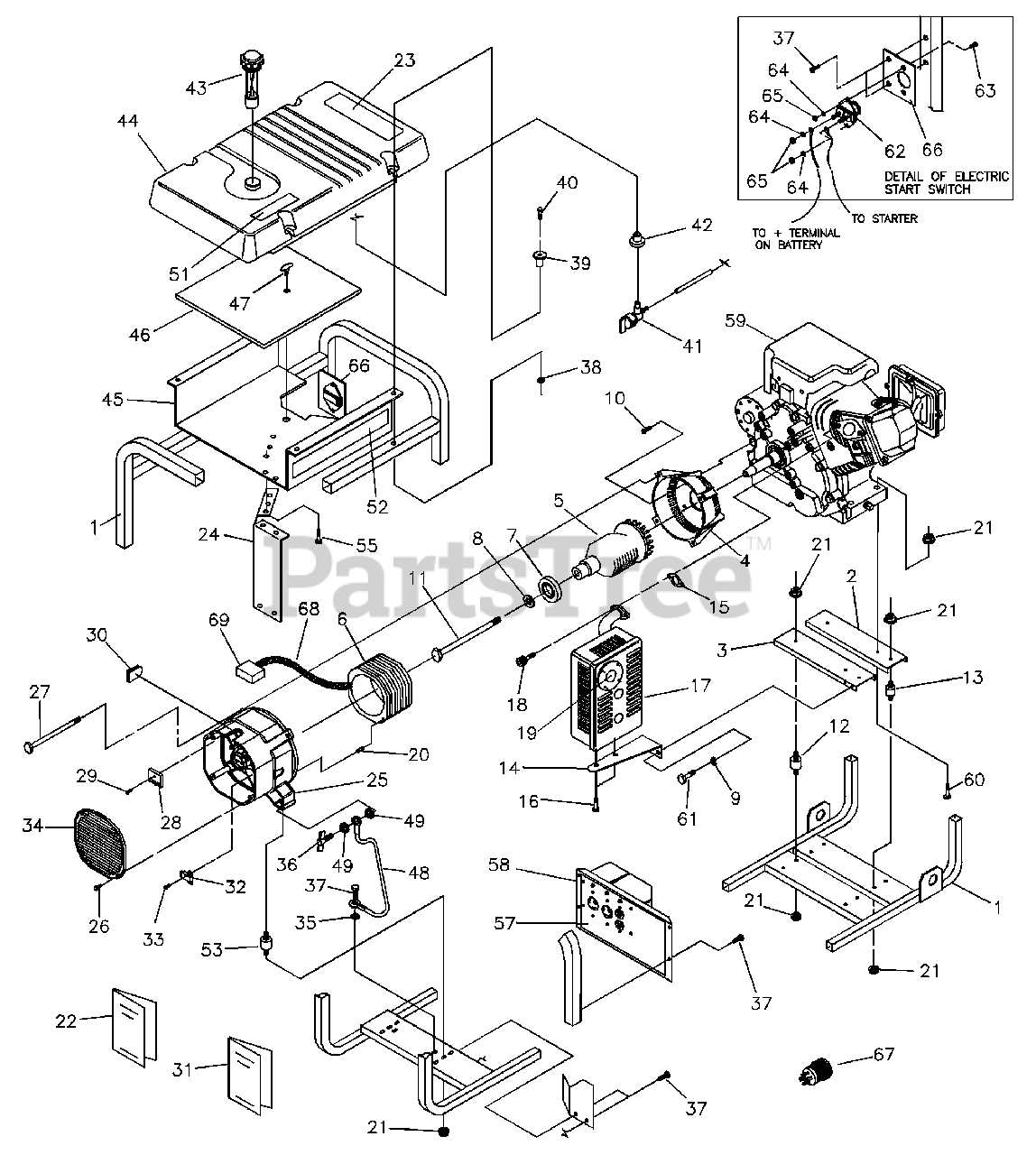

How to Read Parts Diagrams

Understanding visual schematics is crucial for efficient maintenance and repair tasks. These representations provide a clear overview of components, allowing users to identify and locate necessary items quickly.

To effectively interpret these visuals, follow these steps:

- Familiarize Yourself with Symbols: Each illustration uses specific symbols to represent various elements. Knowing what these symbols signify is essential.

