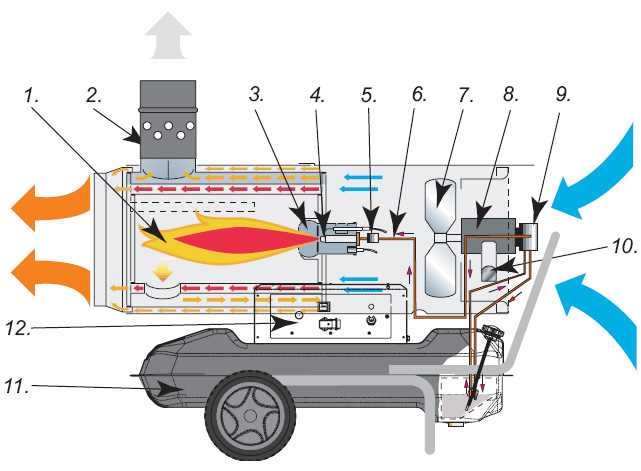

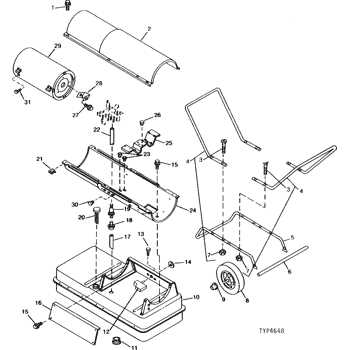

Torpedo Heater Parts Diagram Overview

The intricacies of portable heating solutions are often overlooked, yet they play a crucial role in ensuring efficiency and safety. Gaining insight into the various elements that contribute to the functionality of these appliances can empower users to make informed decisions about their maintenance and usage. Familiarity with these essential components enhances one’s ability to troubleshoot common issues and prolong the lifespan of the unit.

Each section of these devices serves a distinct purpose, from the ignition system that initiates warmth to the mechanisms that regulate temperature. Understanding how these segments interconnect is vital for anyone looking to optimize performance. Additionally, knowledge of specific functionalities can aid in identifying potential problems before they escalate, thus ensuring a smooth and reliable operation.

In the following sections, we will explore the layout and roles of each key element within the unit, providing a clear and comprehensive overview. This information will serve as a valuable resource for both novices and seasoned users alike, fostering a deeper appreciation for the design and engineering behind these essential tools.

Torpedo Heater Overview

This section provides an insightful look into a popular type of portable warming device, highlighting its design, functionality, and applications. These appliances are widely utilized for providing effective heat in various settings, making them essential tools in both residential and industrial environments.

Design and Functionality

The structure of these warming devices is engineered for efficiency and mobility. Typically powered by fuel or electricity, they generate substantial heat output while being compact and easy to maneuver. The heating mechanism operates by circulating warm air, ensuring rapid temperature elevation in enclosed spaces.

Applications and Benefits

These versatile appliances find their use in construction sites, workshops, and garages, providing necessary warmth in chilly conditions. Their ability to deliver immediate heat makes them invaluable during winter months or in poorly insulated areas. Moreover, the mobility of these devices allows users to easily transport them to different locations as needed.

Understanding Heating Mechanisms

Heating devices operate through various principles to transform energy into warmth, providing comfort in diverse environments. Recognizing these principles is essential for effective use and maintenance.

Common mechanisms include:

- Conduction: Heat transfer through direct contact, where warmer materials pass their energy to cooler ones.

- Convection: The movement of fluid or air carries heat, promoting an even distribution throughout a space.

- Radiation: Transfer of energy in the form of electromagnetic waves, allowing heat to travel through air without direct contact.

Each method has its unique applications and efficiencies, making it important to select the right approach based on specific needs.

Considerations when choosing a heating solution include:

- Energy source availability and cost.

- Space requirements and installation ease.

- Desired temperature control and speed of heating.

Understanding these mechanisms helps users maximize performance while ensuring safety and efficiency in their heating solutions.

