Understanding Ridgid Generator Parts Diagram for Effective Maintenance

In the realm of machinery, comprehending the arrangement and functionality of various elements is crucial for efficient operation and maintenance. Each device consists of multiple sections that work in harmony to deliver performance. A clear visualization of these components aids users in identifying, troubleshooting, and replacing them when necessary.

By exploring the intricate relationships between each section, one can gain insights into how they contribute to the overall efficiency of the system. This understanding not only enhances operational knowledge but also empowers users to perform repairs and enhancements effectively. Recognizing the role of each element within the assembly is key to ensuring longevity and reliability.

Delving into detailed representations allows for a better grasp of the mechanics involved. Such visual aids serve as invaluable tools for technicians and enthusiasts alike, simplifying complex information into accessible formats. Whether for routine checks or significant upgrades, being well-acquainted with these layouts is essential for anyone involved in the maintenance of such equipment.

Understanding Ridgid Generators

This section aims to provide a comprehensive overview of portable power sources designed for various applications, focusing on their components and functionality. These machines are essential for supplying electrical energy in locations where conventional outlets are not available, making them invaluable tools for both professionals and DIY enthusiasts.

Key Features: Most of these devices are equipped with an array of features that enhance their usability and efficiency. From fuel type options to wattage capacity, understanding these aspects can significantly impact your choice and overall performance in diverse scenarios.

Maintenance and Care: Proper upkeep is crucial for longevity. Regular inspections and timely replacements of critical components ensure reliability and optimal operation. Familiarizing oneself with the internal layout can aid in troubleshooting common issues that may arise over time.

Applications: The versatility of these machines allows them to be utilized in various settings, from construction sites to home backyards. Knowing which model suits specific needs can greatly enhance productivity and convenience during power outages or outdoor events.

Conclusion: A deeper understanding of these machines not only assists in selecting the right model but also empowers users to maximize their potential through informed usage and maintenance practices.