- Identify Sections: Diagrams are often divided into sections that correspond to different areas of the equipment. Recognizing these can help streamline your search.

- Check Numbering: Look for numerical identifiers that link components to corresponding lists, which detail specifications and descriptions.

- Note Connections: Pay attention to lines and arrows indicating how parts are connected or interact with each other.

- Consult Reference Materials: Utilize manuals or guides that accompany these illustrations for additional context and information.

By mastering these techniques, you can delve deeper into your understanding of the machinery, leading to more efficient troubleshooting and repairs.

Identifying Key Parts in Diagrams

Understanding the essential components in visual representations is crucial for effective maintenance and troubleshooting. By recognizing these elements, one can gain insight into the functionality and operation of the equipment.

Common Symbols: Familiarity with standard symbols used in schematics allows for quicker interpretation. Each symbol often represents a specific function or component.

Labeling: Pay attention to labels that provide vital information about each element. These annotations can clarify the role and relationship between various components.

Connections: Identifying how components are interconnected is key to understanding the flow of energy or information. Arrows and lines often indicate pathways that require careful examination.

In conclusion, a detailed analysis of these visuals can enhance comprehension and ultimately lead to more effective operational practices.

Replacement Parts for Onan Generators

Ensuring optimal performance of your power equipment often requires the timely substitution of specific components. Identifying and acquiring these essential elements is crucial for maintaining functionality and reliability. Whether for routine maintenance or unexpected repairs, understanding available options can greatly enhance your experience.

Quality substitutes play a vital role in the longevity and efficiency of your machinery. Selecting the right items not only improves performance but also minimizes potential downtime. Various suppliers offer a range of choices, from OEM alternatives to aftermarket solutions, catering to different needs and budgets.

When seeking replacements, it is important to reference reliable sources for accurate information regarding compatibility and specifications. Many vendors provide comprehensive catalogs and support to help you navigate your options. Ensuring you have the correct details can save time and prevent unnecessary complications.

Investing in high-quality substitutes ultimately supports better performance and extends the lifespan of your equipment. By prioritizing reliable components, you can rest assured that your machinery will continue to operate effectively and efficiently for years to come.