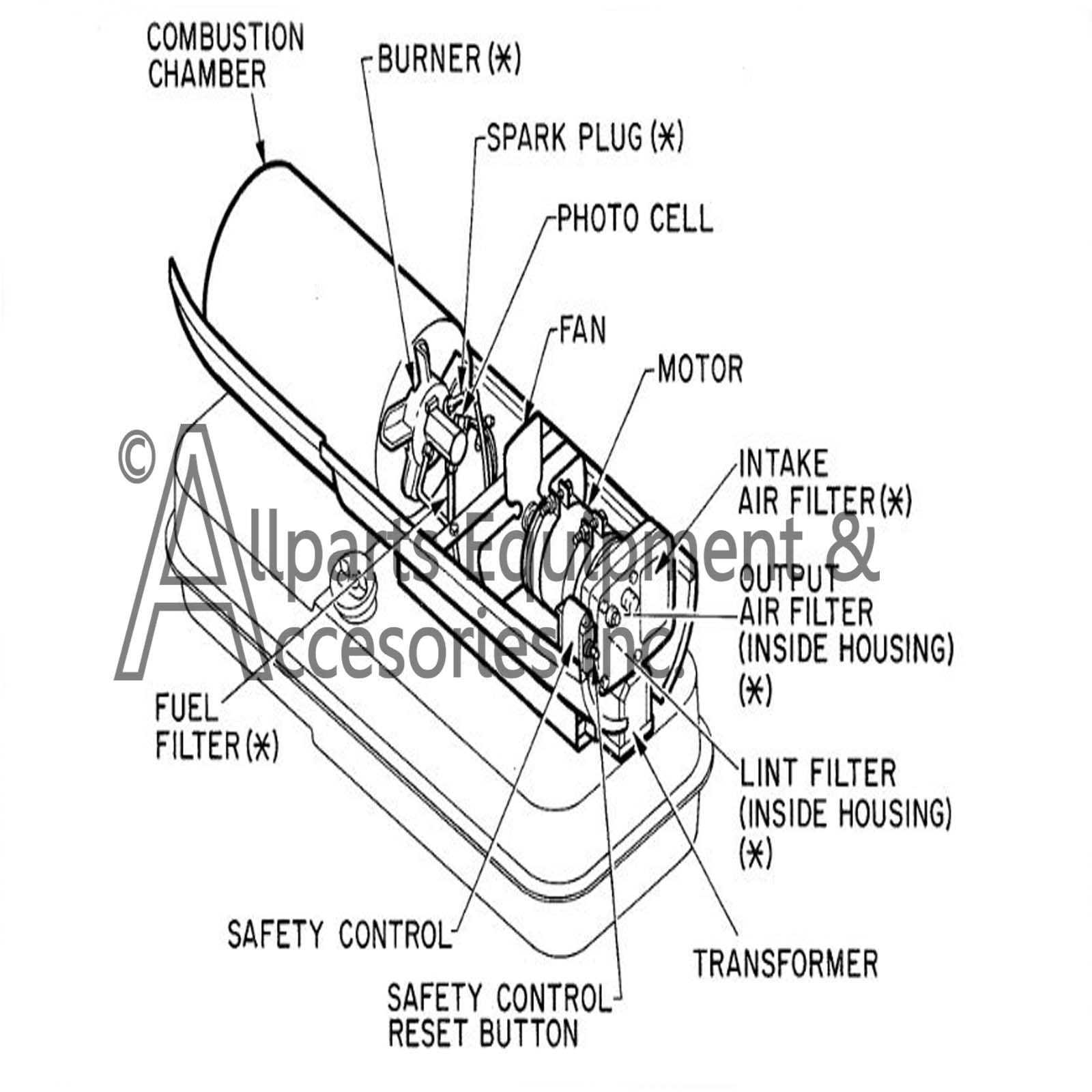

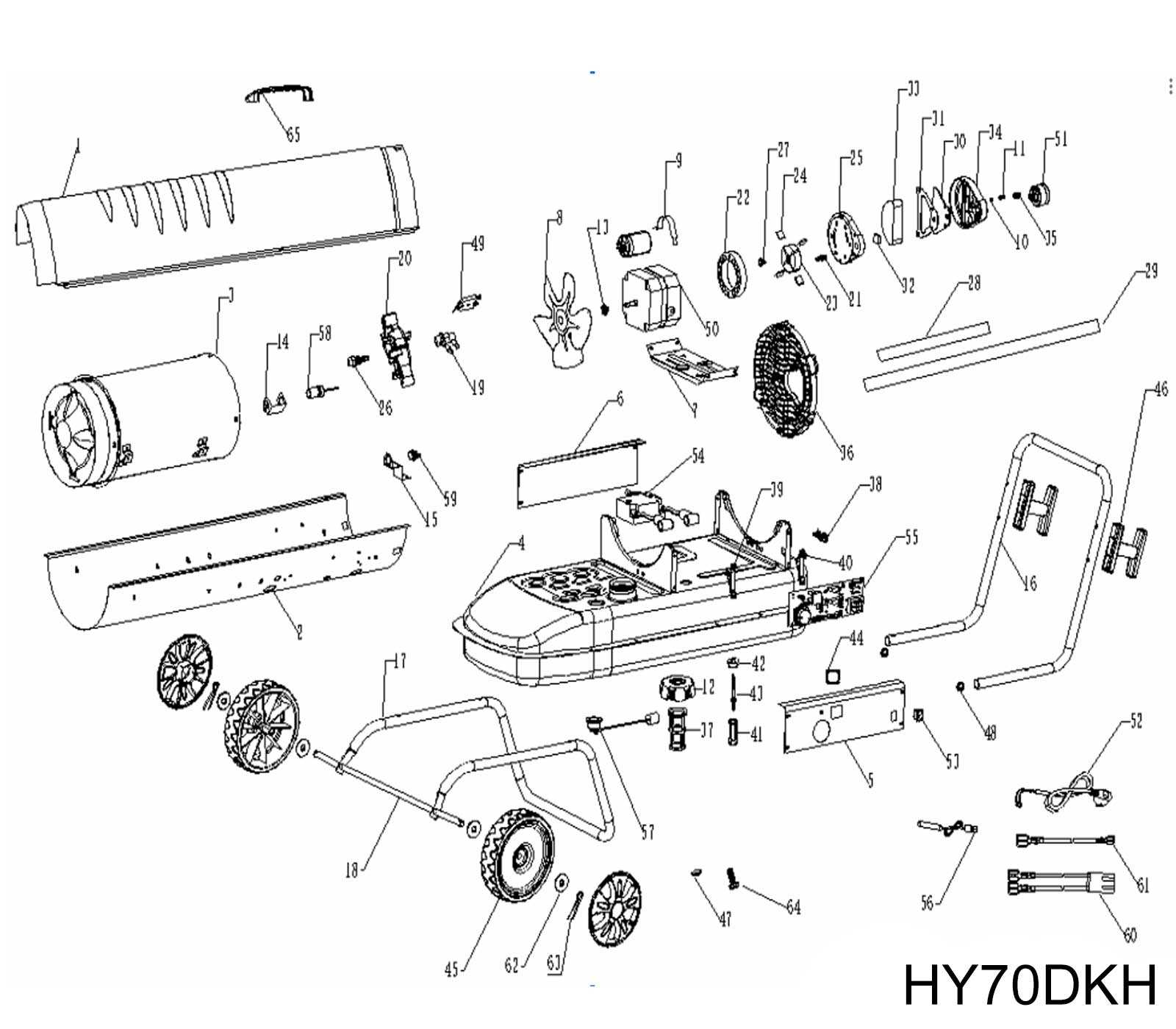

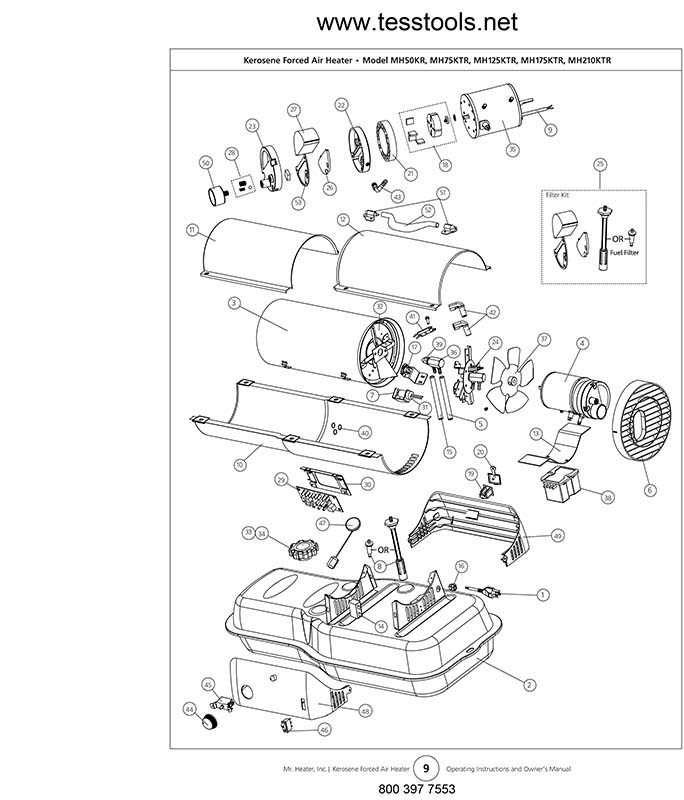

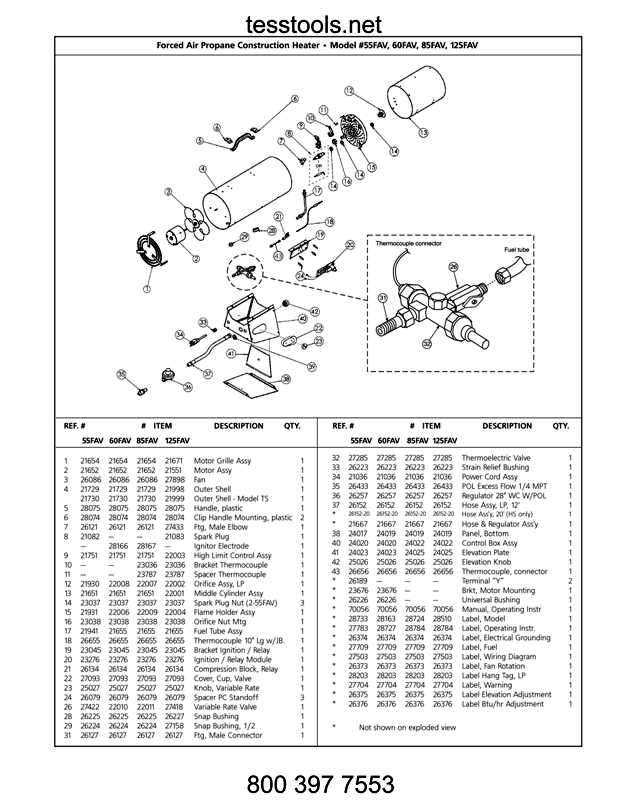

