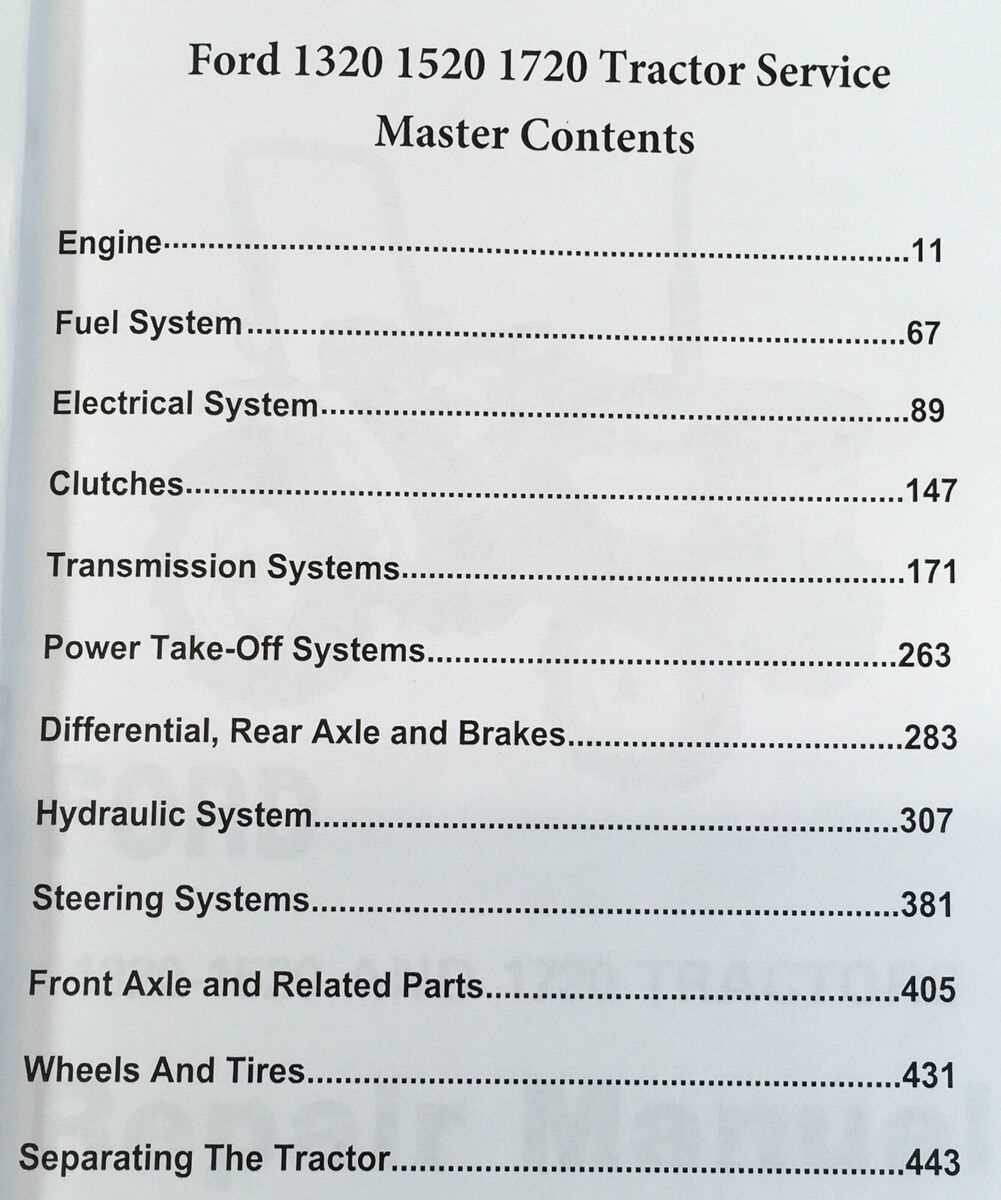

Key Components Overview for New Holland 1720

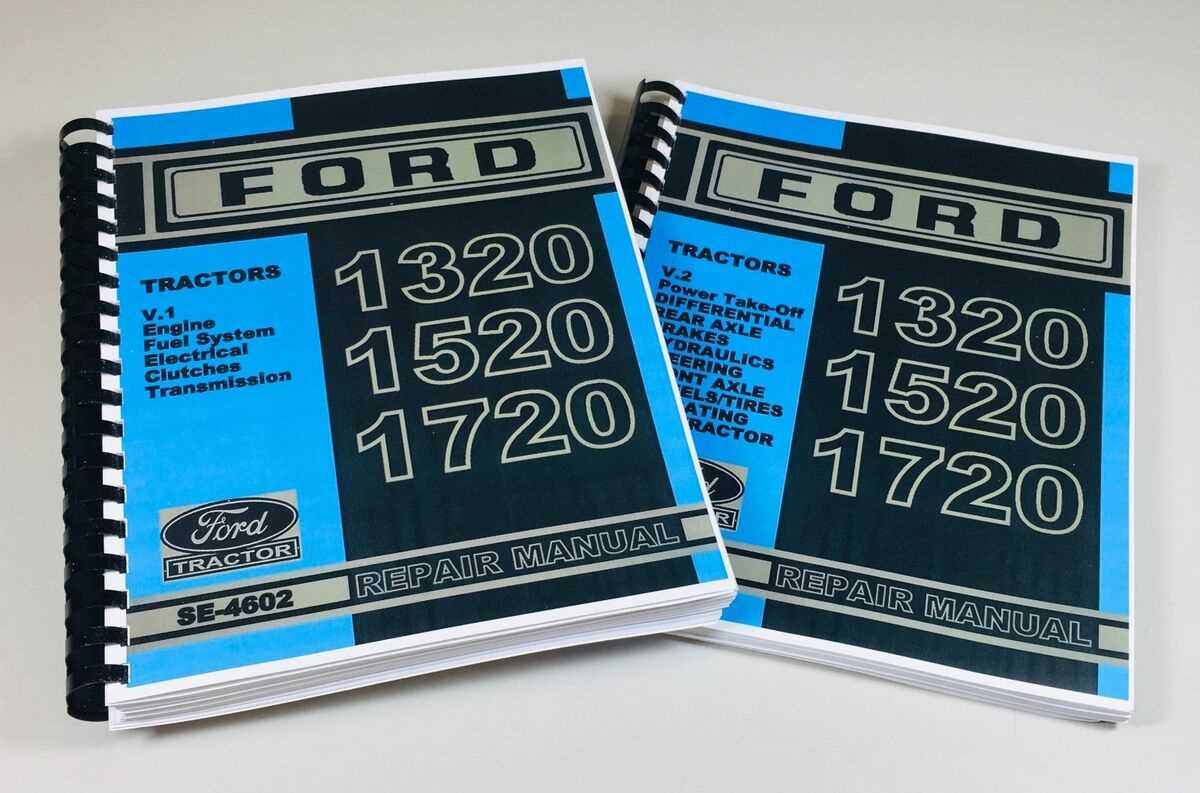

Understanding how various systems and elements within machinery function is crucial for maintenance and repair. Each individual piece plays a significant role in ensuring the smooth operation of the whole structure. Recognizing the layout and interconnections of these elements can simplify the process of identifying issues or performing upgrades.

In this section, we delve into the details of mechanical assemblies, focusing on the relationships between key modules. This knowledge aids in troubleshooting and ensures that the right approach is taken for any necessary adjustments or replacements. A clear visual guide will also enhance your comprehension of these interactions.

New Holland 1720 Parts Overview

Understanding the key components of this agricultural machine is essential for maintaining its performance and ensuring efficient operation. Each section of the equipment plays a crucial role in its functionality, and knowing how these elements work together can help prevent downtime and enhance productivity.

Critical Components for Performance

Several vital elements make up the mechanical structure, each contributing to the overall functionality. From the engine system to the hydraulic mechanisms, every part works in harmony to deliver reliable performance. It’s important to regularly inspect and maintain these elements to ensure smooth operation.

Maintaining Efficiency and Longevity

Proper upkeep of the machine involves focusing on critical areas, such as the transmission, cooling system, and electrical wiring. Regular maintenance and timely replacement of worn-out components are key to extending the lifespan of the equipment and avoiding costly repairs.

