Comprehensive Guide to New Holland 1465 Haybine Parts Diagram

In the realm of farming machinery, maintaining optimal functionality is crucial for efficiency and productivity. Each component plays a significant role in ensuring that the entire system operates smoothly. A comprehensive overview of the various elements involved can greatly assist operators in troubleshooting and performing maintenance tasks.

For those familiar with agricultural implements, recognizing how individual segments interconnect is essential. This knowledge not only aids in repairs but also enhances overall operational understanding. By delving into the intricate details of machinery configurations, users can achieve greater reliability and performance from their equipment.

Exploring the layout of essential components allows for informed decision-making when it comes to repairs or upgrades. With the right insights, maintaining agricultural machinery becomes a more manageable task, ultimately leading to improved yields and reduced downtime.

Understanding New Holland 1465 Haybine

This section delves into the intricacies of a vital agricultural implement designed for efficient crop management. With a focus on functionality and design, we explore how this machine enhances the harvesting process, ensuring optimal results for farmers and landowners alike.

Key Features

- Robust construction for durability

- Efficient cutting mechanisms

- Adjustable height settings for various crop types

- User-friendly controls for ease of operation

Maintenance Tips

- Regularly inspect blades for wear and tear.

- Lubricate moving parts to ensure smooth operation.

- Check hydraulic systems for leaks.

- Clean the machine after each use to prevent buildup.

Understanding the design and operational features of this implement is crucial for maximizing efficiency and prolonging its lifespan, making it an essential tool in modern agriculture.

Key Features of the Haybine Model

This agricultural implement stands out for its innovative design and efficiency in cutting and conditioning crops. Its features enhance productivity, making it a preferred choice for many farmers looking to optimize their hay-making processes.

Design and Build Quality

- Durable construction materials ensure longevity and reliability.

- Compact design facilitates maneuverability in tight spaces.

- Adjustable settings allow customization for different crop types.

Performance and Efficiency

- Powerful cutting mechanisms deliver clean and precise cuts.

- Conditioning components improve drying times significantly.

- Low maintenance requirements contribute to overall cost savings.

These characteristics collectively contribute to a seamless and efficient operation, making this implement an essential tool for modern farming practices.

Importance of Maintenance for Longevity

Regular upkeep is essential for ensuring the extended lifespan and optimal performance of any machinery. By implementing a consistent maintenance routine, users can prevent potential issues before they escalate into costly repairs or complete breakdowns. Proactive care not only enhances the efficiency of equipment but also preserves its value over time.

Routine inspections, timely lubrication, and replacement of worn components are critical practices that contribute to overall functionality. Neglecting these tasks can lead to diminished productivity and may result in unforeseen disruptions during crucial operational periods. By investing time and resources into proper maintenance, owners can enjoy a more reliable and durable machine.

Additionally, maintaining machinery fosters safety for operators and surrounding personnel. Well-maintained equipment is less likely to experience mechanical failures that could pose risks during operation. Thus, prioritizing upkeep is not just about longevity; it is also a matter of ensuring a secure working environment.

Common Issues and Troubleshooting Tips

When operating agricultural mowing equipment, users may encounter a variety of challenges that can hinder performance and efficiency. Understanding these common problems and knowing how to address them can ensure smoother operation and prolonged lifespan of the machinery. This section provides insights into frequent issues and practical troubleshooting strategies.

| Issue | Possible Causes | Troubleshooting Tips |

|---|---|---|

| Overheating | Insufficient lubrication, clogged filters | Check oil levels and change filters; ensure proper lubrication is maintained. |

| Uneven Cutting | Dull blades, improper height adjustment | Sharpen or replace blades; adjust cutting height according to specifications. |

| Strange Noises | Loose components, damaged bearings | Inspect all moving parts; tighten loose bolts and replace damaged bearings. |

| Frequent Breakdowns | Poor maintenance, worn-out parts | Implement a regular maintenance schedule; replace any worn components promptly. |

| Stalling | Fuel issues, air filter blockage | Check fuel quality; clean or replace air filters to ensure proper airflow. |