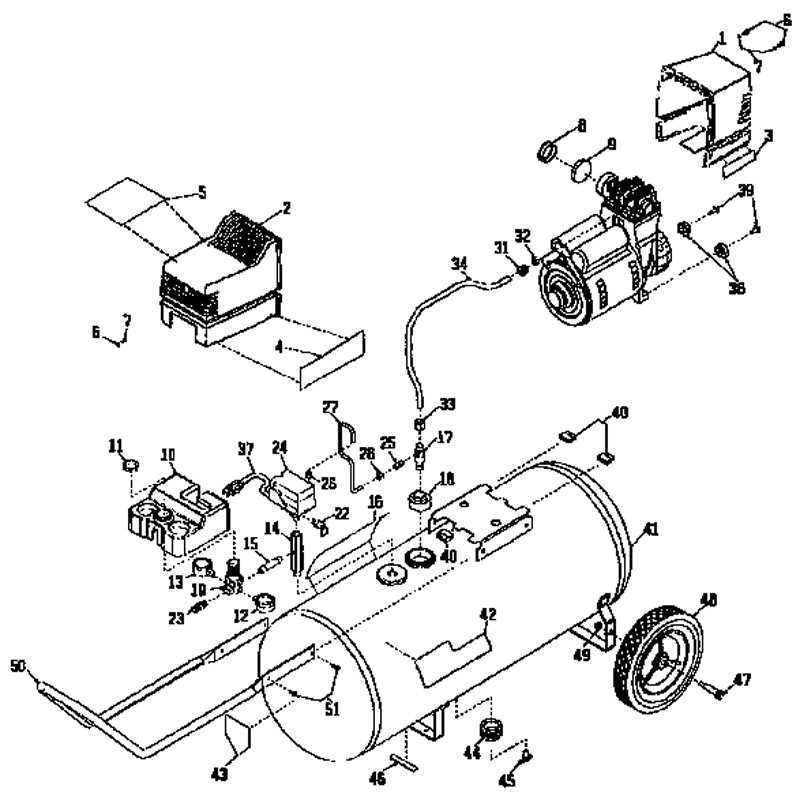

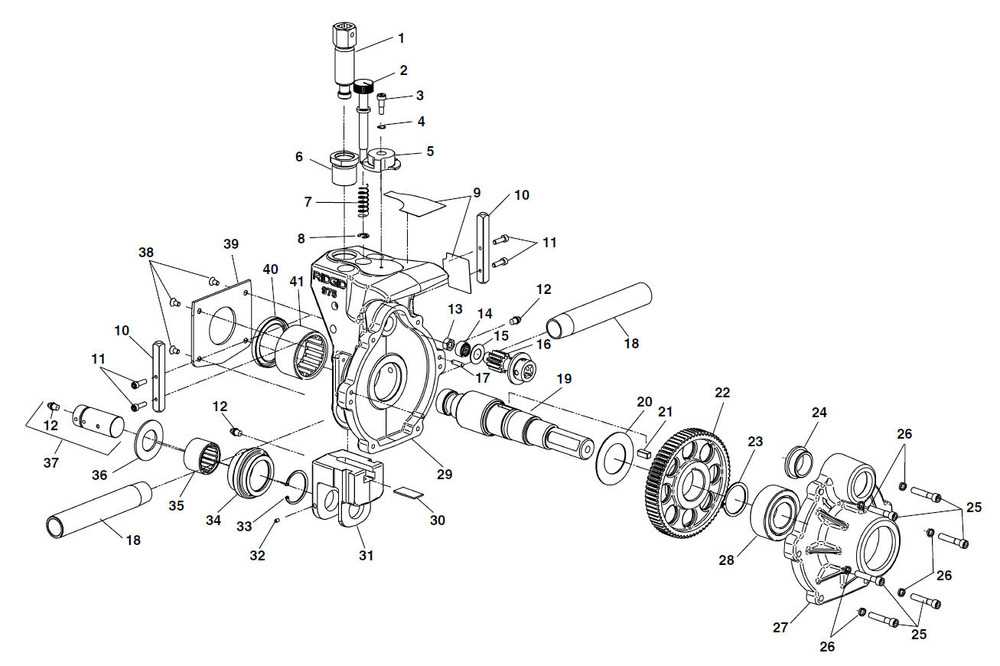

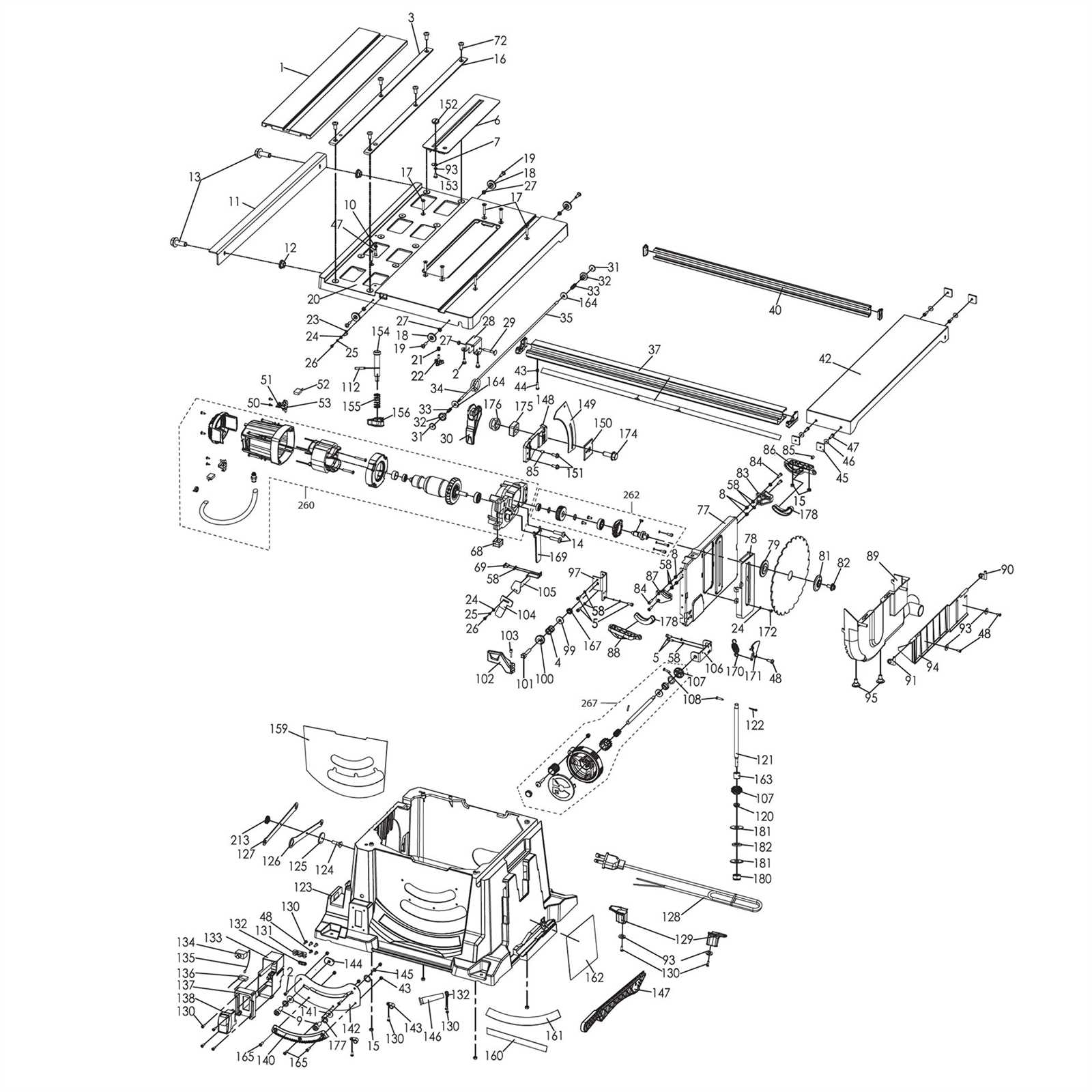

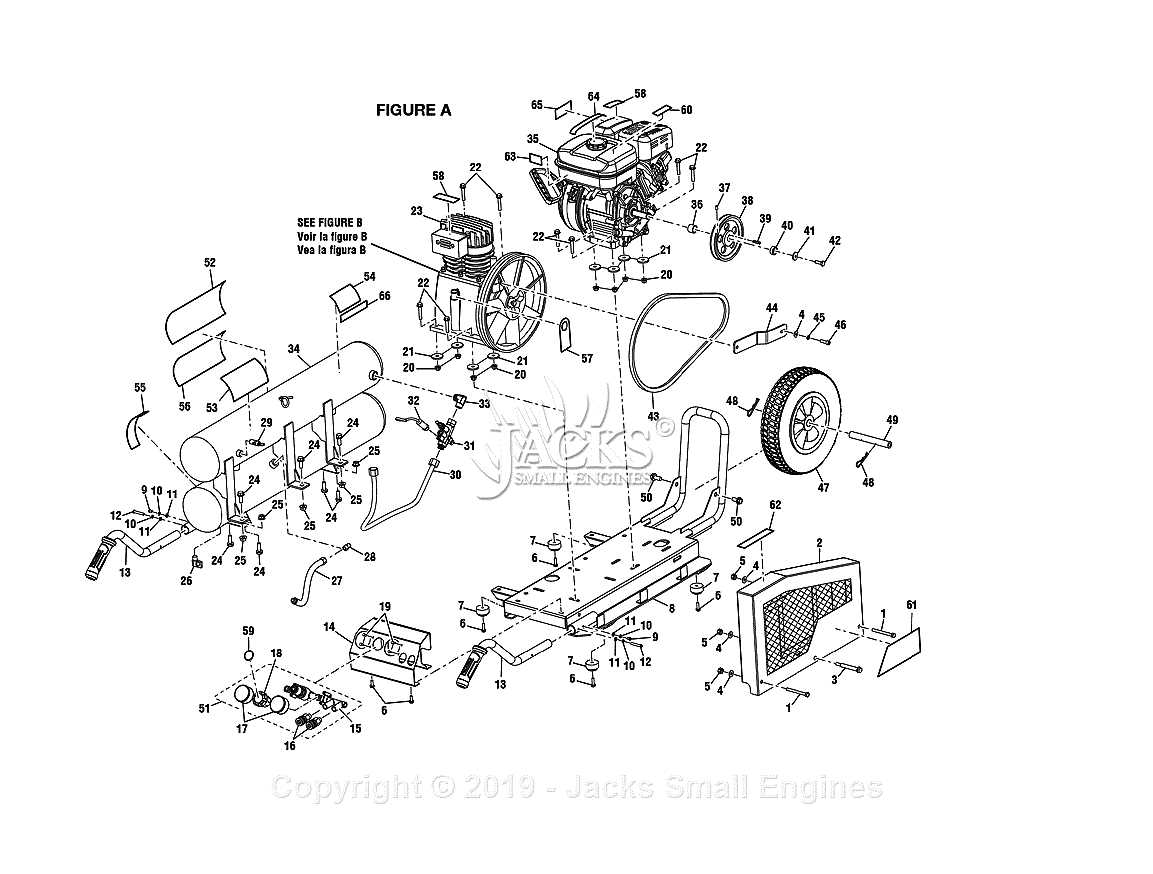

Key Components of Ridgid Generators

Understanding the essential elements of portable power systems is crucial for efficient operation and maintenance. Each component plays a significant role in the overall functionality, ensuring reliable performance when needed most.

Main Elements

- Engine: The heart of the system, responsible for converting fuel into mechanical energy.

- Alternator: Converts mechanical energy into electrical energy, providing the necessary power output.

- Fuel System: Includes the tank, lines, and filters that supply and manage the fuel needed for operation.

- Cooling System: Ensures the engine remains at optimal temperatures to prevent overheating during use.

- Control Panel: Houses the switches and indicators for monitoring and controlling the power output.

Supporting Features

- Chassis: The frame that provides structure and stability to the entire unit.