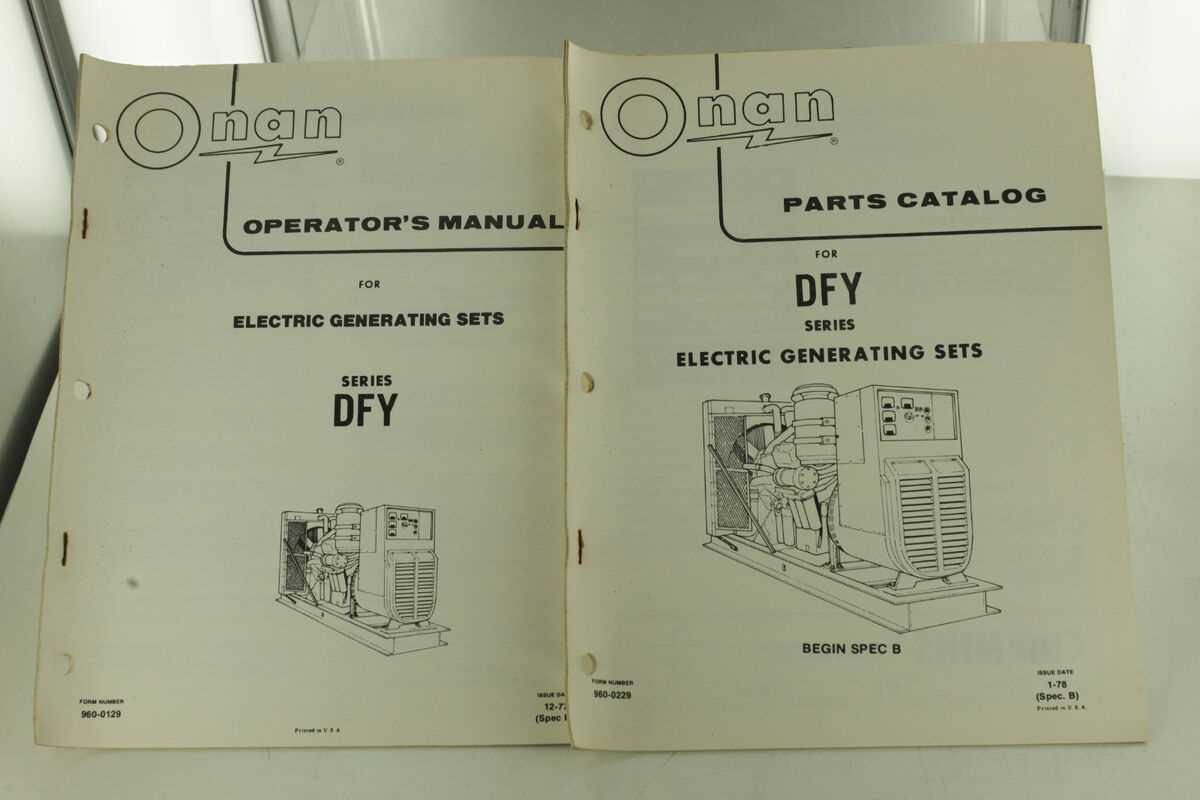

Where to Find Diagram Resources

Finding reliable resources for technical illustrations can significantly enhance your understanding and repair capabilities. Various platforms offer comprehensive visual aids that cater to different needs, making the search for these resources essential for maintenance and troubleshooting.

- Manufacturer Websites: Many original equipment producers provide downloadable manuals and schematics directly on their official sites.

- Online Retailers: E-commerce platforms often feature product listings that include links to technical drawings and user guides.

- Forums and Community Groups: Online communities and specialized forums can be invaluable, as users frequently share documents and images related to repairs.

In addition to the above, consider exploring the following resources:

- Social Media Groups: Joining dedicated groups on platforms like Facebook can connect you with enthusiasts who share similar interests.

- YouTube Channels: Many content creators produce detailed video tutorials that include visual breakdowns and component explanations.

- Technical Libraries: Local or online libraries may offer access to manuals and reference materials that aren’t readily available elsewhere.

By leveraging these various sources, you can gain access to valuable illustrations that aid in your understanding and repair projects.

Troubleshooting with Diagrams

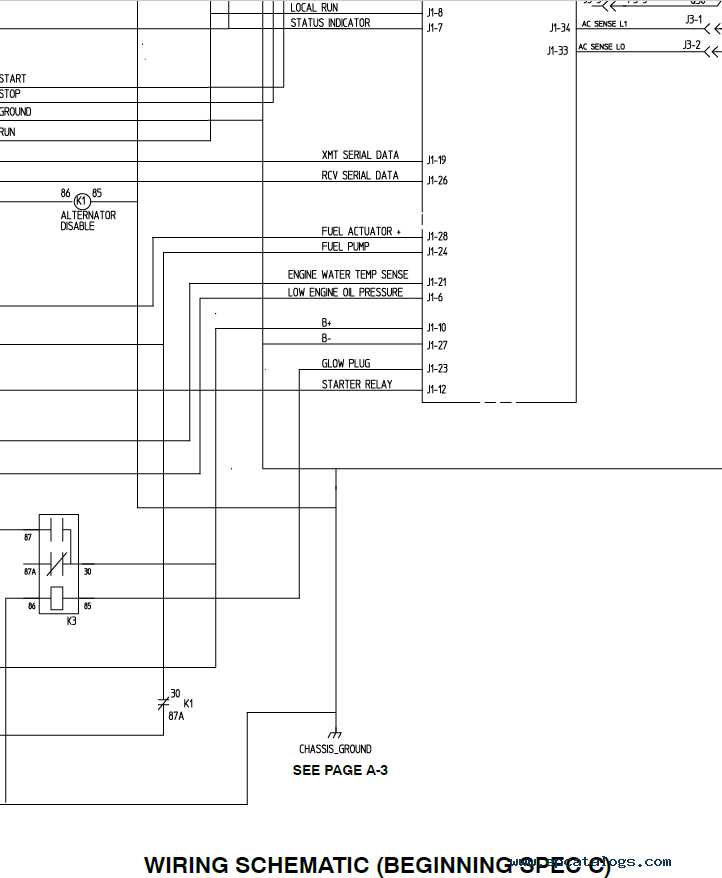

Effective problem-solving often relies on visual representations that outline components and their interconnections. These visuals serve as invaluable tools for identifying issues, understanding functionalities, and determining necessary repairs. By following these structured illustrations, technicians can efficiently navigate complex systems, leading to quicker resolutions.

