Comprehensive Guide to Hayward H250 Pool Heater Parts Diagram

In any climate, ensuring a reliable and efficient temperature management system is essential for comfort and enjoyment. This section will explore the various elements that contribute to the functionality of these systems, highlighting the significance of each component.

Comprehending the intricate layout of these devices can help users maintain and troubleshoot effectively. Each segment plays a vital role in the overall performance, and recognizing them is the first step towards optimal operation.

As we delve into the specifics, we will provide a clear overview of these components, enabling users to understand their ultimate purpose and importance in the system’s efficiency.

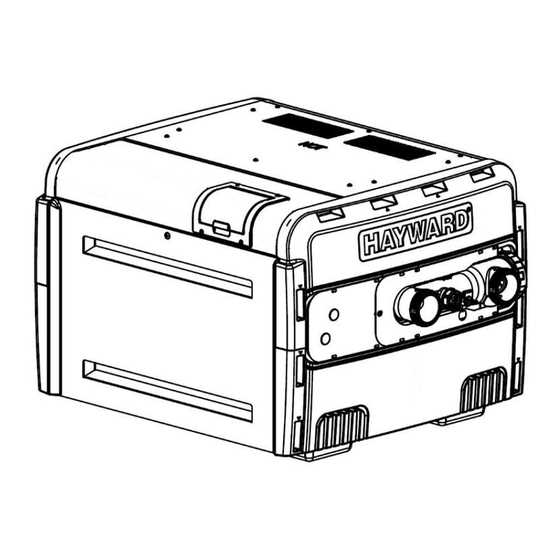

Understanding Hayward H250 Heater Components

This section explores the essential elements of a specific heating unit, focusing on their functionality and interaction. By gaining insight into these components, users can enhance their understanding of how the system operates effectively and efficiently.