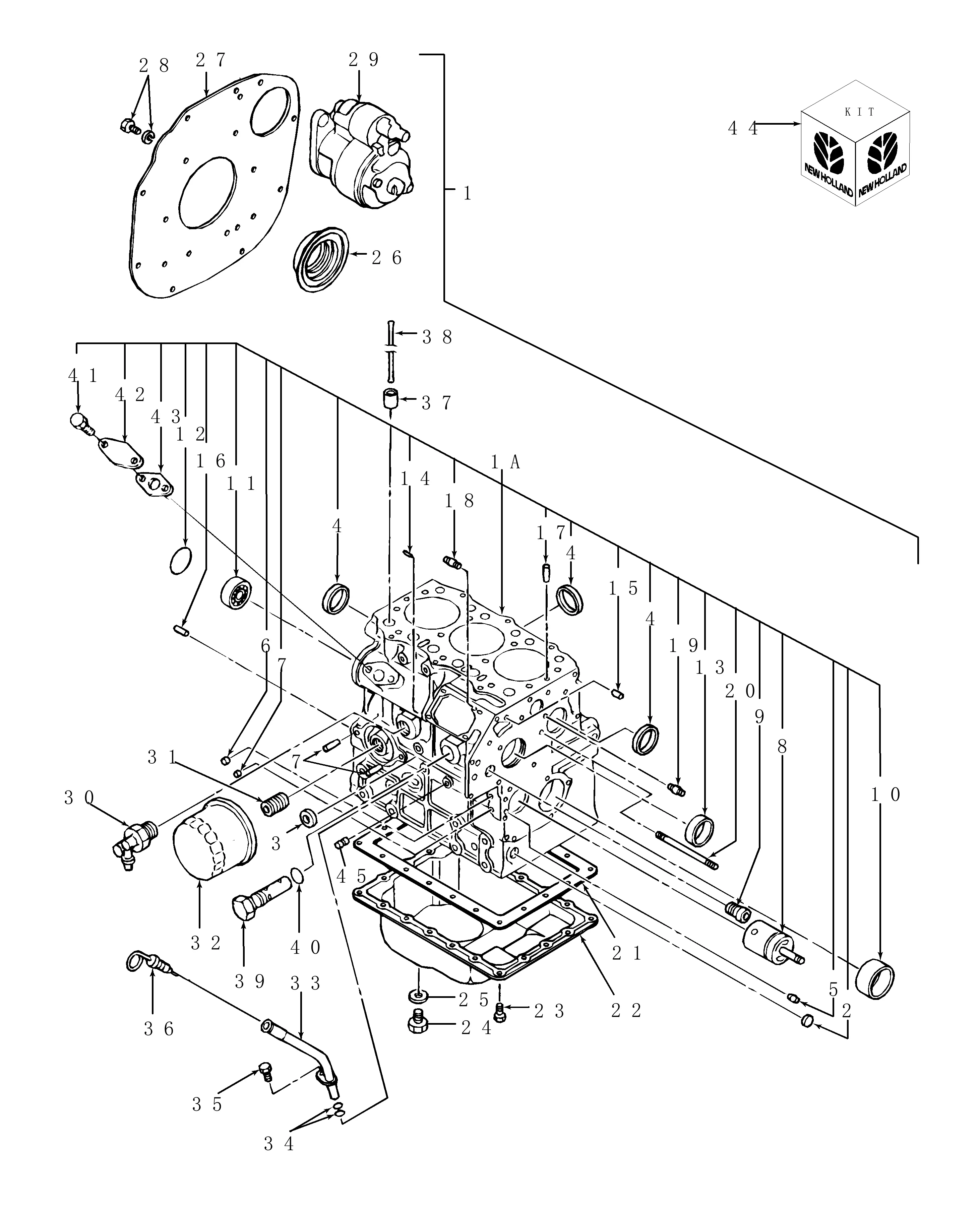

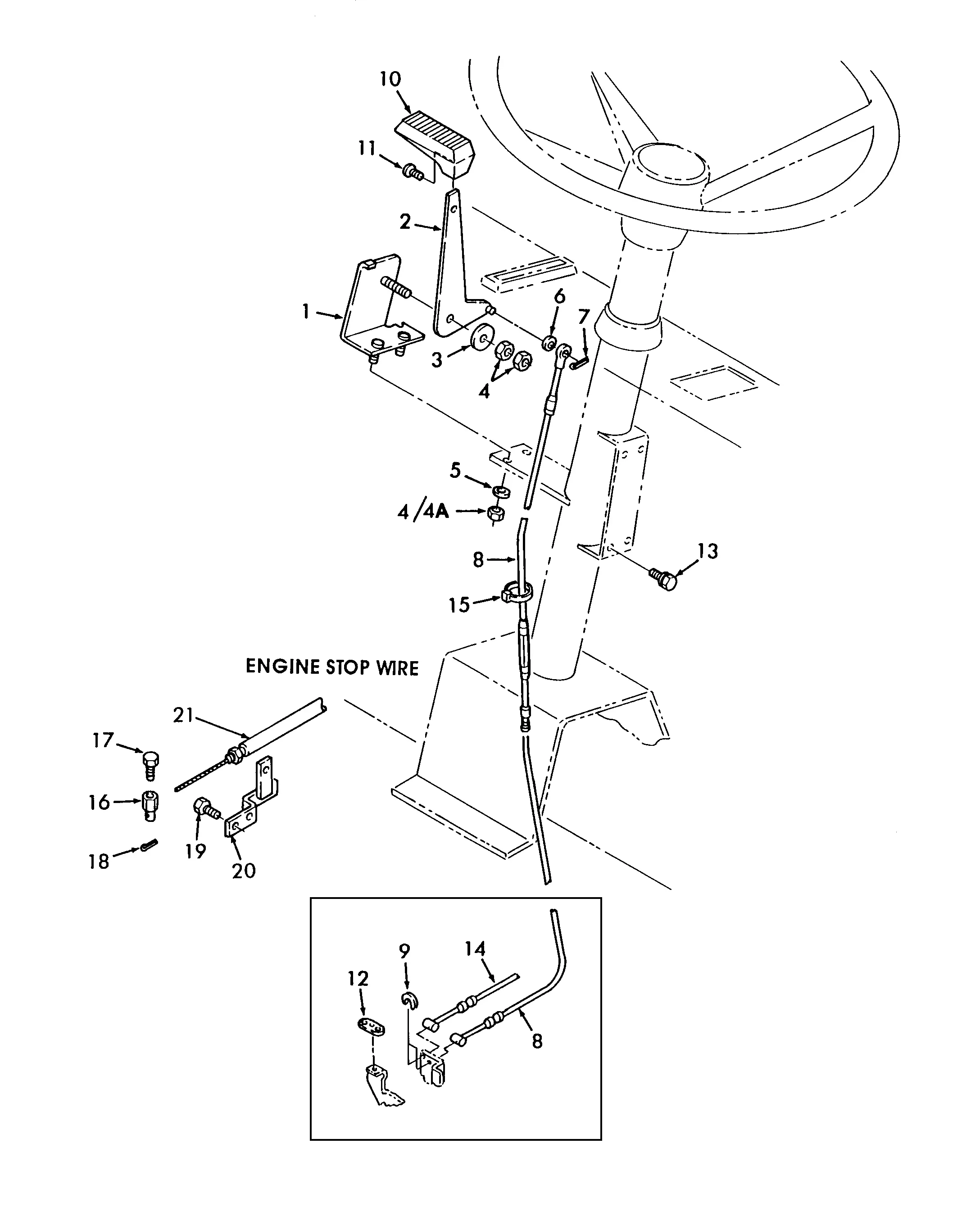

Engine Components Breakdown

The engine’s internal structure consists of various elements working together to ensure optimal performance. Understanding the layout of these elements helps in identifying potential issues and maintaining efficiency. By breaking down the core sections, one can gain a better grasp of how these components interact and support the engine’s operation.

