Understanding the Predator 3500 Generator Parts Diagram

When it comes to ensuring reliable energy output, familiarity with the internal components of your machine is essential. A well-designed energy source relies on various interconnected elements that work in harmony. Grasping the layout and functionality of these components can significantly enhance your experience and troubleshooting capabilities.

Visual aids can serve as a valuable resource for both seasoned users and newcomers alike. By examining a detailed layout, one can gain insights into the intricate relationships between different parts, aiding in maintenance and repair. Understanding each section not only promotes efficiency but also empowers users to take charge of their devices.

Moreover, having a comprehensive view of the system can prevent potential issues down the line. By recognizing how each element interacts, you can identify wear and tear before it escalates into a significant problem. This proactive approach ensures that your energy solution remains dependable and effective over time.

Understanding Predator 3500 Generator Parts

This section provides an overview of the essential components that make up a portable energy source, focusing on their functions and interrelations. Each element plays a crucial role in ensuring efficient operation and reliability during use, making it important to comprehend their significance.

Key Components

- Engine: The heart of the unit, responsible for generating power through combustion.

- Alternator: Converts mechanical energy into electrical energy, facilitating the output of electricity.

- Fuel System: Includes the tank and lines that supply fuel to the engine for combustion.

- Cooling System: Maintains optimal operating temperature to prevent overheating.

- Control Panel: Provides user interface for monitoring output and controlling operation.

Maintenance Tips

- Regularly check and change the oil to ensure engine longevity.

- Inspect the air filter to prevent dust and debris from entering the engine.

- Examine fuel lines for leaks or damage, ensuring a safe operation.

- Clean the exterior to prevent rust and maintain visibility of indicators.

- Store in a dry, sheltered location to prolong lifespan.

Key Components of the Generator

Understanding the essential elements of an electrical power source is crucial for efficient operation and maintenance. Each part plays a significant role in ensuring the reliability and performance of the unit. Here, we outline the vital components that contribute to the functionality and efficiency of this equipment.

| Component | Function |

|---|---|

| Engine | Converts fuel into mechanical energy to generate electricity. |

| Alternator | Transforms mechanical energy into electrical energy. |

| Fuel System | Stores and delivers fuel to the engine for combustion. |

| Cooling System | Maintains optimal operating temperature to prevent overheating. |

| Control Panel | Provides user interface for monitoring and controlling the unit. |

| Chassis | Houses and protects internal components while providing mobility. |

Importance of the Parts Diagram

Understanding the components of any machinery is crucial for effective maintenance and repair. A visual representation of these elements not only aids in identification but also enhances the efficiency of troubleshooting processes. Familiarity with each part ensures that users can address issues promptly and correctly, minimizing downtime and maximizing functionality.

Having access to a visual guide allows users to easily locate and understand the relationship between various components. This knowledge is essential for both amateur and experienced users alike. It fosters confidence in handling repairs and can significantly reduce the likelihood of errors during reassembly or replacement tasks.

| Benefits | Description |

|---|---|

| Enhanced Understanding | Clarifies the roles and functions of each component. |

| Efficient Troubleshooting | Facilitates quick identification of issues. |

| Improved Safety | Reduces risks associated with improper handling. |

| Time Savings | Streamlines repair processes, leading to quicker resolutions. |

In conclusion, utilizing a visual reference for machinery components is indispensable for ensuring proper maintenance and operational efficiency. It empowers users to engage with their equipment knowledgeably and effectively, ultimately leading to better performance and longevity.