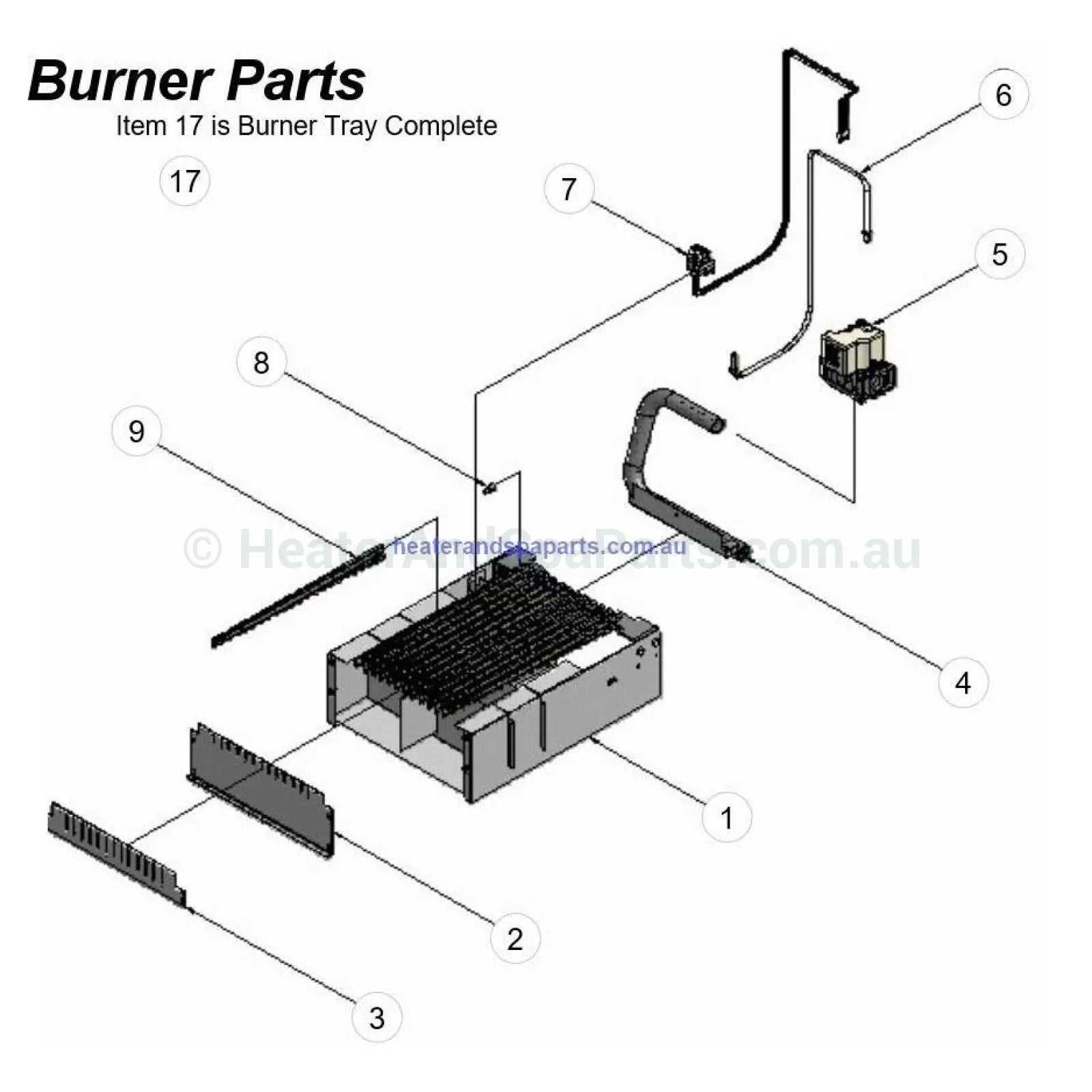

Burner Assembly: This crucial component ignites the fuel source, generating the necessary heat. Proper maintenance ensures optimal performance and safety.

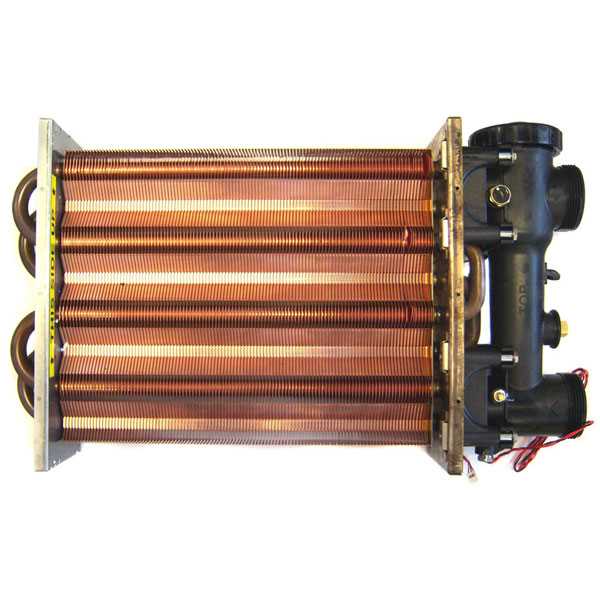

Heat Exchanger: The primary function of this part is to transfer heat from the combustion process to the circulating water, making it vital for efficient heating.

Control System: This feature regulates the temperature and monitors the entire operation, allowing for precise adjustments to maintain desired conditions.

Ventilation System: Proper airflow is essential for combustion efficiency. This system ensures that gases are expelled safely while allowing fresh air to enter.

Electrical Components: These parts include wiring, switches, and sensors, playing a significant role in the functionality and safety of the heating unit.

Understanding these elements is crucial for effective operation and maintenance, ultimately leading to a more enjoyable experience.

Key Parts of the H250 Heater

Understanding the essential components of this heating system is crucial for optimal performance and maintenance. Each element plays a significant role in ensuring effective operation, contributing to both efficiency and reliability.

