Comprehensive Guide to New Holland 479 Haybine Parts Diagram

Understanding the intricate mechanisms of agricultural machinery is crucial for effective maintenance and operation. This section explores the various elements that contribute to the functionality of specific equipment designed for crop management. A comprehensive knowledge of these components not only enhances performance but also extends the lifespan of the machinery.

By examining a detailed layout of these essential elements, operators can quickly identify potential issues and facilitate timely repairs. Each segment plays a pivotal role in ensuring seamless operation, ultimately leading to improved efficiency during the harvesting process. Whether you are a seasoned professional or a newcomer, familiarity with these components will empower you to make informed decisions.

Moreover, delving into the specifics of each unit allows for a better understanding of their interconnectivity. Recognizing how these parts work together can aid in optimizing functionality and troubleshooting any malfunctions. Ultimately, a solid grasp of these elements will contribute to a more productive and effective farming experience.

Understanding Haybine Functionality

The operation of a specific type of agricultural machinery is crucial for efficient crop management. This equipment combines cutting and conditioning processes, enabling farmers to prepare their fields for optimal harvesting. By mastering its functionality, users can enhance productivity and reduce downtime during the farming season.

Key components play a vital role in the overall efficiency of this machinery. The interaction between the cutting mechanism and the conditioning system ensures that the crop is not only harvested but also processed effectively, preserving quality and facilitating drying. Understanding these elements is essential for proper maintenance and troubleshooting.

In summary, familiarity with how this equipment operates empowers users to make informed decisions, ultimately leading to improved agricultural practices and better yield outcomes.