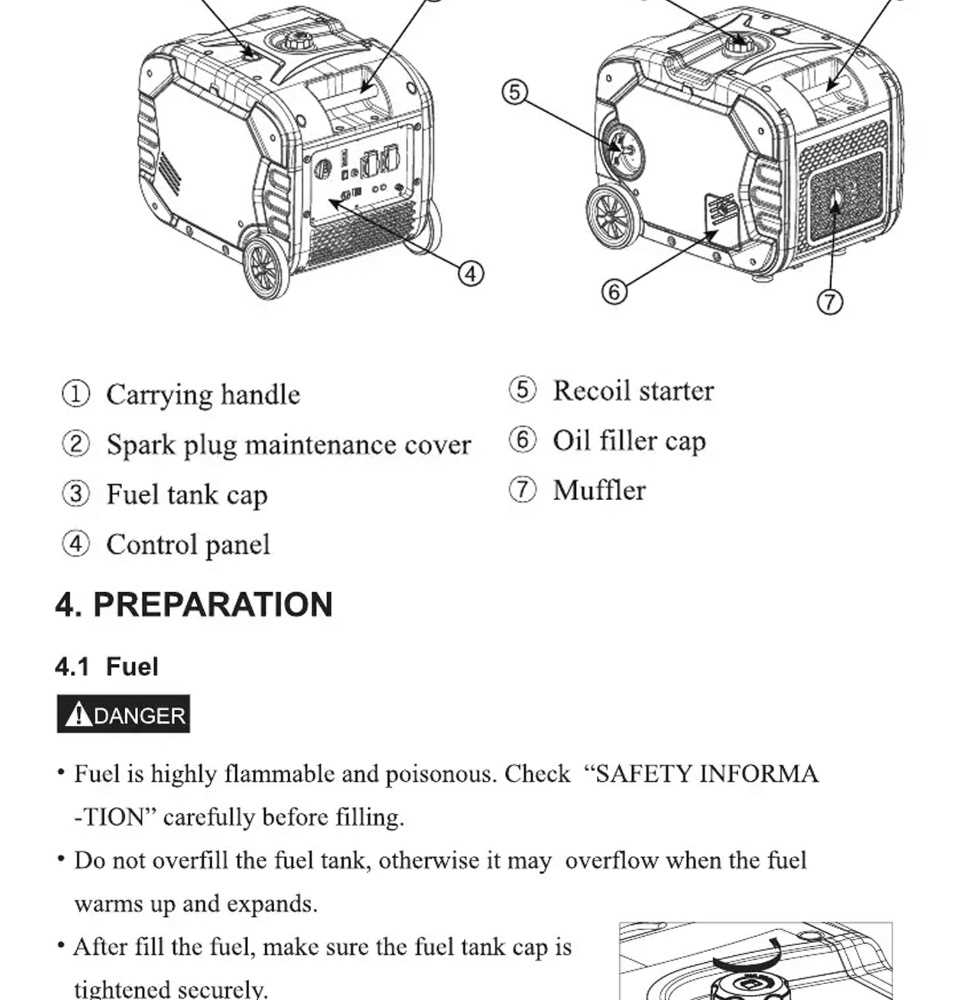

How to Read the Diagram

Understanding a schematic representation can significantly enhance your ability to maintain and troubleshoot machinery. These visual guides provide a comprehensive overview of components and their interconnections, making it easier to identify parts and their functions.

To begin, familiarize yourself with the symbols used in the illustration. Each icon represents a specific element, such as a power source, switch, or connector. Taking the time to learn these symbols will help you interpret the information more efficiently.