Burner Assembly: This vital unit is responsible for generating heat through the combustion process. Proper functioning of the burner is essential for achieving the desired temperature.

Heat Exchanger: This component transfers heat from the combustion process to the water. A well-maintained exchanger ensures maximum energy efficiency and performance.

Thermostat: This device regulates temperature, providing user control over the system. Accurate readings are necessary for maintaining comfortable conditions.

Fan: The fan aids in circulating air, ensuring efficient combustion and optimal heat distribution. Its performance directly impacts the unit’s effectiveness.

Control Panel: This interface allows users to monitor and adjust settings easily. User-friendly controls enhance overall experience and functionality.

Safety Features: Various mechanisms are in place to prevent malfunctions and hazards. These features are essential for safe operation and peace of mind.

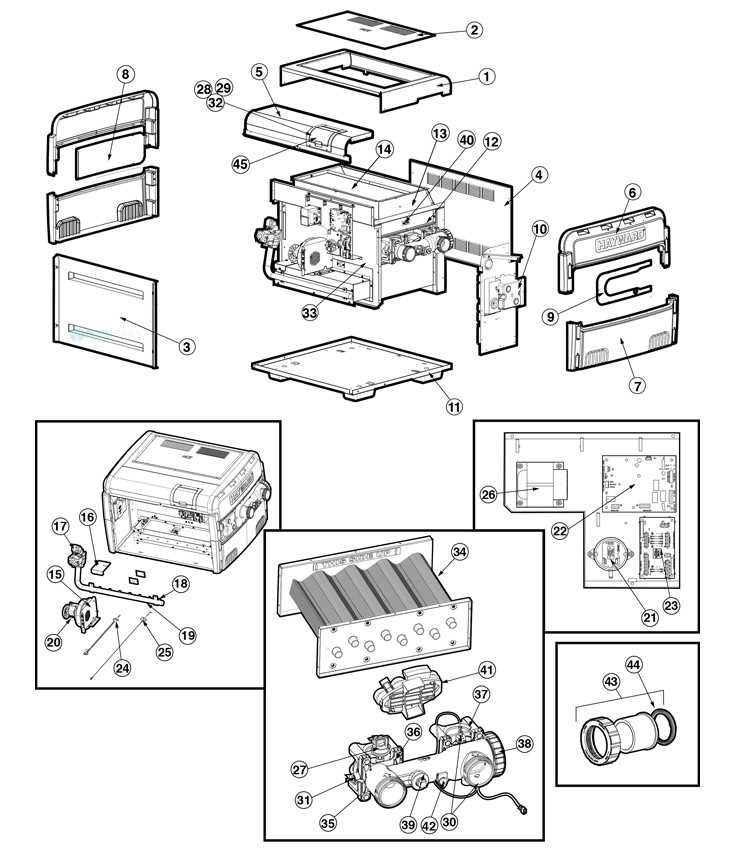