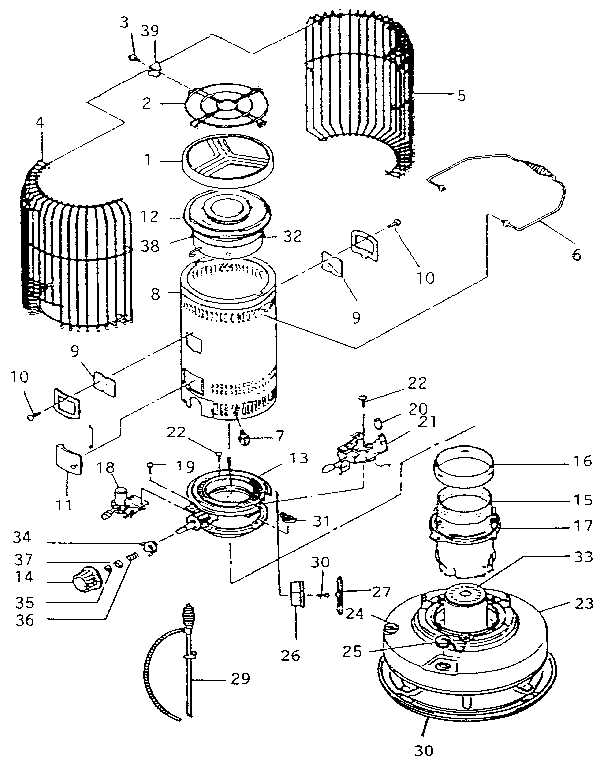

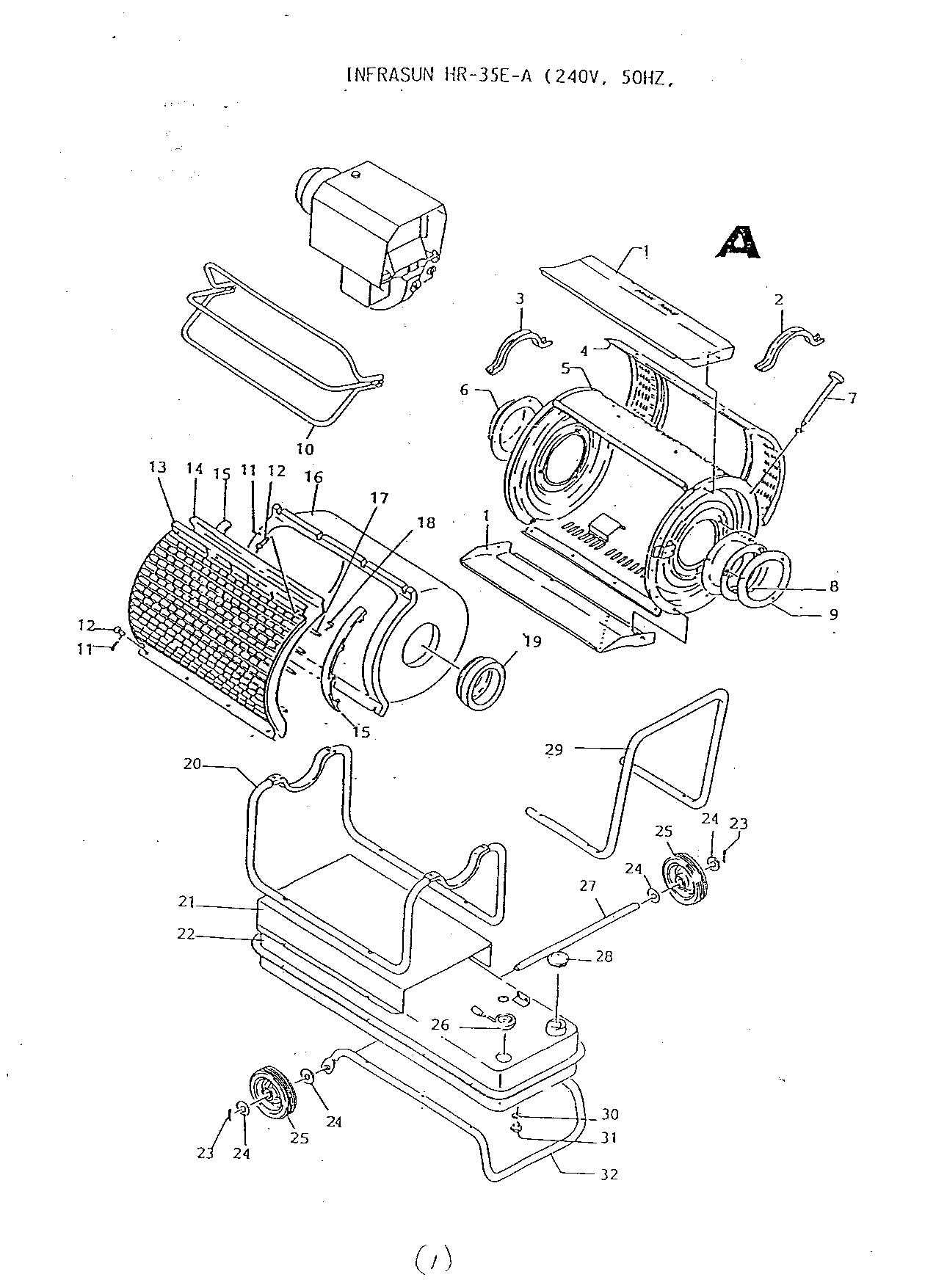

Key Components of Torpedo Heaters

Understanding the essential elements of a portable warming device is crucial for efficient operation and maintenance. Each component plays a vital role in ensuring optimal performance and safety, contributing to the overall functionality of the unit.