When encountering malfunctions, a systematic approach is essential. Utilizing visual aids can clarify the relationships between various elements, helping to pinpoint the root cause of a failure. Below is a table summarizing common issues and their corresponding visual aids that can assist in diagnosing the problem.

| Issue | Description | Visual Aid |

|---|---|---|

| Overheating | Excessive temperature may indicate a cooling system failure. | Cooling System Layout |

| Noise | Unusual sounds can signal mechanical wear or misalignment. | Mechanical Components Overview |

| Power Fluctuations | Inconsistent output may be due to electrical issues. | Electrical Circuit Map |

| Starting Problems | Failure to start can stem from fuel or ignition system issues. | Ignition System Breakdown |

By integrating these visual tools into the troubleshooting process, individuals can enhance their understanding and efficiency, ultimately leading to more effective maintenance and repair efforts.

Comparing Diagrams Across Models

When examining technical schematics across various designs, it becomes essential to identify similarities and differences that may impact functionality and maintenance. Understanding these variations can lead to better troubleshooting and more effective repairs.

Key aspects to consider when comparing schematics include:

- Component Layout: Each model may have distinct arrangements of essential elements, affecting accessibility and serviceability.

- Wiring Configurations: Differences in wiring can influence performance and efficiency, making it crucial to understand how each system is connected.

- Specifications: Variations in specifications might indicate differing capabilities or requirements for operation, impacting overall compatibility.

To effectively analyze these schematics, follow these steps:

- Gather all relevant schematics for the models in question.

- Identify the key components and their functions in each schematic.

- Note the variations in layout and connections, documenting any critical differences.

- Assess how these differences could affect performance or repair procedures.

By conducting a thorough comparison, one can gain valuable insights that enhance understanding and lead to more informed decisions regarding maintenance and upgrades.

Maintenance Tips Using Diagrams

Understanding the intricacies of machinery is crucial for ensuring optimal performance and longevity. Visual representations can significantly enhance comprehension, making it easier to follow procedures and identify components. Regular upkeep is essential, and leveraging these visuals can lead to more efficient maintenance practices.

Regular Inspection

Routine checks are vital for spotting potential issues early. Use visual aids to locate specific elements that require attention, such as fluid levels and filter conditions. This proactive approach can prevent larger problems down the line.

Step-by-Step Guidance

Utilizing illustrations allows for clearer understanding of complex procedures. Follow the outlined steps carefully to ensure each task is completed correctly. This method not only simplifies the process but also minimizes the risk of errors.

Frequently Asked Questions About Parts

This section aims to address common inquiries related to components and their functionalities. Understanding these elements can greatly enhance the user experience and ensure proper maintenance.

| Question | Answer |

|---|---|

| What should I do if a component fails? | If a unit fails, inspect for any visible damage and consult the manual for troubleshooting steps. Replacement might be necessary. |

| How can I identify the correct component for my model? | Refer to the model number and specifications in the user manual or visit the manufacturer’s website for guidance. |

| Are there any maintenance tips to prolong component life? | Regular cleaning, checking connections, and following the maintenance schedule can help extend the lifespan of your components. |

| Where can I find replacement components? | Authorized dealers, online retailers, and specialized stores typically offer a variety of replacement options. |

| What warranty options are available? | Most components come with a warranty that covers defects. Be sure to check the specific terms provided at the time of purchase. |

Ultimate Guide to Ordering Parts

This section aims to simplify the process of acquiring essential components for your machinery. Understanding the steps involved will enhance your efficiency and ensure you receive the correct items.

Here are key steps to consider:

- Identify Your Needs: Clearly outline what components you require.

- Consult Manuals: Refer to documentation for specifications and compatibility.

- Research Suppliers: Look for reputable vendors with positive reviews.

- Check Availability: Ensure the items are in stock before placing an order.

- Compare Prices: Evaluate costs from different sources to get the best deal.

- Review Return Policies: Familiarize yourself with the terms in case of issues.

By following these guidelines, you can confidently navigate the procurement process and secure the components you need efficiently.