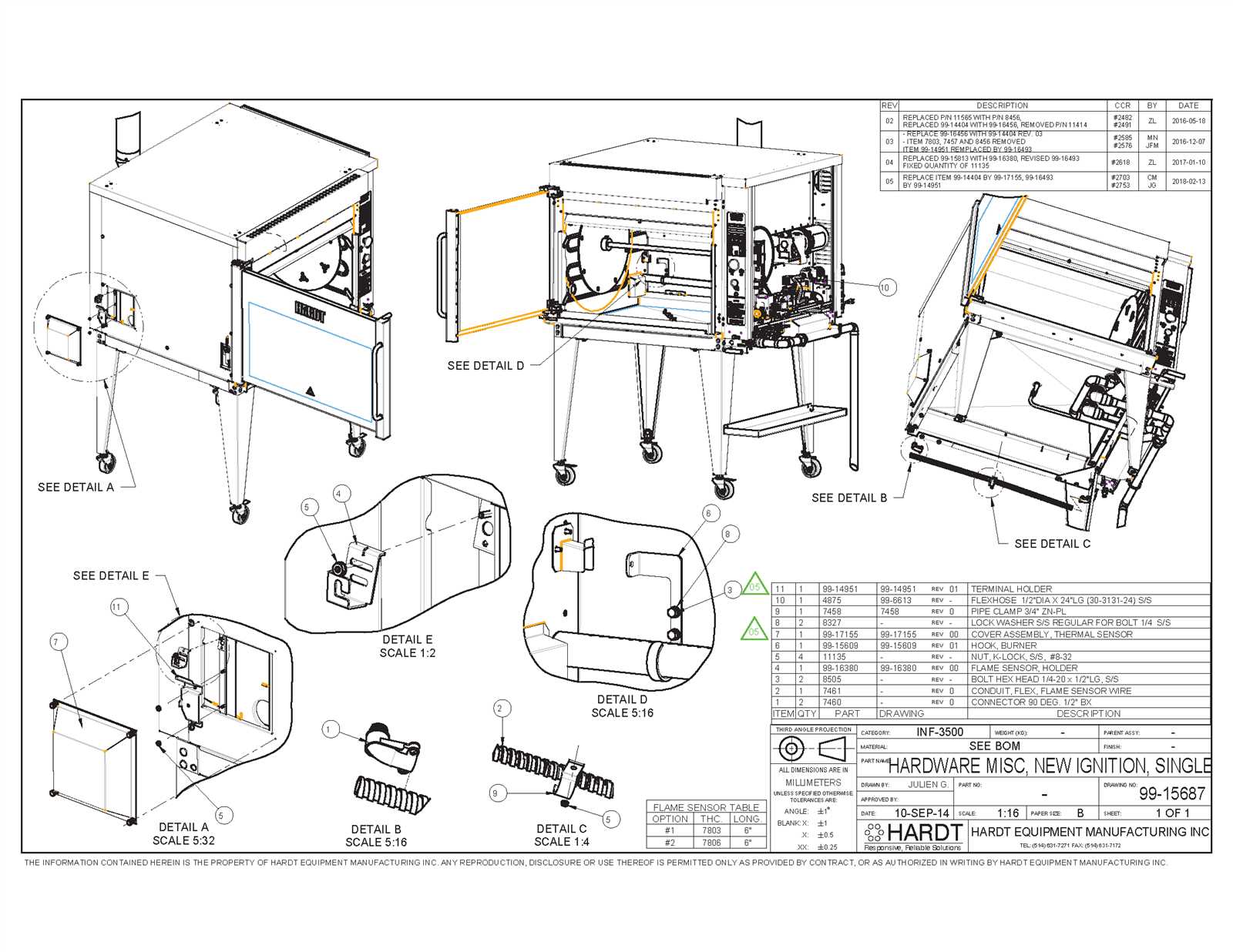

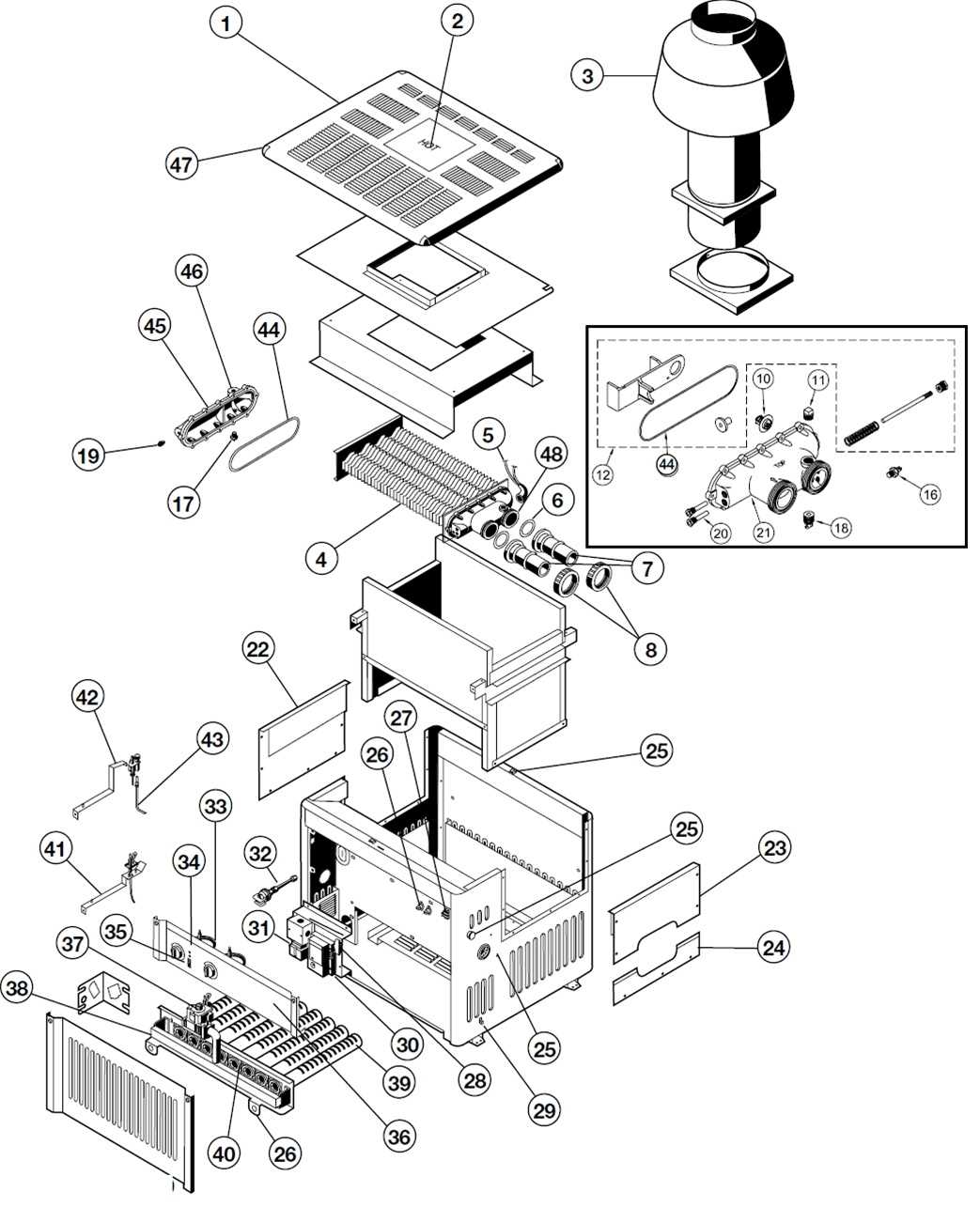

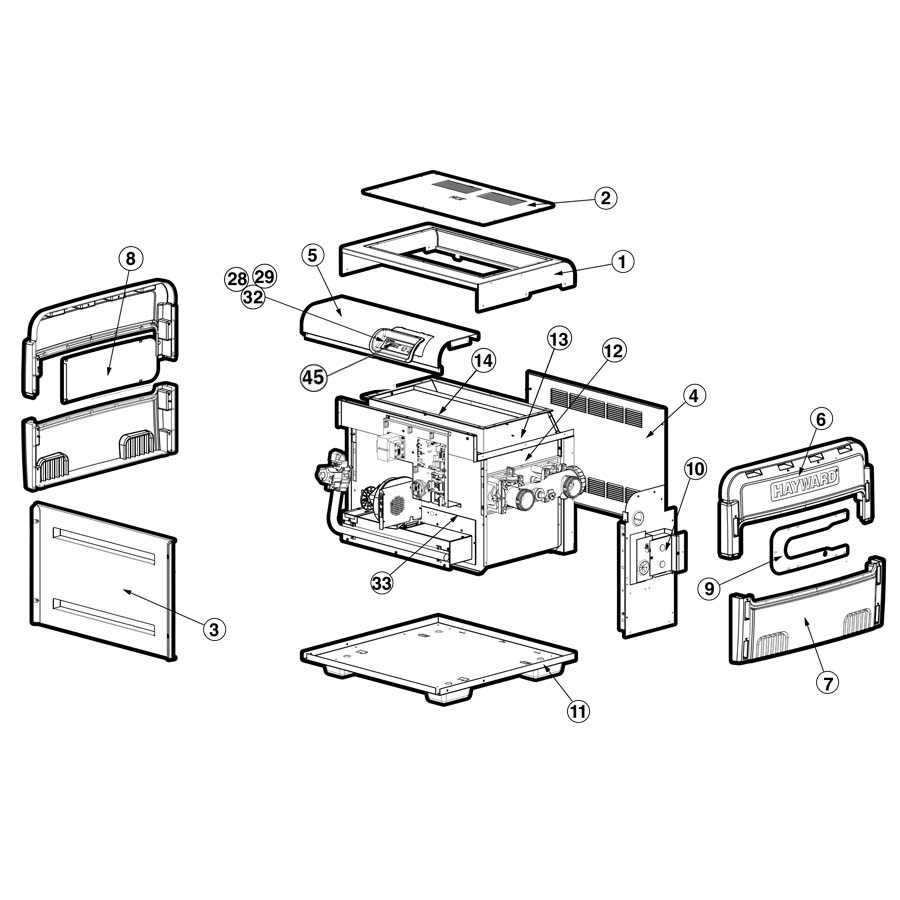

How to Read the Parts Diagram

Understanding a schematic representation is crucial for effective maintenance and repair of equipment. A clear visualization of components helps users identify each element and its function within the system. By familiarizing yourself with this illustration, you can streamline troubleshooting and enhance your knowledge of the unit.

Here are some key steps to effectively interpret the schematic:

- Familiarize Yourself with Symbols: Each part is represented by a unique symbol. Learning these will aid in quick recognition.

- Identify Main Components: Locate the primary elements in the diagram. This will provide context for understanding how they interact.

- Trace Connections: Follow the lines connecting the symbols. These indicate how components are linked and help visualize the flow of operation.