Key Sections of the Engine

Several main areas contribute to the engine’s function. The cylinder block forms the foundation, housing crucial elements such as pistons and crankshaft. Meanwhile, the fuel system regulates the flow of fuel, ensuring the right mixture for combustion. Cooling and lubrication mechanisms are also integral, preventing overheating and reducing friction during operation.

Moving Parts and Their Roles

The pistons, connected to the crankshaft, convert energy from combustion into mechanical motion, driving the machinery. Valves, controlled by the camshaft, manage the intake and exhaust cycles. Timing mechanisms ensure precise synchronization between these components, allowing the engine to operate smoothly.

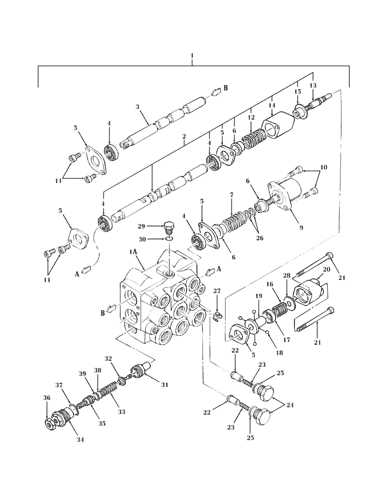

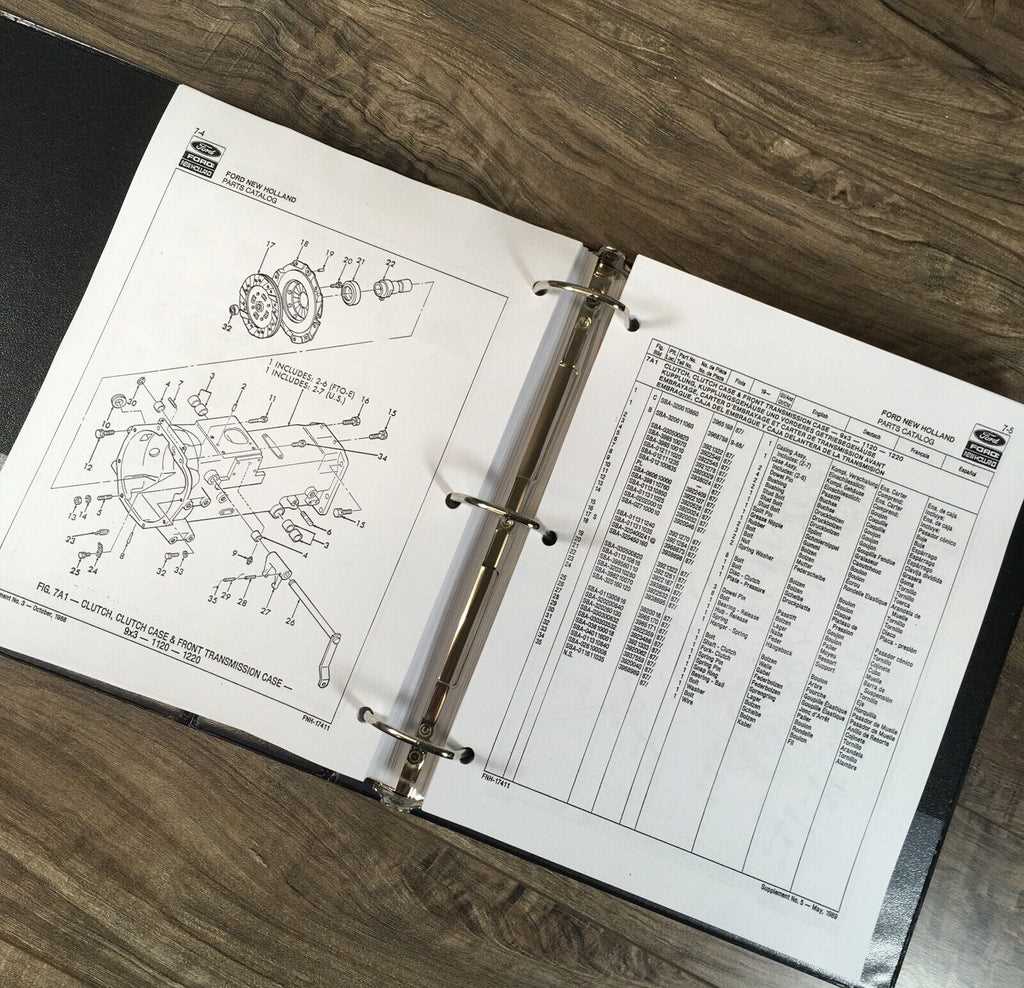