- Exhaust System: Directs exhaust gases away from the engine and user, improving safety and performance.

- Wheels: Facilitate mobility, allowing for easy transport to different locations.

- Starting Mechanism: Can be manual or electric, enabling the system to start quickly and efficiently.

Importance of Maintenance for Longevity

Regular upkeep is essential for ensuring the extended lifespan of any machinery or equipment. Neglecting maintenance can lead to a range of issues, from decreased efficiency to complete failure, resulting in costly repairs and replacements. By committing to routine care, users can prevent minor problems from escalating into major concerns.

Performing scheduled inspections and servicing not only enhances performance but also optimizes operational efficiency. Regular checks allow for the early detection of wear and tear, enabling timely interventions that can save both time and resources. Moreover, consistent maintenance can improve safety, reducing the risk of accidents caused by malfunctioning components.

In addition, maintaining equipment contributes to its resale value. Well-cared-for machines are more appealing to potential buyers, often leading to better offers. Investing time and resources into proper maintenance ultimately yields significant returns, making it a worthwhile priority for any user.

Common Issues with Generator Parts

Understanding the frequent challenges associated with equipment components is essential for effective maintenance and performance. Users often encounter various malfunctions that can hinder the efficiency and longevity of their machines. Addressing these issues promptly can save time and resources.

Wear and Tear: One of the most prevalent problems is the natural deterioration of components due to regular use. Over time, certain elements may weaken or break, leading to suboptimal functionality. Regular inspections can help identify these signs early.

Fuel System Troubles: Blockages or leaks in the fuel delivery system can significantly affect performance. Contaminated fuel or malfunctioning filters often result in decreased power output or starting difficulties. Ensuring cleanliness and proper maintenance can mitigate these risks.