- Refer to Annotations: Look for any labels or notes that provide additional details about specific parts or instructions for use.

By following these steps, you will gain confidence in interpreting the schematic, leading to more efficient diagnostics and repairs.

Common Issues with Heater Parts

Understanding typical problems associated with heating units can enhance their longevity and efficiency. Identifying these challenges early can save time and resources, ensuring optimal functionality.

Frequent Malfunctions

- Overheating due to blocked airflow.

- Inconsistent temperatures caused by faulty sensors.

- Leakage from worn-out seals or connections.

Maintenance Tips

- Regularly clean filters to ensure proper airflow.

- Inspect wiring for any signs of wear or damage.

- Check for leaks and replace any compromised seals.

Replacement Parts for H250 Models

Maintaining the efficiency of your equipment often requires replacing certain components over time. Understanding which elements can be substituted ensures optimal performance and longevity. This section outlines the essential replacement components specifically designed for the H250 series, highlighting their significance and availability.

Essential Components

Key elements such as thermostats, igniters, and control boards play a critical role in the operation of your unit. Regular checks and timely replacements of these components can prevent more significant issues and enhance overall functionality.

Finding Quality Substitutes

When sourcing replacement components, it is crucial to opt for high-quality options that match the specifications of your unit. Reliable suppliers and manufacturers can provide parts that ensure compatibility and durability, thus maintaining the system’s efficiency for years to come.

Identifying Faulty Components

Recognizing malfunctioning elements within your system is crucial for maintaining optimal performance. Several indicators can help you pinpoint issues, enabling timely repairs and ensuring efficiency.