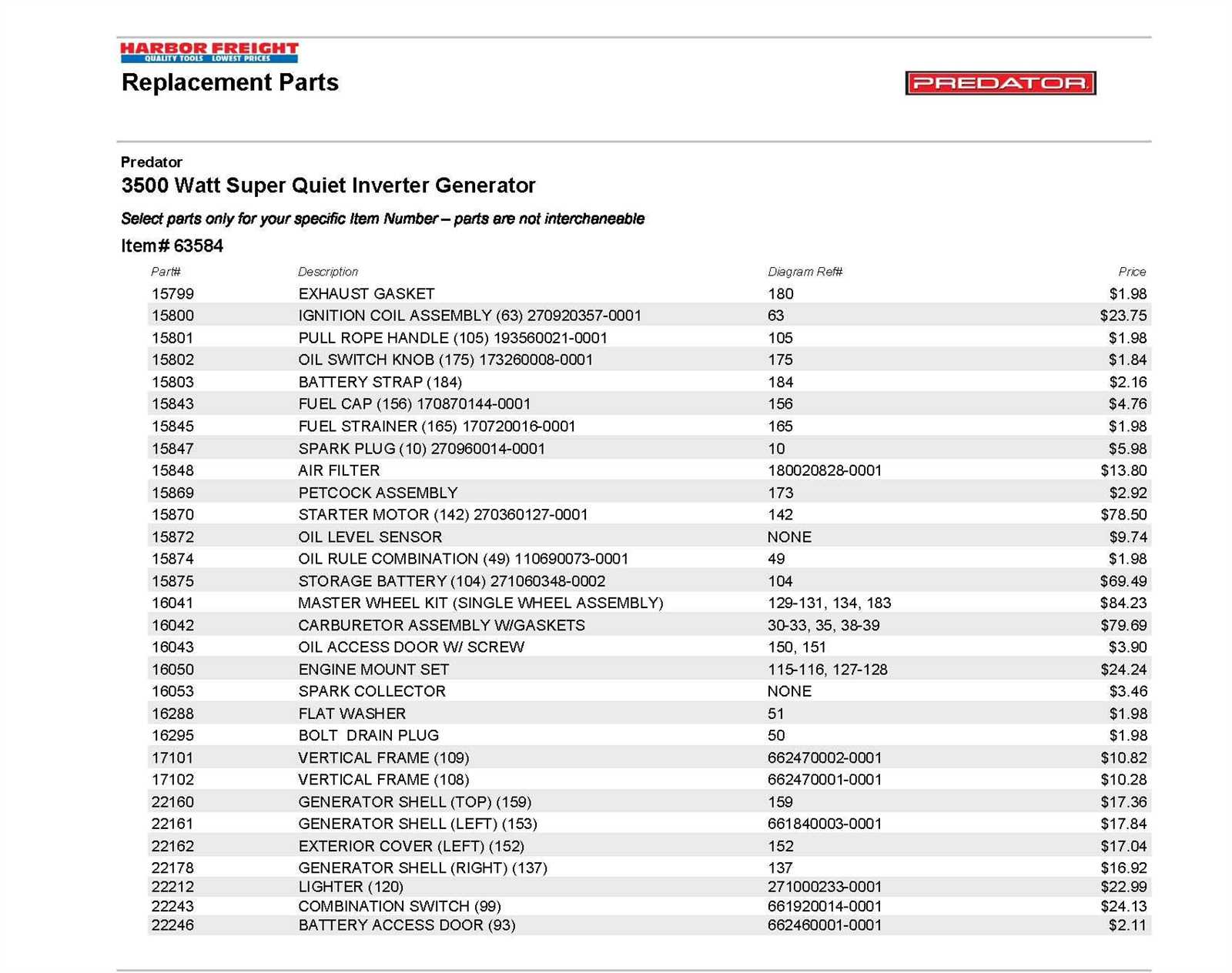

Next, pay attention to the labels and numbers accompanying each component. They often indicate specifications, such as voltage ratings or part numbers, which are crucial for replacements or repairs. Cross-referencing these labels with a parts list can help you find the exact items needed for your project.

Additionally, observe the connections between the elements. Lines typically denote wires or pathways, showing how components interact with one another. Understanding these connections can prevent mistakes during assembly or disassembly.

Finally, practice makes perfect. The more you work with these visual representations, the more intuitive reading them will become. Soon, you’ll be able to navigate through the intricacies with ease, ensuring effective maintenance and problem-solving.

Common Issues with Generator Parts

Understanding the frequent challenges associated with components of portable power systems is essential for maintaining optimal performance. Many users encounter issues that can hinder functionality and efficiency, often resulting from wear and tear, improper maintenance, or environmental factors. Recognizing these common problems allows for timely interventions, ensuring reliability when it’s most needed.