Electrical Failures: Issues with wiring or connections can cause erratic behavior or complete shutdowns. Corrosion and loose connections are common culprits that require careful attention. Regularly checking electrical systems can help prevent unexpected failures.

Cooling System Inefficiencies: An overheating machine can lead to severe damage if the cooling system isn’t functioning properly. Clogs in cooling passages or low coolant levels are frequent issues that should be monitored to avoid catastrophic failures.

Vibration Problems: Excessive vibrations can indicate misalignment or loose components. This not only affects performance but can also lead to further damage if left unaddressed. Regular maintenance checks are vital to ensure stability.

By being aware of these common issues and their potential impact, users can take proactive measures to enhance the reliability and efficiency of their equipment. Consistent monitoring and timely repairs are key to maintaining optimal performance.

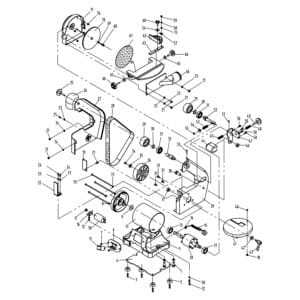

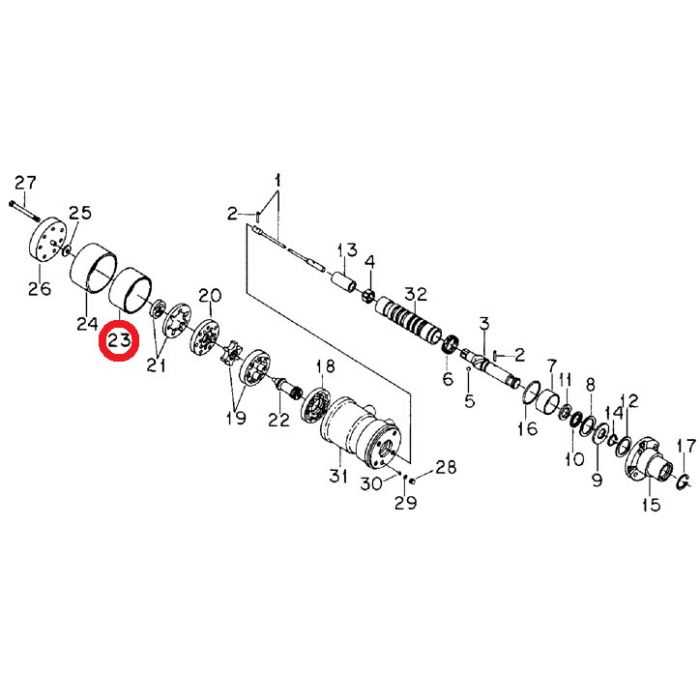

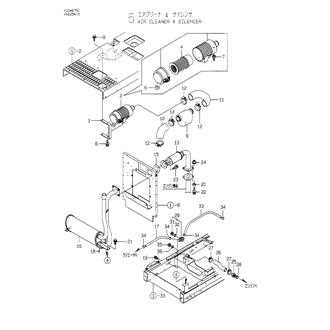

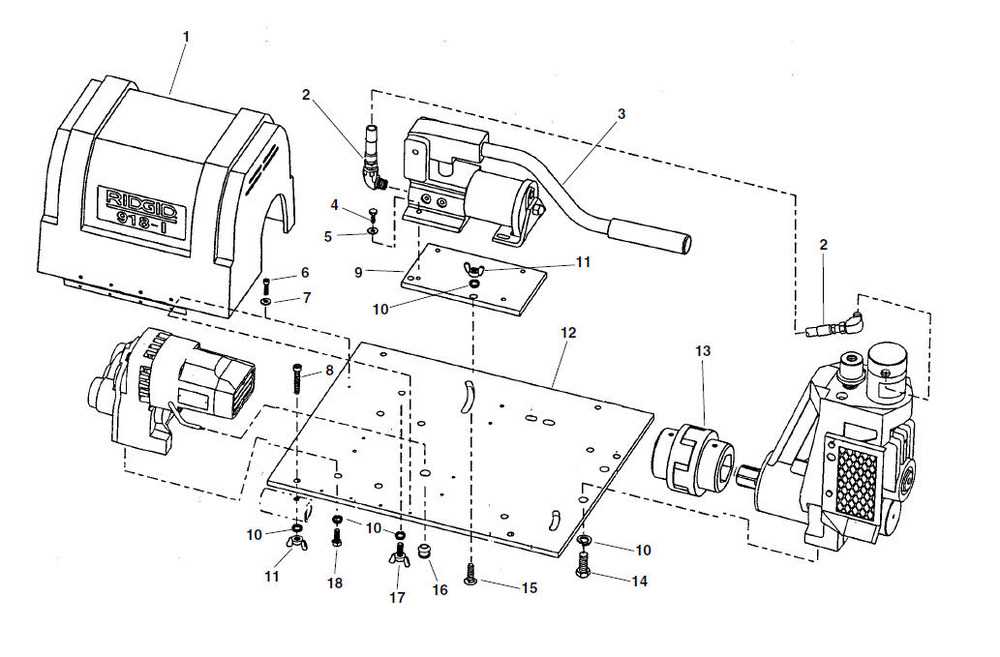

How to Read Parts Diagrams

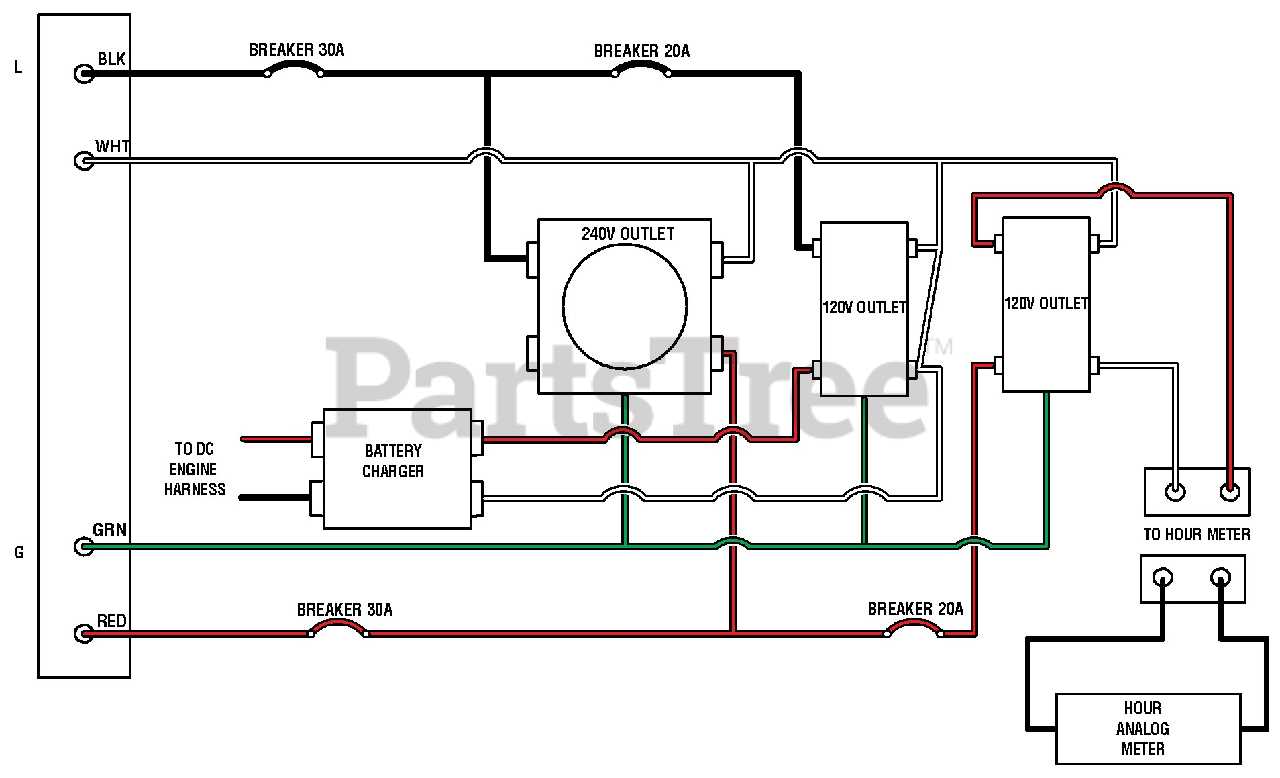

Understanding visual representations of components is crucial for effective maintenance and repair tasks. These illustrations provide valuable insights into the structure and organization of various elements, enabling users to identify and locate specific items efficiently. Mastering the interpretation of these visuals can save time and enhance the overall repair experience.

Key Elements of Visual Representations

When examining these illustrations, it’s essential to familiarize yourself with several key features:

- Labels: Most visuals include labels or part numbers that correspond to specific components, helping to identify each piece accurately.

- Connection Points: Look for lines or arrows indicating how components are linked or interact with one another.