Common signs of defective components include:

- Unusual noises during operation

- Inconsistent performance or failure to start

- Overheating or excessive cycling

- Visible damage or wear on external parts

To assist in the identification process, consider the following steps:

- Conduct a visual inspection of all accessible elements.

- Check for error codes or warning lights on the control panel.

- Test electrical connections for continuity and secure fittings.

- Monitor temperature readings and compare them with expected values.

Addressing these issues promptly can prevent further complications and extend the lifespan of your system.

Maintenance Tips for Pool Heaters

Regular upkeep is essential for ensuring optimal performance and longevity of your heating system. By implementing a few straightforward practices, you can enhance efficiency and reduce the risk of costly repairs.

- Routine Cleaning: Keep the unit clean from debris, leaves, and dirt. A clean exterior promotes better airflow and efficiency.

- Check Filters: Regularly inspect and clean or replace filters as needed. Clogged filters can hinder performance and lead to overheating.

- Inspect Connections: Periodically examine all electrical and plumbing connections for signs of wear or leaks. Tighten loose connections to prevent issues.

- Monitor Water Chemistry: Ensure that the water’s chemical balance is within recommended levels. Imbalances can damage components over time.

- Seasonal Maintenance: Before and after the heating season, conduct a thorough inspection to ensure everything is functioning correctly.

Following these tips will help maintain your system in peak condition, providing warmth and comfort for years to come.

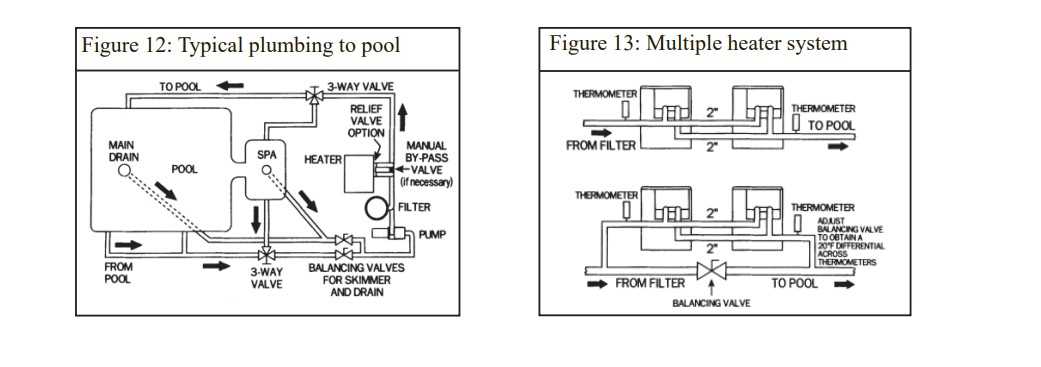

Installation Process for New Parts

Installing new components is essential for maintaining optimal performance and efficiency. This process requires careful planning and execution to ensure everything functions seamlessly. Following a structured approach will help in achieving the best results.

Preparation Steps

Before beginning, gather all necessary tools and components. Ensure that you have a clear understanding of the specifications required for the installation. Read through the instruction manual thoroughly to familiarize yourself with the assembly process.

Installation Procedure

Start by disconnecting any power supply to the system to ensure safety. Remove the old components carefully, taking note of their arrangement for reference. Install the new components, ensuring a secure fit. Once everything is in place, reconnect the power and perform a test to confirm proper functionality. Regular maintenance checks are recommended to prolong the lifespan of the new elements.

Tools Needed for Repairs

Proper maintenance and troubleshooting of equipment require a specific set of instruments to ensure effective and safe operations. Having the right tools not only streamlines the repair process but also enhances the overall efficiency of the tasks at hand.