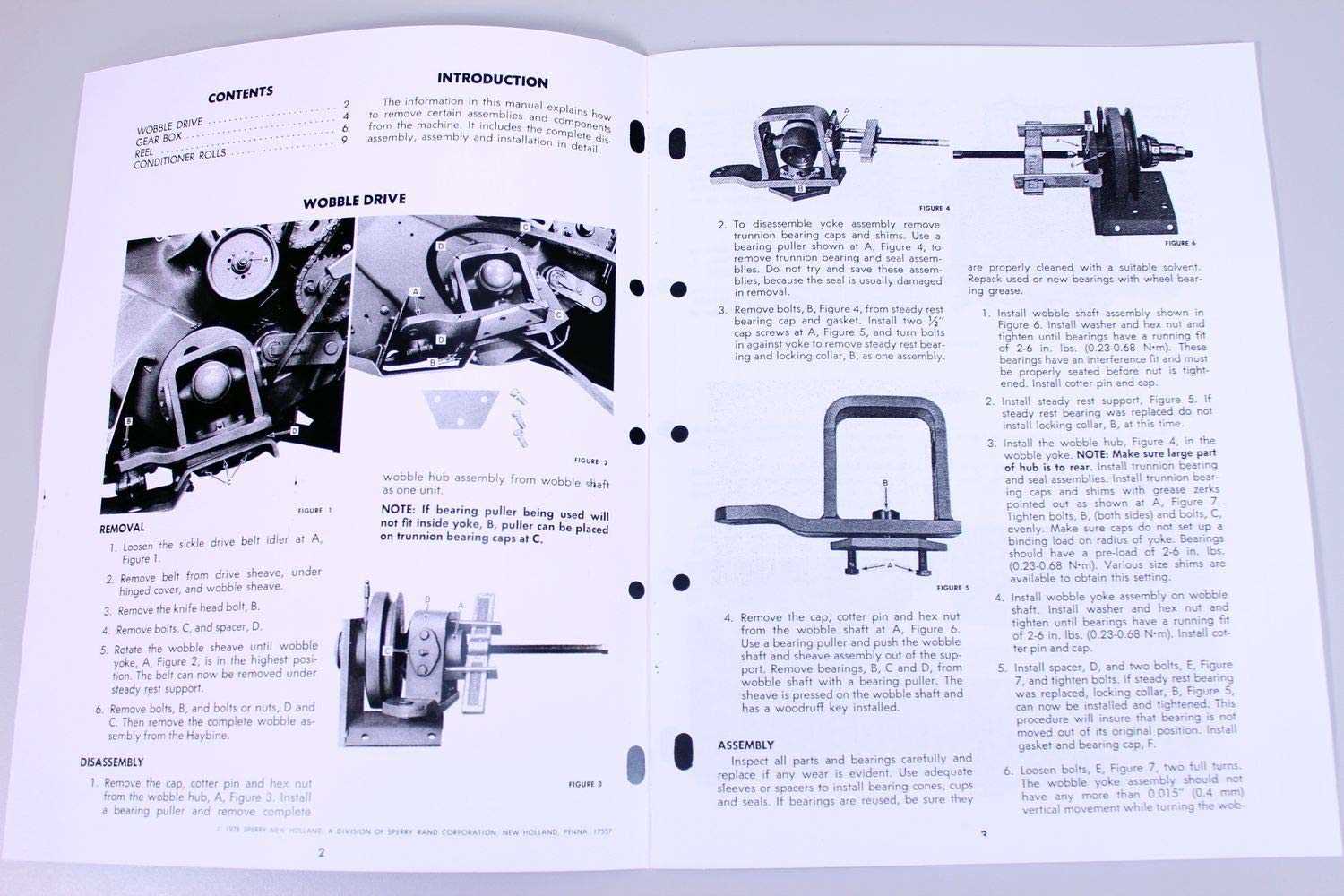

Key Components of New Holland 479

This section explores the essential elements that contribute to the functionality and efficiency of a popular agricultural implement. Understanding these components is crucial for effective operation and maintenance, ensuring optimal performance in the field.

Core Elements

The main parts of this machinery include the cutting mechanism, conditioning system, and frame structure. Each plays a vital role in achieving desired results during forage harvesting.

Maintenance and Care

Proper upkeep of these integral sections is necessary for longevity and performance. Regular inspections and timely replacements help avoid breakdowns and enhance productivity.

| Component | Description |

|---|---|

| Cutter Bar | Facilitates precise cutting of forage. |

| Roller System | Conditions and prepares the crop for drying. |

| Frame Assembly | Provides structural integrity and support. |

Importance of Regular Maintenance

Consistent upkeep of agricultural equipment is crucial for ensuring optimal performance and longevity. Regular checks and servicing help prevent unexpected breakdowns, thereby saving time and resources.

Benefits of Routine Care

- Enhances equipment efficiency

- Reduces the risk of major repairs

- Increases lifespan of machinery

- Improves safety during operation

Key Maintenance Practices

- Regular oil changes and fluid checks

- Inspecting belts and hoses for wear

- Cleaning filters and cooling systems

- Monitoring tire pressure and tread

Identifying Wear and Tear Issues

Understanding the signs of deterioration in agricultural machinery is crucial for maintaining optimal performance and longevity. Recognizing these issues early can prevent costly repairs and ensure efficient operation during critical seasons.

| Component | Signs of Wear | Recommended Action |

|---|---|---|

| Cutting Blades | Dull edges, uneven cuts, visible nicks | Sharpen or replace blades as needed |

| Drive Belts | Cracks, fraying, slipping | Inspect regularly; replace if damaged |

| Gearbox | Noisy operation, oil leaks, overheating | Check fluid levels; service or replace as necessary |

| Wheels and Tires | Uneven wear, punctures, low pressure | Inspect for damage; maintain proper inflation |

Regular maintenance checks are essential to spot these wear indicators. Timely intervention can significantly extend the life of your equipment and enhance productivity.

Common Replacement Parts Needed

Maintaining agricultural equipment often requires the replacement of various essential components to ensure optimal performance. Understanding which elements are frequently needed can help in efficient management and minimize downtime during operations.

Wear Components

Cutting blades and roller bearings are vital for effective operation. These items endure significant wear and tear, necessitating regular checks and timely replacements to maintain functionality and efficiency.

Drive Mechanisms

Belts and chains play crucial roles in transmitting power throughout the machinery. Ensuring these elements are in good condition can prevent mechanical failures and enhance overall reliability.