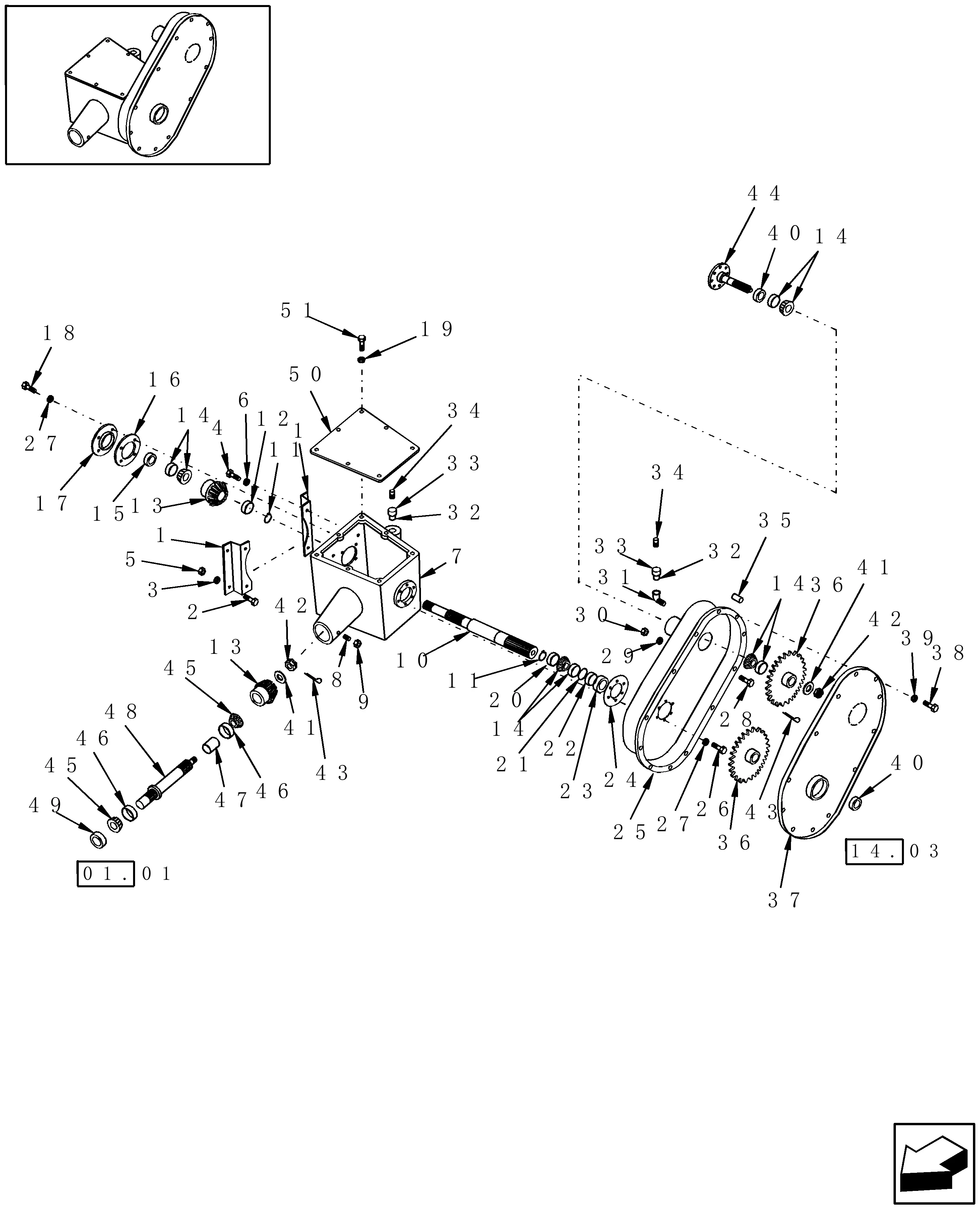

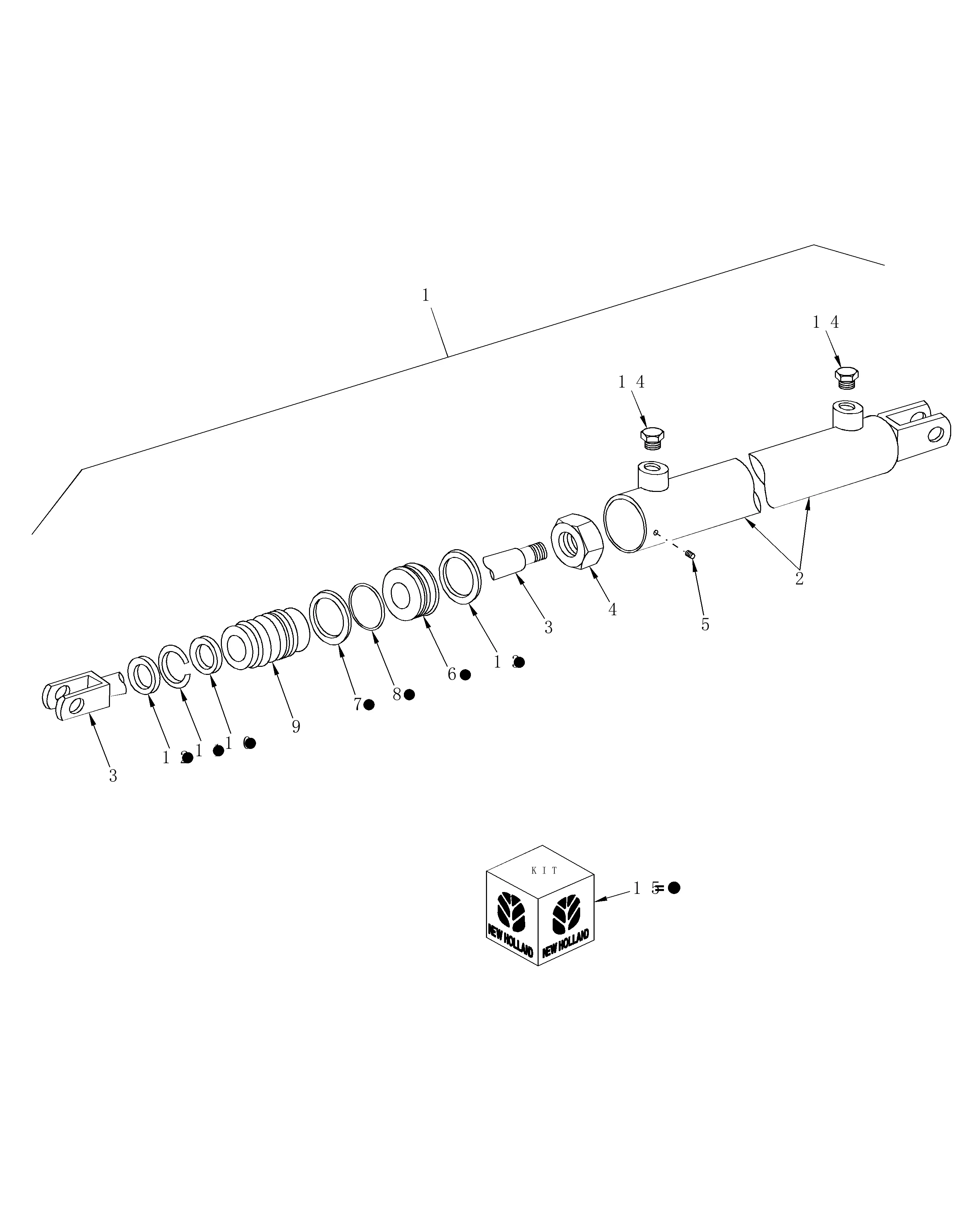

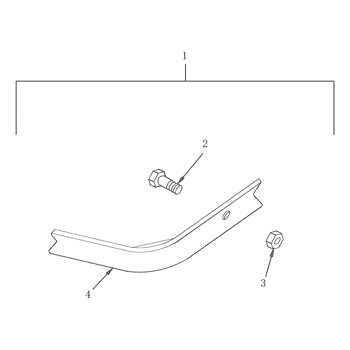

Essential Parts and Their Functions

Understanding the key components of a forage harvesting machine is crucial for optimal operation and maintenance. Each element plays a specific role, contributing to the overall efficiency and effectiveness of the equipment. Familiarity with these elements can enhance performance and extend the lifespan of the machinery.

Key Components

- Cutter Bar: The primary mechanism for cutting grass or hay, ensuring a clean and efficient harvest.

- Reel: This part lifts and feeds the crop into the cutter bar, promoting smooth operation and consistent cutting.

- Drive System: Powers various parts of the machine, enabling movement and functionality.

- Auger: Assists in moving cut material from the cutter bar to the collection area, facilitating the harvesting process.

Support and Control Elements

- Frame: The structural backbone that supports all components, ensuring stability during operation.

- Hydraulic System: Provides the necessary power for lifting and adjusting components, enhancing maneuverability.

- Controls: The interface for operators to manage machine functions, crucial for precise handling.

Recognizing the importance of these key elements not only aids in understanding the machinery but also enhances troubleshooting and repair efforts when necessary.

Where to Find Replacement Parts