Frequent Problems

Some of the typical challenges faced include fuel system clogs, electrical connection failures, and wear on mechanical elements. Each of these issues can disrupt operation and lead to more significant complications if not addressed promptly.

Maintenance and Prevention

Regular maintenance can mitigate many of these problems. Cleaning, inspections, and timely replacements are critical to extending the lifespan of components and ensuring seamless operation.

| Issue | Symptoms | Solutions |

|---|---|---|

| Fuel Clogs | Difficulty starting, sputtering | Clean fuel lines, replace filter |

| Electrical Failures | Power loss, flickering lights | Inspect connections, check wiring |

| Mechanical Wear | Unusual noises, reduced output | Lubricate parts, replace worn components |

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended lifespan of your equipment. Regular attention to various components not only enhances performance but also prevents potential breakdowns. Implementing a few simple maintenance practices can make a significant difference in durability and efficiency.

Regular Inspections

Conducting routine checks can help identify issues before they escalate. Consider the following:

- Examine connections for signs of wear or corrosion.

- Check for leaks around seals and hoses.

- Ensure air filters are clean and free from debris.

Cleaning and Lubrication

Keeping components clean is vital for smooth operation. Regularly lubricate moving parts to reduce friction and wear:

- Use appropriate cleaning agents for surfaces.

- Apply suitable lubricants to joints and bearings.

- Remove dust and dirt from cooling vents to prevent overheating.

By adhering to these practices, you can maximize efficiency and prolong the life of your equipment.

Where to Find Replacement Parts

When your equipment needs a refresh, locating the right components is essential for optimal performance. There are several avenues you can explore to obtain the necessary items, ensuring your device remains in peak condition.

Online Retailers

Many online platforms specialize in a wide variety of machinery accessories. These websites often provide detailed descriptions and specifications, making it easier to find what you need. Additionally, they frequently offer competitive pricing and customer reviews to guide your purchasing decisions.

Local Stores

Visiting nearby hardware or specialty shops can also yield favorable results. These establishments often carry a selection of components and can provide personalized advice. Building a relationship with local suppliers can lead to better support and recommendations over time.

| Source | Advantages | Considerations |

|---|---|---|

| Online Retailers | Convenient, wide selection, competitive prices | Shipping times, potential for wrong parts |

| Local Stores | Immediate access, expert advice, support | Limited stock, potentially higher prices |