Essential Instruments

Among the various implements, certain ones stand out as crucial for any repair job. Here are the primary tools that will facilitate your work:

| Tool | Purpose |

|---|---|

| Screwdriver Set | For loosening and tightening screws on various components. |

| Wrench Set | To adjust and secure nuts and bolts effectively. |

| Multimeter | For measuring electrical properties and diagnosing issues. |

| Pliers | To grip and manipulate small parts or wires. |

Additional Helpful Tools

In addition to the essential instruments, having a few extra tools can enhance your repair capabilities. Consider adding the following to your toolkit:

| Tool | Purpose |

|---|---|

| Flashlight | To illuminate dark areas for better visibility during repairs. |

| Safety Gear | To protect yourself while working on equipment. |

| Tape Measure | For ensuring accurate measurements of components. |

| Cleaning Supplies | To maintain cleanliness and prevent debris buildup. |

Electrical Components Explained

Understanding the various electrical components involved in temperature regulation systems is crucial for effective maintenance and operation. These components work together to ensure efficient performance, safety, and longevity of the entire setup. Familiarity with their functions can greatly assist in troubleshooting and enhancing overall efficiency.

Key Electrical Components

Several key elements play a pivotal role in the functioning of these systems. Below is a brief overview of their purposes and characteristics.

| Component | Description |

|---|---|

| Thermostat | Regulates the desired temperature by controlling the power to the system based on the current temperature reading. |

| Contactor | A switch that controls the electrical supply to the system, enabling or disabling operation as needed. |

| Relay | A device that opens or closes circuits electromechanically or electronically, providing control over the system’s operations. |

| Fuse | Protects the system by breaking the circuit in case of overload or short circuit, preventing damage to components. |

Maintenance and Safety Considerations

Regular inspection and maintenance of these electrical components are essential to ensure safe and efficient operation. Look for signs of wear, corrosion, or loose connections, as these can compromise performance. Additionally, understanding how each part interacts with others helps in diagnosing issues effectively.

Heat Exchanger Functionality

The heat exchanger plays a crucial role in transferring thermal energy between two or more fluids, ensuring efficient temperature regulation in various systems. This component allows for the seamless movement of heat without mixing the fluids involved, maintaining the integrity of each medium.

Essentially, the heat exchanger facilitates the heating or cooling process by maximizing surface area contact while minimizing resistance to flow. This efficiency is vital in maintaining optimal performance and energy conservation.

In practical terms, the design and material of the heat exchanger influence its effectiveness, as well as the overall energy efficiency of the system. Understanding these factors is essential for anyone involved in maintenance or design.

Understanding Control Systems

Control systems play a crucial role in automating processes and ensuring optimal performance across various applications. They utilize feedback mechanisms to maintain desired outputs, allowing for precision and efficiency in operation.

Components of Control Systems

- Controllers: Devices that dictate the desired output based on input signals.

- Sensors: Instruments that monitor system variables and provide data to the controller.

- Actuators: Components that execute the controller’s commands to alter the system’s state.

Types of Control Systems

- Open-loop Systems: Operate without feedback; rely solely on initial input.

- Closed-loop Systems: Utilize feedback to adjust outputs and improve accuracy.

Understanding these elements is essential for effective implementation and troubleshooting in various technical environments.

Finding Genuine Replacement Parts

When it comes to maintaining your equipment, sourcing authentic components is crucial for ensuring optimal performance and longevity. High-quality replacements not only fit perfectly but also meet the manufacturer’s standards, which can prevent future malfunctions and costly repairs.

Why Authenticity Matters

Utilizing genuine components guarantees compatibility and reliability. Imitations may save money initially, but they often lack the durability needed for long-term use. Choosing original parts minimizes risks associated with improper fitting and subpar materials, enhancing the overall efficiency of your system.

Where to Find Original Components

Look for authorized retailers or official websites that specialize in equipment accessories. These sources typically provide detailed descriptions and diagrams to assist you in identifying the exact items required. Online forums and user communities can also be valuable resources for recommendations on trustworthy suppliers.