Locating components for agricultural machinery can be a straightforward process with the right resources. Understanding where to search and what options are available will help ensure efficient repairs and maintenance. Whether you are seeking specific items or a broader range of supplies, there are several avenues to explore.

Online Retailers

Many websites specialize in offering a wide selection of equipment components. Online marketplaces and dedicated agricultural supply stores can provide both new and refurbished items. Make sure to compare prices and check customer reviews to ensure quality.

Local Dealerships and Salvage Yards

Visiting local dealerships can yield useful results, especially for original manufacturer products. Additionally, salvage yards often have a variety of used components at lower prices, which can be ideal for older models.

| Source | Description |

|---|---|

| Online Retailers | Wide selection, often competitive pricing. |

| Local Dealerships | Original manufacturer parts, reliable support. |

| Salvage Yards | Used components at reduced prices, good for older machines. |

Reading Parts Diagrams Effectively

Understanding visual representations of machinery components is essential for maintenance and repair tasks. These illustrations serve as valuable guides, allowing users to identify and locate individual elements quickly. Mastering the art of interpreting these visuals can enhance efficiency and accuracy in any mechanical project.

Key Techniques for Interpretation

- Familiarize Yourself with Symbols: Different illustrations use specific symbols to denote various components. Learning these symbols can significantly speed up your understanding.

- Pay Attention to Labels: Descriptive labels often accompany visuals, providing crucial information about each part’s function and specifications.

- Study the Layout: Analyze the arrangement of components. Understanding how parts fit together can help you identify what you need more effectively.

Steps to Follow

- Start with the Overview: Look at the entire illustration to grasp the general structure before zooming in on specific areas.

- Identify Key Components: Locate the primary parts first, then explore related elements that connect to them.

- Refer to the Manual: Use accompanying documentation to clarify any uncertainties regarding the visual representation.

Comparing OEM and Aftermarket Parts

When it comes to machinery maintenance, the choice between original components and their alternatives is crucial. Understanding the differences can help in making informed decisions that affect performance, longevity, and overall value.

Quality and Performance

One of the main factors to consider is the quality and performance of the components. Here are some key points:

- OEM Components: Designed specifically for the machinery, ensuring compatibility and reliability.

- Aftermarket Options: May vary in quality; some may exceed OEM standards, while others might not meet necessary specifications.

Cost Considerations

Price differences are significant when evaluating options. Consider the following:

- OEM Prices: Typically more expensive due to brand reputation and guaranteed quality.

