Understanding the Components of Heat Exchanger Diagrams

In the realm of thermal management systems, a comprehensive grasp of the various elements that contribute to effective energy transfer is essential. These mechanisms play a pivotal role in a multitude of industries, ensuring optimal performance and efficiency.

Visual representations serve as invaluable tools for comprehending the intricate relationships between these essential components. By examining the arrangement and functionality, one can better appreciate how each segment interacts to facilitate the overall process.

As we delve into the specifics, the ultimate goal is to enhance our understanding of these systems. This knowledge not only aids in design and maintenance but also fosters innovation within the field of thermal energy management.

Understanding Heat Exchanger Functionality

This section explores the principles that govern the transfer of thermal energy between fluids. By examining various elements involved, one can appreciate how efficiency and effectiveness are achieved in numerous applications.

Key Principles

- Conduction: The process by which heat moves through materials.

- Convection: The transfer of heat through fluid motion.

- Radiation: Heat transfer through electromagnetic waves.

Applications and Benefits

- Industrial Processes: Used for cooling and heating in manufacturing.

- HVAC Systems: Essential for maintaining comfortable environments.

- Energy Recovery: Allows for improved efficiency in power generation.

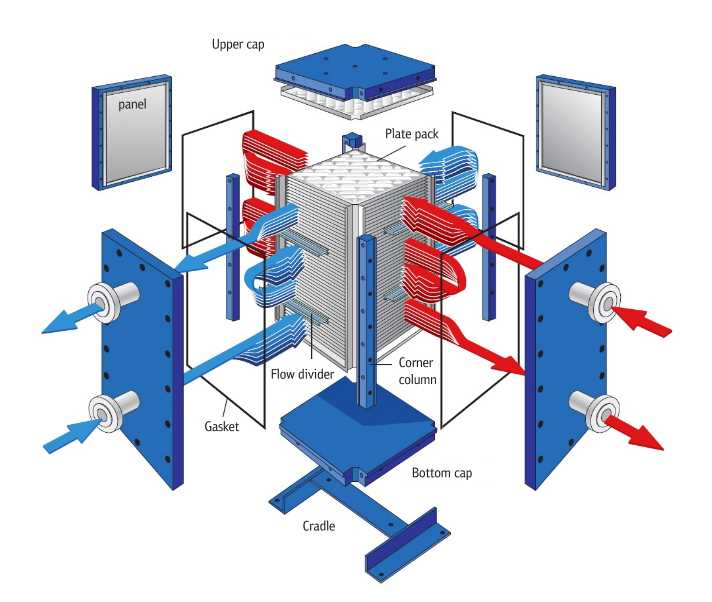

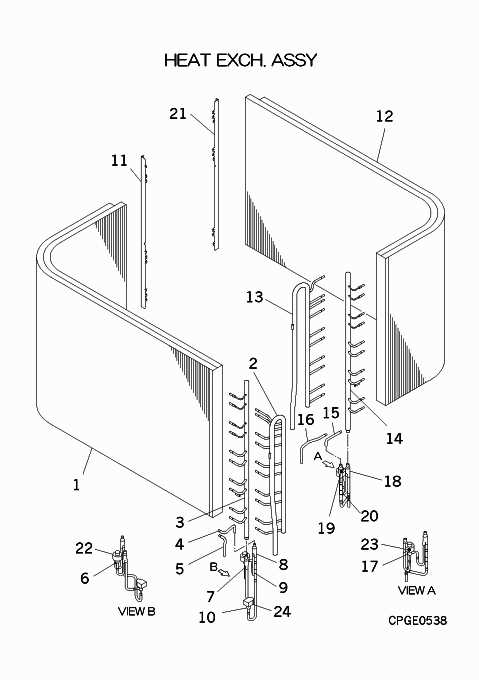

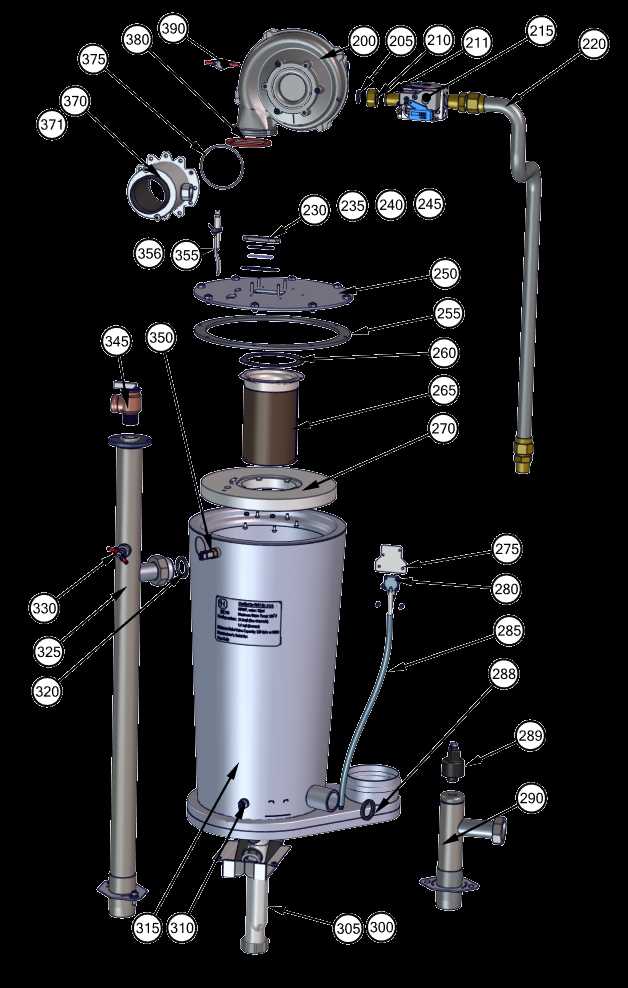

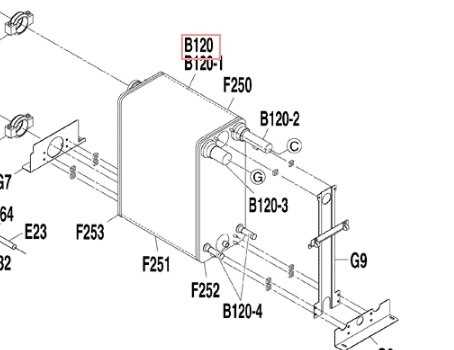

Key Components of Heat Exchangers

Understanding the fundamental elements of thermal transfer devices is crucial for optimizing performance in various applications. These crucial parts facilitate the efficient movement of thermal energy between different fluids, ensuring effective temperature regulation and energy conservation.

One primary element is the surface area where the two fluids interact, which plays a significant role in maximizing energy transfer. Additionally, the flow paths of the fluids are designed to enhance contact and promote turbulence, thereby increasing efficiency. Moreover, insulation is essential to minimize losses and maintain desired temperatures within the system.

Support structures are also vital, providing stability and alignment for all components, ensuring seamless operation. Finally, seals and gaskets prevent leaks, safeguarding the integrity of the entire system and maintaining optimal performance.

Types of Heat Exchanger Designs

This section explores various configurations and structures utilized for transferring thermal energy between fluids. Understanding these designs is crucial for selecting the most efficient solution for specific applications.

Shell and Tube Configuration