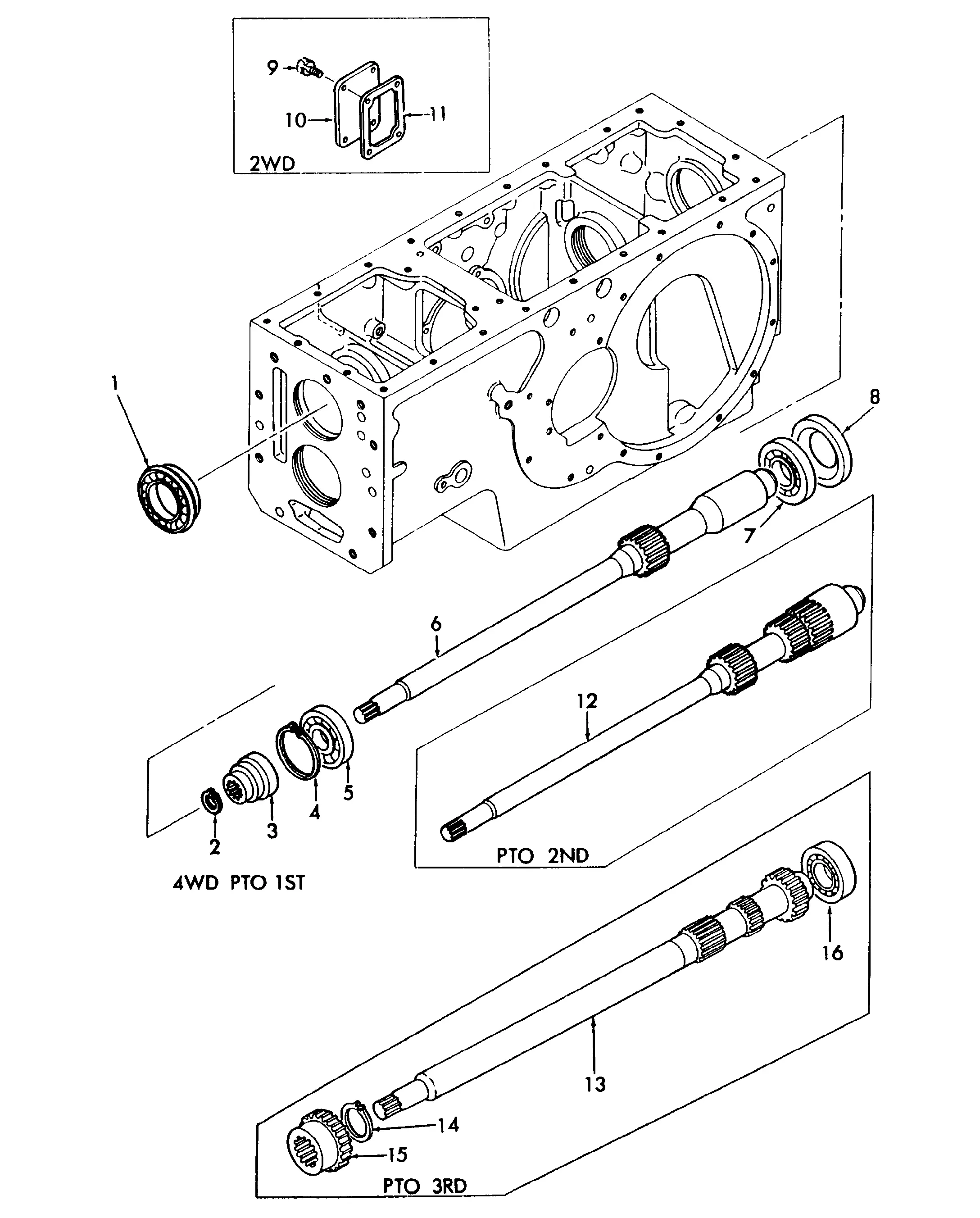

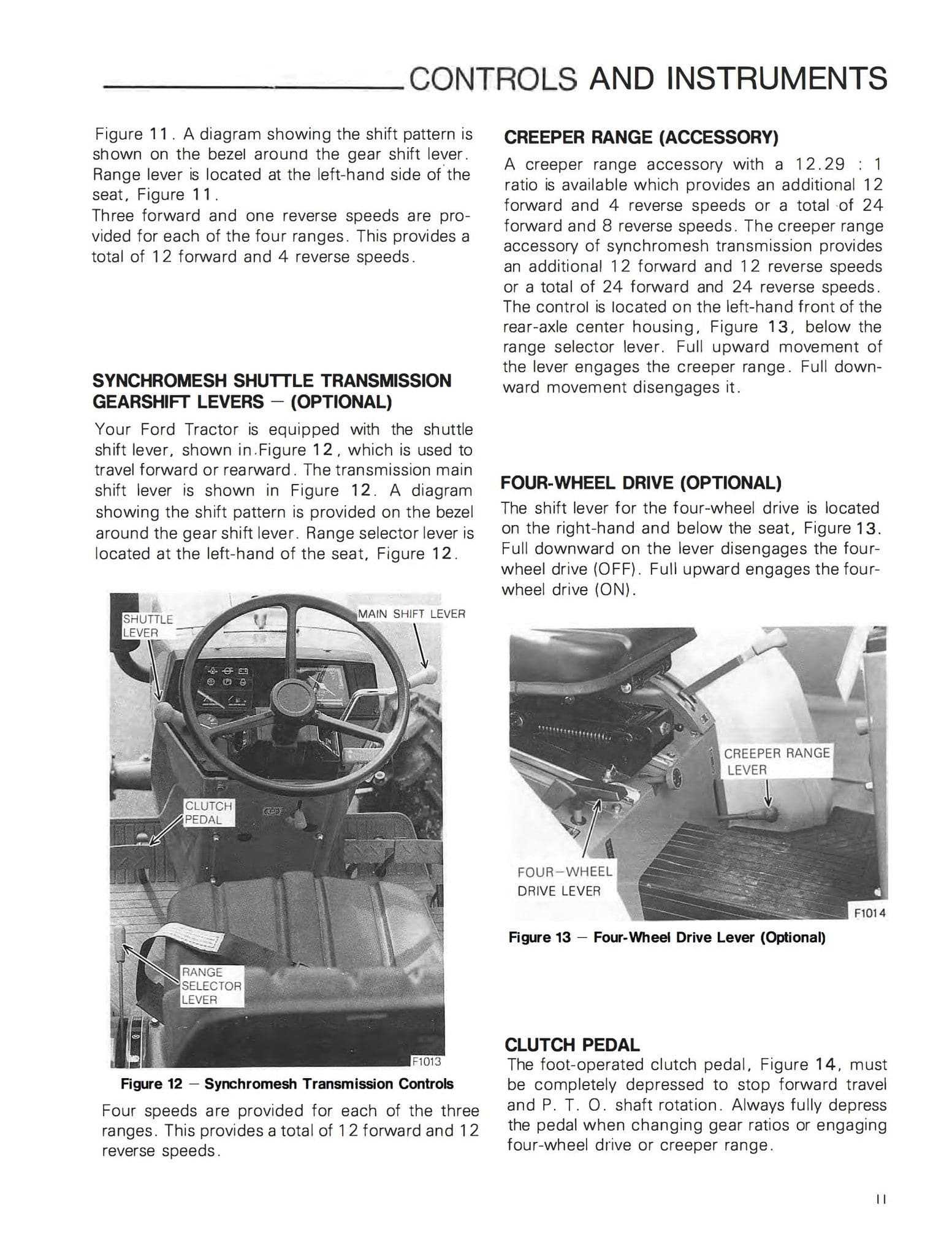

Transmission System Diagram

The transmission system is crucial for transferring power from the engine to the wheels, ensuring efficient movement and control of the vehicle. This section provides a detailed look at the key components involved in the power transfer process, highlighting how different parts work together to maintain optimal performance.

| Component | Function | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Clutch | Engages and disengages the engine from the transmission. | ||||||||||

| Gearbox | Alters the torque and speed ratio between the engine and the wheels. | ||||||||||

| Driveshaft | Transfers rotational power from the gearbox to the differential. | ||||||||||