Combustion Chamber: This is where fuel is ignited to produce heat. The design of the chamber significantly impacts efficiency and emission levels, making it a critical area to monitor for proper operation.

Fan: The fan circulates heated air throughout the space, enhancing warmth distribution. A well-functioning fan is essential for quick heating and maintaining a comfortable environment.

Fuel Tank: This component holds the necessary fuel for combustion. The size and material of the tank affect how long the device can operate before needing a refill, influencing overall convenience.

Thermostat: The thermostat regulates temperature settings, allowing users to maintain desired warmth levels. This control mechanism is important for energy efficiency and user comfort.

Exhaust System: Proper venting of combustion gases is crucial for safety. The exhaust system ensures that harmful fumes are safely directed away from the area, protecting users from potential hazards.

Familiarity with these vital components enhances the ability to effectively utilize the device, ensuring both safety and comfort in various settings.

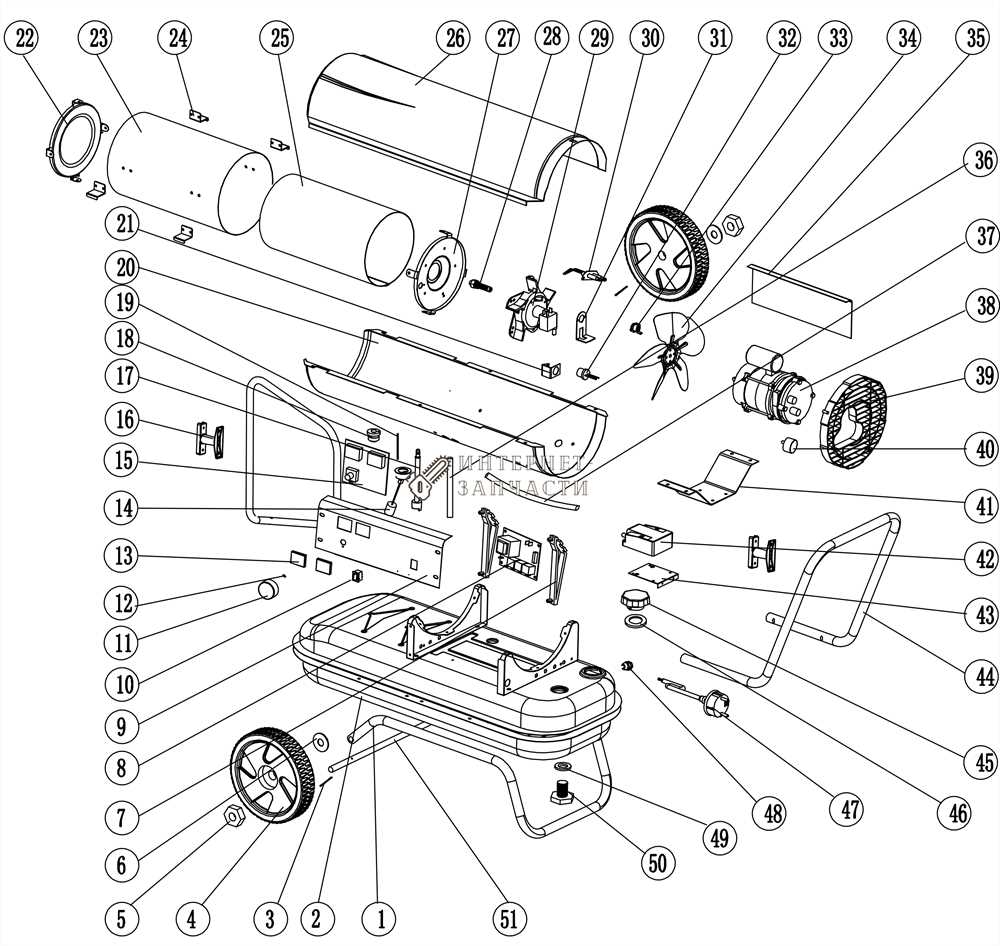

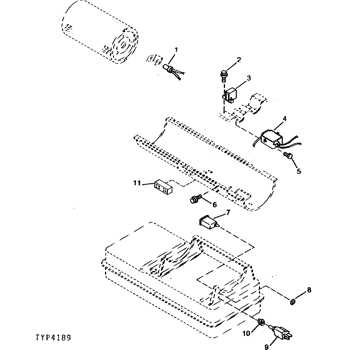

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for effective maintenance and troubleshooting. Such illustrations provide a visual guide that simplifies the identification of individual elements and their relationships within a system. By mastering this skill, you can enhance your ability to carry out repairs and ensure optimal performance of your equipment.

Key Elements to Look For

When examining an illustration, focus on several critical aspects:

- Labels: Each part is usually marked with a unique identifier, which may be numerical or alphanumeric.

- Connections: Arrows or lines often indicate how components are linked, highlighting flow or interactions.

- Legend: A legend or key may be provided, explaining symbols and terminology used in the illustration.