- Color Coding: Some representations utilize color to differentiate between various categories or functions of parts.

Steps to Interpret Visual Guides

Follow these steps to enhance your comprehension of these visual aids:

- Start with the Legend: If available, review the legend or key that explains symbols and colors used in the illustration.

- Identify the Main Components: Focus on the larger assemblies before delving into smaller parts.

- Trace Connections: Follow lines or arrows to understand how elements fit together and interact.

- Cross-Reference with Manuals: Use additional resources, such as user manuals or online guides, for further clarification on specific items.

By honing your skills in reading these visual aids, you’ll enhance your ability to tackle repair projects with confidence and precision.

Essential Tools for Repairs

When it comes to fixing machinery or equipment, having the right instruments at your disposal can make all the difference. A well-equipped toolkit not only streamlines the repair process but also enhances your efficiency and effectiveness. Understanding which tools are essential can help you tackle various tasks with confidence and precision.

Basic Hand Tools

Every repair job starts with a solid foundation of basic hand tools. Wrenches, screwdrivers, and pliers are fundamental for disassembling components and making necessary adjustments. A reliable set of these tools ensures that you can handle most tasks, from tightening bolts to removing screws. Additionally, a sturdy utility knife and a set of precision tools are invaluable for more intricate work.

Power Tools and Accessories

In more complex situations, power tools can significantly speed up the repair process. Drills, saws, and sanders provide the power needed for cutting and shaping materials effectively. It’s also crucial to have the right accessories, such as drill bits and blades, to match the specific requirements of your project. Investing in quality power tools not only enhances performance but also ensures safety during operation.