| Differential | Distributes power to the

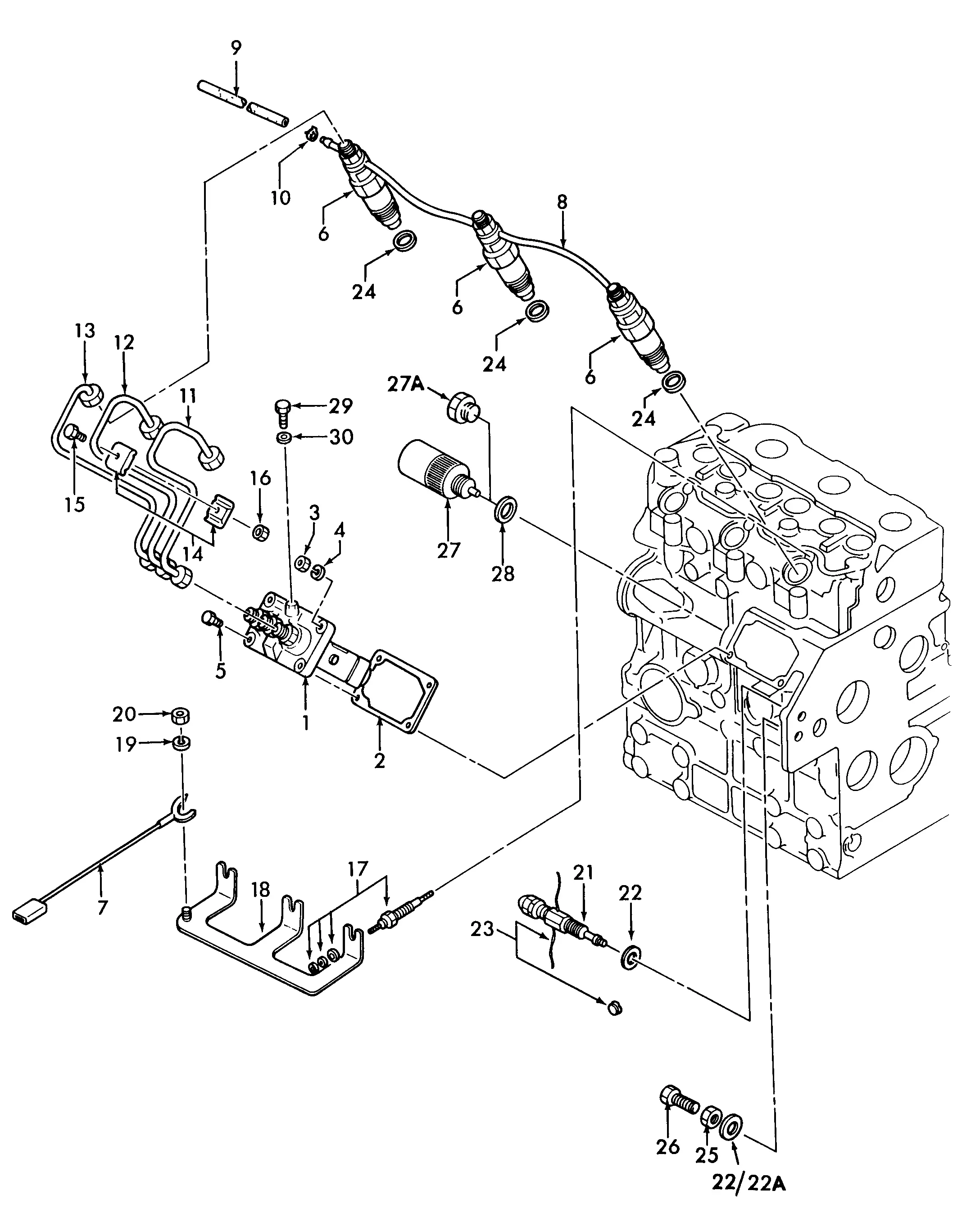

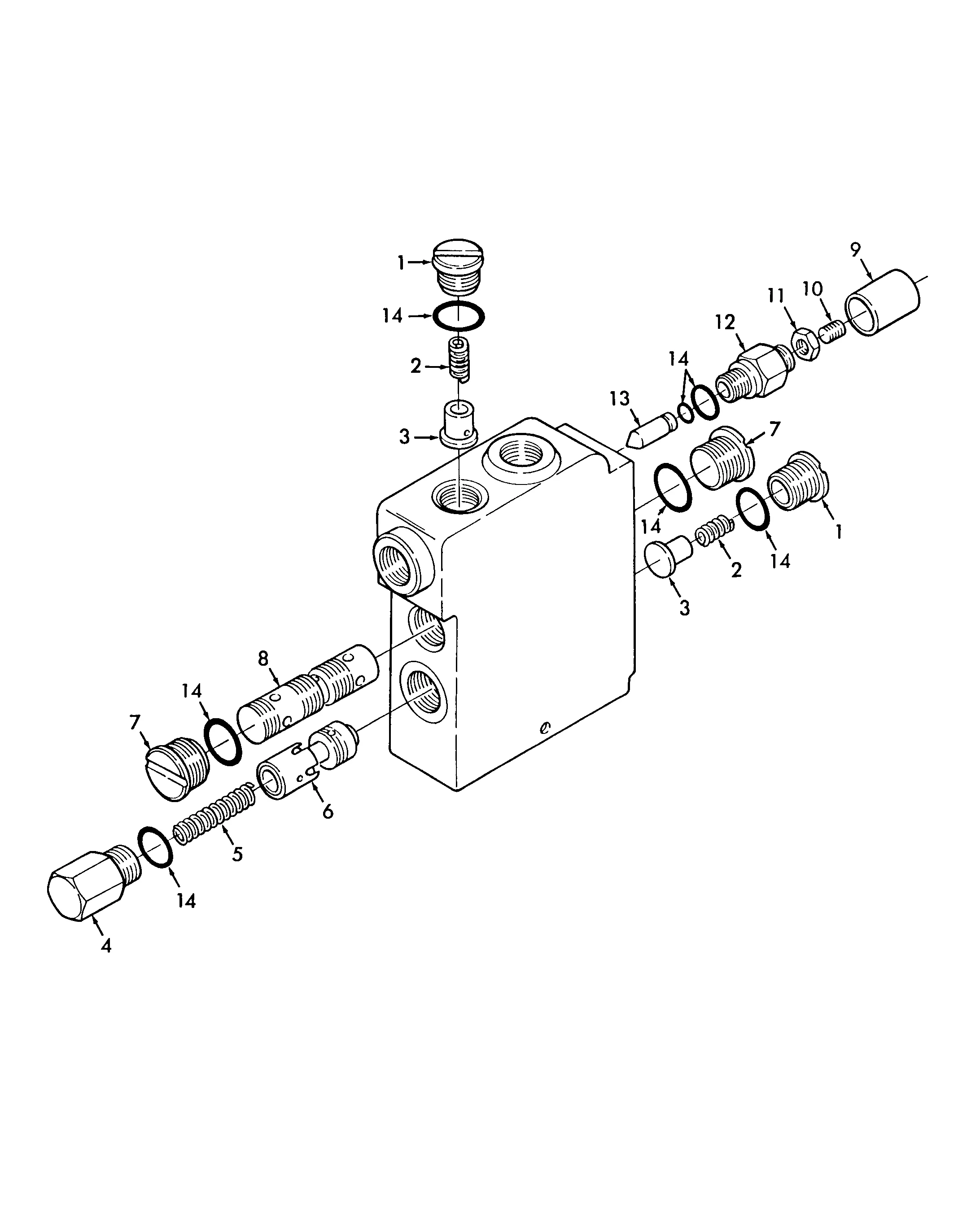

Hydraulic Parts and FunctionsHydraulic systems play a critical role in powering essential machinery operations. These systems convert fluid power into mechanical energy, enabling precise control and efficient movement. Understanding the components within these systems is crucial for maintaining optimal performance and ensuring reliability in various applications. Key Components of the Hydraulic System

Supporting Elements for Smooth Operation

|

| Component | Description |

|---|---|

| Fuel Tank | Stores the fuel before it is sent to the engine. |

| Fuel Filter | Removes impurities from the fuel to protect the engine. |

| Fuel Pump | Moves fuel from the tank to the engine at the required pressure. |

| Fuel Injectors | Sprays the correct amount of fuel into the combustion chamber for optimal performance. |

Rear Axle and Differential Parts

The rear axle and differential assembly plays a crucial role in the overall functionality of agricultural machinery. This section provides insights into the various components that contribute to the effective operation and performance of this vital system. Understanding these elements is essential for maintenance and repairs, ensuring optimal functionality and longevity.