- Aftermarket Costs: Often more affordable, but potential savings must be weighed against risks of inferior quality.

Ultimately, the choice between original and alternative components should reflect individual needs, budget constraints, and the desired level of quality assurance.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance tasks is essential to prevent accidents and injuries. Proper precautions not only protect the individual performing the repairs but also safeguard the equipment and surrounding environment. Adhering to safety protocols contributes to a more efficient and effective working process.

- Wear Personal Protective Equipment (PPE): Always don appropriate gear, including gloves, goggles, and steel-toed boots, to shield against potential hazards.

- Disconnect Power Sources: Before starting any work, make sure to unplug or turn off all power sources to avoid accidental activation.

- Inspect Tools and Equipment: Regularly check all tools for damage or wear. Using faulty equipment can lead to serious injuries.

- Work in a Well-Ventilated Area: Ensure proper airflow to minimize exposure to harmful fumes or dust.

- Keep the Work Area Organized: Maintain a clutter-free workspace to reduce the risk of tripping or misplacing tools.

By following these guidelines, individuals can create a safer environment for themselves and others during maintenance activities.

Tips for Optimizing Performance

Enhancing the efficiency of your agricultural machinery requires attention to several key factors. Proper maintenance, timely adjustments, and appropriate operating conditions can significantly impact the productivity and longevity of your equipment. Implementing these strategies will help ensure that your machinery operates at its best, leading to improved results in the field.

Regular Maintenance

Routine inspections are essential for identifying potential issues before they escalate. Clean all components regularly to prevent buildup that can hinder performance. Lubricate moving parts to reduce friction and wear. Additionally, replace worn or damaged components promptly to maintain optimal functionality.

Operating Conditions

How to Properly Store the Equipment

Storing agricultural machinery correctly is essential for ensuring longevity and optimal performance. Proper storage practices protect your investment from environmental damage, wear, and mechanical failures. By following a few key steps, you can significantly extend the life of your equipment and maintain its efficiency.

Clean and Inspect

Before placing your machinery in storage, thoroughly clean it to remove dirt, debris, and residues. Pay special attention to areas prone to rust and corrosion. After cleaning, conduct a comprehensive inspection to identify any potential issues that need addressing, such as worn parts or leaks. Addressing these concerns proactively can save time and money in the long run.

Choose the Right Location

Selecting an appropriate storage location is crucial. Ideally, the area should be dry, well-ventilated, and protected from direct sunlight and harsh weather conditions. If possible, use a dedicated shed or barn to shield the equipment from the elements. Consider using tarps or covers for additional protection. Ensuring that the equipment is stored properly will minimize exposure to moisture and temperature fluctuations.

User Reviews and Experiences

This section highlights the insights and feedback from users who have utilized the equipment in their agricultural practices. Their firsthand accounts can offer valuable perspectives on performance, reliability, and overall satisfaction.

Many users emphasize the importance of regular maintenance and the impact it has on longevity and functionality. Here are some common themes found in their reviews:

- Durability: Numerous users report that the machine holds up well under heavy use, often lasting many seasons with proper care.

- Efficiency: Farmers appreciate the efficiency of the machinery, noting reduced downtime and quicker work completion during peak seasons.

- Ease of Use: Many find the design user-friendly, making it accessible for operators of various skill levels.

- Parts Availability: Reviewers often comment on the ease of sourcing replacement components, which contributes to smooth operations.

However, some users also share challenges they faced:

- Initial Setup: A few individuals mention difficulties during the initial setup process, suggesting that clearer instructions could be beneficial.

- Maintenance Requirements: Some users highlight that while the machine is robust, it does require regular maintenance to keep it running optimally.

- Technical Support: A handful of reviews express a desire for improved customer support and more responsive service from manufacturers.

Overall, user experiences reflect a balance of positive feedback and constructive criticism, providing potential buyers with a comprehensive understanding of what to expect.