One of the most common structures, this design features a series of tubes, with one fluid flowing through the tubes while another surrounds them in a shell. This arrangement allows for effective heat transfer and easy maintenance.

Plate Type Design

This configuration consists of thin plates stacked together to create channels for fluid flow. It offers a compact solution with high efficiency, ideal for applications requiring significant energy transfer in limited spaces.

Materials Used in Construction

The selection of materials plays a crucial role in the effectiveness and durability of thermal transfer devices. Various substances are employed to optimize performance and withstand operational demands, ensuring longevity and efficiency.

Metals are commonly utilized due to their excellent conductivity. Copper and aluminum are favored for their lightweight properties and high thermal efficiency, making them ideal for various applications.

Plastics offer an alternative in specific environments where corrosion resistance is paramount. Polypropylene and polyethylene can be advantageous for certain fluids and conditions, providing a balance between cost and performance.

Composite materials are increasingly popular for their unique benefits, combining multiple properties to enhance functionality. These materials can provide both strength and insulation, tailored to specific requirements.

In conclusion, understanding the materials utilized in these constructions is essential for optimizing their design and functionality, ultimately leading to improved operational outcomes.

Common Applications in Industries

Various sectors rely on systems designed for thermal transfer to optimize their processes, ensuring efficient energy management and operational effectiveness. These systems play a critical role in maintaining desired temperatures, enhancing productivity, and ensuring safety in diverse applications.

In the chemical industry, such systems facilitate reaction control by maintaining specific thermal conditions, crucial for product quality. Similarly, in power generation, they assist in recovering energy from waste streams, contributing to sustainability efforts.

Food processing employs these systems to regulate temperatures during cooking and cooling, preserving product integrity. In the HVAC sector, they are vital for climate control in residential and commercial buildings, ensuring comfort and efficiency.

Additionally, in petroleum refining, these systems are essential for distillation and other thermal processes, significantly impacting output quality and efficiency. Their versatility across industries highlights their importance in modern engineering and operations.

Maintenance Practices for Longevity

Ensuring the durability and efficiency of thermal devices requires consistent upkeep and attention. Regular maintenance not only extends the lifespan of these systems but also enhances their performance, preventing costly breakdowns and inefficiencies.