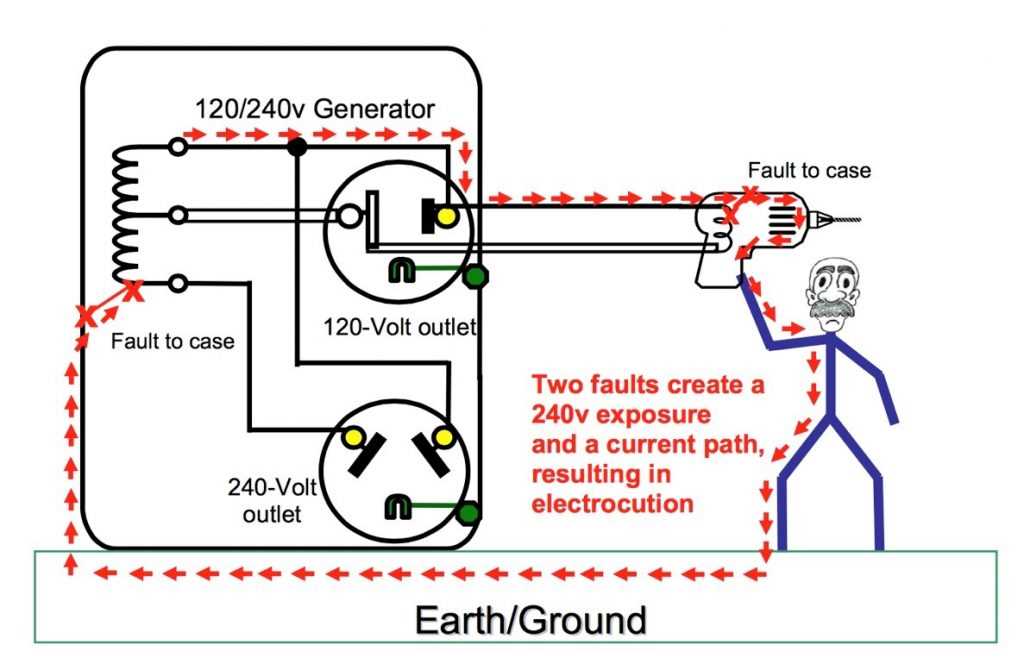

DIY Repairs and Safety Guidelines

Engaging in maintenance and troubleshooting of your equipment can save both time and money. However, it is crucial to approach these tasks with a clear understanding of the potential hazards and necessary precautions. Following proper procedures not only ensures your safety but also enhances the longevity of the device.

Essential Safety Precautions

Before embarking on any repair, always disconnect the power source to prevent accidental activation. Wear appropriate protective gear, such as gloves and goggles, to safeguard against injuries. Additionally, ensure your workspace is well-ventilated and free from clutter to minimize risks.

Basic Repair Techniques

Familiarize yourself with the common issues that can arise and the respective solutions. Start by consulting the user manual for guidance on troubleshooting steps. For example, replacing worn components or tightening loose connections can often resolve performance problems. Utilize the right tools for each task to avoid damaging any parts.

Remember: If you encounter a problem beyond your expertise, it’s wise to seek assistance from a qualified technician to prevent further complications.