Finding Authentic Replacement Parts

When it comes to maintaining machinery, ensuring the use of genuine components is crucial for optimal performance and longevity. Authentic replacements not only fit perfectly but also meet the quality standards set by the manufacturer. Here are some key considerations to keep in mind when searching for reliable components.

Why Authenticity Matters

Using original components offers several advantages:

- Reliability: Genuine parts are designed to work seamlessly with your equipment.

- Warranty Protection: Many manufacturers require the use of authentic components to maintain warranty coverage.

- Performance Assurance: Original parts help maintain the efficiency and functionality of your machinery.

Where to Find Genuine Components

Locating authentic replacements can be straightforward if you know where to look:

- Manufacturer’s Website: Start by checking the official site for a list of authorized distributors.

- Authorized Dealers: Visit or contact local dealers who are recognized by the manufacturer.

- Reputable Online Retailers: Ensure the site specializes in equipment components and has positive reviews.

- Forums and Community Groups: Engage with other users to get recommendations on trusted sources.

By following these guidelines, you can ensure that your machinery remains in top condition with authentic replacements that uphold its integrity and functionality.

Safety Precautions When Repairing Generators

Ensuring safety during maintenance and repair tasks is crucial to prevent accidents and injuries. Proper precautions should be observed to create a secure working environment. Being aware of potential hazards and following best practices can significantly reduce risks associated with handling electrical and mechanical equipment.