Regular Inspection

- Conduct periodic visual checks for any signs of wear or damage.

- Monitor for leaks and corrosion that may compromise function.

- Inspect seals and connections for proper integrity.

Cleaning Procedures

- Implement routine cleaning to remove debris and fouling.

- Utilize appropriate solvents and techniques to avoid damage.

- Schedule deep cleans based on usage intensity and operational environment.

Thermal Efficiency Considerations

When assessing the performance of a thermal transfer system, one must evaluate the effectiveness of energy conversion and transmission. This involves understanding various factors that influence overall productivity, including material selection, flow arrangement, and temperature differentials.

Optimal functioning hinges on minimizing energy losses while maximizing the transfer of thermal energy. A well-designed apparatus can significantly enhance productivity, reducing operational costs and environmental impact. Analyzing the relationship between surface area and fluid dynamics plays a crucial role in achieving these goals.

Moreover, regular maintenance and monitoring are essential to sustain high performance levels over time. Identifying inefficiencies and making timely adjustments can lead to substantial improvements in energy utilization. Ultimately, the pursuit of efficiency is vital for both economic viability and sustainability.

Identifying Performance Issues

Recognizing inefficiencies in thermal systems is crucial for maintaining optimal functionality. Various factors can contribute to decreased effectiveness, and pinpointing these issues can lead to improved performance and energy savings.

- Poor temperature regulation

- Unusual pressure drops

- Increased energy consumption

- Frequent maintenance requirements

- Unexplained fluctuations in output

To address these challenges, consider the following steps:

- Conduct regular performance assessments.

- Monitor key operational parameters.

- Analyze flow patterns and distribution.

- Inspect for potential blockages or leaks.

- Review maintenance records for recurring issues.

By systematically evaluating these elements, one can ultimately enhance the reliability and efficiency of the system.

Innovations in Heat Exchange Technology

Recent advancements in thermal management systems have transformed the landscape of energy efficiency and resource optimization across various industries. Innovative approaches are being developed to enhance performance, reduce costs, and minimize environmental impact. These technologies aim to facilitate more effective thermal transfer processes, ultimately leading to improved operational efficacy.

One of the most significant trends is the incorporation of advanced materials that offer superior conductivity and durability. Nanotechnology has emerged as a key player, allowing for the creation of surfaces that enhance thermal transfer while resisting corrosion. This development not only improves efficiency but also extends the lifespan of equipment.

Another exciting avenue is the integration of smart technologies into thermal systems. Sensors and automation enable real-time monitoring and adjustments, ensuring optimal performance under varying operational conditions. This dynamic capability significantly reduces energy consumption and enhances reliability.

Moreover, the focus on sustainability has led to the exploration of alternative fluids that can operate at lower temperatures, reducing the overall energy required for transfer. These eco-friendly solutions contribute to a reduced carbon footprint while maintaining high efficiency.

As the demand for energy-efficient solutions continues to grow, the ongoing research and development in this field promise to yield even more groundbreaking advancements, paving the way for a more sustainable future.

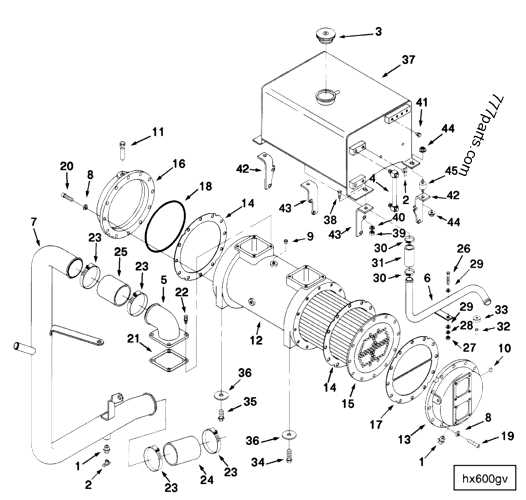

Diagrammatic Representation Explained

Visual illustrations serve as powerful tools for conveying complex systems and their functionalities. By employing graphical elements, one can simplify intricate relationships and interactions, making them more accessible for understanding. This approach is particularly beneficial in technical fields, where clarity is paramount.

Importance of Visual Aids

Utilizing schematic representations allows for an immediate grasp of various components and their roles within a system. By breaking down intricate setups into manageable visuals, it becomes easier to identify critical functions and flow paths. This not only aids in comprehension but also enhances troubleshooting capabilities.

Elements of Effective Illustrations

An impactful representation should include clear labeling and logical organization of elements. Color coding can further differentiate functions, while arrows and lines help illustrate movement and interaction. Together, these features create a cohesive and informative visual that facilitates better retention of knowledge.