Where to Find Genuine Parts

Locating authentic components for your agricultural machinery is crucial for ensuring optimal performance and longevity. Understanding where to source these items can save you time and money while maintaining the reliability of your equipment.

Authorized Dealers

Visiting certified retailers is one of the most reliable methods to acquire original components. These dealers typically have a comprehensive inventory and can provide expert advice on compatibility and installation.

Online Resources

Many reputable websites specialize in agricultural equipment, offering a wide range of authentic items. Always verify the seller’s credentials and read customer reviews to ensure you are purchasing high-quality goods.

Benefits of Using OEM Components

Utilizing original equipment manufacturer (OEM) components ensures optimal performance and reliability in machinery. These components are specifically designed to meet the exact specifications and standards set by the manufacturer, leading to enhanced durability and efficiency. The advantages of choosing OEM parts over generic alternatives are significant and can greatly impact the overall functionality of equipment.

Quality Assurance

One of the primary benefits of OEM components is the assurance of quality. Here are some key points to consider:

- Manufactured to precise specifications.

- Subjected to rigorous testing and quality control.

- Guaranteed to fit perfectly, reducing installation issues.

Long-Term Cost Savings

While OEM components may have a higher upfront cost, they often lead to savings in the long run. Consider the following:

- Reduced maintenance costs due to lower failure rates.

- Increased lifespan of the equipment.

- Less frequent replacements needed, resulting in savings over time.

In conclusion, the use of OEM components not only enhances performance but also provides peace of mind, making them a wise investment for maintaining machinery effectively.

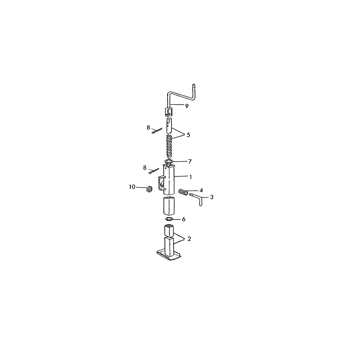

Visualizing the Parts Diagram

Understanding the intricate assembly of machinery components is essential for effective maintenance and repair. A visual representation of these elements provides clarity and helps in identifying the relationship between various parts. This guide aims to enhance comprehension through detailed illustrations and descriptions.

Benefits of Visual Representation

- Facilitates quick identification of components

- Enhances understanding of assembly and disassembly procedures

- Improves troubleshooting efficiency

- Serves as a reference for replacement and upgrades

Key Elements to Consider

- Labels and Annotations: Clearly marked components aid in easy navigation.

- Color Coding: Different colors can signify various functions or groups.

- Scale and Proportions: Accurate dimensions ensure a realistic view of part sizes.

- Interactive Features: Digital representations may offer clickable elements for additional information.

Tips for Efficient Repairs

Maintaining machinery effectively can significantly enhance productivity and prolong the lifespan of equipment. Proper planning, understanding components, and having the right tools at hand are essential for executing repairs swiftly and accurately.

Preparation is Key

Before starting any maintenance work, gather all necessary tools and materials. Create a checklist of components that may need attention. Familiarize yourself with the machinery’s layout and common issues associated with it. This proactive approach minimizes downtime and streamlines the repair process.

Utilize Quality Resources

Accessing reliable manuals and resources can provide invaluable guidance. Diagrams, if available, illustrate component locations and assembly sequences. Additionally, consider joining forums or groups dedicated to your equipment type for tips and shared experiences from fellow operators.

Remember: Taking the time to prepare adequately and leveraging quality resources will lead to smoother and more efficient repair experiences.

Understanding Warranty and Support Options

When acquiring agricultural machinery, it’s essential to grasp the various guarantees and assistance available. These options ensure that you can maintain your equipment effectively and address any issues that may arise over time.

Typically, warranties cover specific components for a designated period, offering peace of mind regarding repairs or replacements. It’s important to review the terms thoroughly, as some coverage may vary based on usage or maintenance practices.

Additionally, many manufacturers provide customer support services, including technical advice and troubleshooting resources. Utilizing these services can help you optimize performance and extend the life of your machinery.