Key Components

- Axle Housing: Provides structural support and houses the differential.

- Differential Gear: Allows the wheels to rotate at different speeds, especially when turning.

- Wheel Bearings: Facilitate smooth rotation of the wheels while supporting the axle.

- Pinion Shaft: Connects the drive shaft to the differential, transferring torque.

- Ring Gear: Engages with the pinion gear, facilitating power transfer to the wheels.

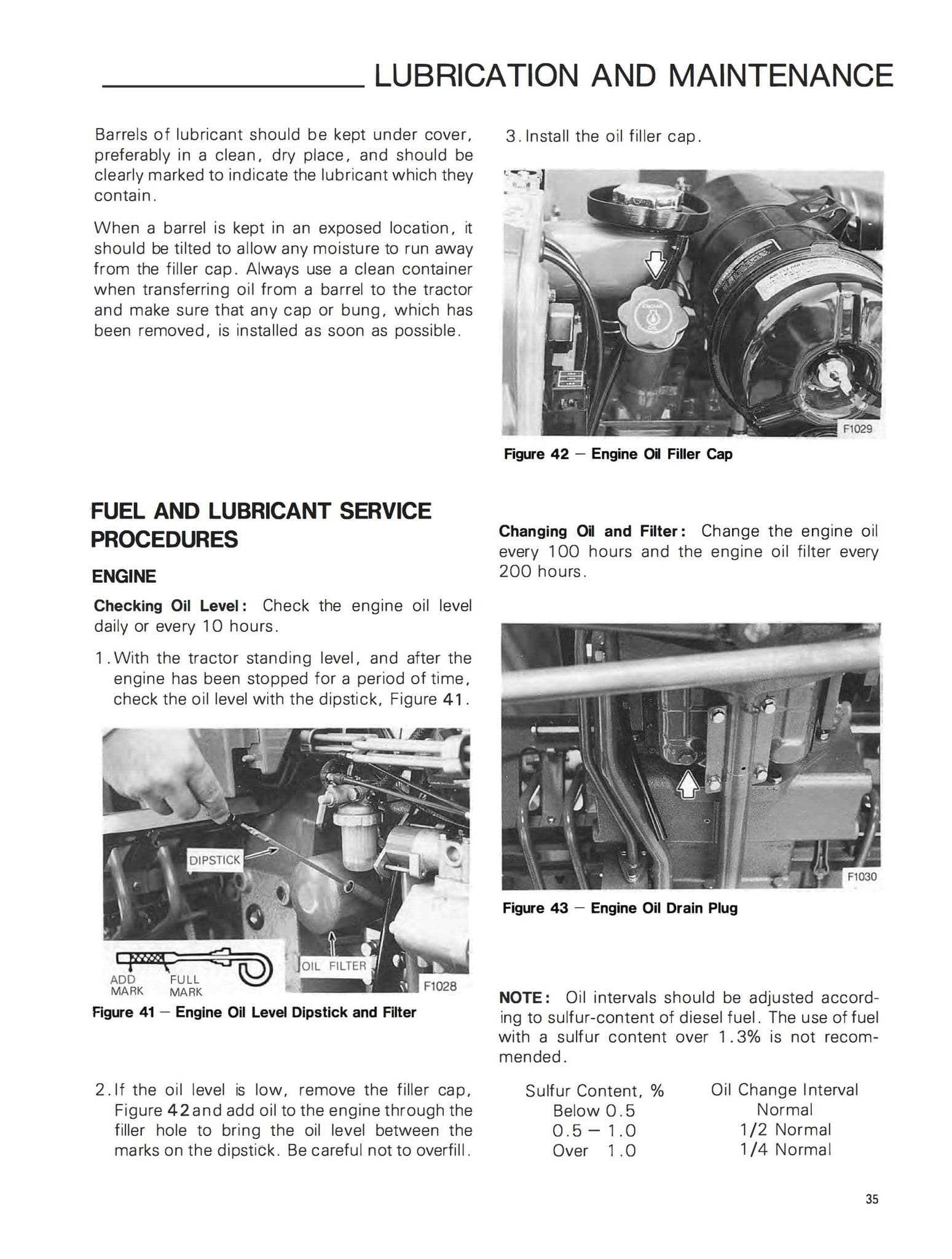

Maintenance Tips

- Regularly check fluid levels to ensure proper lubrication.

- Inspect for signs of wear or damage to components.

- Replace worn bearings and seals promptly to prevent leaks.

- Maintain proper alignment during assembly to avoid undue stress.

- Consult a service manual for specific torque settings during reassembly.

Front-End Loader Attachments

Front-end loaders are versatile implements that enhance the capabilities of tractors, allowing them to perform various tasks efficiently. These attachments play a crucial role in agriculture and construction, making them essential for effective material handling.

Different types of front-end loader attachments cater to various operational needs. Here are some common options:

- Bucket: Ideal for digging, scooping, and transporting materials like soil, gravel, and debris.

- Forks: Useful for lifting and moving pallets, bales, and other bulky items with ease.

- Grapple: Designed for gripping irregularly shaped objects, such as logs or scrap materials.

- Snow Plow: Effective for clearing snow from driveways, roads, and parking lots during winter.

- Land Plane: Perfect for grading and leveling surfaces, ensuring a smooth finish.

Choosing the right attachment depends on the specific tasks required, maximizing the loader’s efficiency and productivity in various applications.