Interpreting the Information

Once you identify the key elements, consider the following approach to effectively interpret the information:

| Step | Description |

|---|---|

| 1 | Start with the legend to understand symbols and terms. |

| 2 | Locate each component and note its identifier. |

| 3 | Analyze connections to understand how parts interact. |

| 4 | Refer to additional resources if further clarification is needed. |

By following these steps, you can gain a comprehensive understanding of the schematic, allowing you to navigate repairs and maintenance with confidence.

Common Issues and Solutions

When dealing with portable heating devices, users often encounter a variety of challenges that can affect performance and efficiency. Understanding these common problems and their corresponding solutions can enhance the longevity of the equipment and ensure optimal functionality.

Frequent Problems

- Inconsistent temperature output

- Excessive noise during operation

- Failure to ignite or start

- Unusual odors when in use

- Overheating and automatic shut-off

Effective Solutions

- Inconsistent temperature output: Check for obstructions in the airflow and ensure that the device is clean and free from dust buildup.

- Excessive noise: Inspect for loose components or debris that may be causing vibrations, and tighten any loose screws.

- Failure to ignite: Verify fuel levels and ensure that the ignition system is functioning properly; replace faulty components if necessary.

- Unusual odors: Ensure proper ventilation and clean the unit regularly to prevent the accumulation of residues.

- Overheating: Regularly check the thermostat settings and ensure that the unit is not obstructed, allowing for adequate airflow.

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires consistent attention and proper care. By implementing a few straightforward practices, you can extend the lifespan of your unit and enhance its performance. Here are some essential tips to keep in mind.

- Regular Cleaning: Dust and debris can accumulate, affecting efficiency. Clean the exterior and accessible components regularly to maintain optimal function.

- Check Connections: Inspect electrical connections and fuel lines periodically. Look for signs of wear or damage and replace any compromised parts immediately.

- Routine Inspections: Schedule periodic checks to identify potential issues before they escalate. Professional evaluations can help pinpoint areas needing attention.

- Monitor Performance: Keep an eye on the unit’s performance. Any unusual noises or decreased output may indicate underlying problems that need to be addressed.

- Follow Manufacturer Guidelines: Adhere to the recommended maintenance schedule provided by the manufacturer. This ensures that all necessary procedures are carried out timely.

By following these practices, you can ensure that your equipment operates efficiently and reliably for years to come.

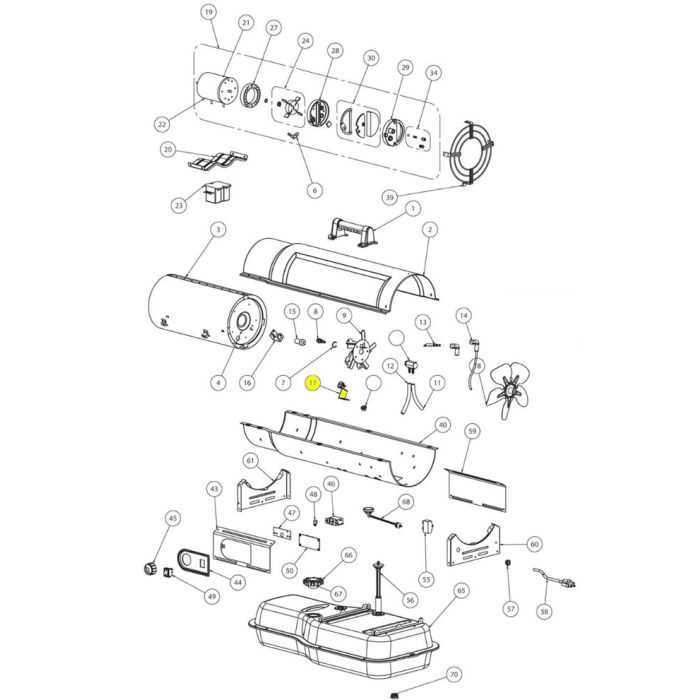

Safety Features in Torpedo Heaters

When it comes to portable warming devices, ensuring user safety is paramount. Various features are integrated into these units to minimize risks and enhance secure operation, making them reliable for both indoor and outdoor use.

- Overheat Protection: This feature automatically shuts down the unit if it reaches unsafe temperatures, preventing potential fires.

- Tip-Over Switch: If the device is accidentally knocked over, this switch immediately cuts off power, reducing the risk of hazards.

- Fuel Safety Mechanisms: Many units include safeguards against leaks and spills, ensuring that fuel remains contained and preventing dangerous situations.

- Automatic Restart: In the event of a power failure, this function ensures that the unit will not automatically restart, reducing the chances of accidents upon reconnection.

- Child Lock Features: Some models offer controls that can be locked, preventing unauthorized adjustments and enhancing safety in family environments.

By incorporating these essential safety features, users can enjoy the benefits of efficient warmth while minimizing risks associated with operation.