Before beginning any work, it is essential to prepare adequately. Here are some important safety measures to consider:

| Precaution | Description |

|---|---|

| Disconnect Power | Always disconnect the power source before starting any repairs to avoid electric shock. |

| Use Personal Protective Equipment | Wear safety goggles, gloves, and non-slip footwear to protect against injuries. |

| Work in a Well-Ventilated Area | Ensure proper ventilation to avoid inhaling harmful fumes that may be emitted during repairs. |

| Read the Manual | Consult the user manual for specific safety guidelines and maintenance procedures relevant to the equipment. |

| Keep a First Aid Kit Nearby | Have a first aid kit readily available to address any minor injuries that may occur. |

By adhering to these guidelines, individuals can foster a safer repair process and mitigate potential dangers associated with maintenance activities.

Upgrading Your Generator’s Performance

Enhancing the efficiency and reliability of your power source can significantly impact its overall functionality and lifespan. By implementing strategic improvements, you can achieve optimal output and ensure seamless operation during critical times.

Here are several effective ways to boost performance:

- Regular Maintenance: Consistent upkeep, including oil changes and filter replacements, is essential for peak efficiency.

- Fuel Quality: Use high-grade fuel to prevent engine knocking and promote smoother operation.

- Upgrade Components: Consider replacing outdated or inefficient parts with high-performance alternatives.

Additionally, implementing the following tips can lead to further enhancements:

- Adjust the Air-Fuel Mixture: Tuning the mixture can optimize combustion and increase power output.

- Inspect Electrical Systems: Regularly check wiring and connections to prevent energy loss and ensure reliable functionality.

- Utilize Performance Additives: Certain additives can improve efficiency and protect engine components.

By focusing on these areas, you can significantly elevate the performance of your equipment, ensuring it meets your energy needs effectively.

Customer Reviews on Ridgid Parts

This section presents insights from users regarding their experiences with components from a well-known brand. Feedback from consumers is invaluable as it sheds light on product reliability, performance, and overall satisfaction. Understanding these reviews can help prospective buyers make informed decisions when considering these essential tools.

Positive Experiences

Many customers have praised the durability and efficiency of the items they have purchased. Users often highlight the quality of materials used, noting that they withstand rigorous tasks and provide consistent performance over time. Here are some of the commendable aspects frequently mentioned:

| Feature | Customer Feedback |

|---|---|

| Durability | “These components have held up exceptionally well under heavy use.” |

| Performance | “I’ve noticed a significant improvement in efficiency since upgrading.” |

| Value for Money | “Highly recommend for anyone looking for reliable tools that don’t break the bank.” |

Areas for Improvement

While many reviews are positive, some users have pointed out areas that could be enhanced. Constructive criticism often revolves around the availability of replacement components and customer service response times. Here are some common concerns:

| Issue | Customer Feedback |

|---|---|

| Availability | “It’s sometimes challenging to find specific components when needed.” |

| Customer Support | “Response times could be faster when seeking assistance.” |

Where to Seek Professional Help

When dealing with mechanical issues, finding the right assistance is crucial for effective solutions. Whether you are experiencing malfunction or need maintenance, professional support can ensure that your equipment operates optimally. Here are some avenues to consider when seeking expert help.

- Authorized Service Centers: Look for service locations that specialize in your brand. They typically have trained technicians familiar with specific models and their requirements.

- Local Repair Shops: Many independent workshops offer quality service and can handle a range of mechanical challenges. Check for reviews and testimonials to gauge their reliability.

- Online Forums: Engaging with communities dedicated to your type of machinery can provide valuable insights. Members often share recommendations for reputable professionals.

- Manufacturer Support: Reach out to the customer support team of the manufacturer. They can guide you to certified professionals and provide troubleshooting assistance.

- DIY Tutorials: While not professional help, many instructional videos and articles can assist with common issues. However, ensure you have the skills required to follow through safely.

Choosing the right source of assistance can significantly impact the longevity and performance of your equipment. Prioritize quality and expertise to achieve the best results.