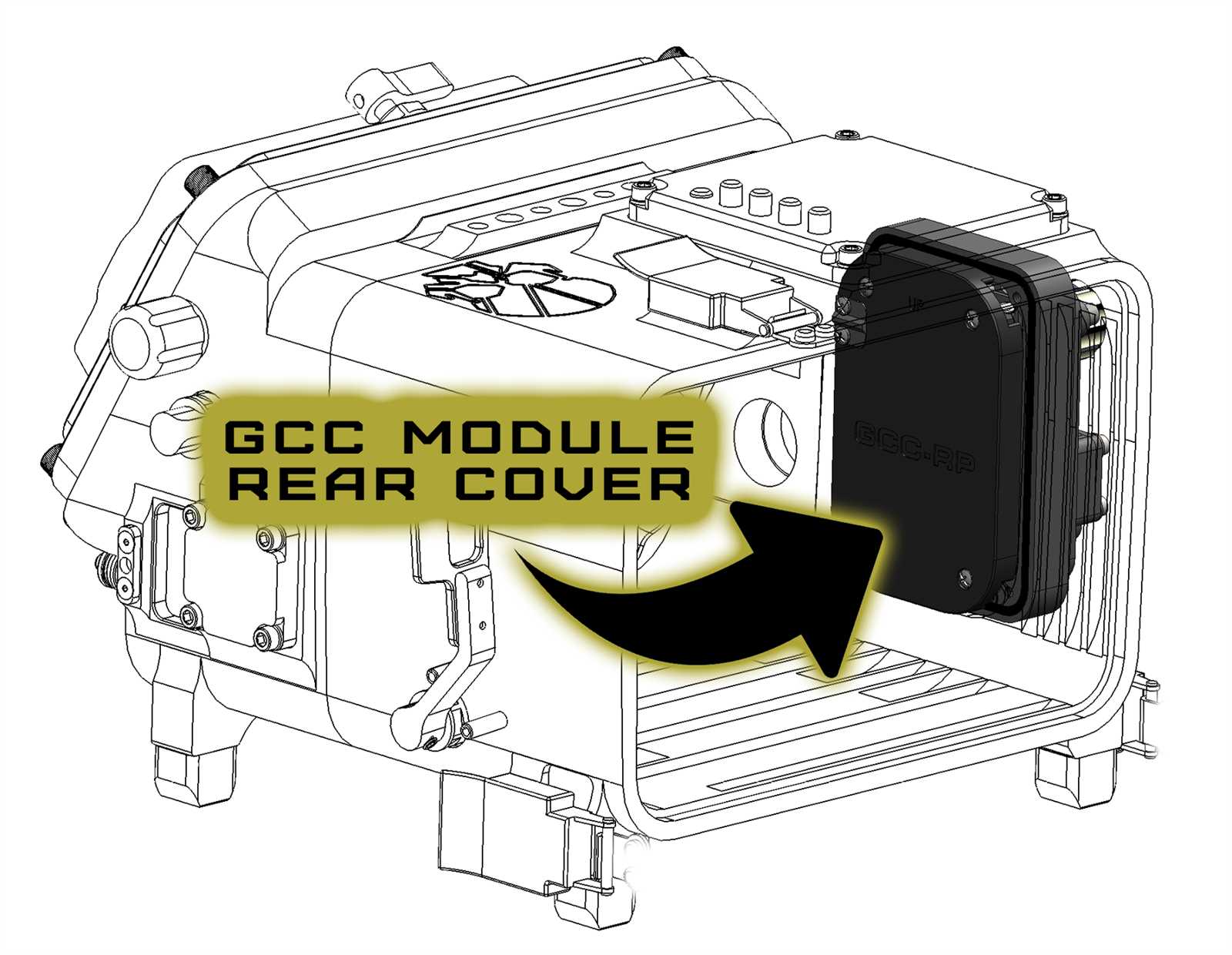

Upgrading Your Generator’s Performance

Enhancing the efficiency of your power supply unit can lead to better reliability and increased output. By focusing on key components and improvements, you can significantly elevate its functionality for various applications.

Here are some strategies to consider for boosting your unit’s performance:

- Regular Maintenance: Ensure all parts are clean and functioning properly. Regular oil changes and air filter replacements can make a substantial difference.

- Fuel Quality: Using high-quality fuel can improve combustion efficiency. Consider using additives to enhance performance.

- Upgrade Components: Look for high-performance alternators or better ignition systems that can provide more power and stability.

Additionally, consider the following enhancements:

- Install a New Muffler: A less restrictive exhaust can improve airflow and overall efficiency.

- Adjust the Carburetor: Fine-tuning the air-fuel mixture can optimize combustion and power output.

- Utilize Eco Mode: If available, this feature can help regulate output based on demand, saving fuel and reducing wear.

By implementing these upgrades, you can maximize the capabilities of your equipment, ensuring it meets your energy needs effectively and efficiently.

Frequently Asked Questions About Parts

This section aims to address common inquiries related to components and their functionalities. Understanding these elements is essential for maintaining optimal performance and ensuring longevity.

What should I consider when replacing components?

When contemplating a replacement, it’s crucial to assess compatibility with your unit. Ensure the specifications match and consider the quality of the replacement to maintain efficiency and safety.

How can I identify the specific component I need?

To accurately identify a required element, refer to the user manual or online resources. Look for model numbers and descriptions, and consider consulting with experts or support services for guidance.

Resources for Further Learning

Exploring the intricacies of mechanical systems can be an enriching experience. A variety of resources are available to enhance your understanding and skills. Whether you’re a novice or an experienced enthusiast, the following materials will aid in your journey of knowledge acquisition.

Books and Manuals

- Technical Handbooks: Comprehensive guides covering the fundamentals and advanced concepts.

- DIY Repair Manuals: Step-by-step instructions for troubleshooting and maintenance.

- Industry Standards: Publications that outline best practices and safety protocols.

Online Resources

- Video Tutorials: Visual aids demonstrating techniques and repairs.

- Forums and Communities: Platforms for sharing experiences, tips, and solutions.

- Manufacturer Websites: Official resources providing updates, specifications, and customer support.