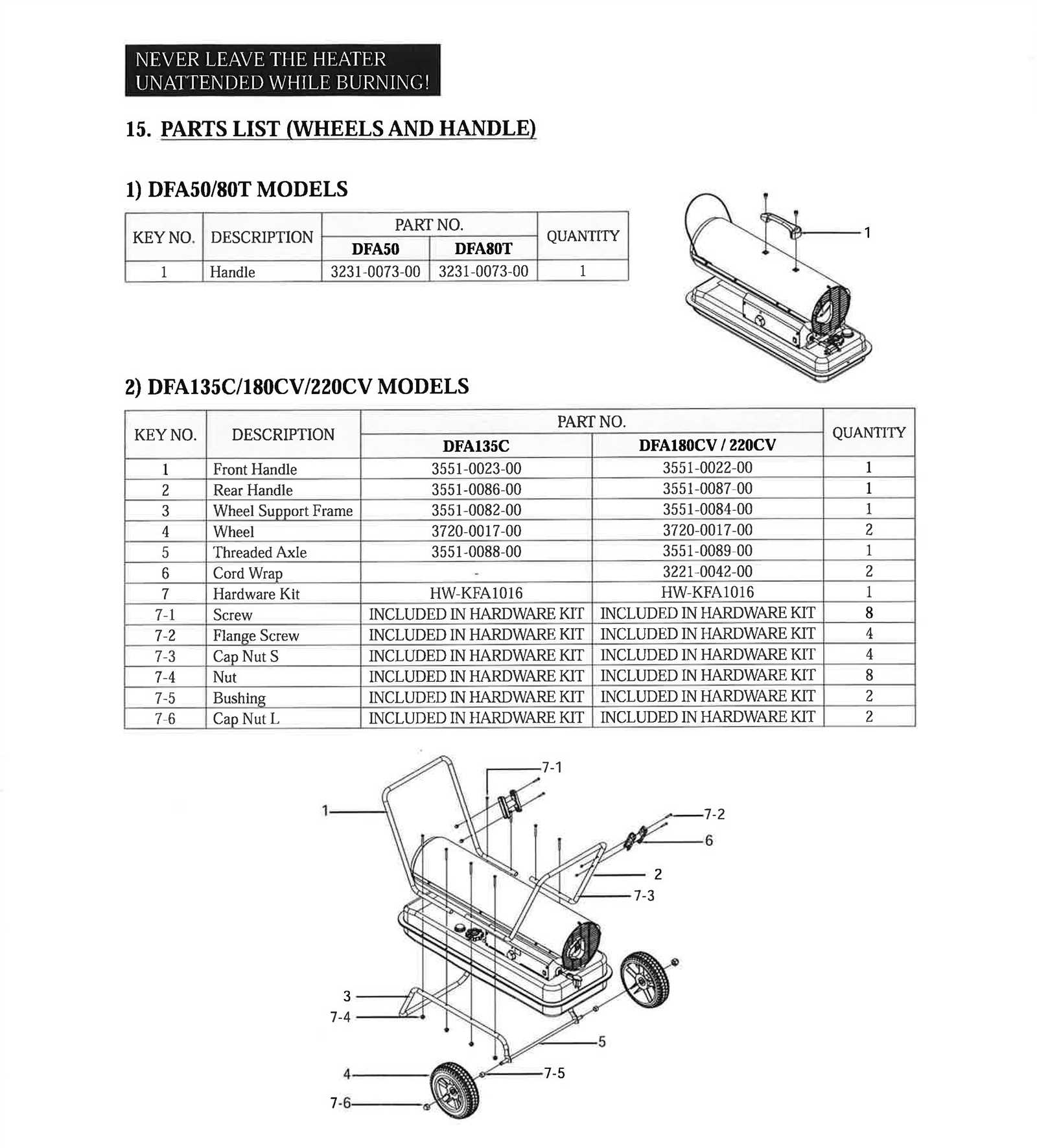

Replacement Parts: When and Why

Ensuring optimal performance of any device often hinges on the timely substitution of worn or damaged components. Recognizing the signs that indicate a need for new elements is crucial in maintaining efficiency and safety. Understanding the reasons behind replacements can save time and resources in the long run.

Identification of Issues: Over time, wear and tear can lead to decreased functionality. If you notice irregularities in performance, such as unusual noises or inconsistent operation, it may be time to investigate further. Prompt attention can prevent minor issues from escalating into significant malfunctions.

Cost-Effectiveness: Replacing individual components can be more economical than investing in an entirely new system. When specific elements fail, assessing the feasibility of substitution can lead to considerable savings while prolonging the life of the overall unit.

Safety Considerations: Compromised parts can pose safety risks, including potential hazards to users and the environment. Timely replacements not only enhance functionality but also ensure safe operation. Regular checks and timely substitutions contribute to a safer working environment.

Improved Efficiency: New components can enhance the overall efficiency of the equipment. Upgrading to modern alternatives can provide better performance, lower energy consumption, and reduce environmental impact. Staying current with advancements in technology can yield significant benefits.

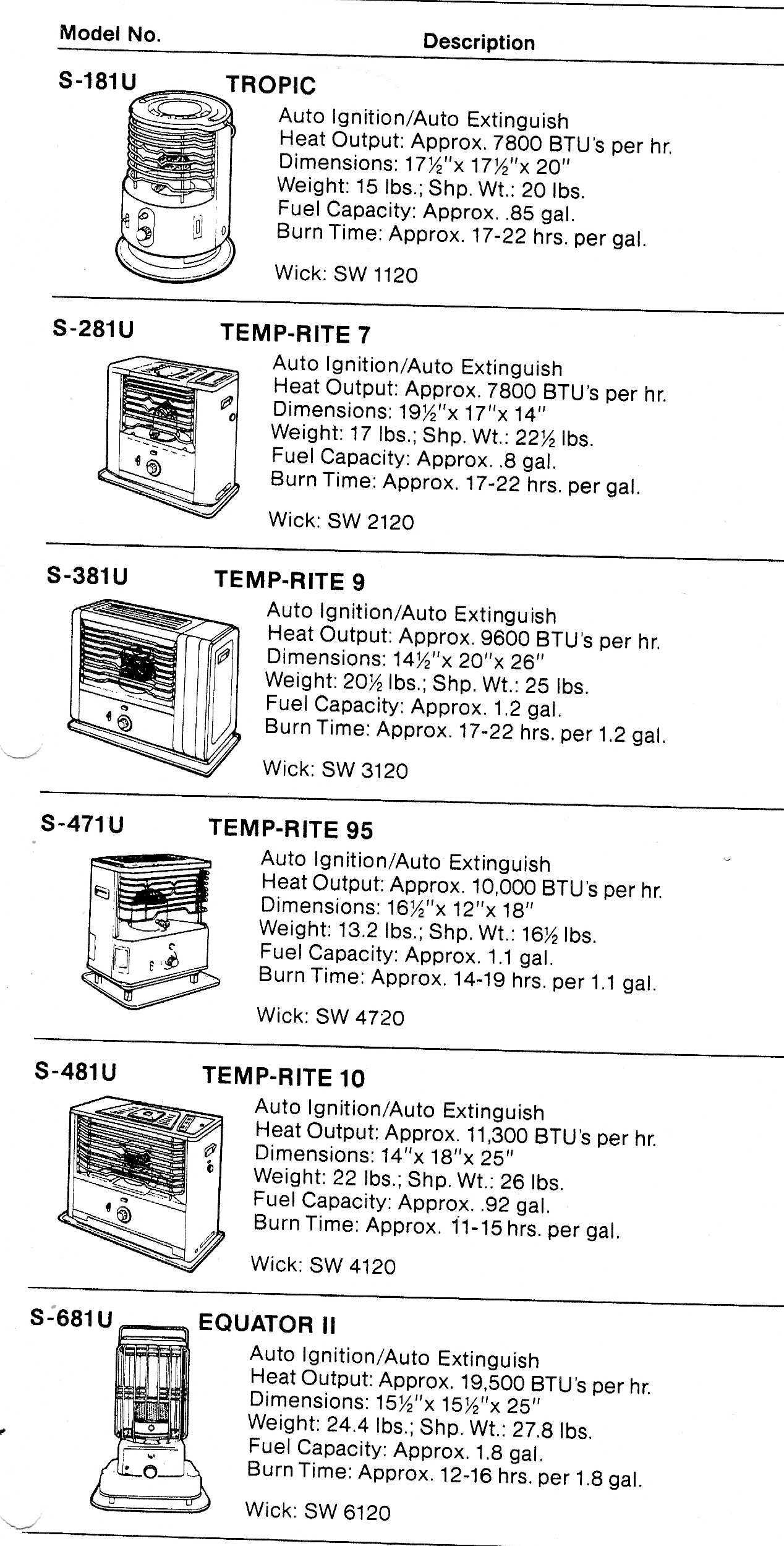

Comparing Different Heater Models

When exploring various warming devices, it’s essential to consider their distinct features and functionalities. Each model comes with its own set of advantages, making it suitable for different environments and user preferences. Understanding these differences can significantly influence the choice that best meets individual needs.

Efficiency and Performance

Efficiency varies among models, impacting energy consumption and heating speed. Some devices are designed for quick heating, ideal for large spaces, while others may provide sustained warmth over longer periods. Assessing the energy ratings and output levels can help determine which option aligns with your requirements.

Portability and Design

Another critical aspect is the portability and aesthetic design of the units. Some are compact and lightweight, allowing for easy movement between rooms, while others are more robust and may require a designated installation space. Evaluating the design features, such as safety mechanisms and ease of use, can enhance overall satisfaction with the selected model.

Best Practices for Usage

Utilizing any heating device effectively requires attention to safety and efficiency. Understanding how to operate these systems properly ensures not only optimal performance but also longevity. Adhering to recommended guidelines can significantly enhance your experience and minimize potential risks.

Safety Precautions

Before initiating operation, ensure that the area is well-ventilated to prevent any buildup of harmful gases. Always check the equipment for any signs of wear or damage. Using a timer or thermostat can help maintain a consistent temperature and reduce energy consumption. Additionally, keep flammable materials at a safe distance to avoid accidents.

Maintenance Tips

Regular upkeep is crucial for maintaining efficiency. Clean the device frequently to remove dust and debris that can hinder performance. Inspect connections and seals periodically to ensure they remain intact. Consider scheduling professional inspections at least once a year to address any underlying issues that may not be immediately visible.